Automatic grabbing and aligning device

An automatic, rotating rod technology, applied in the direction of measuring device, mechanical device, mechanical measuring device, etc., can solve the problems of no transmission function, limited size detection of the compression spring, etc., to achieve easy transmission, increase in length and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

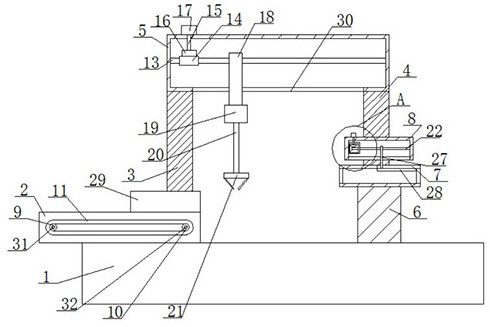

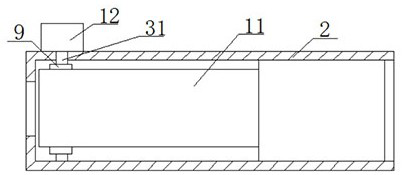

[0026] refer to Figure 1-5 , the automatic grasping and aligning device includes a base 1, a transmission base 2 is fixedly installed on the top of the base 1, a first support column 3 and a second support column 4 are fixedly installed on the top of the base 1, the first support column 3 and the second support column One end of the support column 4 is fixedly installed with the same top frame 5, the bottom of the top frame 5 is provided with a first long hole 30, the top of the base 1 is fixedly installed with a pillar 6, and the top of the pillar 6 is fixedly installed with a scale cylinder 7, the scale cylinder The top of 7 is slidingly connected with a scale 28, and one side of the second support column 4 is fixedly installed with a drive frame 8, and the drive frame 8 is rotatably connected with a second screw rod 22, and one end of the second screw rod 22 is fixedly connected with a first bevel gear 23. The second screw rod 22 is threadedly connected with a second movin...

Embodiment 2

[0035] refer to Figure 1-5 , the automatic grasping and aligning device, including a base 1, the top of the base 1 is welded with a transmission seat 2, the top of the base 1 is welded with a first support column 3 and a second support column 4, the first support column 3 and the second One end of the support column 4 is welded with the same top frame 5, the bottom of the top frame 5 is provided with a first long hole 30, the top of the base 1 is welded with a pillar 6, and the top of the pillar 6 is welded with a scale cylinder 7, the scale cylinder The top of 7 is slidingly connected with a scale 28, and one side of the second support column 4 is welded with a drive frame 8, and the drive frame 8 is rotatably connected with a second screw 22, and one end of the second screw 22 is welded with a first bevel gear 23. The second screw rod 22 is threadedly connected with a second moving plate 27, and one side of the second moving plate 27 is provided with a second threaded hole,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com