Rough casting size detection device and detection method

A detection device, blank size technology, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problems of low efficiency, affecting production efficiency, complicated operation, etc., to avoid complicated workload, improve the scope of application, The effect of flexible detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

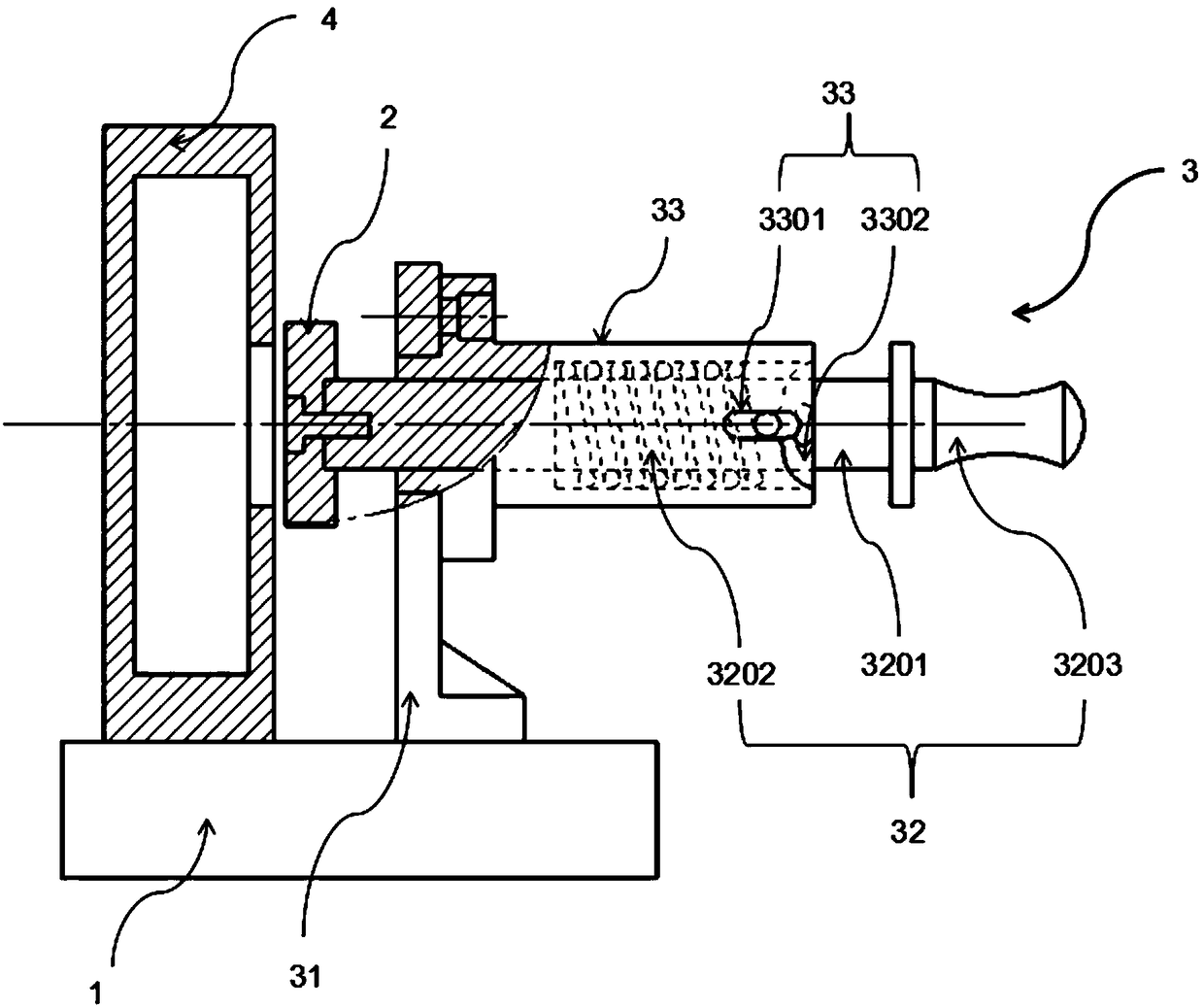

[0020] Such as figure 1 Shown is a casting blank size detection device, including a base 1, a detection template 2 and a propulsion mechanism 3, the propulsion mechanism 3 includes a support frame 31, a drive assembly 32 and a guide 33, and the support frame 31 is arranged on the base On the seat 1, the guide member 33 is connected to the support frame 31 through a through hole in the middle of the support frame 31, the drive assembly 32 is passed through the guide member 33, and the detection template 2 It is set at one end of the propulsion mechanism 3 facing the detection area, and the detection area is set at the other end of the base 1 opposite to the support frame 31 .

[0021] As an optimization of this embodiment, one side of the base 1 is placed on the ground of the inspection site, and the other side is provided with a certain levelness to ensure the benchmark of the casting to be inspected.

[0022] As an optimization of this embodiment, the support frame 31 is an ...

Embodiment 2

[0027] In order to improve the detection efficiency of the detection device, when there are multiple parts to be detected on a casting to be detected, in order to be able to detect each part to be detected at one time, multiple sets of the propelling parts can be set on the base 1 Mechanism 3, and different detection templates 2 are installed according to the parts to be detected, so that the detection of multiple parts to be detected can be completed in one positioning of the casting to be detected. The propulsion mechanism 3 can be connected to the base 1 through bolts; the propulsion mechanism 3 can also be connected to the base 1 through slide rails.

Embodiment 3

[0029] In order to further improve the accuracy of the detection device, a mechanism that can move up and down and left and right can also be provided on the long arm of the support frame 31, so as to ensure that the detection template 2 can be aligned with the site to be detected.

[0030] The detection method of described casting blank size detection device is as follows:

[0031] S101, placing the casting 4 to be detected on the base 1, and making the detection part of the casting to be detected face the propulsion mechanism 3;

[0032] S102, installing a detection template 2 consistent with the detection position of the belt on the propulsion mechanism 3, such as figure 1 shown;

[0033] S103, adjusting the position of the propulsion mechanism 3 so that the detection template 2 is aligned with the position to be detected;

[0034] S104, gradually push the detection template 2 to the position to be detected through the operating handle 3203;

[0035] S105, if the detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com