Transmission mechanism for automatic assembly of eyebrow pencils

A technology of automatic assembly and transmission mechanism, which is applied in the direction of conveyor, transportation and packaging to achieve the effect of stable operation, convenient transmission and meeting assembly requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

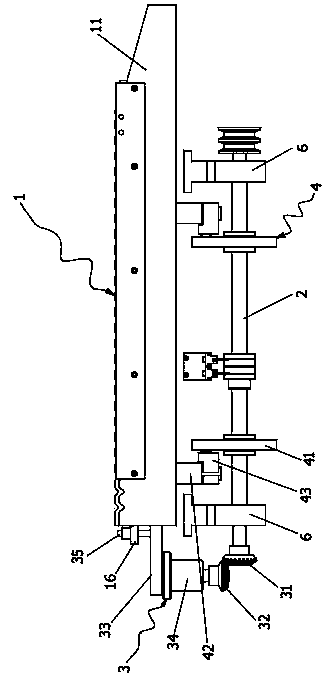

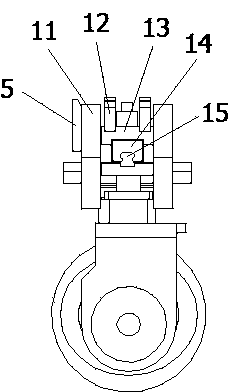

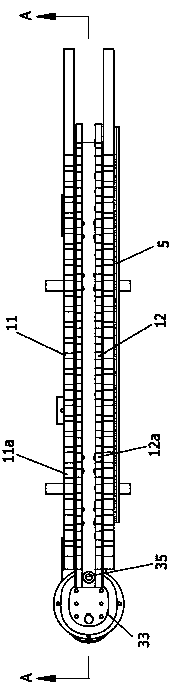

[0024] Figure 1 to Figure 7 It is a schematic diagram of the structure of the present invention.

[0025] The reference signs are: conveyor belt 1, fixed conveyor plate 11, groove grid 11a, movable conveyor plate 12, concave arc grid 12a, connecting block 13, sliding block 14, sliding rail 15, reciprocating link 16, main drive cam Shaft 2, reciprocating cam mechanism 3, first bevel gear 31, second bevel gear 32, reciprocating cam disc 33, cam main shaft 34, reciprocating cam follower shaft 35, undulating cam mechanism 4, undulating cam 41, circulating cam follower shaft 42. Circulating camshaft connecting sleeve 43, limiting side plate 5, bearing connecting seat 6.

[0026] like Figure 1 to Figure 7 As shown, the automatic assembly transmission mechanism of the eyebrow pencil of the present invention includes a conveyor belt 1 located on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com