Material packaging machine

A packaging machine and material technology, applied in the field of packaging, can solve the problems of large workload, high energy consumption, and the unsmooth opening of bags, etc., and achieve the effect of reducing workload and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

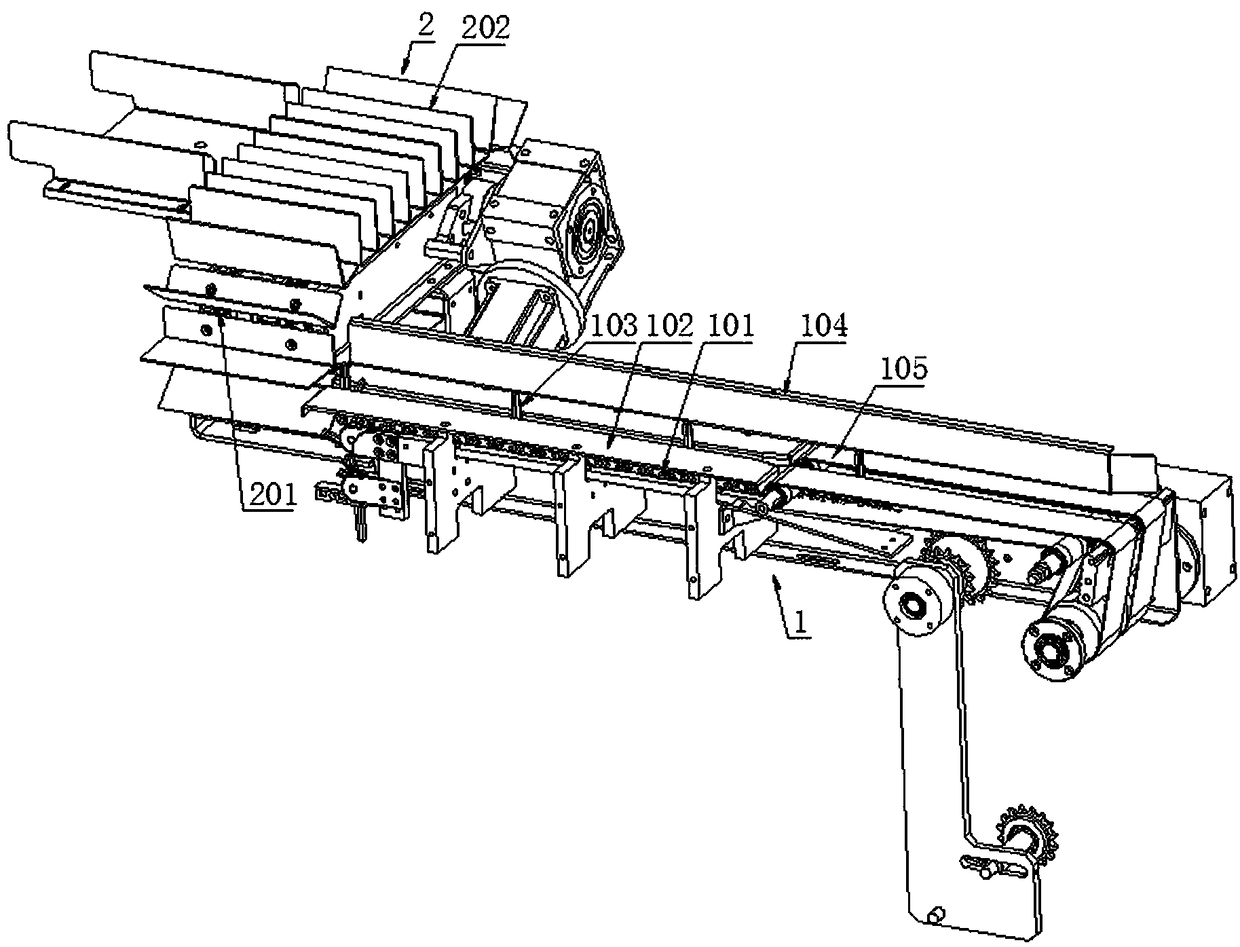

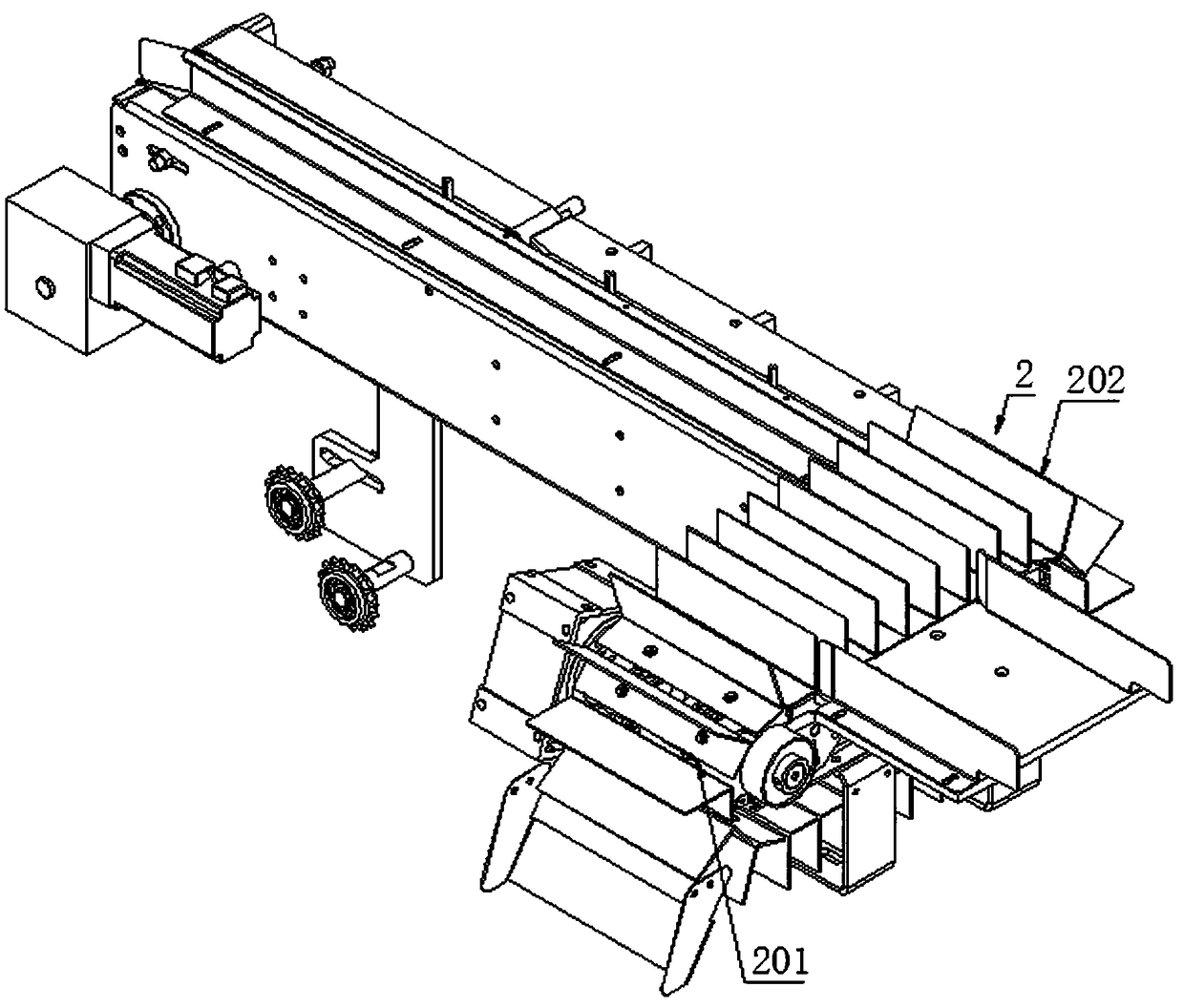

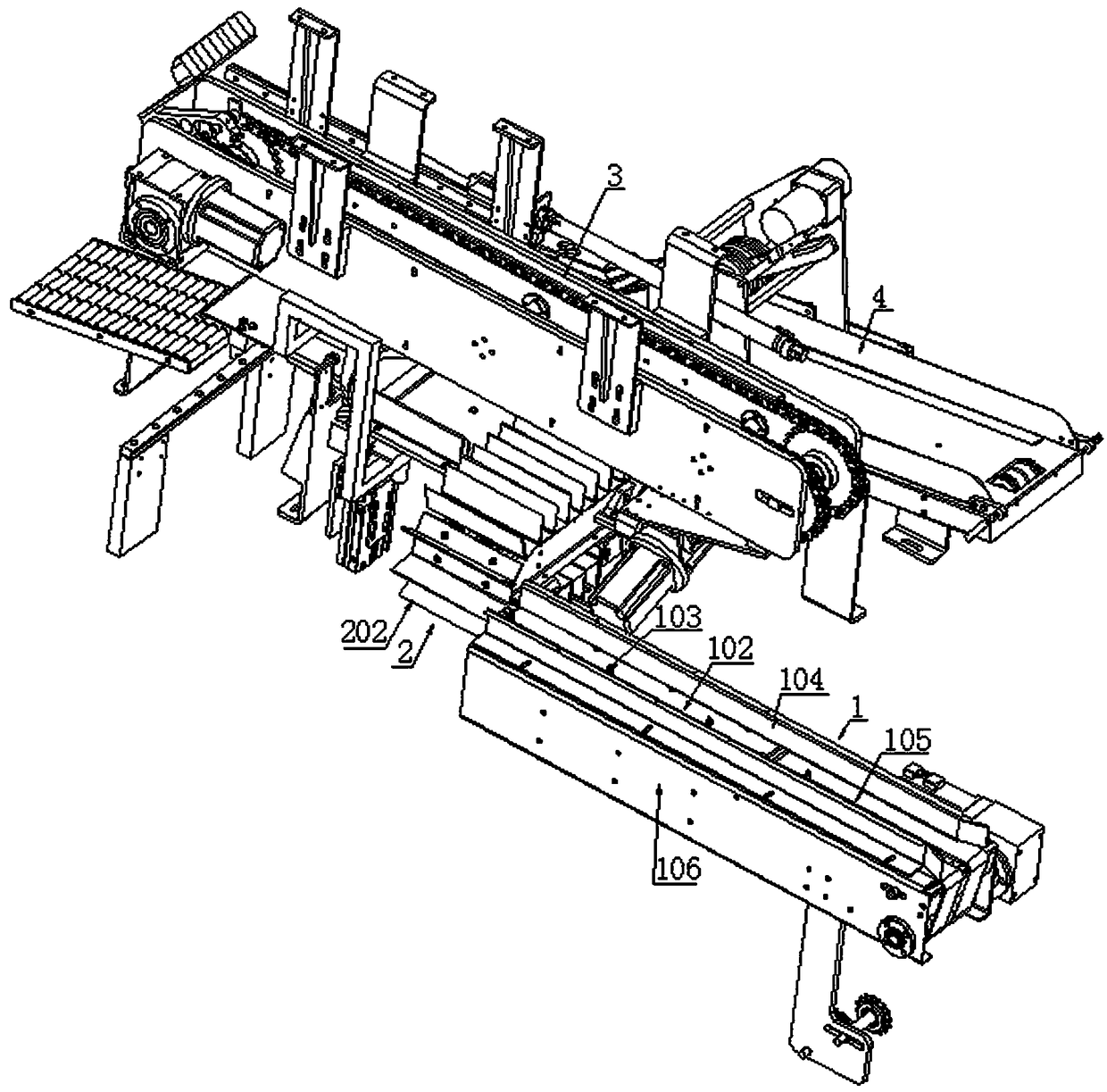

[0079] A material packaging machine includes a material conveying and turning device, a material shifting mechanism 3, a bag feeding mechanism 4, a suction cup 6, and a bag connecting and opening device. The bag connecting and opening device includes a bag connecting and conveying mechanism 51 and a bag opening mechanism 7. The conveying mechanism 51 includes a bag-bearing plate 501 and a translation mechanism that enables the bag-bearing plate 501 to reciprocate between the bag receiving station 505 and the bag opening station. The bag holder 501 is provided with suction on the side corresponding to the position of the prefabricated bag opening. Hole 503; The bag opening mechanism 7 includes a bag opening claw 701, and the side of the bag opening claw 701 is arc-shaped. The function of the adsorption hole 503 is to absorb the mouth of the prefabricated bag at the bag receiving station 505, fix the prefabricated bag on the bag bearing plate 501, absorb the lower side of the pref...

Embodiment 2

[0087] A material packaging machine includes a material conveying and reversing device, a material shifting mechanism 3, a bag feeding mechanism 4, a suction cup 6 and a bag connecting and opening device. The bag connecting and opening device includes a bag connecting conveying mechanism 51 and a bag opening mechanism 7. The function of the conveying mechanism 51 is to realize the bag receiving and conveying action of prefabricated bags, and its specific structure may be:

[0088] The bag-receiving conveying mechanism 51 includes a bag-receiving plate 501 and a translation mechanism that enables the bag-receiving plate 501 to reciprocate between the bag-receiving station 505 and the bag-opening station. The bag-receiving plate 501 is opened on the side corresponding to the position of the prefabricated bag opening. There are adsorption holes 503;

[0089] The translation mechanism includes a power source and a guide 502. The bag-bearing plate 501 is movably mounted on the guide 502...

Embodiment 3

[0092] A material packaging machine includes a material conveying and reversing device, a material shifting mechanism 3, a bag feeding mechanism 4, a suction cup 6 and a bag connecting and opening device. The bag connecting and opening device includes a bag connecting conveying mechanism 51 and a bag opening mechanism 7. The function of the conveying mechanism 51 is to realize the bag receiving and conveying action of prefabricated bags, and its specific structure may be:

[0093] The bag-receiving conveying mechanism 51 includes a bag-receiving plate 501 and a translation mechanism that enables the bag-receiving plate 501 to reciprocate between the bag-receiving station 505 and the bag-opening station. The bag-receiving plate 501 is opened on the side corresponding to the position of the prefabricated bag opening. There are adsorption holes 503;

[0094] The translation mechanism includes a power source and a guide 502. The bag-bearing plate 501 is movably mounted on the guide 502...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com