Back-to-back assembly type biserial angular contact ball bearing and assembling method thereof

A double row angular contact and ball bearing technology, applied in the direction of rolling contact bearings, bearings, bearing components, etc., can solve the problem of cumbersome preloading operation, and achieve the effect of simple installation process, reduced installation difficulty, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

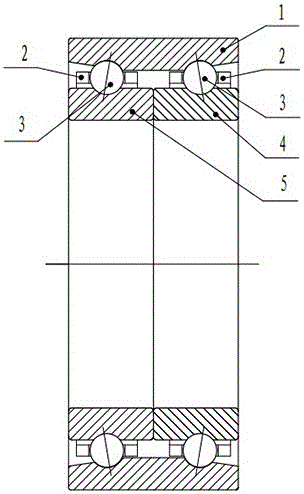

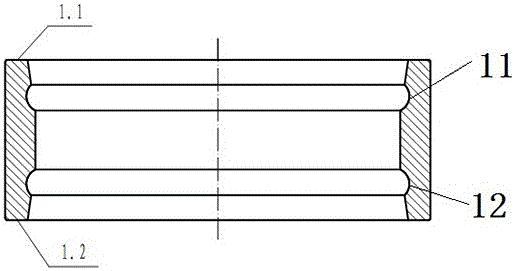

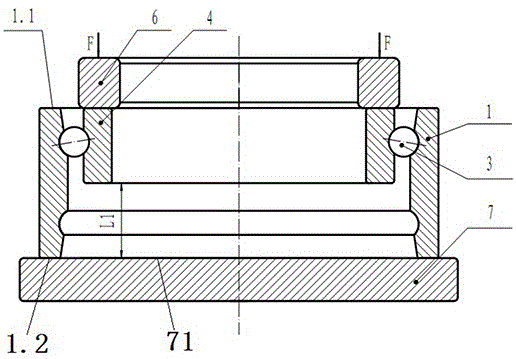

[0020] like figure 1 , figure 2 As shown, an embodiment of a back-to-back assembled double-row angular contact ball bearing, the back-to-back assembled double-row angular contact ball bearing in this embodiment includes an outer ring 1 extending axially along the front-to-back direction, and the outer ring 1 The inner circumferential surface is provided with a first inner channel and a second inner channel arranged at intervals along the front and rear directions, and the two inner channels on the outer ring are in one-to-one correspondence with the two inner channels in the axial direction of the outer ring. End arrangement. The outer ring 1 is fitted with a first inner ring 4 corresponding to the first inner channel and a second inner ring 5 corresponding to the second outer channel. There are outer grooves on the outer peripheral surface of the inner ring, and the outer grooves of the two inner rings and the two inner grooves of the outer ring are filled with steel balls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com