Key switch device with connecting rods and supporting plate molded separately through one plate material

A support plate and key switch technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of small plastic connecting rod structure, hole shaft structure, and increased mold design and manufacturing costs, and achieve structural strength and structural rigidity. , Structural strength and durability, improve the effect of height inconsistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

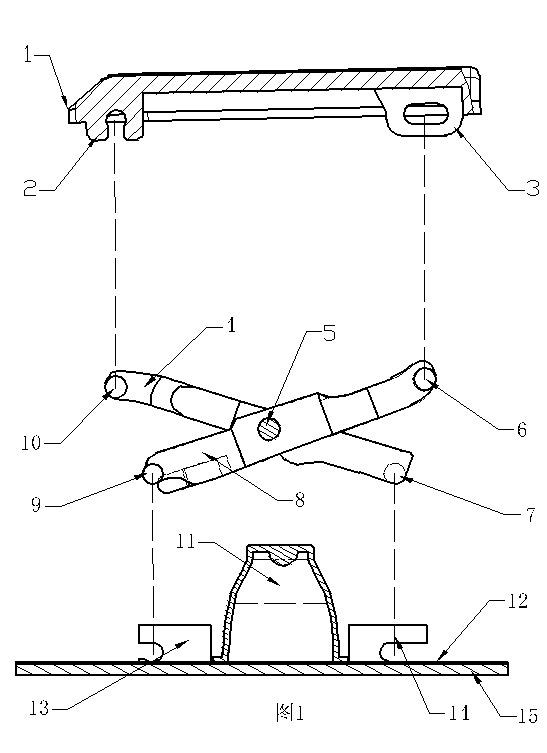

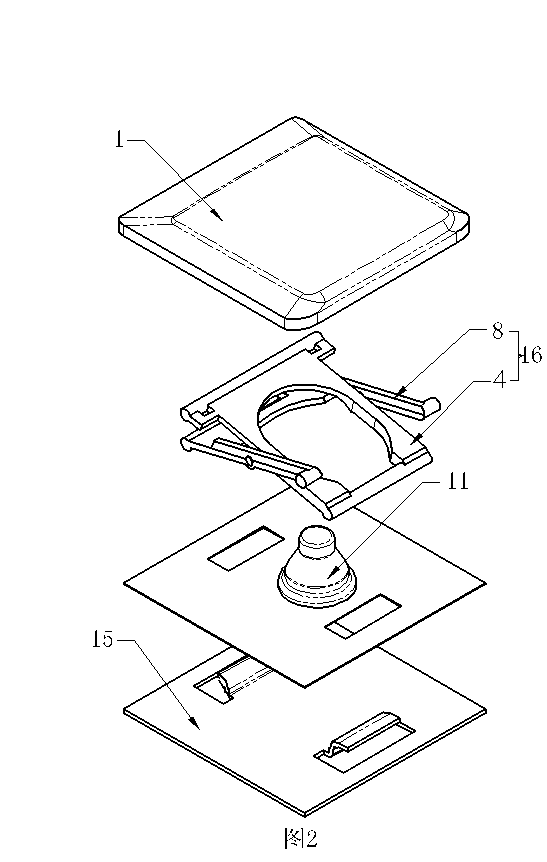

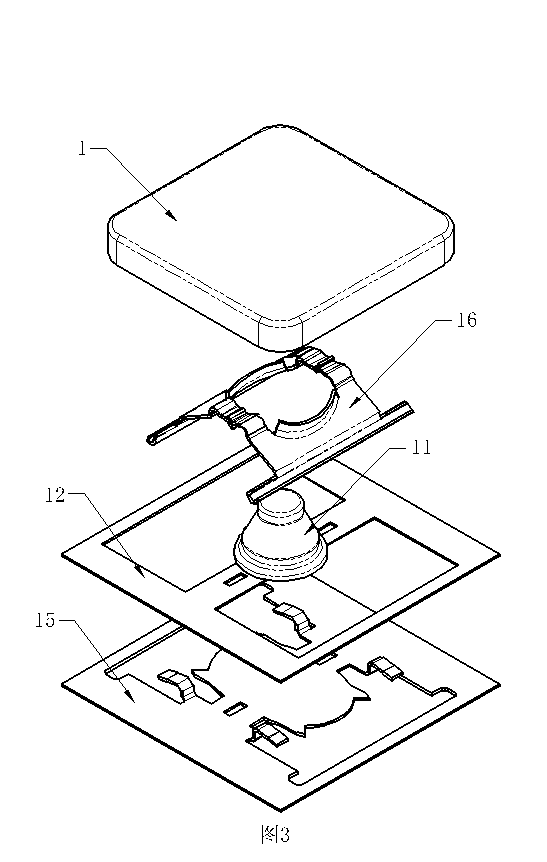

[0056] As shown in FIG. 3, the key switch device of the present invention includes a key cap 1, an elastic body 11, a membrane switch sheet 12, a support plate 15, and a pair of link supports 16. The upper end of the connecting rod support 16 is rotationally connected or slidingly connected with the keycap 1, and the lower end is rotationally connected or slidingly connected with the support plate 15. In the present invention, the upper end of the connecting rod support 16 forms a rotational connection with the keycap 1 and forms a sliding connection with the support plate 14.

[0057] As shown in Figure 4, the substrate sheet 17 structure of the present invention. The dotted line in the figure indicates the shape and size of the connecting rod sheet 18.

[0058] It should be ensured that the size and shape of the substrate sheet 17 are similar to the size and shape of the support plate 15.

[0059] As shown in FIG. 5, the substrate sheet 17 is formed into a connecting rod sheet 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com