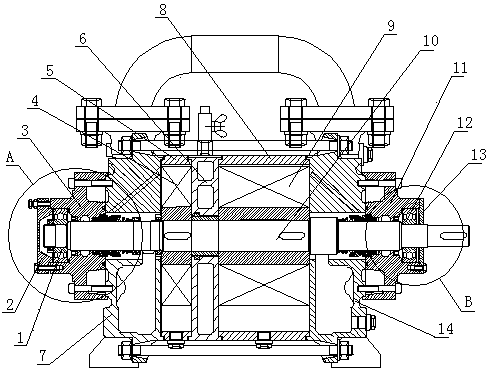

Double stage vacuum pump clearance adjusting device

A gap adjustment device and a two-stage vacuum pump technology, which are applied to components, pumps, and pump components of pumping devices for elastic fluids, can solve problems such as short service life, easy damage, and low performance, and achieve service life Long, easy to adjust, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

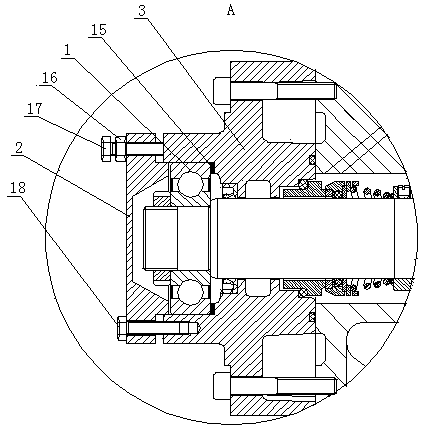

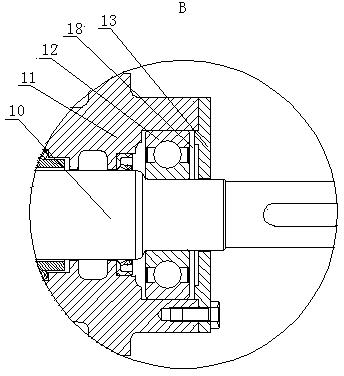

[0013] The two-stage vacuum pump gap adjustment device shown in the figure, the two-stage vacuum pump includes a first-stage pump body 8, a second-stage pump body 5, an intermediate flow distribution plate 6, a pump shaft 10, a first-stage impeller 9, a second-stage impeller 4, and a suction body 14 , spit body 7 and bearing body, on the right side of suction body 14 and on the left side of spit body 7, bearing body 11,3 is respectively provided with, and bearing body links to each other with suction body and spit body through bolt, and pump shaft 10 passes bearing 1,12 Installed on the bearing body, the bearing body 11 on the side of the suction body is provided with a driving end bearing gland 13, and the driving end bearing gland 13 is fixed on the bearing body by bolts, and the gap between the driving end bearing gland 13 and the driving end bearing 12 Bearing axial sliding gap 18 is left, and when the bearing cover of the driving end is pressed on the bearing body, the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com