Machining process of loading and unloading conveying device and step shaft sleeves of centerless grinding machine

A technology of centerless grinding machine and transmission device, which is applied in the direction of grinding machines, metal processing equipment, and machine tools designed for grinding the rotating surface of workpieces, etc. It can solve the problems of reducing production efficiency, affecting labor costs, and affecting the quality of finished products, so as to reduce labor intensity. , Increase grinding efficiency and save processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to understand better, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments:

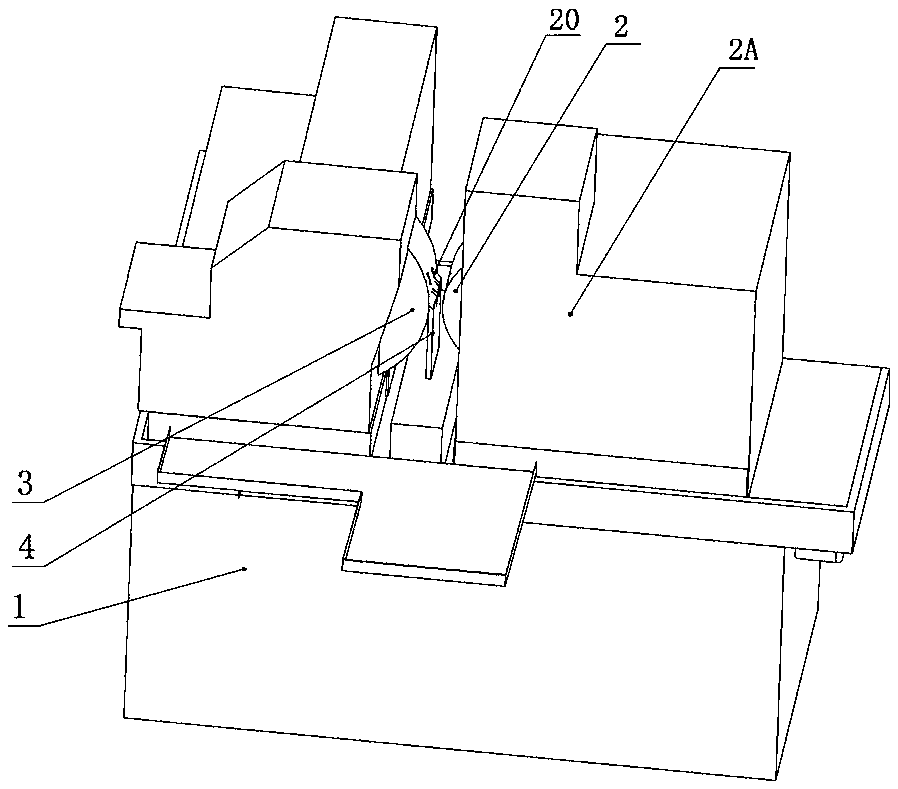

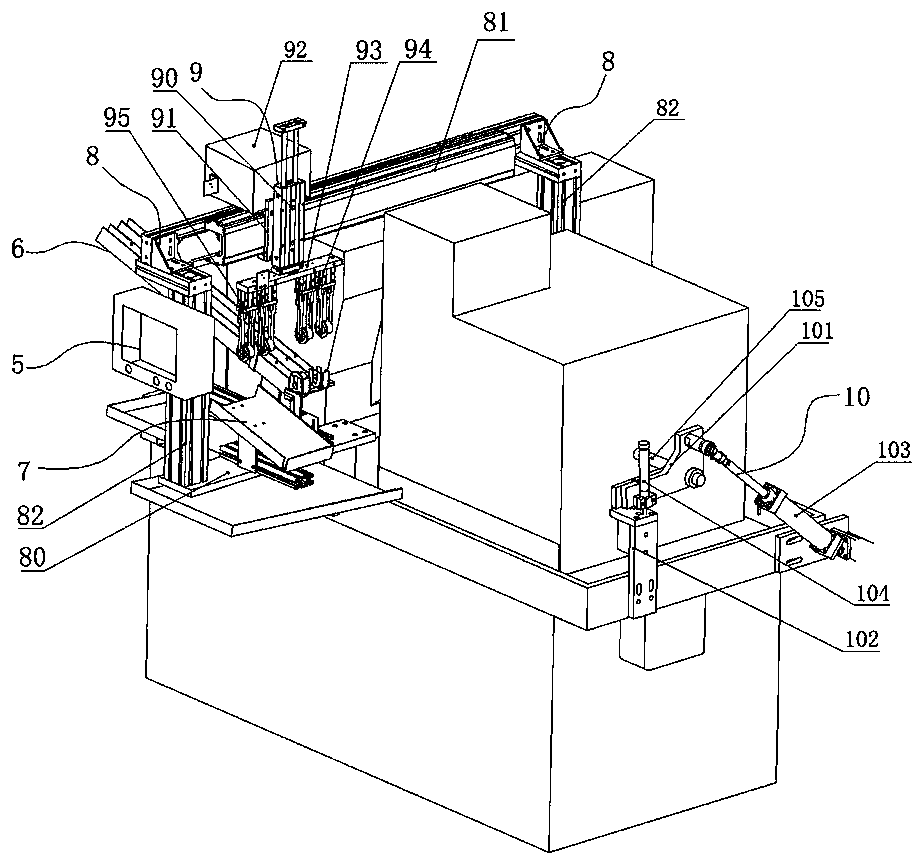

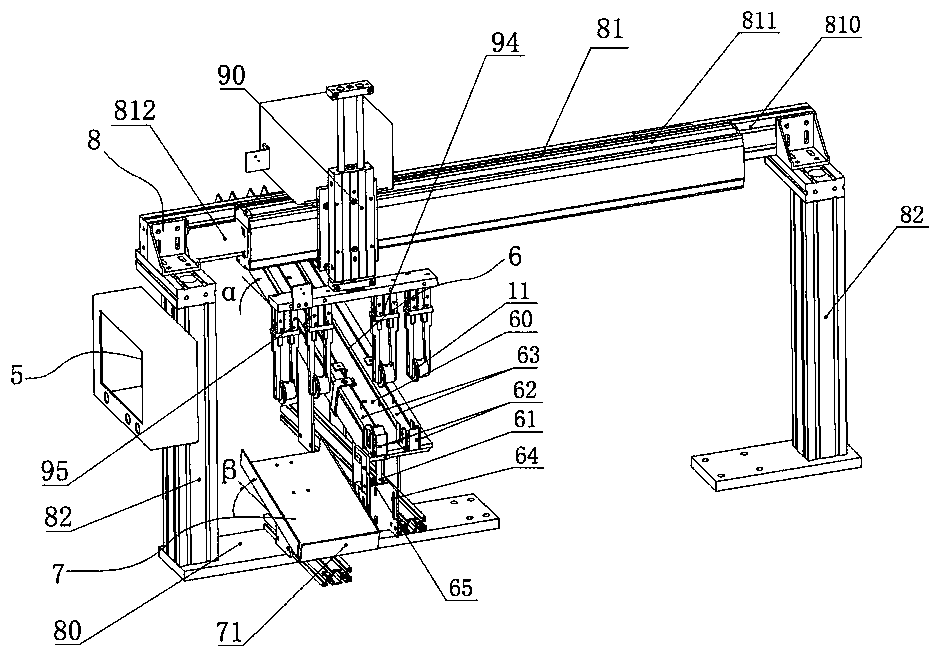

[0035] like figure 1 , figure 2 , image 3 , Figure 4The loading and unloading transmission device of the centerless grinding machine shown, wherein the centerless grinding machine includes a grinding machine seat 1, a grinding wheel 2, an adjustment wheel 3 and a workpiece support 4, and the loading and unloading transmission device includes a control cabinet 5, a feeding mechanism 6, and a feeding bin 7 , loading and unloading conveying mechanism 8, loading and unloading clamping mechanism 9 and propulsion device 10; Described loading and unloading conveying mechanism 8 comprises the base 80 that is placed on the grinding machine seat 1, slide guide rail part 81 and two Y-axis support seats 82, two A Y-axis support seat 82 is placed on the front and rear s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com