Double-work-head special-shaped insertion machine

A technology of special-shaped head and plug-in machine, which is applied in the direction of assembling printed circuits of electrical components, electrical components, and electrical components, can solve the problems of speed barriers and long time of plug-in machine insertion, save the back and forth time for reclaiming materials, and improve the plug-in machine. Assembly speed, the effect of meeting assembly requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings.

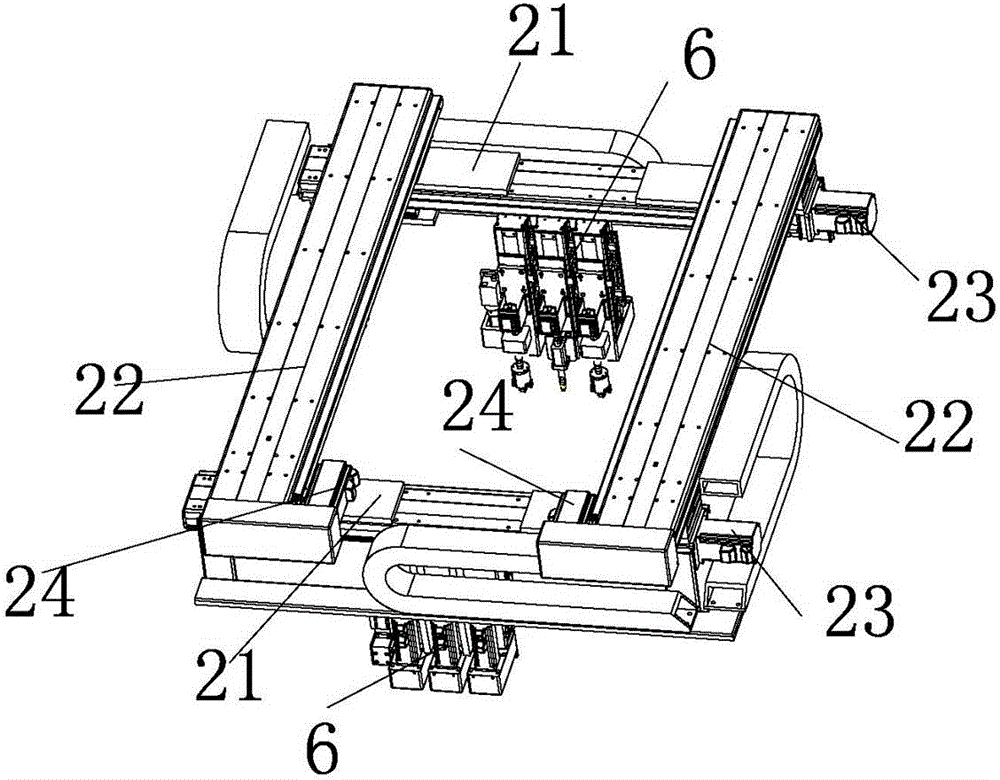

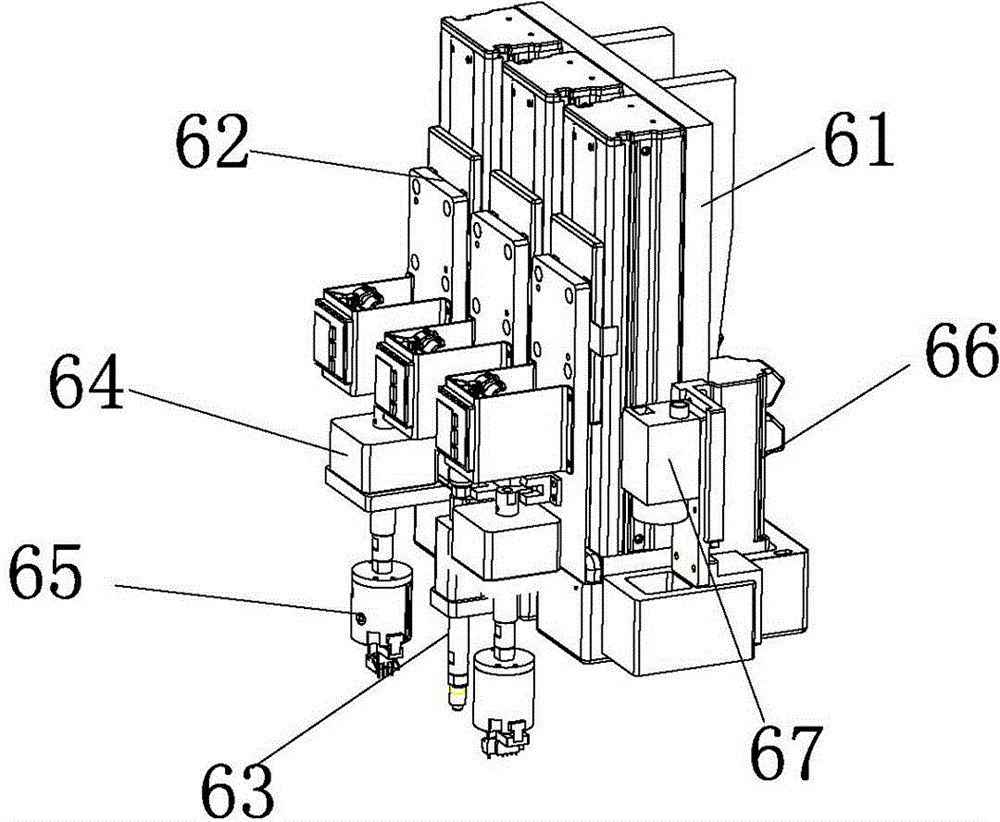

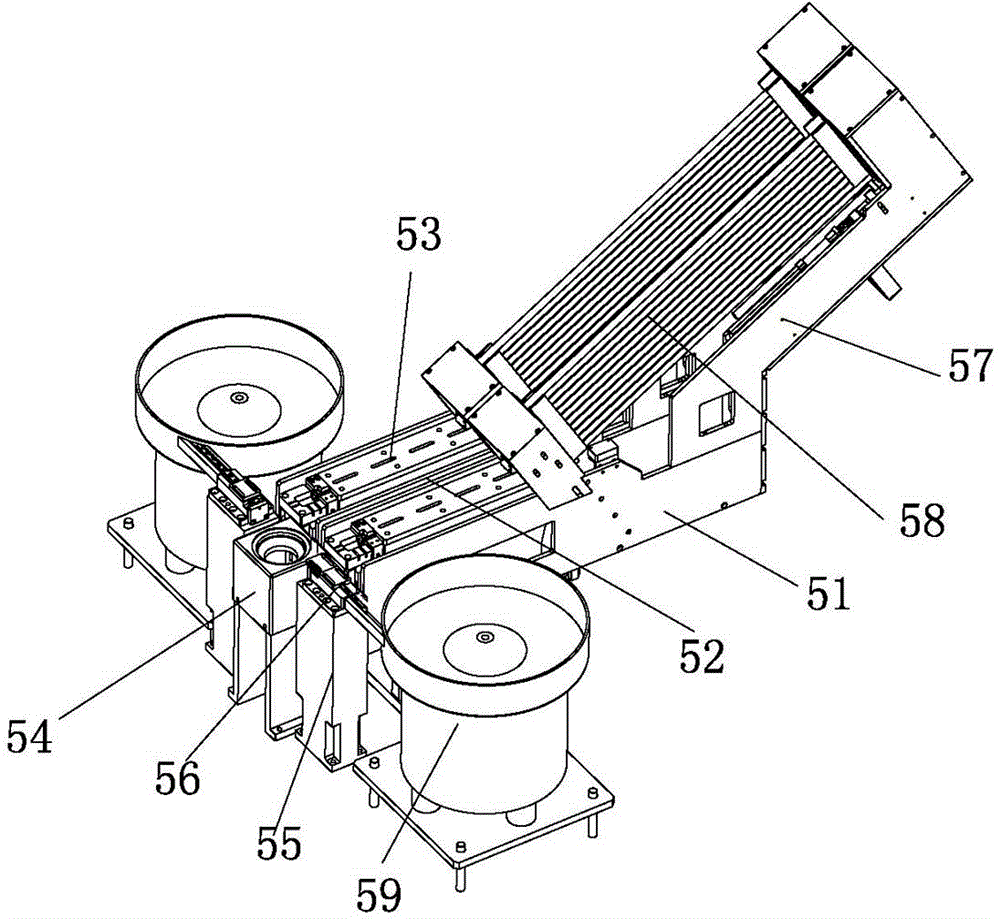

[0019] Such as figure 1 As shown, a special-shaped plug-in machine with double working heads includes a frame 1, which is characterized in that a transport bracket 3 for installing a transport device 2 with a plurality of working heads is arranged on the frame 1, and the middle part of the upper end of the frame 1 There is a PCB conveying and positioning device 4, and the two sides of the upper end of the frame 1 are respectively provided with feeding devices 5 that convey electronic components to the PCB conveying and positioning device 4, and the handling device 2 transports and inserts the electronic components conveyed by the two feeding devices 5. The PCB transported on the positioning device 4 is on the PCB. This equipment is connected with the automatic plate loosening machine, and the upper equipment conveys the PCB board to the equipment to the PCB conveying an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com