High-entropy single-crystal metal oxide with cation disordered rock salt structure and preparation method and application thereof

An oxide and cation technology, applied in chemical instruments and methods, inorganic chemistry, nickel compounds, etc., can solve the problems of poor cycle performance, large grain size, affecting material stability, etc., to achieve excellent cycle performance, high ratio The effect of capacity and energy density, promising commercial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

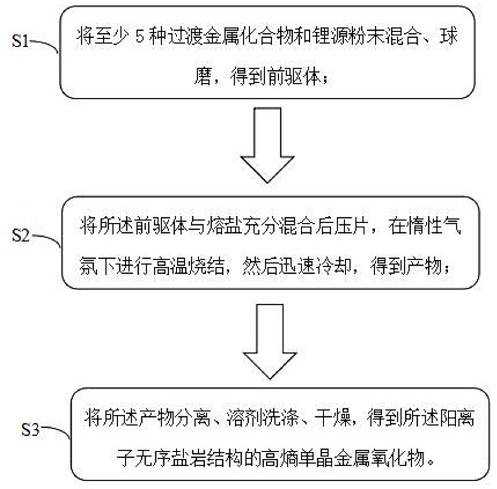

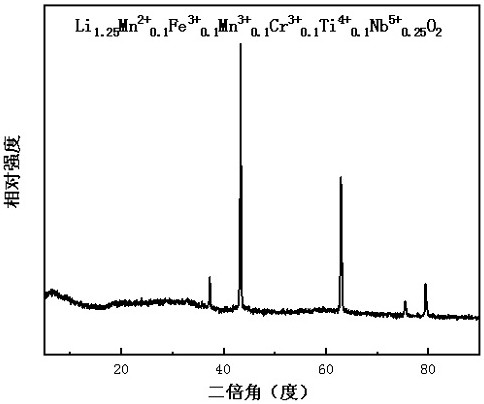

[0037] This embodiment provides a high-entropy single crystal metal oxide Li with a cationic disordered salt rock structure 1.25 mn 2+ 0.1 Fe 3 + 0.1 mn 3+ 0.1 Cr 3+ 0.1 Ti 4+ 0.1 Nb 5+ 0.25 o 2 and its preparation method, the preparation process of the preparation method is as follows figure 1 shown, including the following steps:

[0038] S1. Weigh Li according to the requirements of the stoichiometric ratio 2 O, MnO, Fe 2 o 3 , Mn 2 o 3 、Cr 2 o 3 、TiO 2 , Nb 2 o 5 , where Li 2 O excess of 5% to prevent loss during high temperature sintering;

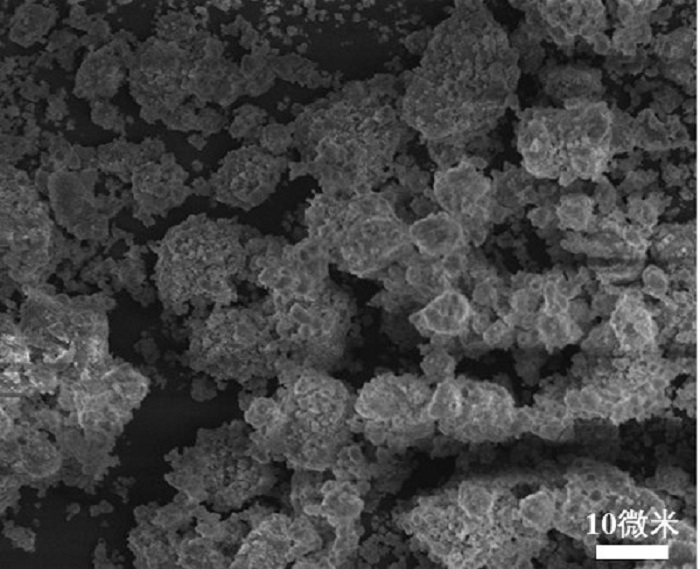

[0039] S2. Mix the precursor uniformly by ball milling to obtain precursor powder. The ball-to-material ratio is 10:1, the ball milling time is 12 h, and the rotation speed is 500 r / min; the SEM image of the obtained precursor is as follows figure 2 shown;

[0040] S3. Weigh the precursor powder, add KCl molten salt with a molar ratio of 1:1 to the precursor and mix evenly; press the tablet under a pressure...

Embodiment 2

[0047] This embodiment provides a high-entropy single crystal metal oxide Li with a cationic disordered salt rock structure 1.25 Ni 2+ 0.1 Fe 3 + 0.1 mn 3+ 0.1 Cr 3+ 0.1 Ti 4+ 0.1 Nb 5+ 0.25 o2 And the preparation method thereof, the preparation method is the same as the steps and Example 1, but the raw materials and proportioning are different, specifically weighed according to the stoichiometric ratio of the target molecule. The metal oxide XRD collection of illustrative plates of the present embodiment sees Figure 5 , SEM picture as Figure 6 shown.

[0048] The Li obtained in this embodiment 1.25 Ni 2+ 0.1 Fe 3+ 0.1 mn 3+ 0.1 Cr 3+ 0.1 Ti 4+ 0.1 Nb 5+ 0.25 o 2 The material is used as the positive electrode active material of the lithium ion secondary battery, and is made into the positive electrode sheet and assembled into the lithium ion half battery. Using the constant current charge and discharge mode, the charge and discharge test was perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com