Large-scale electronic element attaching-inserting joint and attaching-inserting method therefor

An electronic component and large-scale technology, applied in the direction of electrical components, electrical components assembly printed circuit, printed circuit, etc., can solve the problem that it is difficult to ensure the insertion of large electronic components, affecting the insertion speed, insertion accuracy and work of the insertion machine. Efficiency and other issues, to achieve the effect of increasing the speed of placement and insertion, and improving the accuracy of placement and insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

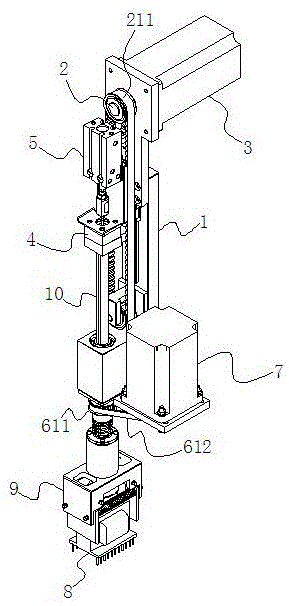

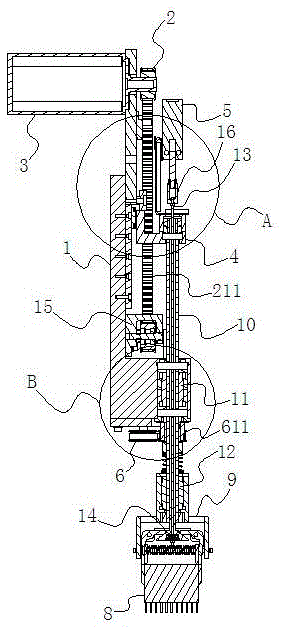

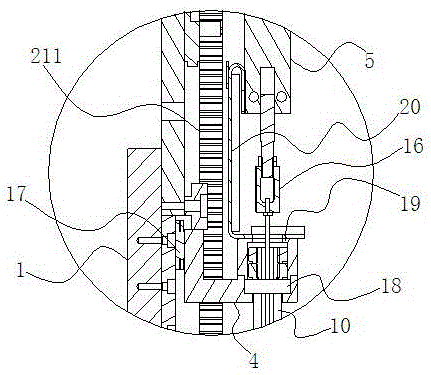

[0046] Example: such as figure 1 with figure 2 As shown, a large-scale electronic component sticking plug includes a sticking plug support 1, a synchronous belt device 2 arranged on one end of the sticking plug support 1, and a control motor 3 (synchronous belt) for driving the synchronous belt device 2 Device one 2 includes driving wheel one, driven wheel one and synchronous belt one 211), L-shaped slider 4 fixed on the synchronous belt one 211 of synchronous belt device one 2, and clamping on the L-shaped slider 4 The cylinder 5 and the timing belt device 2 6 arranged on the other end of the sticking plug support 1 and the control motor 2 7 for driving the timing belt device 2 6 (the timing belt device 2 6 includes the driving wheel 2, the driven wheel 611 and the synchronous belt Take two 612);

[0047] The large electronic component sticker plug also includes a ball spline assembly and a chuck 9 for clamping the large electronic component 8. The ball spline assembly includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com