Assembly base used on automobile seat assembling line

An assembly line and car seat technology, which is applied to assembly machines, workpiece clamping devices, metal processing equipment, etc., can solve problems such as inability to meet centralized automated production, inability to realize seat rotation, and affect seat assembly efficiency, etc., to achieve The effect of meeting assembly requirements and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

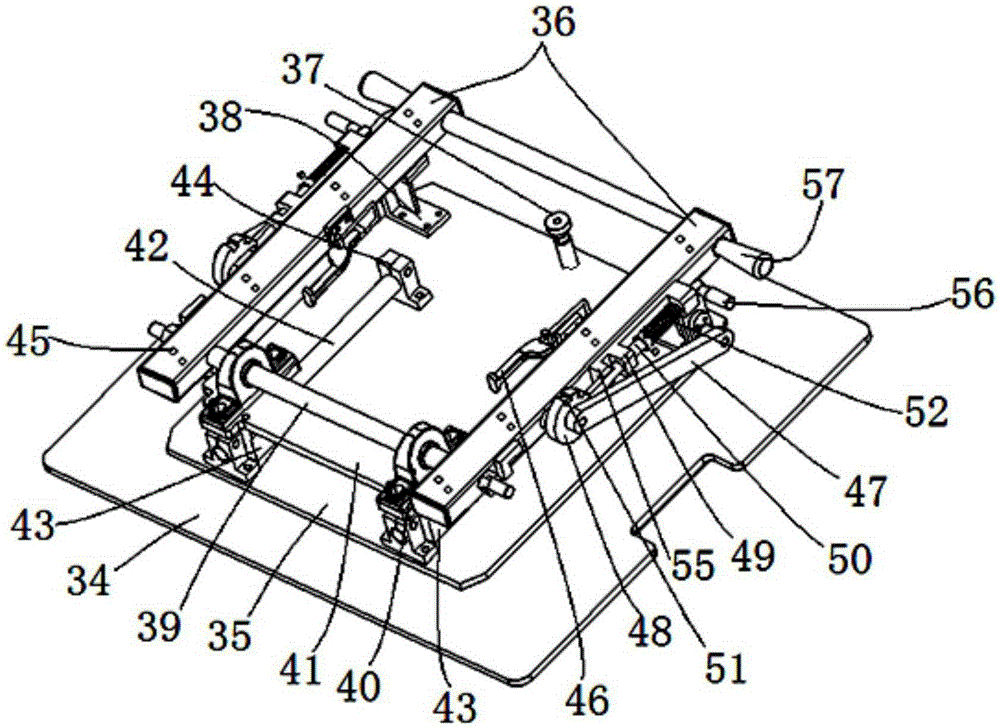

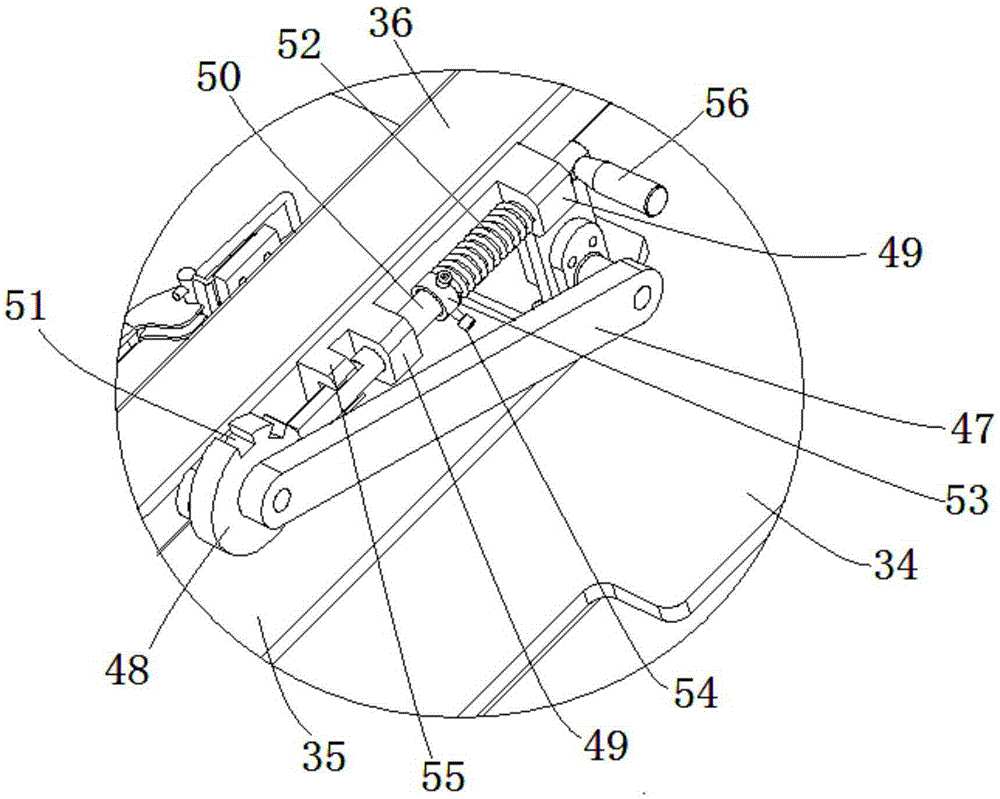

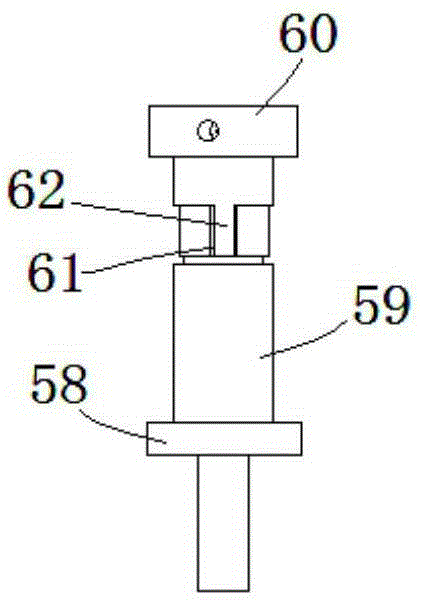

[0022] Such as figure 1 and figure 2 Shown, be used for the assembly base of automobile seat assembly production line, comprise the base plate 34 that is placed on the conveyor chain of assembly line, be located at base plate 34 and support plate 35 and support rail 36 that can rotate around base plate 34; Support plate 35 There is a locking pin 37 that cooperates with the positioning pin hole set on the bottom plate 34; the support plate 35 is provided with a support seat 38 supported on one end of the support rail 36, and the other end of the support rail 36 is connected by a cross bar 39; The two ends of the cross bar 39 are provided with a bearing 40 that is rotationally connected with the cross bar 39, and the cross bar 39 and the support 40 are connected by bearings installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com