Device for grinding coffee or other alimentary substances

A technology of nutrients and grinding devices, applied in the direction of coffee mills, spice mills, household appliances, etc., can solve the loss of initial reference distance, the accuracy of adjustment and the negative impact of the actual particle size obtained, the lack of particles of coffee or other nutrients and other problems, to achieve the effect of easy replacement, prevention of grinding problems, and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

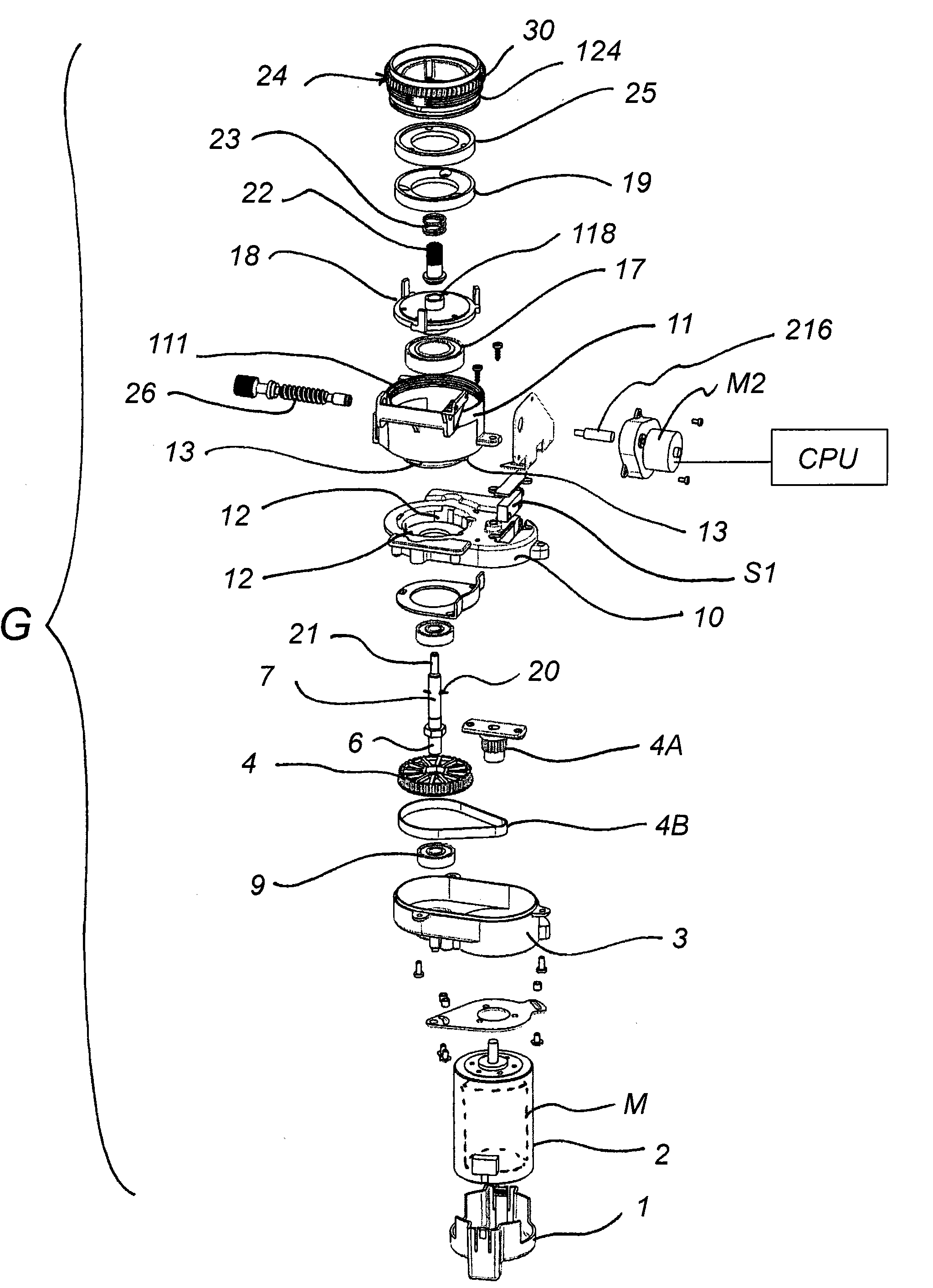

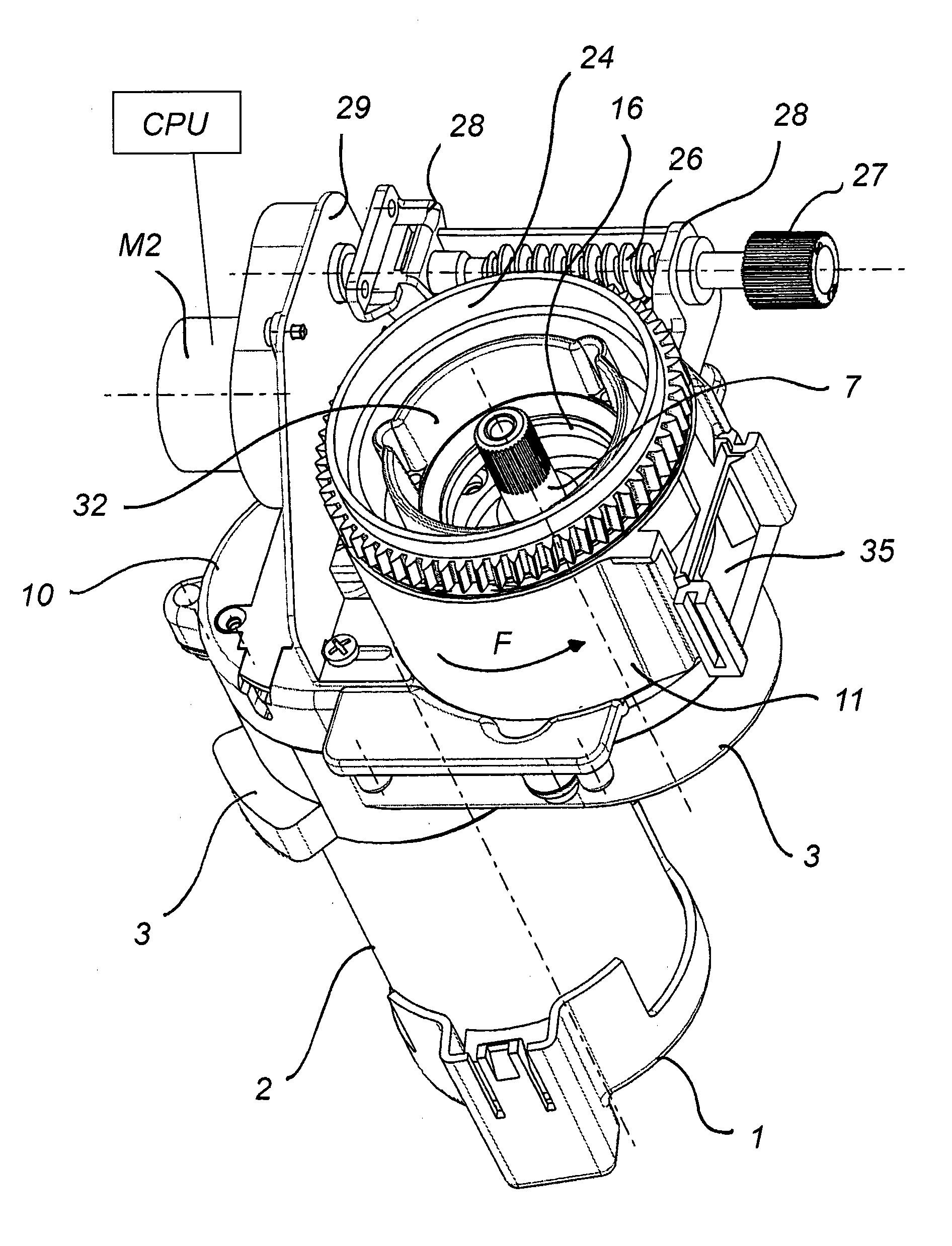

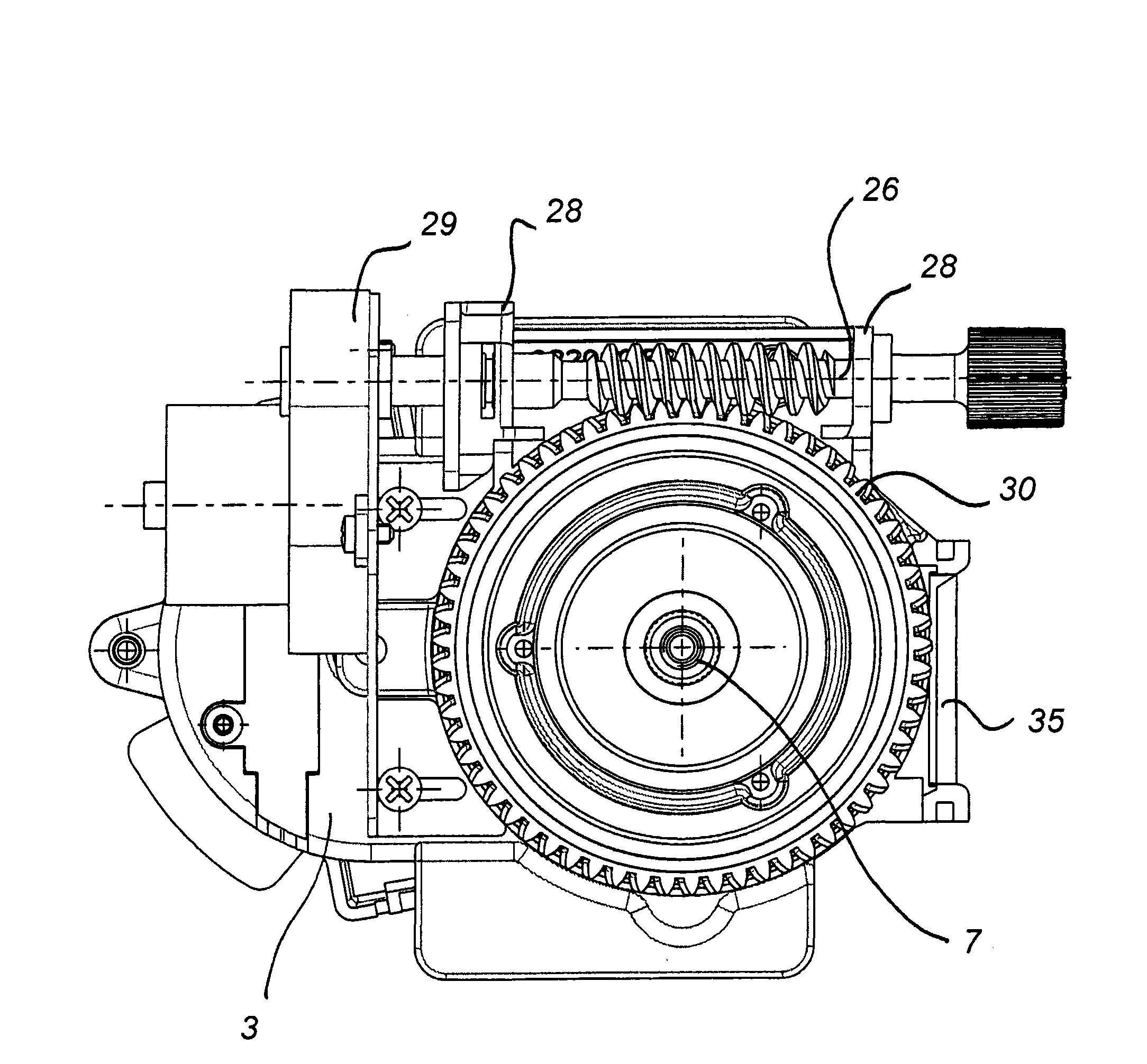

[0058] Refer to attached Figure 1-6 , a hollow cylindrical member 2 is arranged on the fixed plate 1 shown, and a conventional motor M, for example, is installed inside the cylindrical member to drive the grinding device G. The fixing plate 1 secures the device to an external surface, such as the surface of an automatic or semi-automatic beverage preparation and dispensing machine (for example known by the acronym "HoReCa", the type of machine in the hotel-restaurant-café field).

[0059] The cylindrical element 2 is connected to a support base 3 inside which is mounted a gear 4 which is driven in rotation by a motor M via a pinion 4A and a transmission belt 4B in a known manner. The support base 3 is closed below by a wall 5 which functions to support the end 6 of the shaft 7 integral with the gear 4 . The shaft 7 is mounted in a vertical position and is cantilevered from the support base 3 via the hub 8 of the gear 4 , being integrally supported with the base on bearings 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com