Platformization vehicle body floor structure and assembling method thereof

A body floor and platform-based technology, applied in the direction of upper structure, upper structure sub-assembly, vehicle parts, etc., can solve the problem that it is difficult to ensure the universalization of parts of the front floor assembly, reduce the development cycle and development cost, and affect the front floor assembly. In order to achieve the effects of low cost and technical difficulty, increase the rate of continued use, and increase the rate of generalization of the platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

[0028] For the convenience of description, define the length direction of the lower body of the vehicle platform as the first direction.

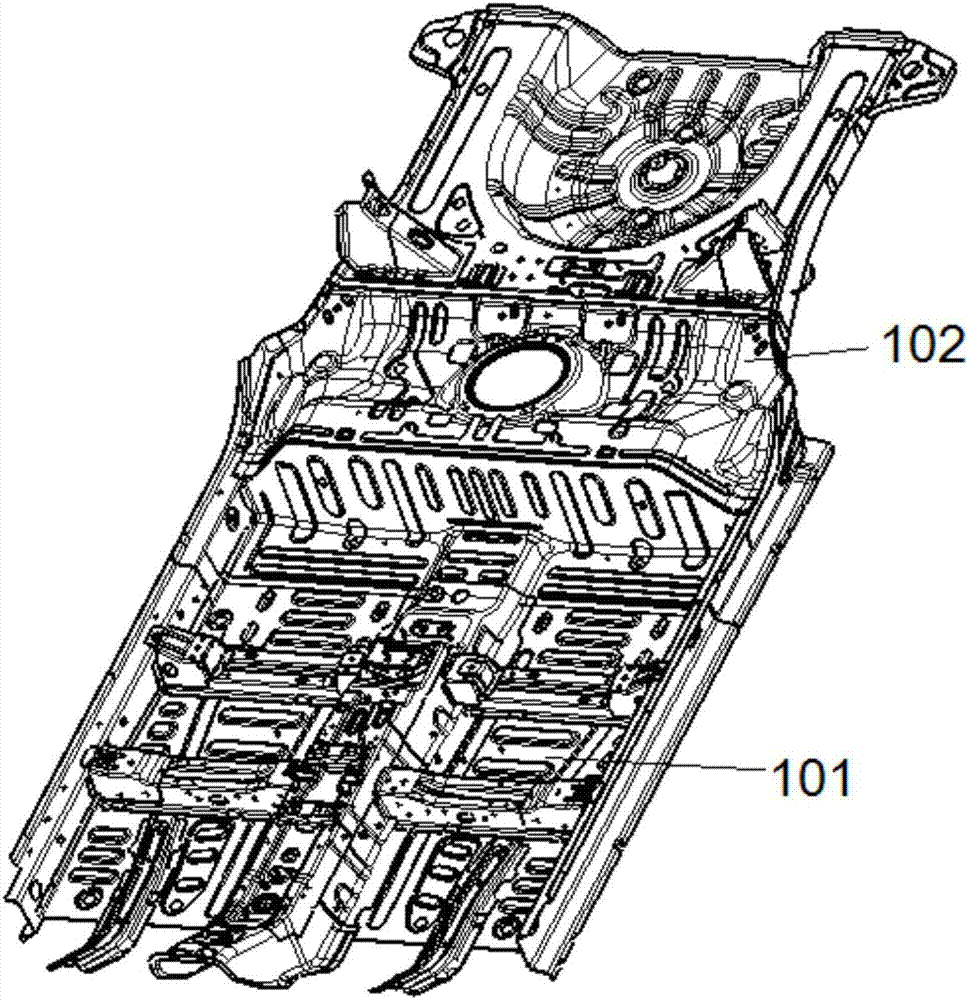

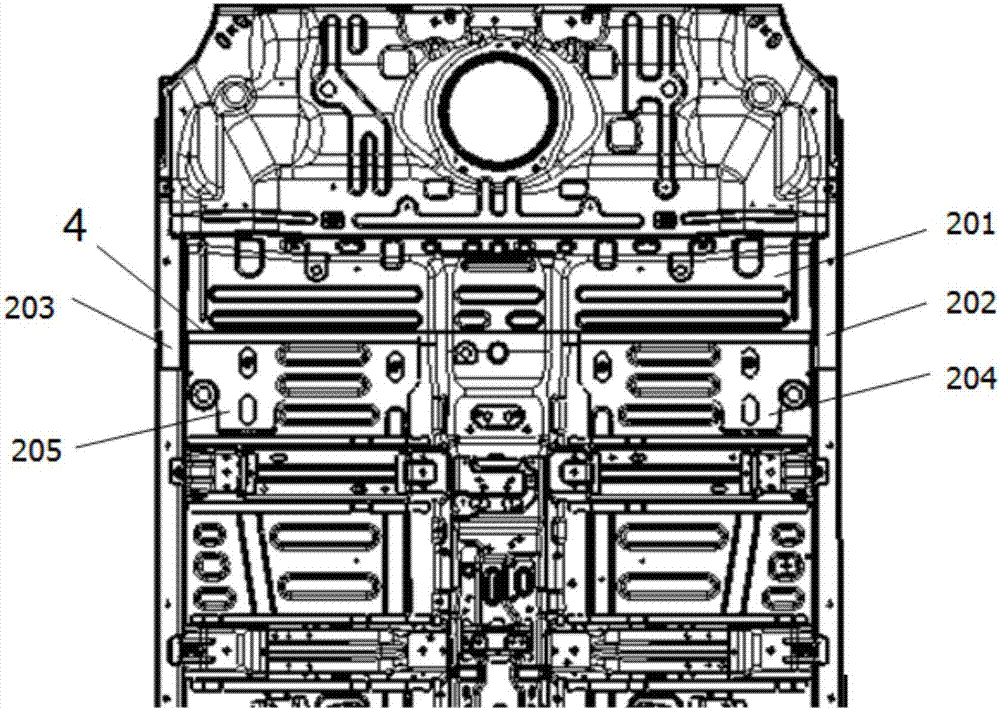

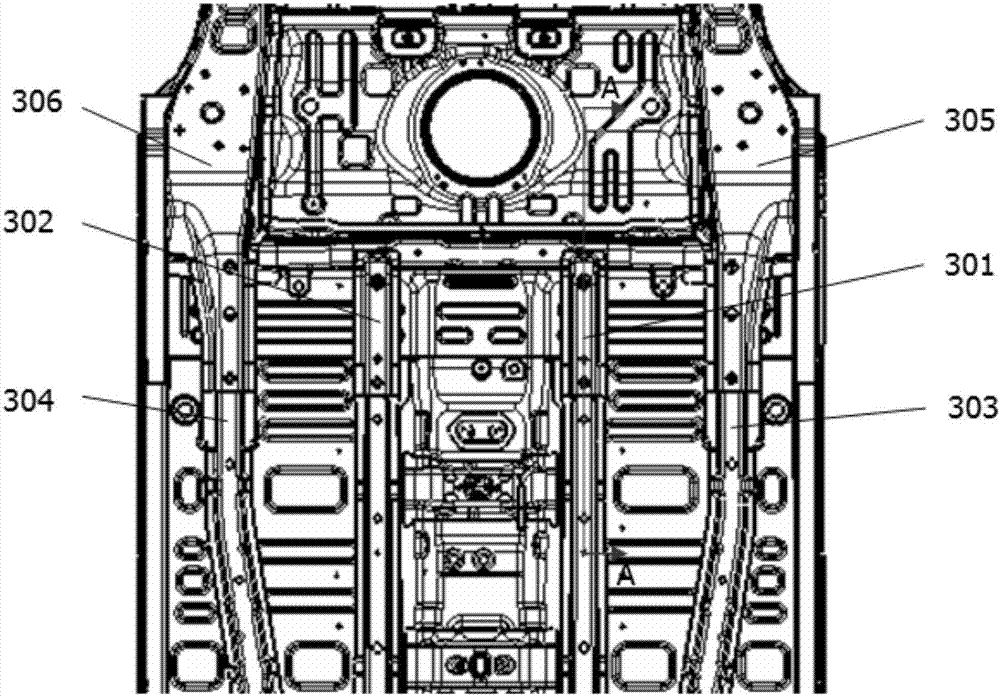

[0029] Such as Figure 1-Figure 4 As shown, this kind of platform body floor structure includes a front floor assembly 101 and a rear floor assembly 102. The rear floor assembly 102 includes a mid-sole connecting plate 201 connected to the front floor of the front floor assembly 101, including a The rear section of the sill connected to the front sill of the floor assembly 101 includes the rear longitudinal beam of the middle channel connected with the longitudinal beam of the central channel of the front floor assembly 101 and the rear longitudinal beam connected with the front floor longitudinal beam of the front floor assembly 101 . The front floor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com