Auxiliary device for aero-engine casing assembling

A technology for aero-engines and auxiliary devices, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as difficulty in casing assembly, and achieve the effects of shortening pre-installation time, shortening adjustment time, and balanced airflow temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

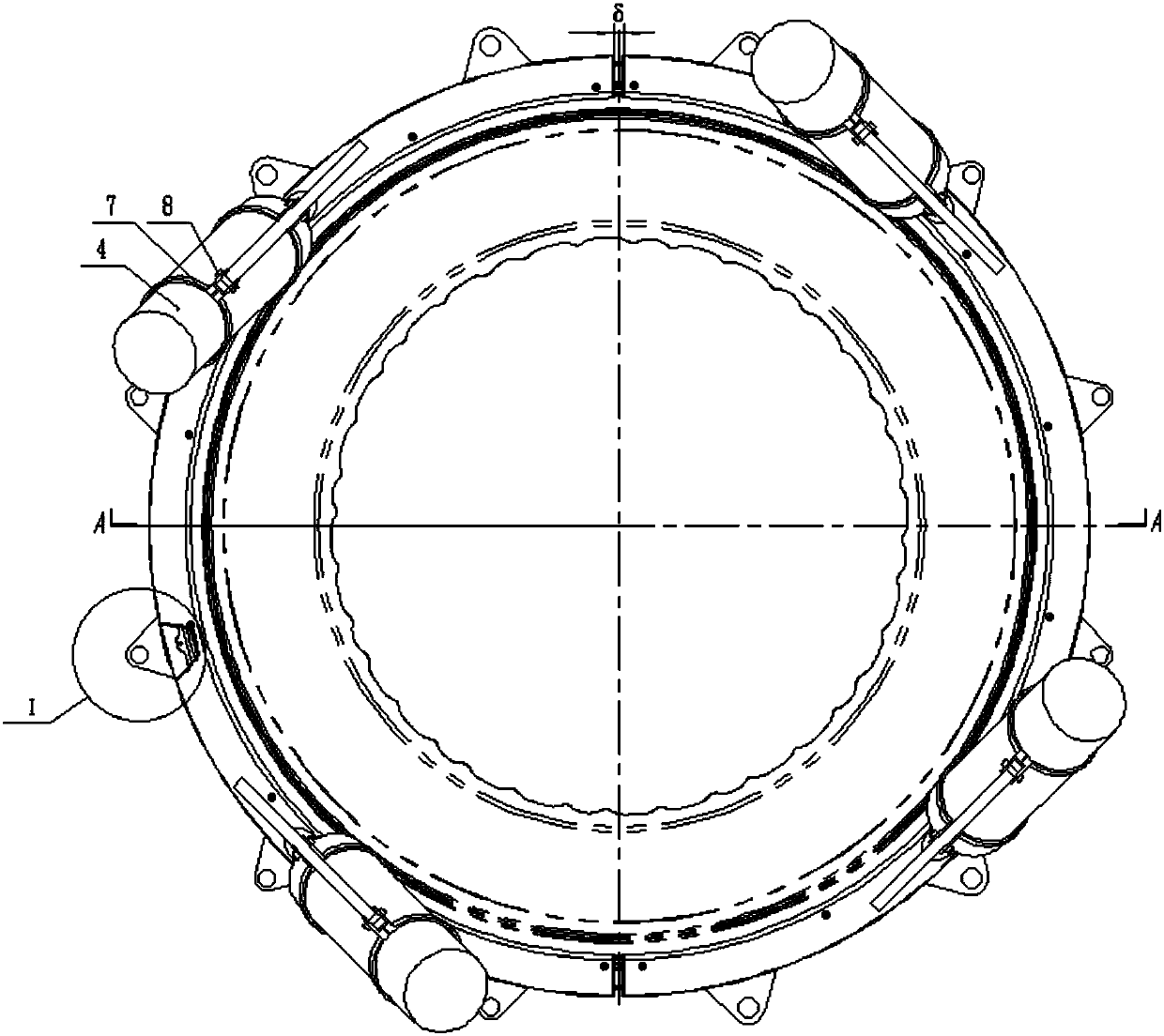

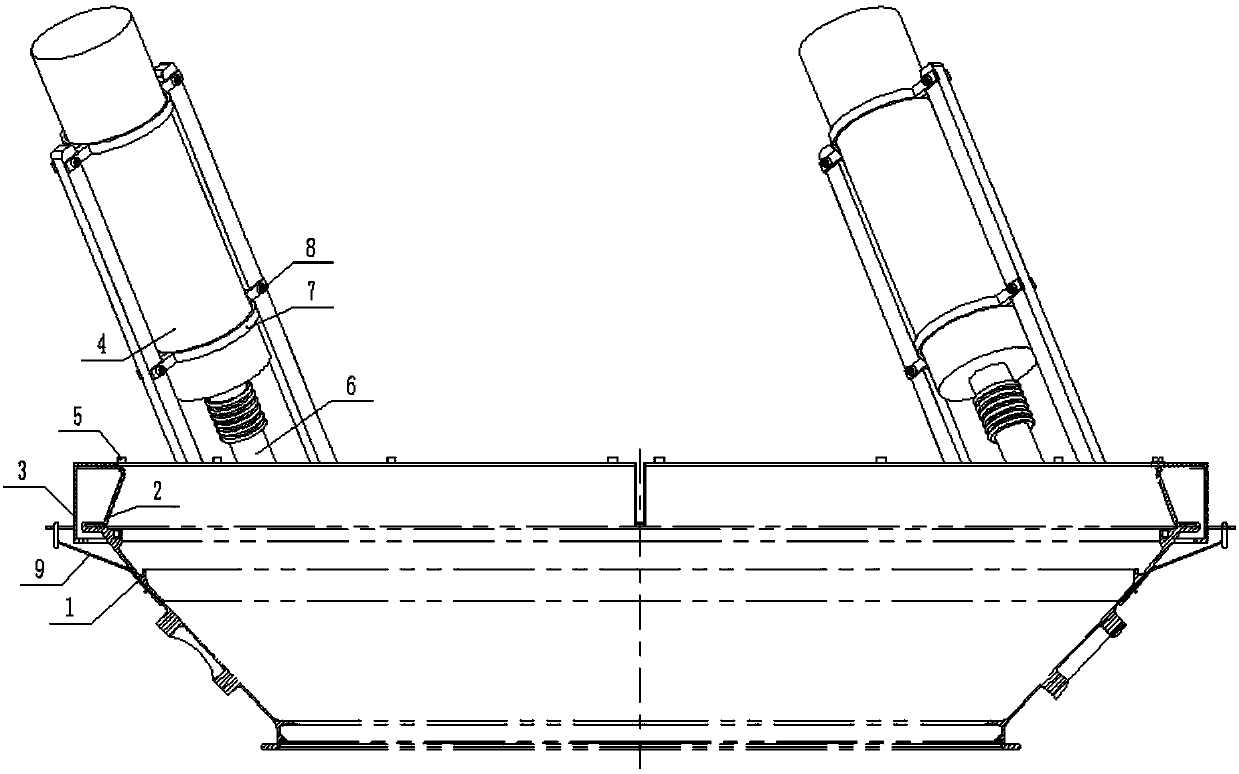

[0030] The auxiliary device used in the assembly of the aero-engine casing provided by this embodiment, such as figure 1 and figure 2 As shown, it includes an annular channel that surrounds the flange seam of the casing section 1 to be assembled and four hot air blowers 4 arranged on the annular channel. The outlet of the hot air blower communicates with the annular duct through the hot air pipe 6 .

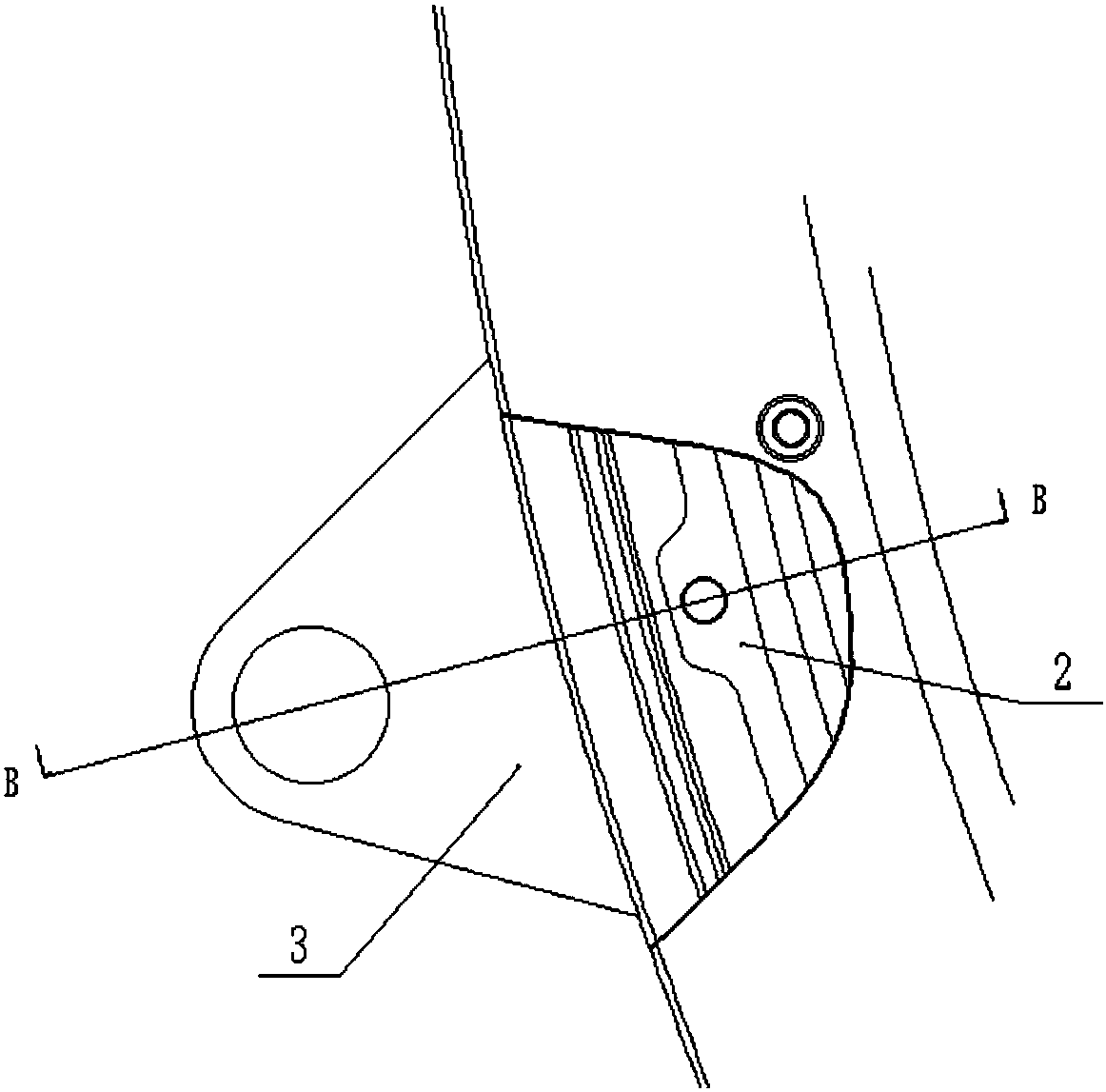

[0031] Such as Figure 1 to Figure 4As shown, the annular channel is a split structure in the middle, and each part is equipped with 2 hot air blowers. After the two parts of the annular channel are assembled together, there is an assembly gap of 4 mm between the butt end faces. Each part of the annular channel is composed of a supporting ring 2 with a groove-shaped cross-section structure opening outward and a cover ring 3 with a groove-shaped cross-section structure opening inward. The annular edge of the groove wall under the support ring is a convex-concave lace structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com