An annealing furnace inlet sealing device

An inlet sealing and annealing furnace technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of lack of protective gas recovery device, injury to workers, leakage of protective gas, etc., to prevent serious thermal deformation, save maintenance time, Guaranteed sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The annealing furnace inlet sealing device according to the present invention will be further explained and illustrated in conjunction with the accompanying drawings and specific embodiments below, but such explanations and illustrations do not constitute improper limitations on the technical solution of the present invention.

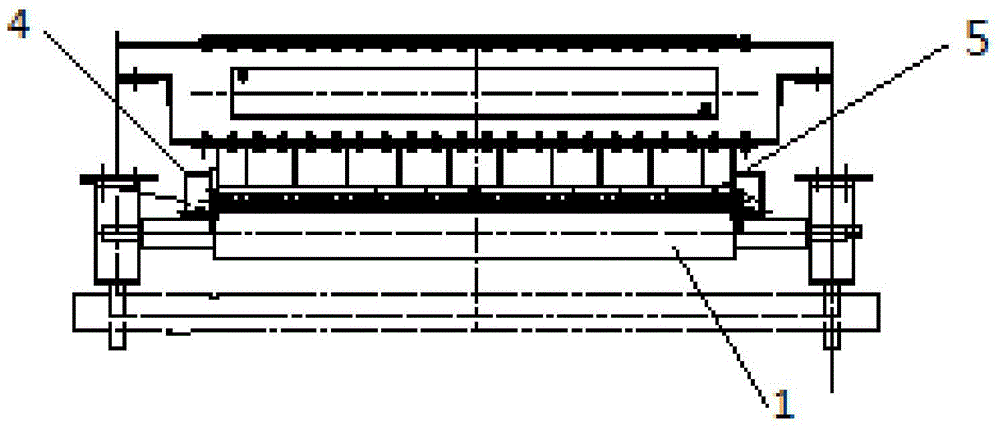

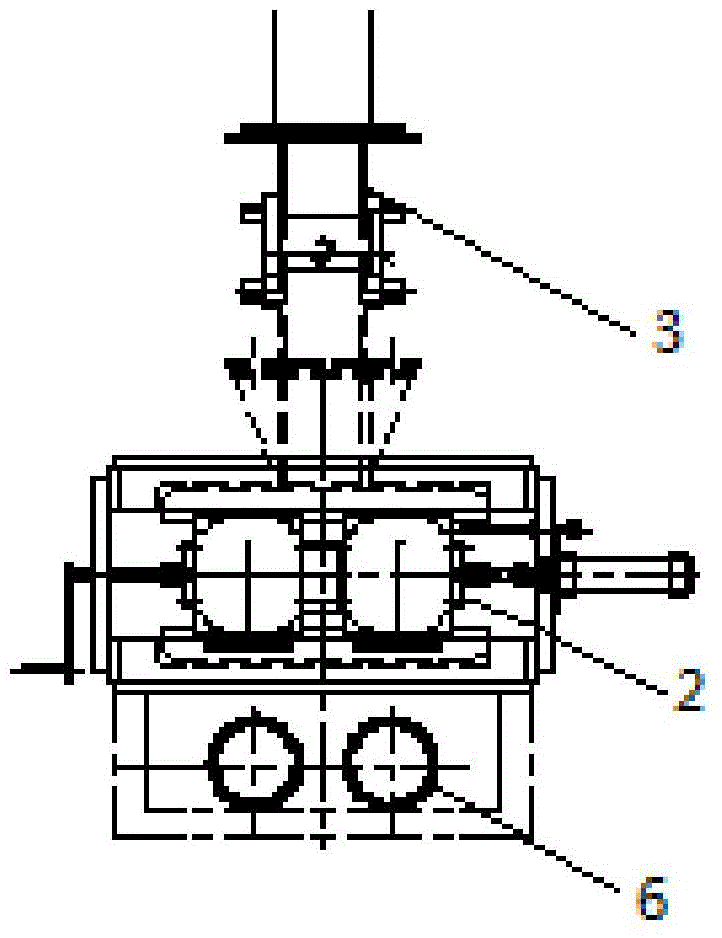

[0047] figure 1 and figure 2 The structures of the annealing furnace entrance sealing device according to the present invention under different viewing angles in one embodiment are shown respectively.

[0048] like figure 1 and figure 2 As shown, the annealing furnace inlet sealing device is provided with a pair of sealing rollers 1, which also includes a sealing roller gap adjustment device 2, a cooling device 3, an end sealing device 4, a sealing roller axial sealing device 5 and a suction pipe 6 .

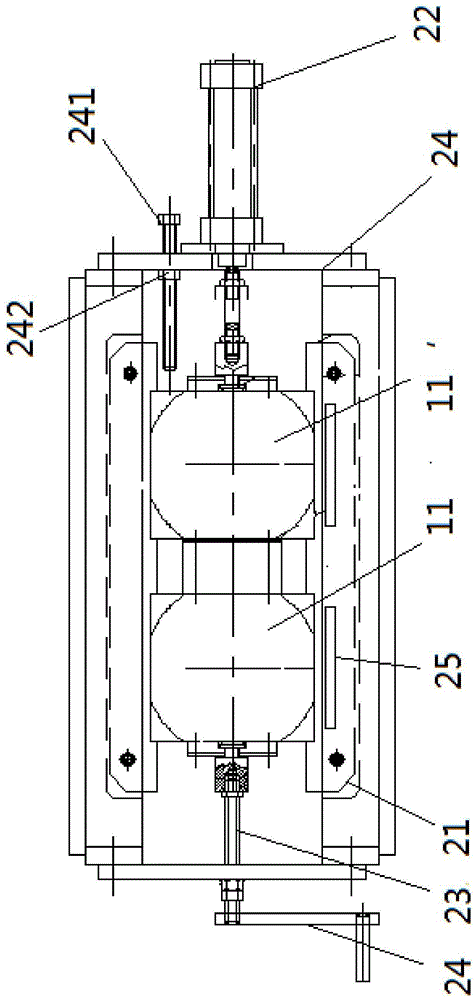

[0049] image 3 It shows the structure of the sealing roll gap adjustment device in the annealing furnace entrance sealing device accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com