A turn-over alignment press-fitting device

A technology of aligning pressing and turning shafts, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of cumbersome procedures and low work efficiency, and achieve the effects of saving time, saving materials, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

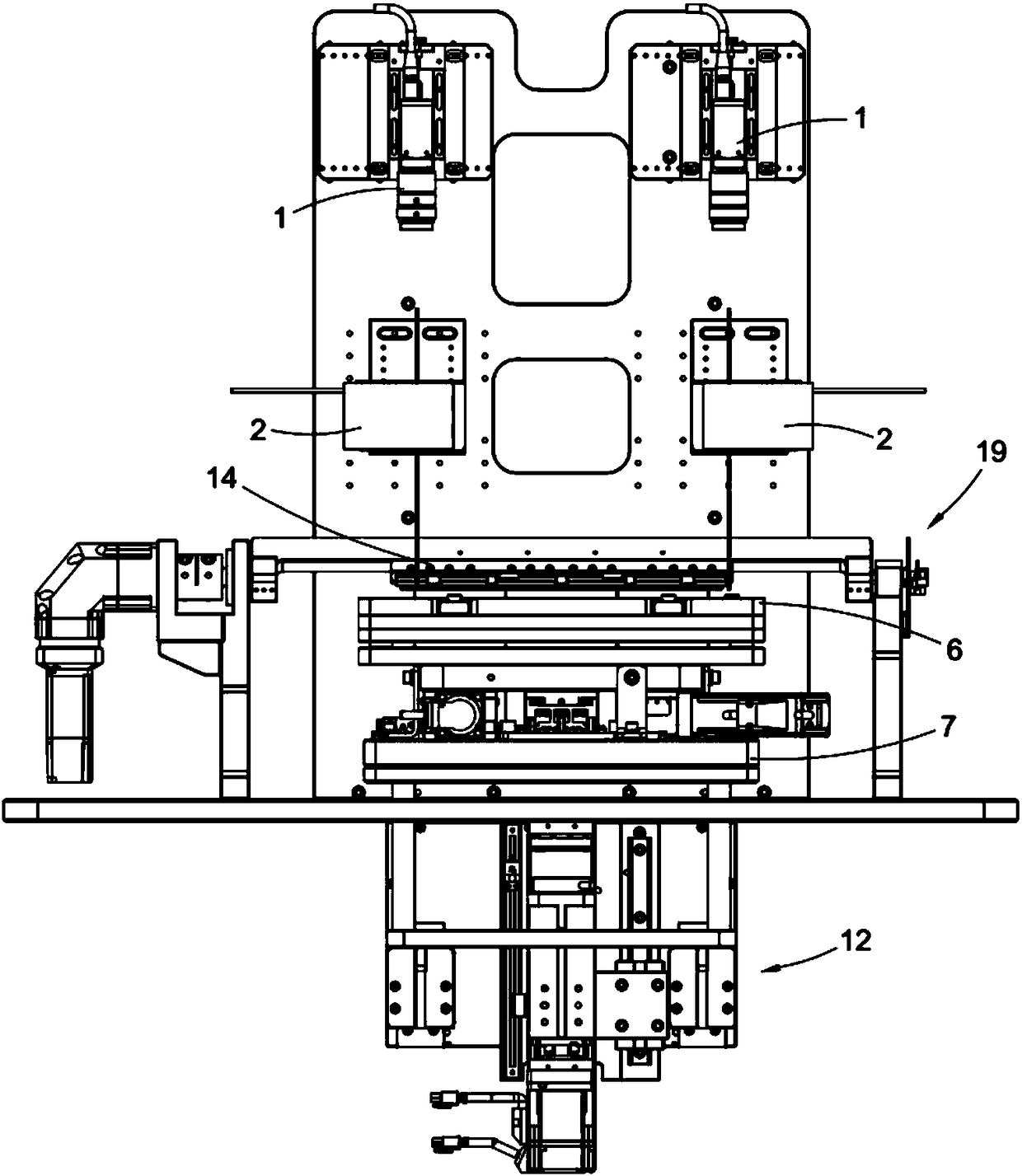

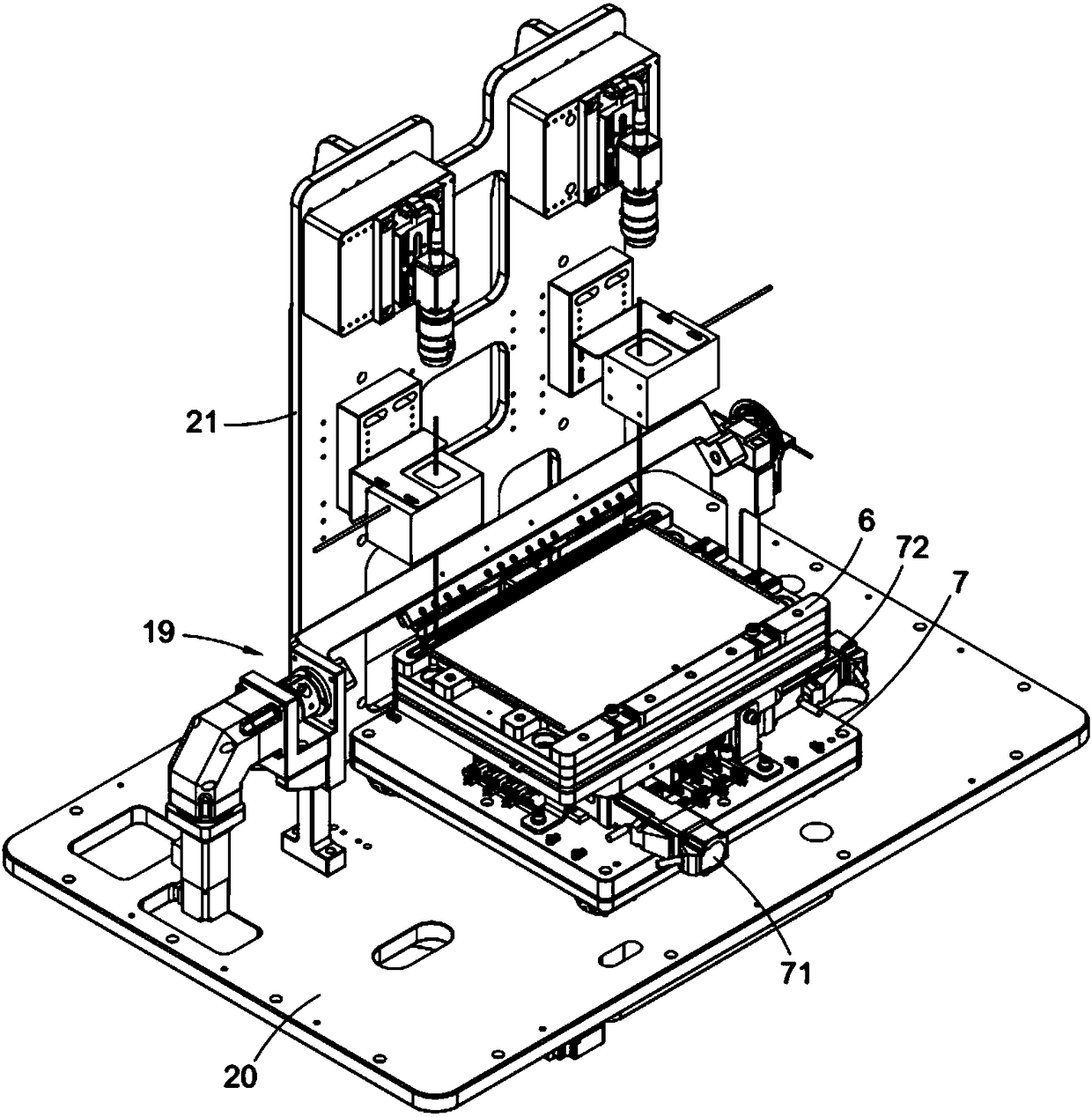

[0024] Such as figure 1 , a flip alignment pressing device, including the lower carrier 6 and the upper carrier 14.

[0025] combine Figure 1 to Figure 4 , the lowering tool 6 is installed on the alignment platform 7, and the alignment platform is provided with a longitudinal driving element 71 and a lateral driving element 72 to realize the longitudinal and lateral movement of the lowering tool, and then, the second product on the lowering tool and the upper The first product on the tool 14 is aligned; the alignment platform is installed on the lifting module 12. A pressure sensor 8 is provided between the lifting module 12 and the alignment platform 7 .

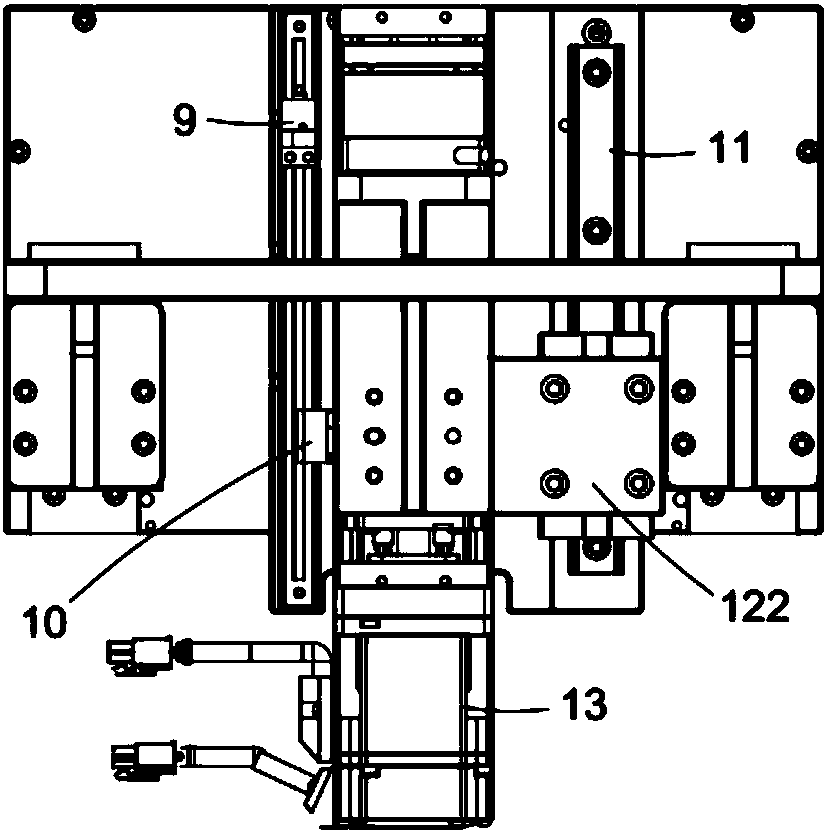

[0026] combine image 3 , Figure 4 , the above-mentioned lifting module 12 includes a screw mandrel 121 connected to the second motor 13, a lifting module 122 matched with the screw mandrel, a slide rail 11 matched with the lifting module, and the slide rail is parallel to the screw mandrel 121; the second motor 13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com