Clamping fixture for correcting vehicle frame

A frame and fixture technology, applied in the tool field of relative position relationship, can solve the problems affecting the assembly process, scrap parts, reduce production efficiency, etc., and achieve the effect of reducing scrap parts, reducing production costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

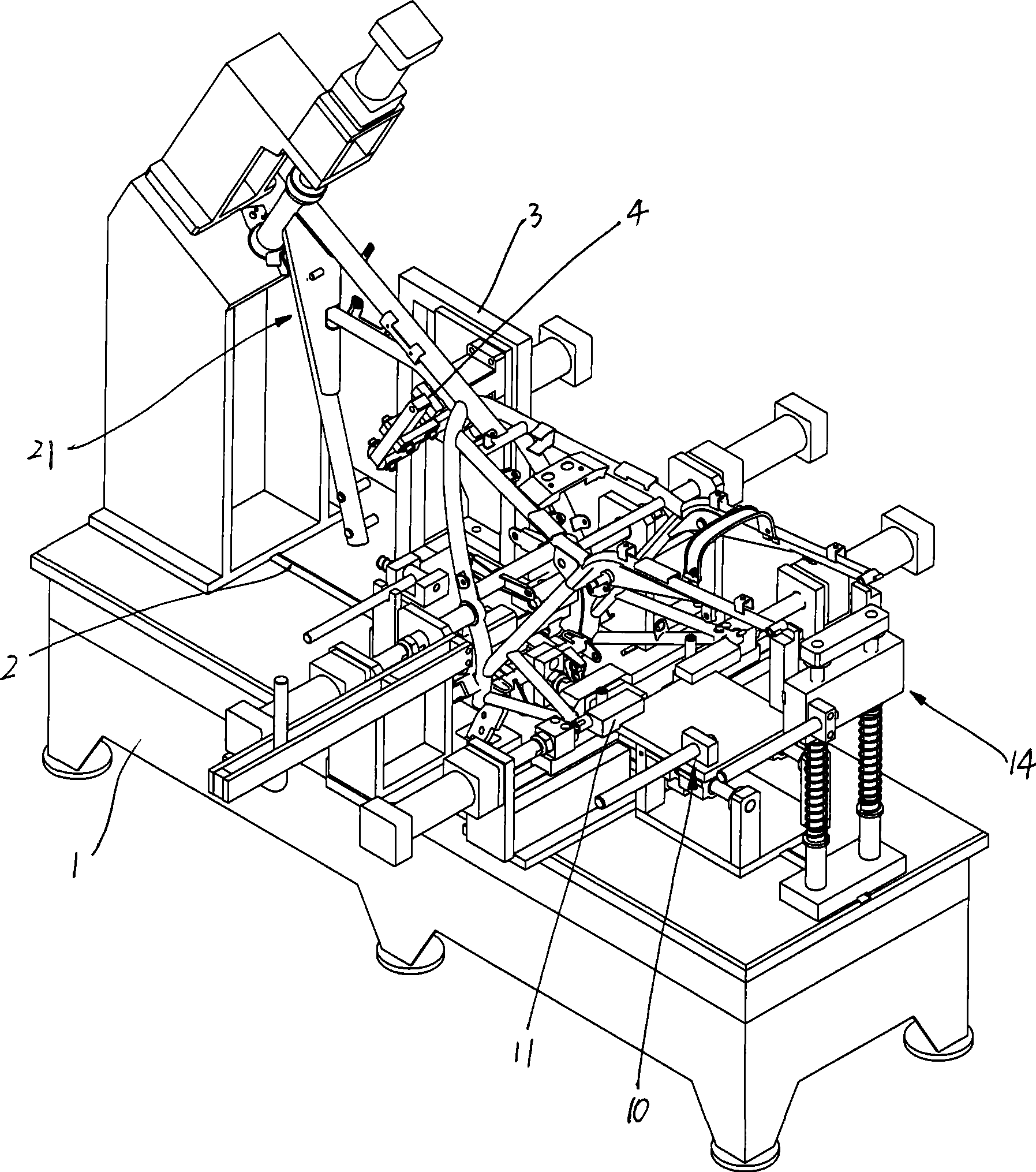

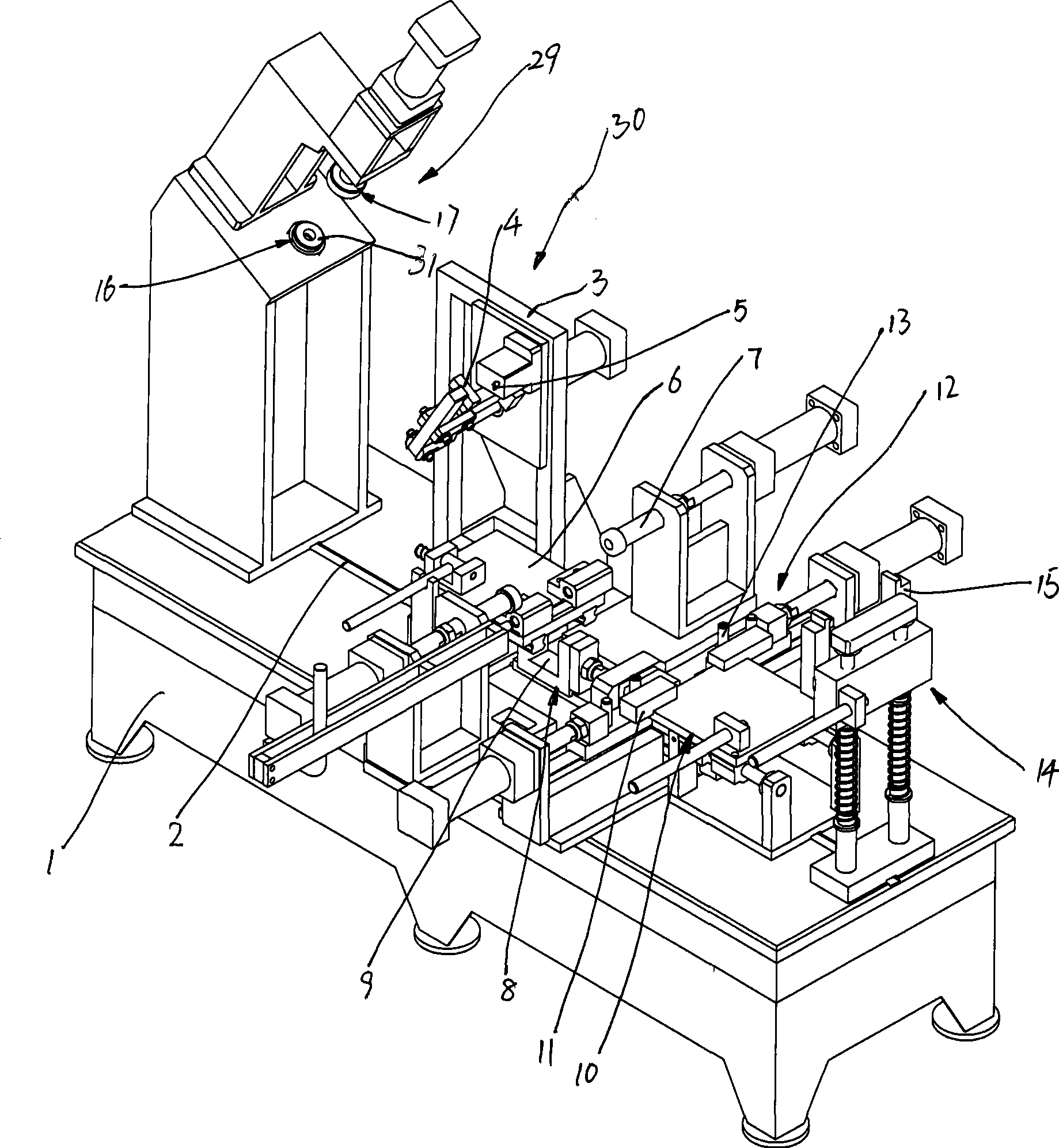

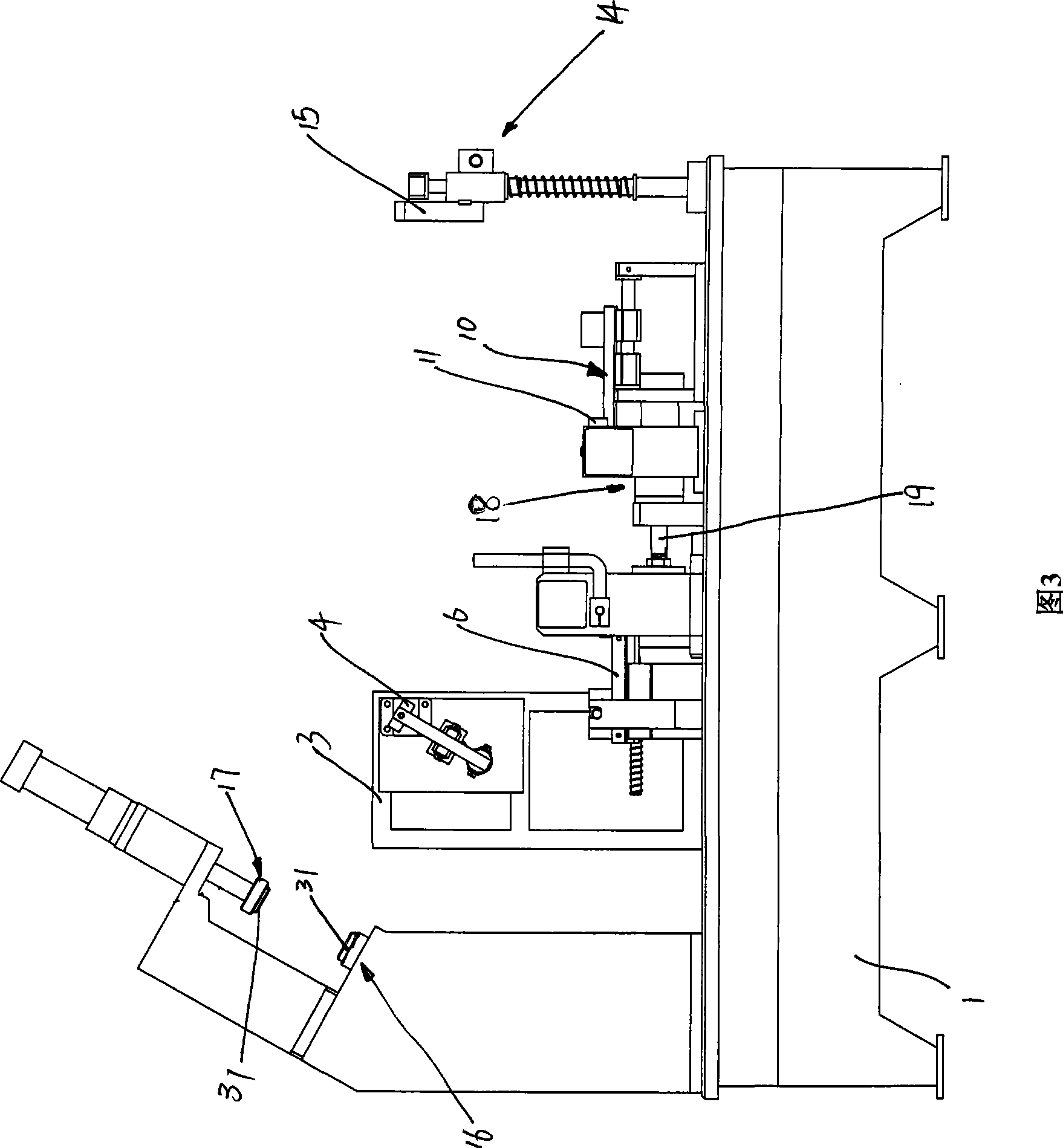

[0018] See attached figure 1 As shown in FIG. 4 , a frame correction jig includes a frame 1 and a fixing device fixed on the frame 1 for fixing the frame 21 .

[0019] Described fixing device comprises the workpiece clamping seat 29 (attached) that is fixedly arranged on the front portion of described frame 1 and is used for clamping the front portion of vehicle frame 21 figure 1 The middle left side is "front", the right side is "rear"), fixedly arranged behind the workpiece clamping seat 29 and used for positioning the workpiece positioning seat 30 of the vehicle frame 21, elastically arranged on the frame 1 and the support base 14 that can be lifted in the vertical direction.

[0020] The workpiece holder 29 includes a positioning block 16 fixedly arranged on the frame 1 and a die 17 movably arranged above the positioning block 16 (the positional relationship of "upper" and "lower" in this specification with attached figure 1 Corresponding to the upper and lower position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com