Automatic riveting device for sealing inner container of water heater

An automatic riveting and water heater technology, applied in the field of mechanical processing, can solve the problems of small application range, affecting riveting quality, low work efficiency, etc., and achieve the effect of highly flexible grasping, easy control, and compact device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

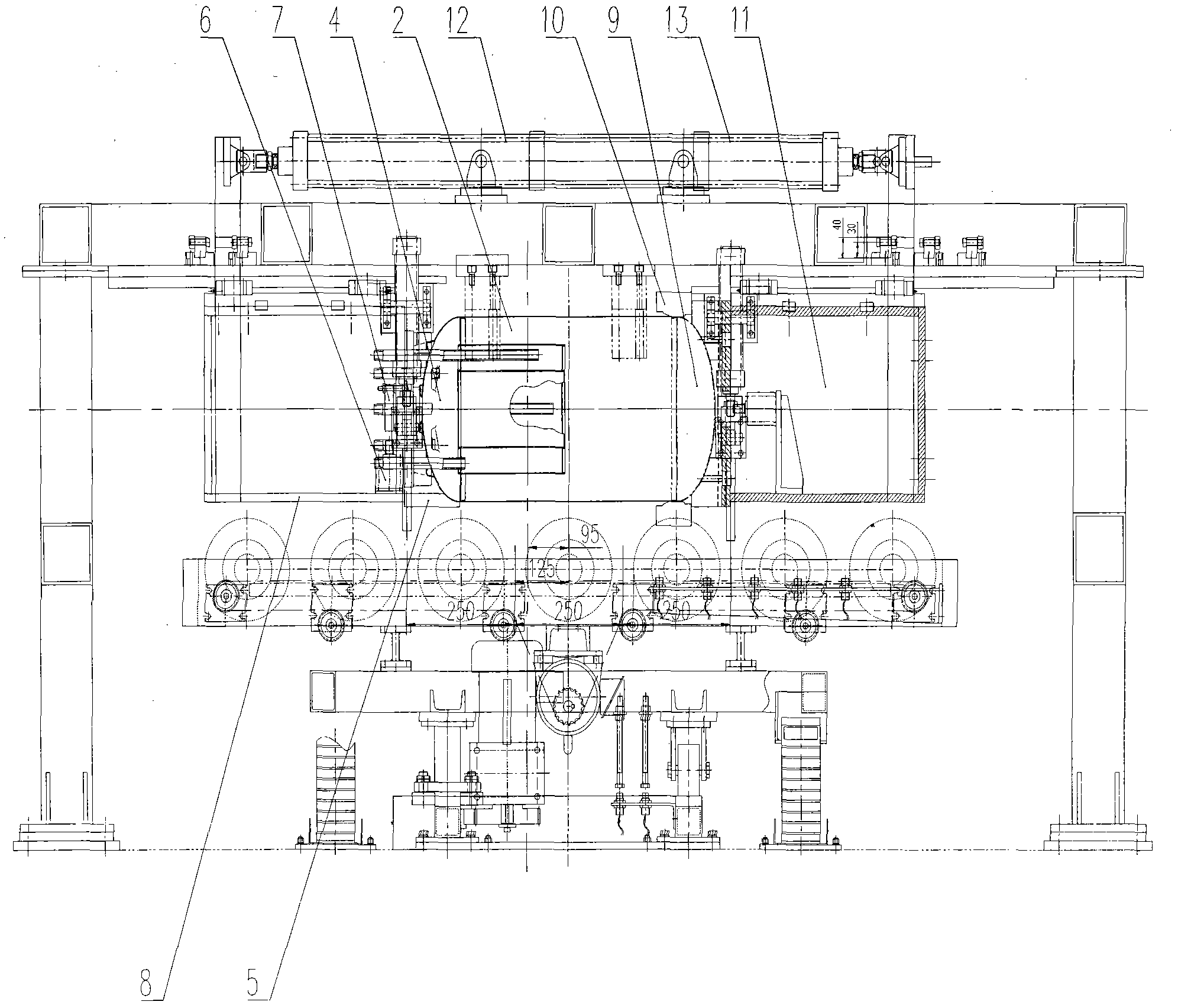

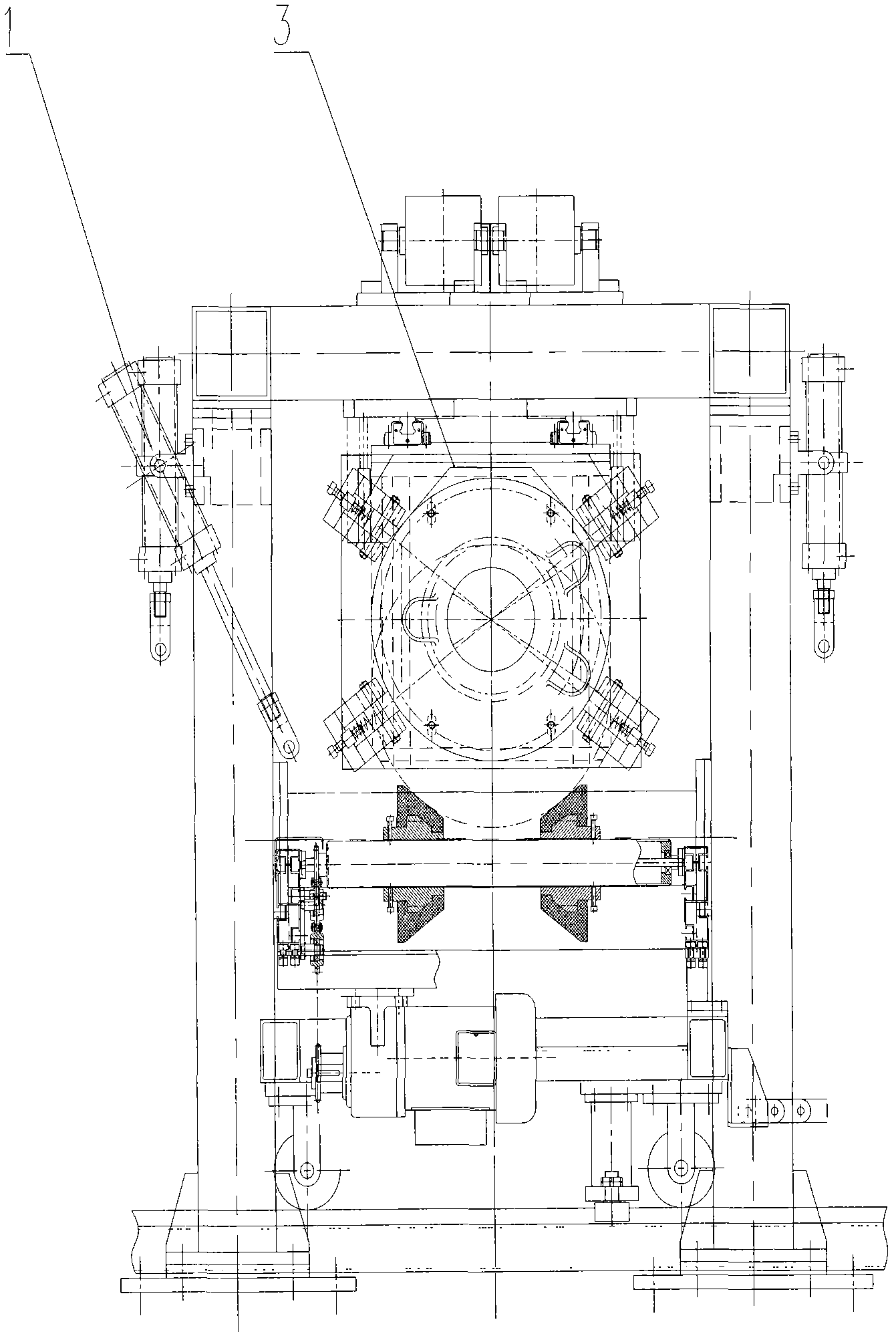

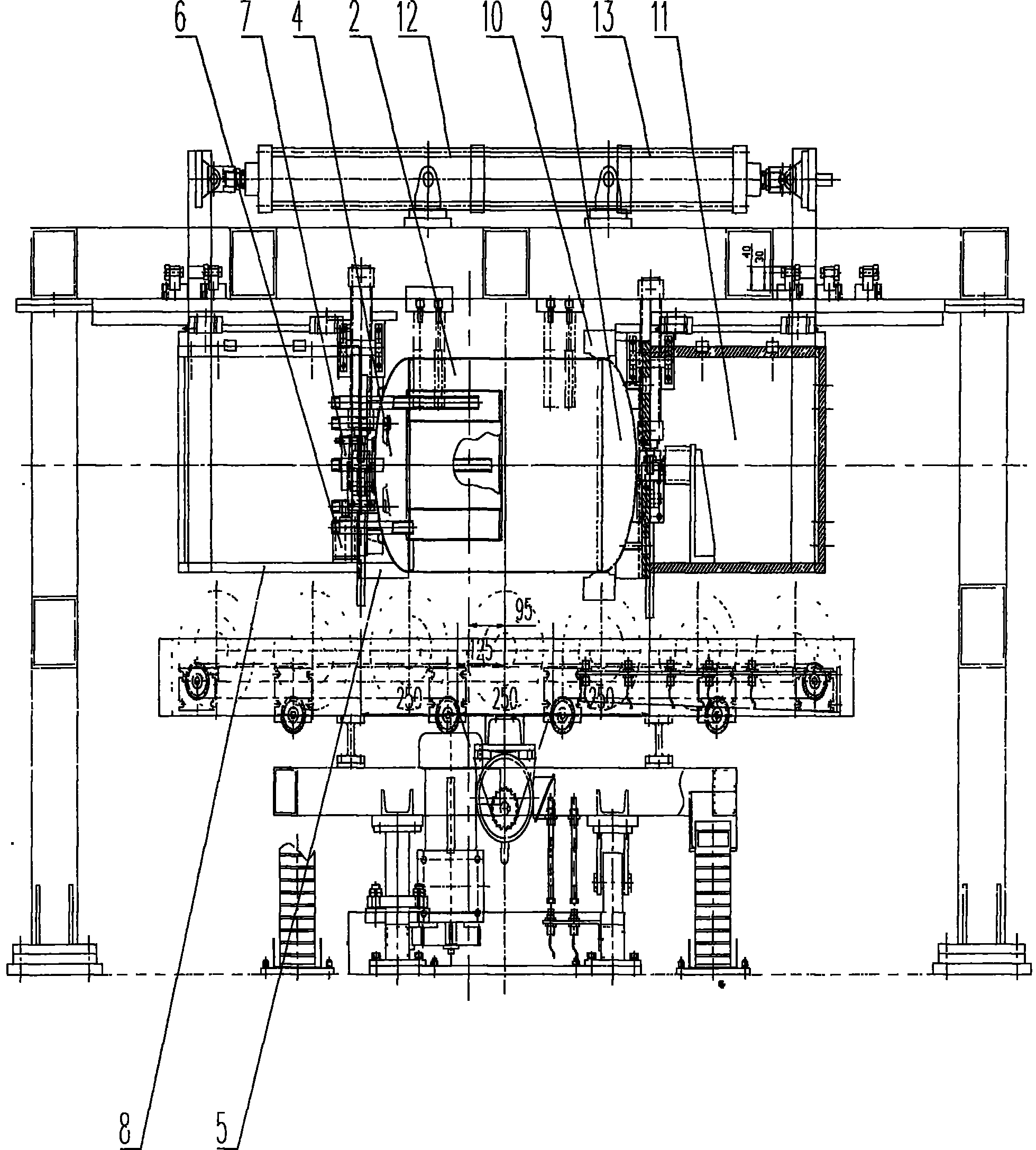

[0010] As shown in the figure: an automatic riveting device for the water heater sealed inner tank, the device includes two columns 14, and a beam 15 is installed on the two columns 14, and a grabbing robot is fixedly installed on both sides of the beam 15 1. A V-shaped positioning block 3 is installed on the lower end surface of the crossbeam 15 located in the middle of the two grasping manipulators 1, and the position of the V-shaped positioning block 3 is adjustable. The V-shaped positioning block 3 on both sides Corresponding guide grooves are respectively provided on the lower end surface of the crossbeam 15, and movable left and right fixing seats 8, 11 are respectively installed in the described guiding grooves, and the corresponding ends of the left and right fixing seats 8, 11 End cover positioning blocks 5 and 10 are installed respectively, and a cylinder is installed on the left fixed seat 8, and several clamping claws 7 are installed on the end of the piston rod of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com