Bamboo stick stringing device

A bamboo stick and threading technology, which is applied in food forming, food science, application, etc., can solve the problems of low efficiency, inability to solve bamboo stick splitting, and bamboo stick tip being easy to split

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

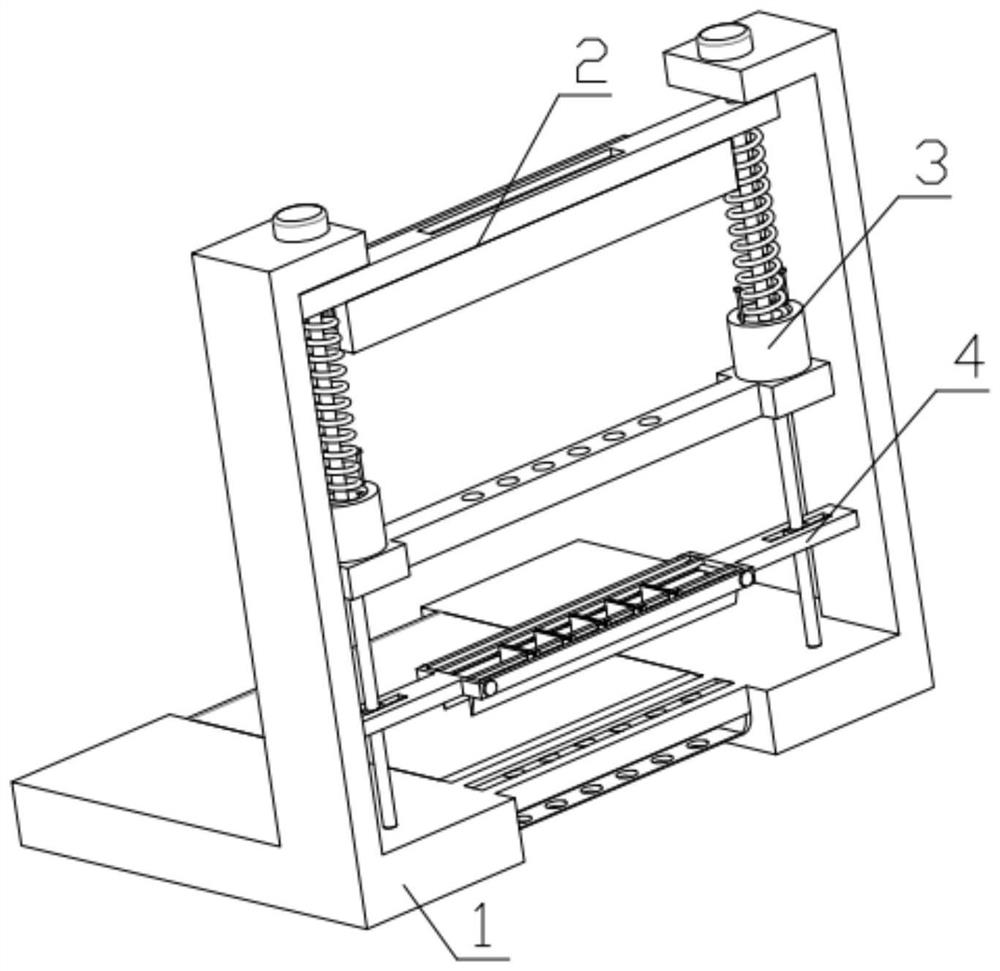

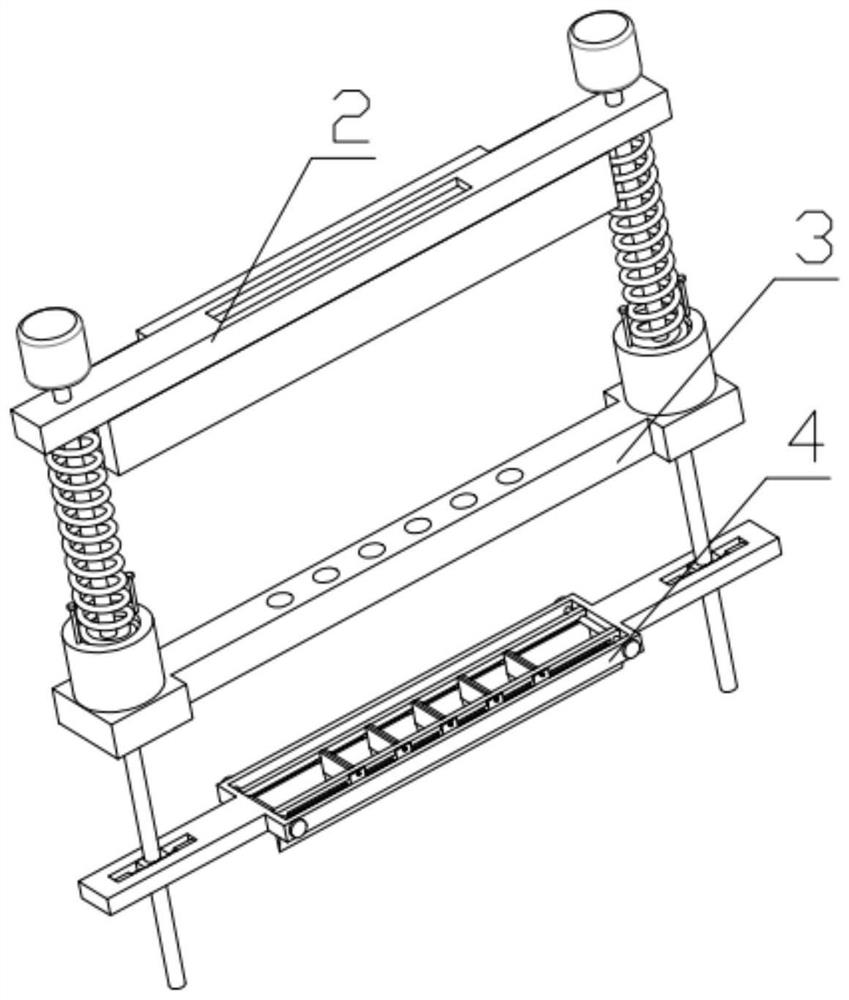

[0036] Combine below Figure 1-17 Description of this embodiment, a bamboo stick stringing device, including a transmission base 1, a transfer mechanism 2, a bamboo stick correction mechanism 3 and a cutting mechanism 4, the described transfer mechanism 2 is fixedly installed on the transmission base 1, and the bamboo stick The correction mechanism 3 is fixedly installed on the sign transfer mechanism 2, the bamboo stick correction mechanism 3 is slidably installed on the sign transfer mechanism 2, and the cutting mechanism 4 is threadedly connected with the sign transfer mechanism 2.

specific Embodiment approach 2

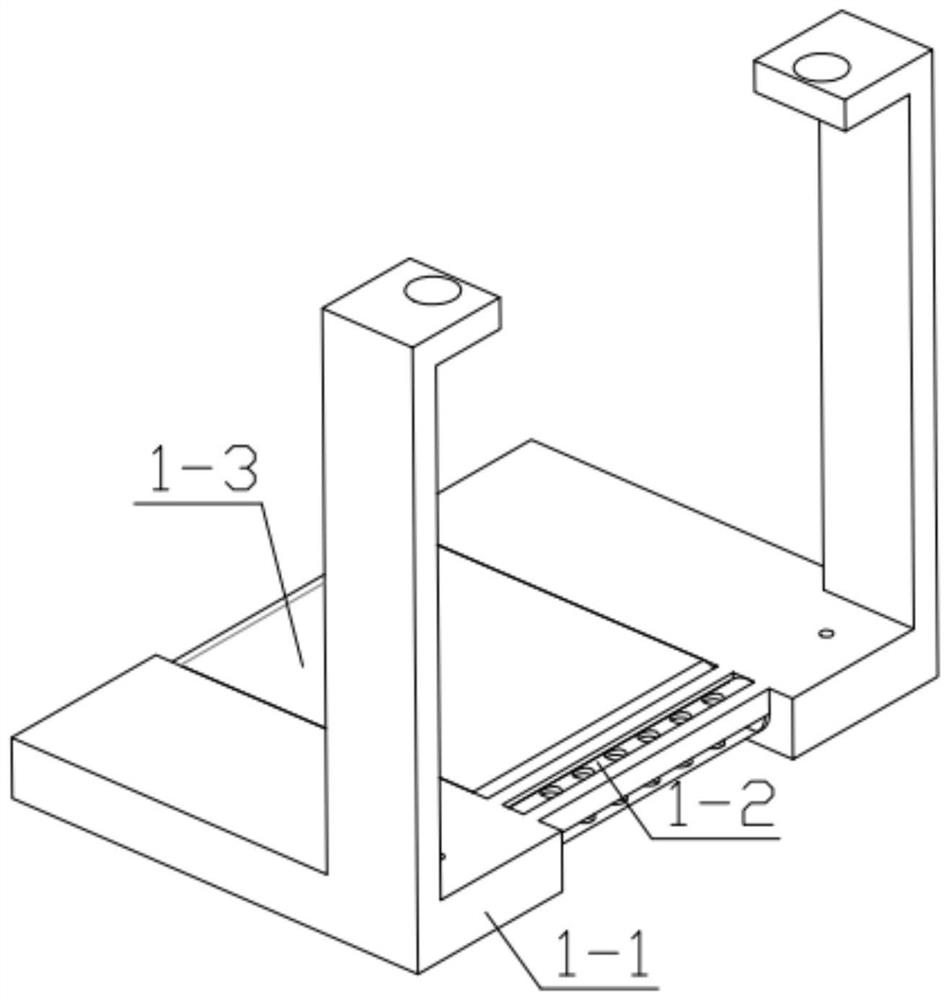

[0037] Combine below Figure 1-17 Describe this embodiment, this embodiment will further explain the first embodiment, the transmission base 1 includes a main frame 1-1, a porous cylinder 1-2, a conveyor belt 1-3, an auxiliary transmission shaft 1-4, and a main transmission shaft 1 -5, the first motor 1-6, the second motor 1-7, the auxiliary transmission shaft 1-4 is rotatably installed in the groove provided on the main frame 1-1, and the main transmission shaft 1-5 is rotatably installed on the main frame 1 In the groove provided on -1, the main transmission shaft 1-5 is fixedly installed on the output end of the first motor 1-6, and the first motor 1-6 is fixedly installed in the groove provided on the main frame 1-1. The second motor 1-7 is fixedly installed in the groove provided on the main frame 1-1, the output end of the second motor 1-7 is fixedly installed with a porous cylinder 1-2, and the porous cylinder 1-2 is rotatably installed on the main frame 1- 1, the conv...

specific Embodiment approach 3

[0039] Combine below Figure 1-17 Describe this embodiment, this embodiment will further explain Embodiment 2, the described sign transfer mechanism 2 includes a third motor 2-1, a lifting threaded rod 2-2, a top plate 2-3, and a bamboo stick groove plate 2-4 , L-shaped slide plate 2-5, back plate 2-6, strip slide plate 2-7, rubber pad 2-8, cam 2-9, first spring 2-10, second spring 2-11, fourth motor 2 -12, the third motor 2-1 is fixedly installed in the through hole provided on the main frame 1-1, the output end of the third motor 2-1 is fixedly installed with a lifting threaded rod 2-2, and the lifting threaded rod 2-2 rotates Installed in the groove provided on the main frame 1-1, the lifting threaded rod 2-2 is threadedly connected with the top plate 2-3, and the top plate 2-3 is fixedly equipped with the bamboo stick groove plate 2-4, and the concave groove of the top plate 2-3 An L-shaped slide plate 2-5 is slidably installed in the groove, and the L-shaped slide plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com