Processing process of ball bag-shaped stainless steel retainer

A processing technology and cage technology, which is applied in the field of bearing processing, can solve the problems of roughness and parallel difference between the two ends of the product, are not suitable for the processing of a single part, and affect the drilling process, etc., so as to improve the accuracy and roughness, and ensure Product quality, effect of good positioning benchmarks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

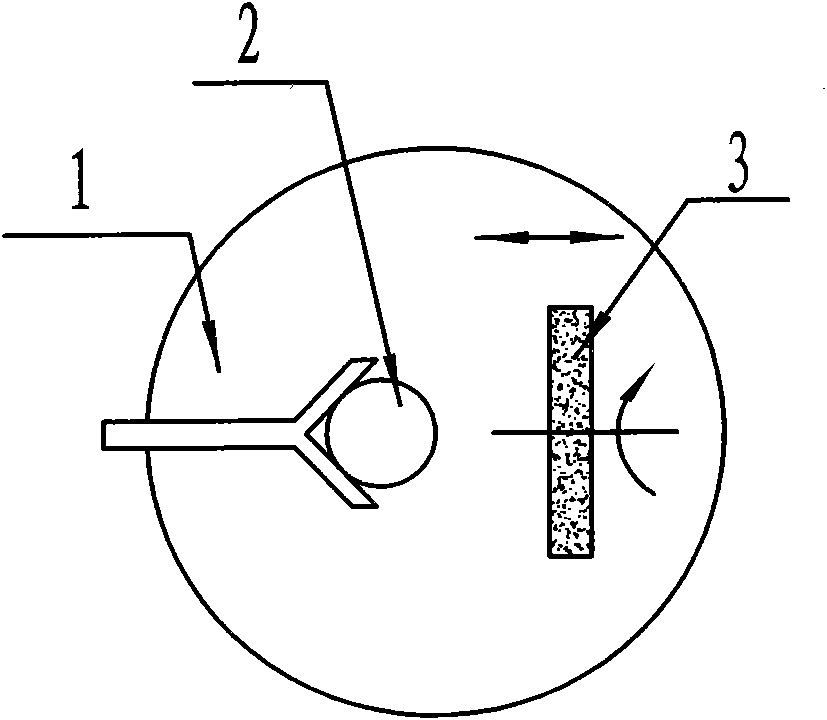

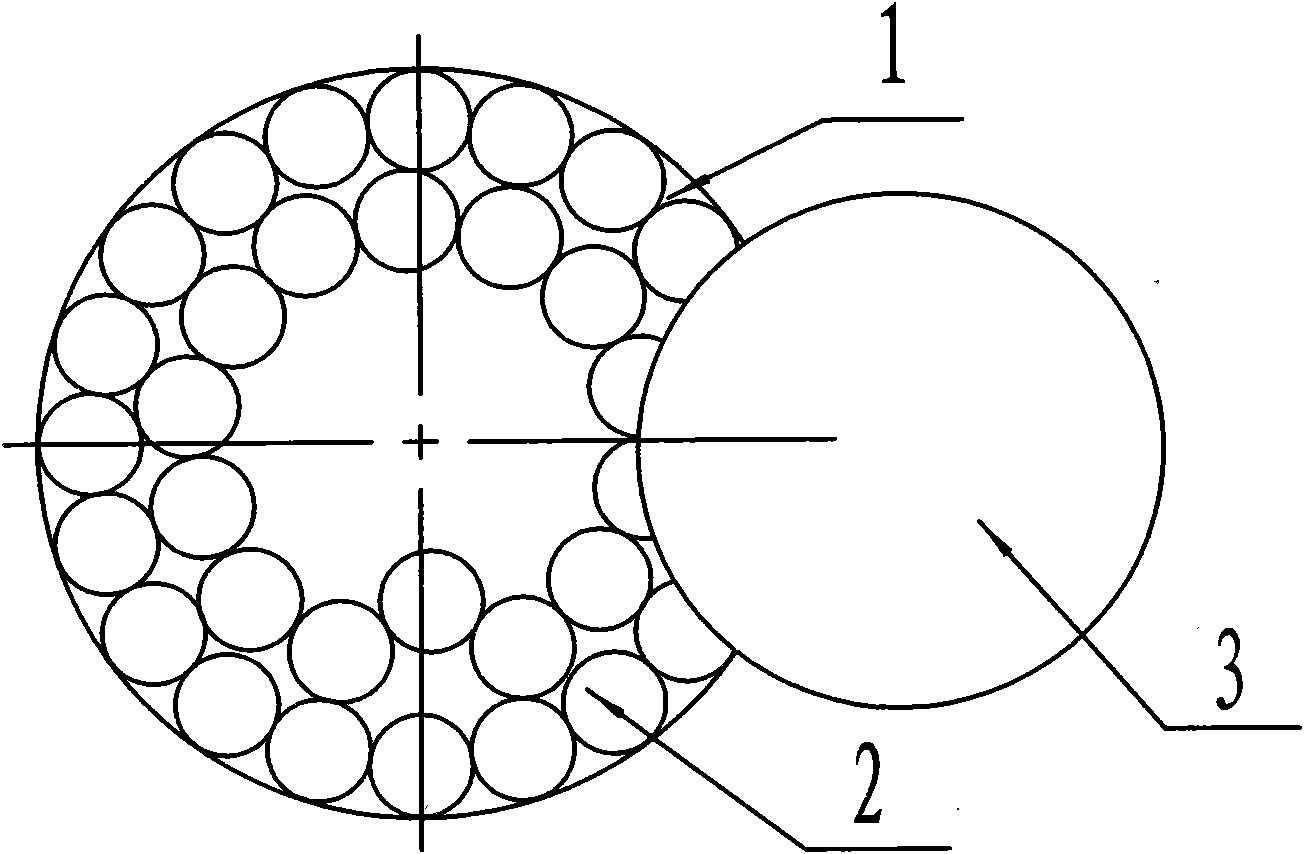

[0024] The present invention is described in conjunction with accompanying drawing and embodiment:

[0025] A ball pocket type stainless steel cage processing technology, the process flow is:

[0026] 1. Rough turning end face, inner diameter, outer diameter, cutting: use C630 lathe for processing, remove the surface oxide skin on each surface of the forging, and cut the long tube material into the height size required by each workpiece.

[0027] 2. Turning section: CA6140 lathe is used to process, and the height and dimension of each workpiece are unified.

[0028] 3. Soft grinding outer diameter: M1083 outer diameter grinder is used for processing, which improves the surface accuracy and roughness of the outer diameter, and obtains a good processing benchmark for the subsequent process.

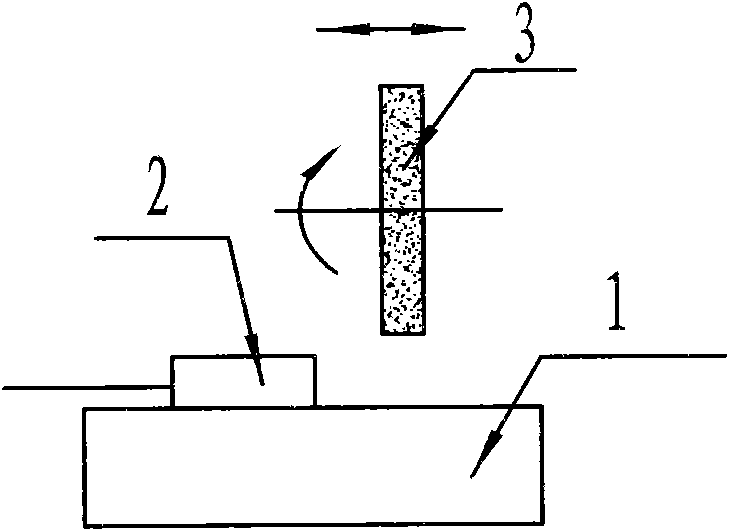

[0029] 4. Soft grinding of both ends of the workpiece: soft grinding of both ends of the workpiece is carried out on a high-precision horizontal axis surface grinder MG7340, and an auxilia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com