Pressing and grinding equipment for sanitary towel production

A technology for sanitary napkins and equipment, which is applied in the field of high-temperature sterilization and pressure-grinding equipment, can solve the problems of no transmission equipment and no sterilization, and achieve the effects of simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

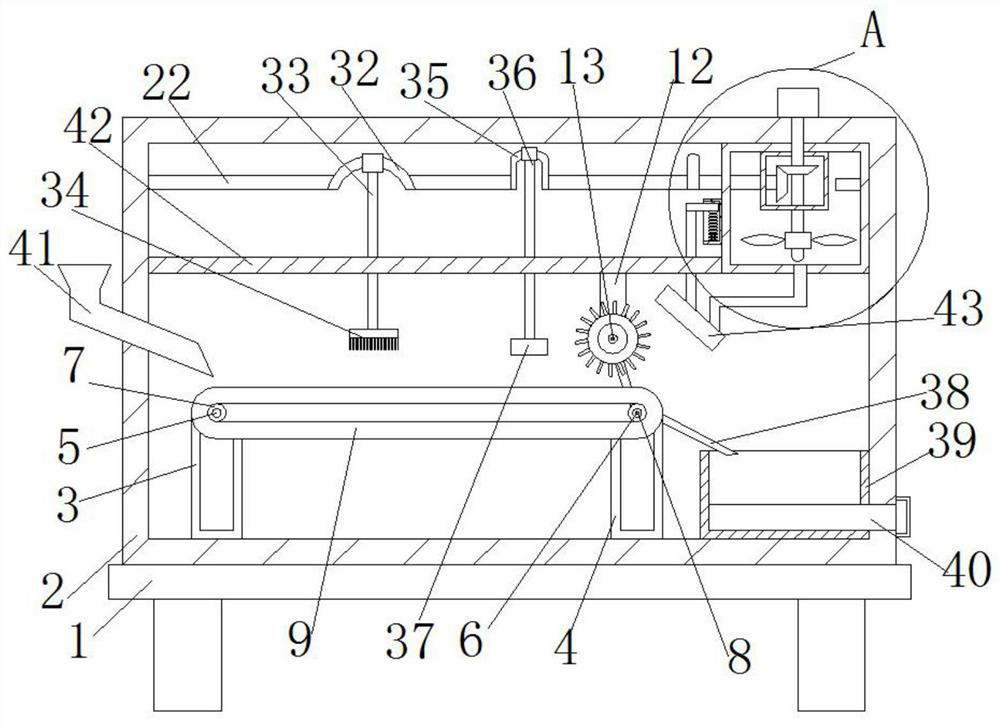

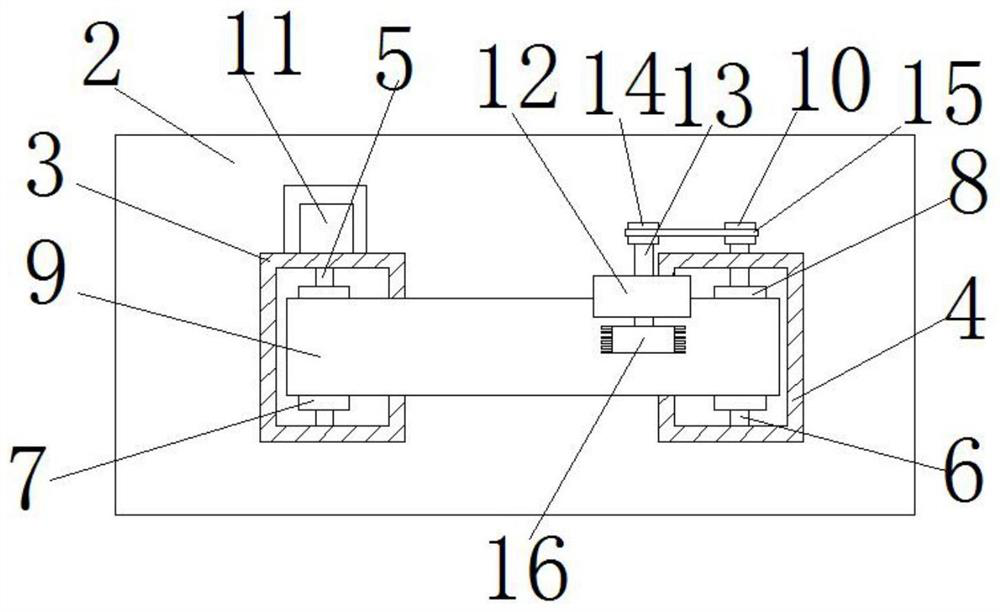

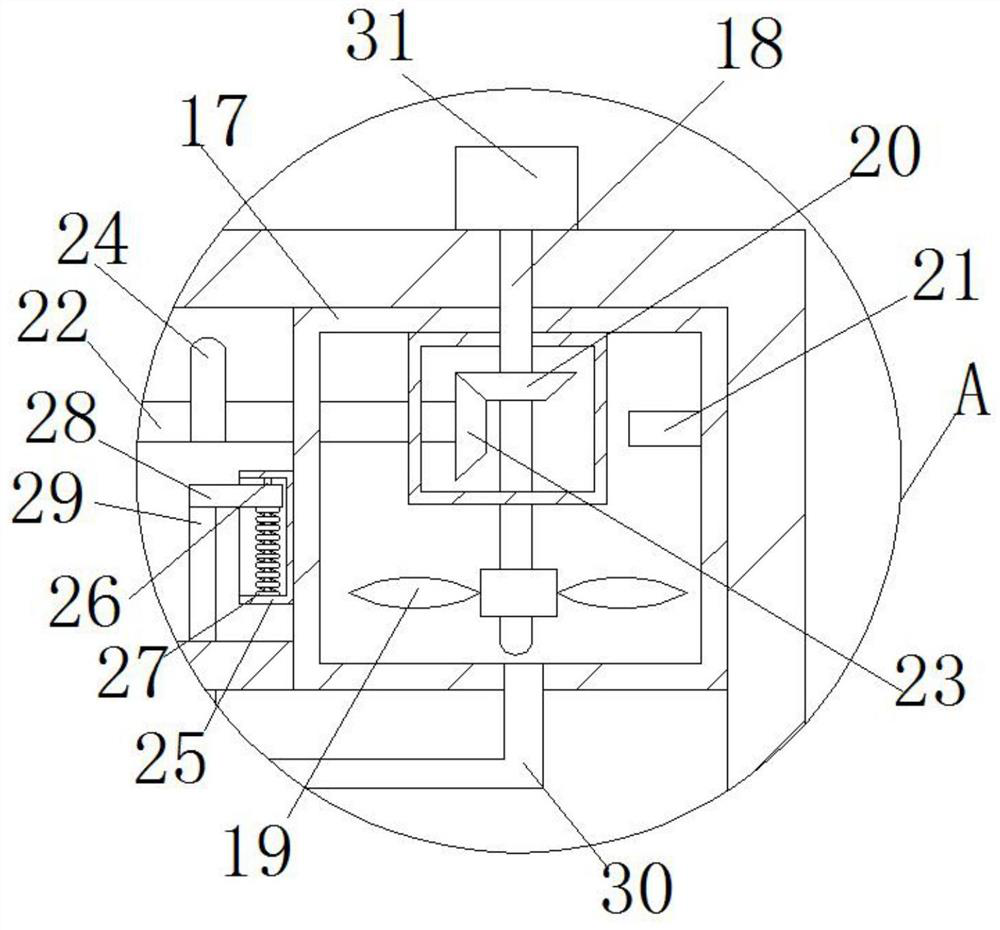

[0026] Please refer to Figure 1-Figure 5 , a kind of pressing and grinding equipment for sanitary napkin production, comprising a bottom plate 1, a box body 2 is fixedly installed on the top of the bottom plate 1, a partition 42 is fixedly installed in the box body 2, and a first branch is fixedly installed on the bottom inner wall of the box body 2. Seat 3 and the second bearing 4, the first bearing 3 and the second bearing 4 are respectively rotated and connected with the first rotating rod 5 and the second rotating rod 6, respectively on the first rotating rod 5 and the second rotating rod 6 The first drive column 7 and the second drive column 8 are fixedly connected, and the same conveyor belt 9 is connected between the first drive column 7 and the second drive column 8. One end of the second rotating rod 6 is fixedly connected to the first cylinder 10, The bottom of the partition 42 is fixedly installed with a cheek support plate 12, and the cheek support plate 12 is rot...

Embodiment 2

[0037] Please refer to Figure 1-Figure 5, a kind of pressing and grinding equipment for sanitary napkin production, comprising a bottom plate 1, a box body 2 is welded and installed on the top of the bottom plate 1, a partition plate 42 is welded and installed in the box body 2, and a first branch is welded and installed on the bottom inner wall of the box body 2 Seat 3 and the second bearing 4, the first bearing 3 and the second bearing 4 are respectively rotated and connected with the first rotating rod 5 and the second rotating rod 6, respectively on the first rotating rod 5 and the second rotating rod 6 The first drive column 7 and the second drive column 8 are connected by welding, the same conveyor belt 9 is connected between the first drive column 7 and the second drive column 8, and one end of the second rotating rod 6 is welded to the first cylinder 10, The bottom of the partition 42 is welded with a cheek support plate 12, and the cheek support plate 12 is rotatably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com