Self-regulating brake apparatus for weft-feeding device

A brake device and weft feeder technology, applied in transportation and packaging, textiles, textiles and papermaking, etc., can solve the problems of complex structure of the brake body, increase the size and quality of the brake body, and reduce mass and inertia Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

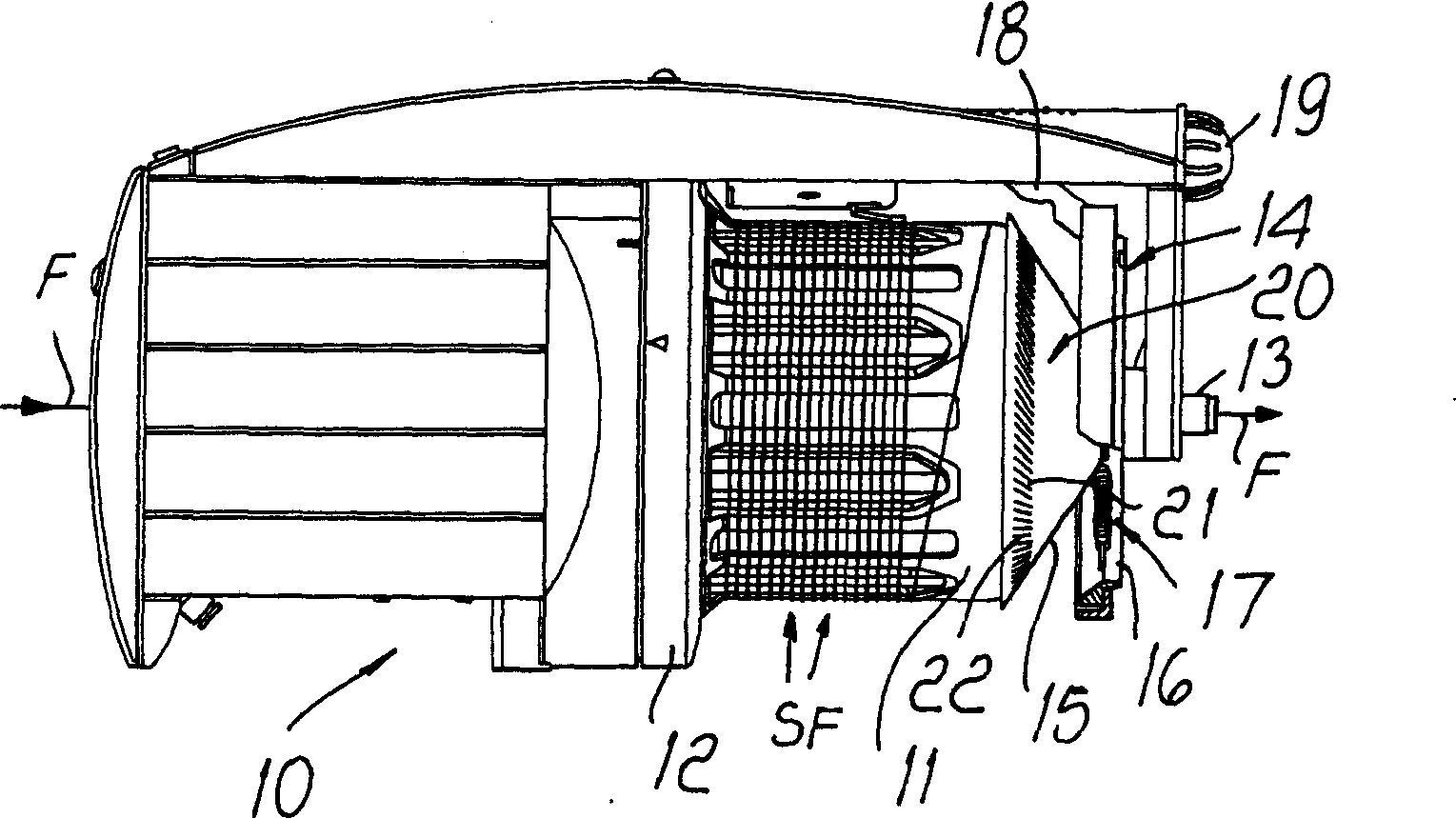

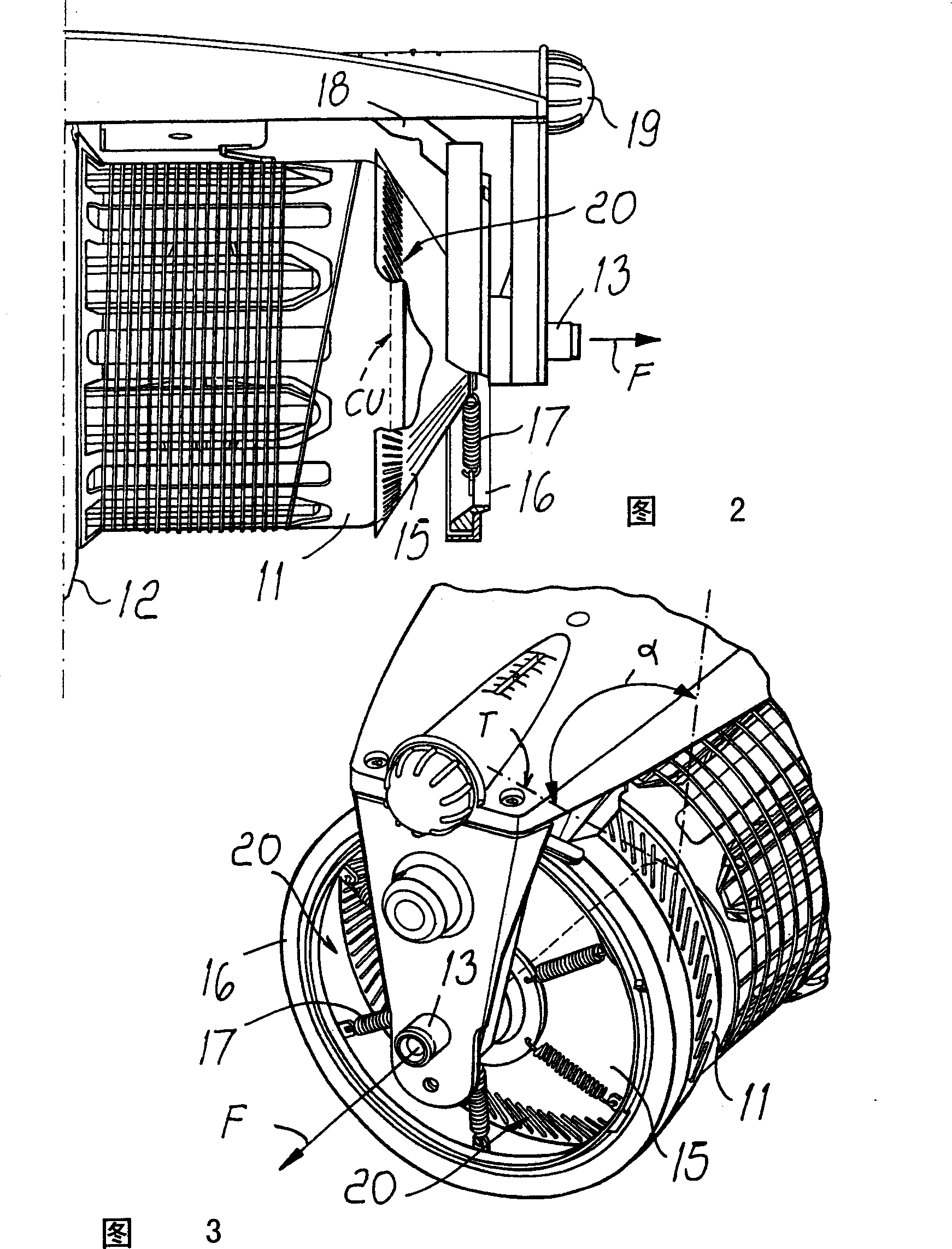

[0030] see first Figures 1 to 6 , reference numeral 10 represents a traditional weft feeder, which includes a fixed drum 11, and a hollow arm rigidly connected with a rotating disc 12 mounted on the base of the drum is wound on the fixed drum 11 in the form of a fishing reel for storage Weft yarns in the form of multi-turn yarns SF. In a manner known per se, when the weaving machine (not shown) requires the yarn F during weft insertion, the yarn F is released from the drum and passed through a thread guide element 13 coaxial with the drum; During the unwinding movement, the yarn is subjected to the action of the self-adjusting device 14 . The device is designed to maintain tension in the yarn by self-adjusting braking action to create a constant or substantially constant tension in the yarn as the yarn advance speed changes during insertion.

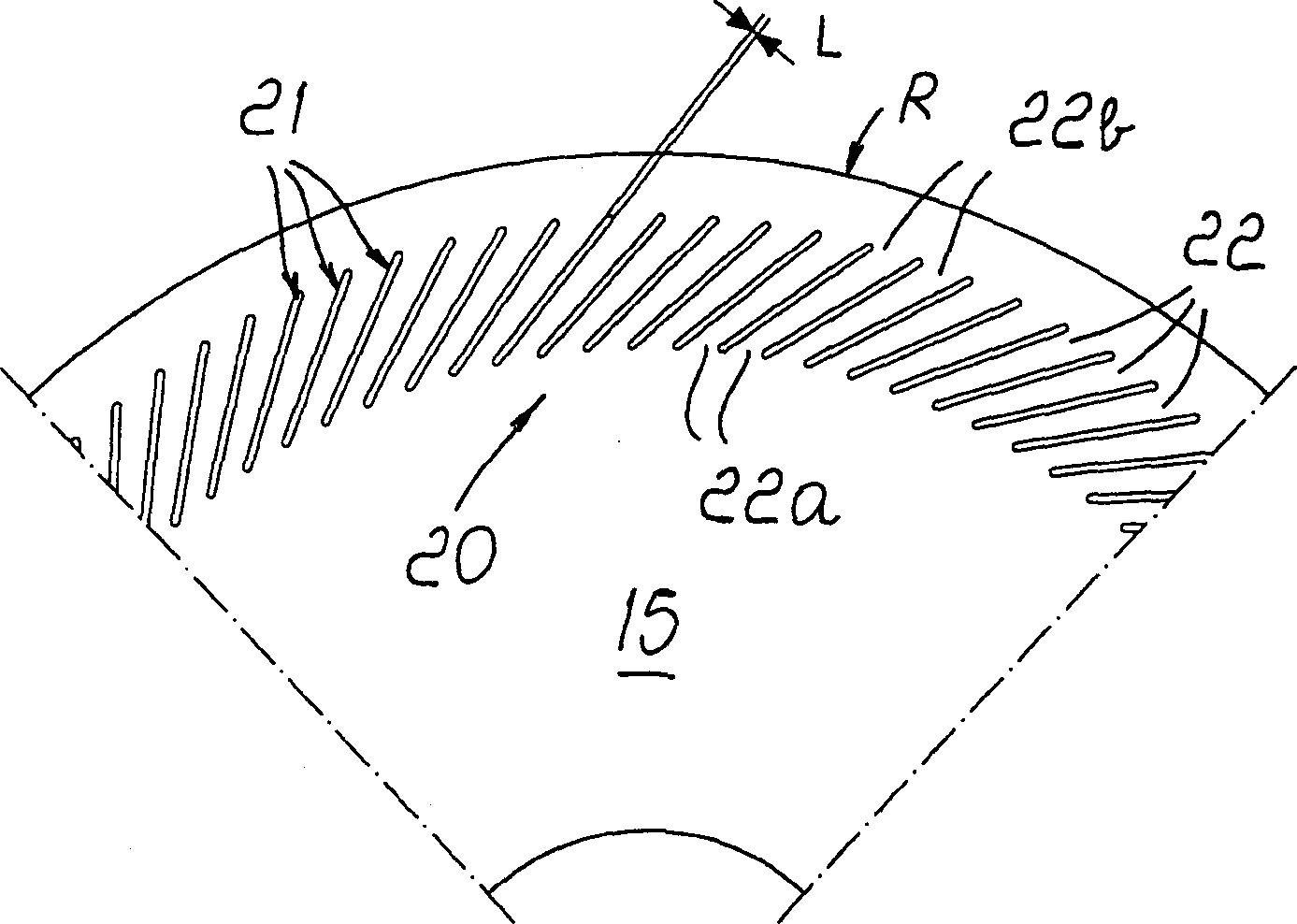

[0031] To this end, the device 14 located between the drum 11 and the yarn guide element 13 comprises a frusto-conical brake body 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com