Metal-plastic composite mobile phone shell and forming method thereof

A mobile phone shell and plastic technology, which is applied to other household appliances, household components, household appliances, etc., can solve the problems of easy existence of bonding strength and bonding process, high cost of amorphous alloys, and few application occasions, so as to avoid physical problems. Effects of damage, environmental protection, good dimensional accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Select a 2014 aluminum alloy rolled sheet with a thickness of 0.8mm, and machine it into a billet with a size of 120mm×70mm×0.8mm and a fillet radius of 30mm. After being stamped and formed by a special drawing die to reach the predetermined deformation, it is taken out from the die to obtain The base layer of the aluminum alloy mobile phone case with good surface quality, strong rigidity, and high precision in shape and size. Immerse the formed base aluminum alloy in sodium hydroxide solution, take it out after 10 minutes, remove surface dust, oil and other impurities, and then immerse it in low-concentration nitric acid solution for 3 minutes to remove the lye remaining on the base aluminum alloy , take it out, wash it in pure water, and dry it for later use.

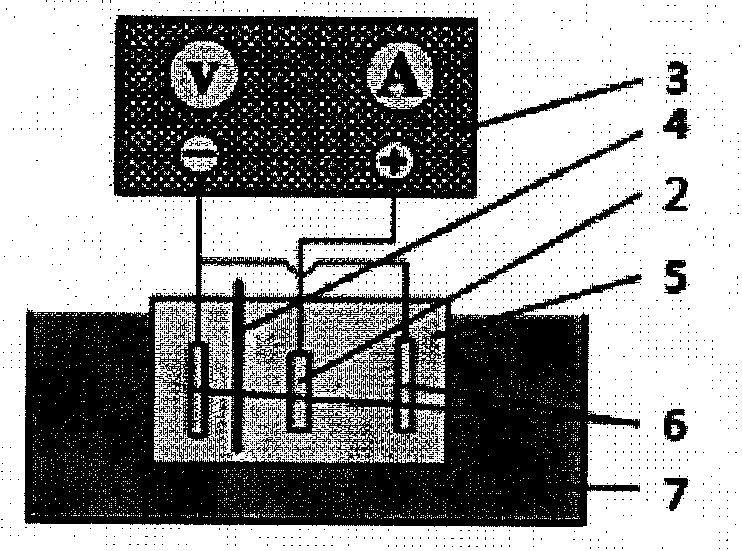

[0035]Add 150g / L sulfuric acid and oxalic acid solution to the electrolytic cell 5 to configure the electrolytic solution, fix the cleaned and dried aluminum alloy plate to the anode 1 of the electrolytic cell ...

Embodiment 2

[0038] Select a magnesium alloy rolled sheet with a thickness of 0.8mm and a grade of AZ91D, machine it into a billet with a size of 120mm×70mm×0.8mm and a fillet radius of 30mm, and coat the special drawing die and the billet with polytetrafluoroethylene lubricant respectively. Then stamping and forming to obtain the base layer of the magnesium alloy mobile phone shell with good surface quality, strong rigidity, and high precision in shape and size. Place the formed base magnesium alloy in absolute ethanol and acetone solution for 15 minutes to thoroughly remove possible stains and other impurities on the surface, then clean it with pure water and dry it for use.

[0039] Micro-arc oxidation equipment was used to conduct experiments in a sodium aluminate system solution with a concentration of 9g / L. The AZ91D sample was connected to the positive pole of the power supply, and the stainless steel oxidation tank was connected to the negative pole. The process parameters were: cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com