Insertion operating head of middle-sized electronic component and insertion method of insertion operating head

A technology of electronic components and operation heads, which is applied in the direction of electrical components, electrical components, and electrical components assembling printed circuits, which can solve the problem of difficulty in ensuring the insertion and insertion of medium-sized electronic components, affecting the insertion and insertion speed of the insertion machine, and the insertion and insertion accuracy. Work efficiency and other issues, to achieve the effect of convenient and quick control, increase the speed of insertion and insertion, and improve the precision of insertion and insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

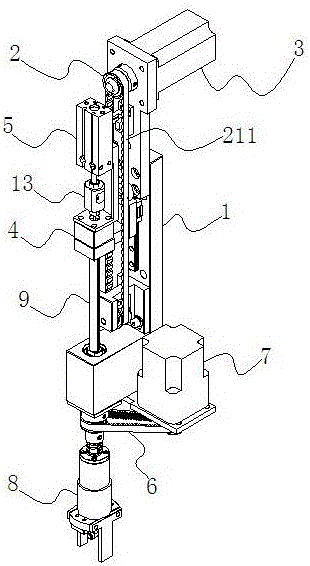

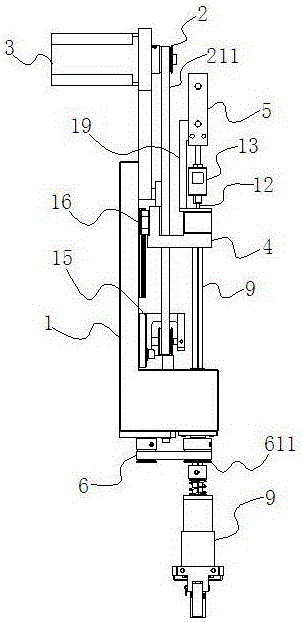

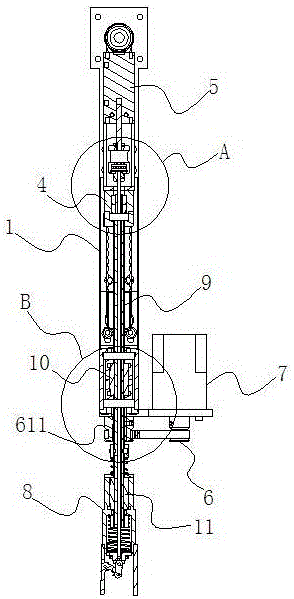

[0048] Example: such as Figure 1 to Figure 4As shown, a medium-sized electronic component sticking and inserting operation head includes a plug support 1, a timing belt device-2 arranged on one end of the plug support 1, and a control motor-3 for driving the timing belt device-2 ( Synchronous belt device one 2 comprises driving wheel one, driven wheel one and synchronous belt one 211), the L-shaped slide block 4 that is fixed on the synchronous belt one 211 of synchronous belt device one, the clip that is arranged on the L-shaped slide block 4 Tight cylinder 5 and the timing belt device two 6 that are arranged on the other end of the sticking plug support 1 and the control motor two 7 for driving the timing belt device two 6 (the timing belt device two 6 includes driving wheel two, driven wheel two 611 and timing belt two);

[0049] The medium-sized electronic component sticking and inserting operation head also includes a ball spline assembly and a single-side movable jaw t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com