Rotary spray head and cosmetic container with rotary spray head

The technology of a cosmetic container and a rotating nozzle is applied in the container of cosmetic powder, the container for packaging cosmetics, and the container for dressing, etc., which can solve the problem of inability to meet the requirements of quick material retrieval, and achieve the effect of simple assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

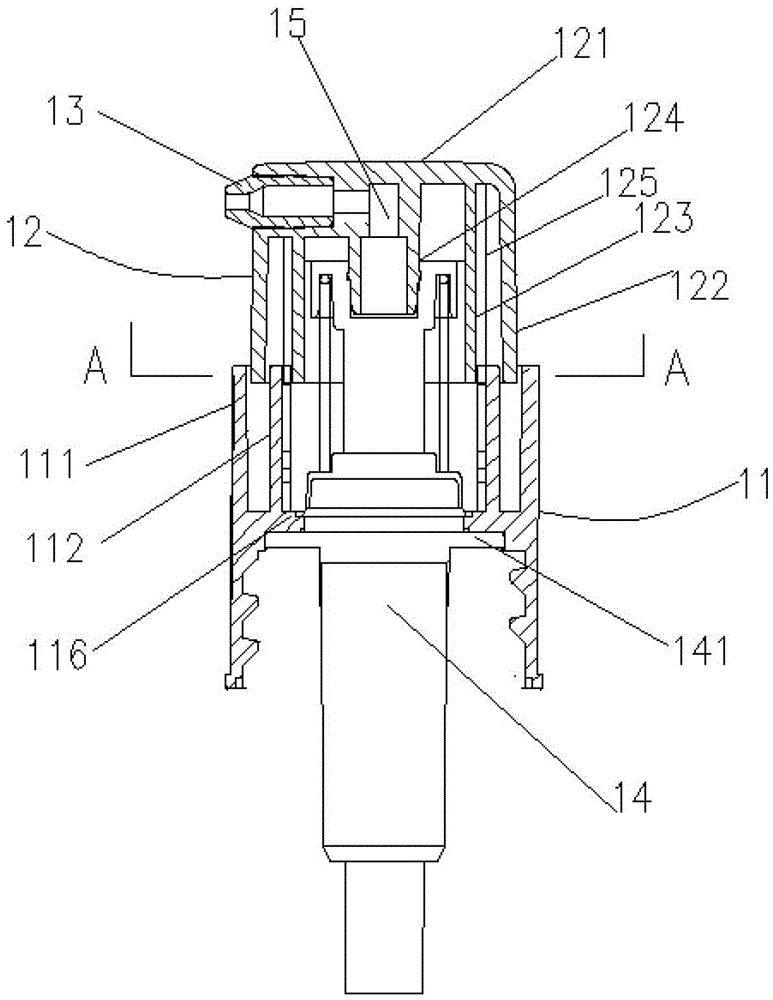

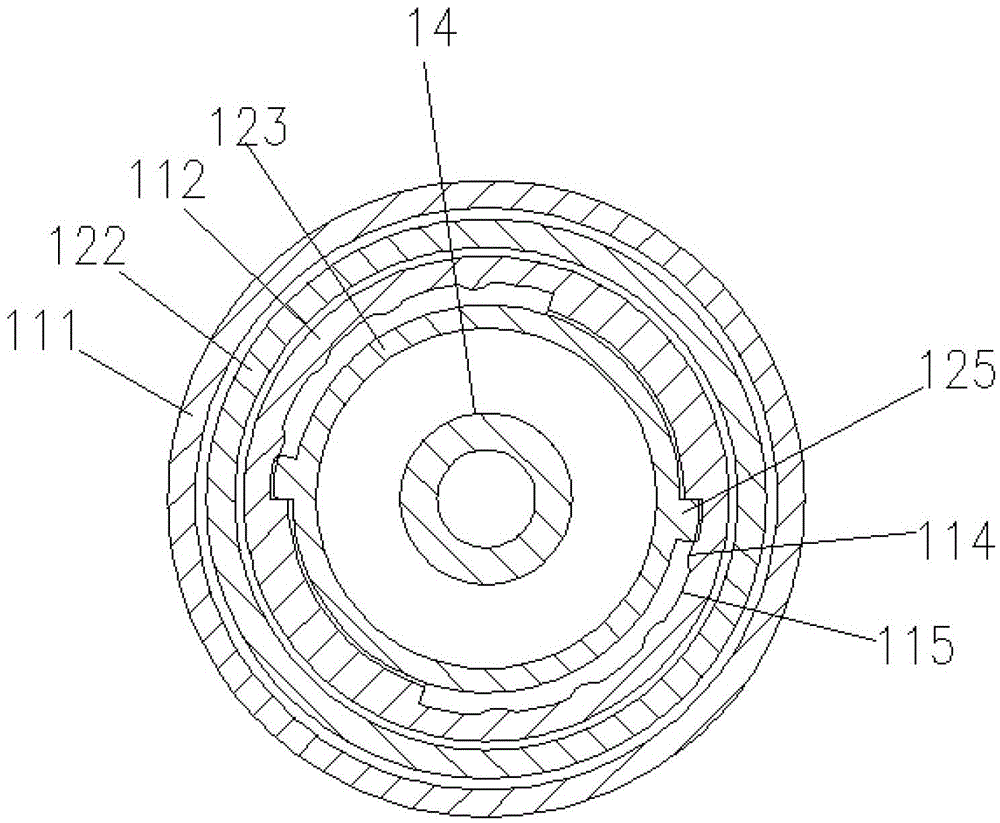

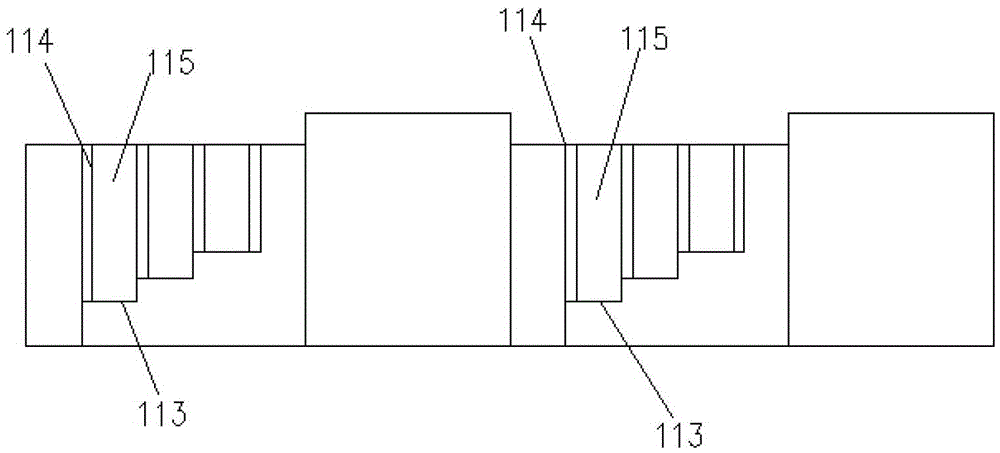

[0030] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a rotary spray head 1 includes a spray head body 11 and a button 12, a nozzle 13 is provided on one side of the top of the button, a pump body 14 is fixedly connected to the bottom of the button, and the axial middle part of the button communicates with the nozzle and the button. The pump body forms a feed flow channel 15, the button radially stops and is positioned on the nozzle body, the button can be positioned at different angles relative to the nozzle body in the circumferential direction, and along the The axial sliding stops of the spray head body are at positions of different heights. Because the positions of different angles in the circumferential direction correspond to the positions of the axial sliding stoppers of the button on the nozzle body at different heights, that is, the axial sliding distances of the pressing buttons corresponding to different heights, the shorter the axial sliding di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com