External gear pump and hydraulic transmission hydraulic system

A hydraulic transmission and hydraulic system technology, applied in the direction of pumps, pump components, machines/engines, etc., can solve the problems of low volumetric efficiency and inability to work at high temperature for a long time, achieve high volumetric efficiency, save required space, The effect of meeting the needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

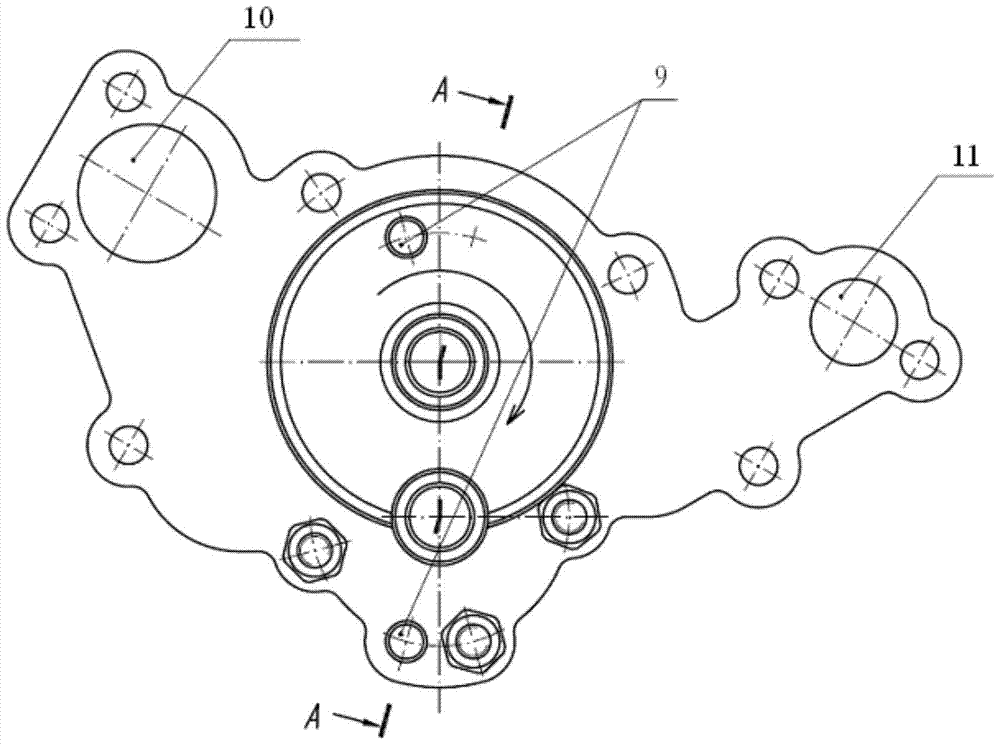

[0035] like Figure 1-4 As shown, an external gear pump provided by an embodiment of the present invention is applied to a hydraulic transmission hydraulic system, wherein the hydraulic transmission hydraulic system includes a hydraulic system, a transmission and an oil tank, and the external gear pump includes: a housing and A gear mechanism, the housing is fixedly connected with the transmission case, the inner cavity of the housing is a sealed inner cavity, one side of the inner cavity is provided with an oil pressure port, and the oil pressure port is connected with the hydraulic system, and the other side of the inner cavity is provided with There is an oil suction port, and the oil suction port is connected to the oil tank; the gear mechanism is arranged in the casing, and is movably connected with the casing, one end of the gear mechanism is bonded to the transmission, and the transmission drives the gear mechanism to rotate in the casing; the casing includes the front c...

Embodiment 2

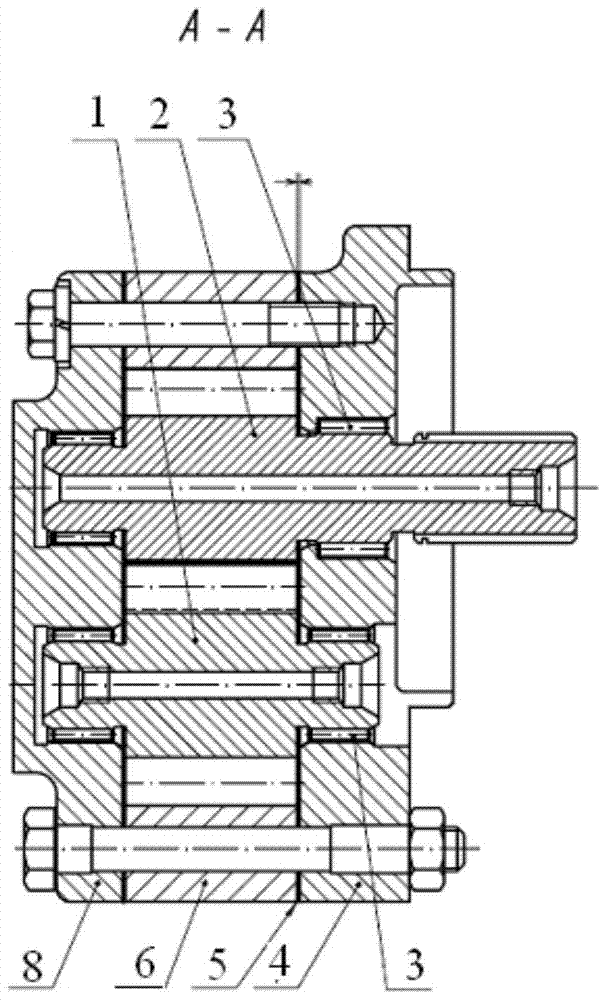

[0048] An external meshing gear pump provided by an embodiment of the present invention is composed of a driving gear 2 and a driven gear 1 with the same number of teeth and modules, and a front housing 4, an intermediate housing 6 and a rear housing 8. The two ends of the gear 2 and the driven gear 1 are supported by needle bearings 3, the front housing 4, the middle housing 6 and the rear housing 8 are sealed by a gasket 5, and the right side of the driving gear 2 is splined by the transmission Driven by the structure, the driving gear 2 drives the driven gear 1 to rotate according to the rotation direction shown by the arrow in the figure, and the volume of the two closed cavities formed between the driving and driven gear 1 and the housing changes when the gears mesh.

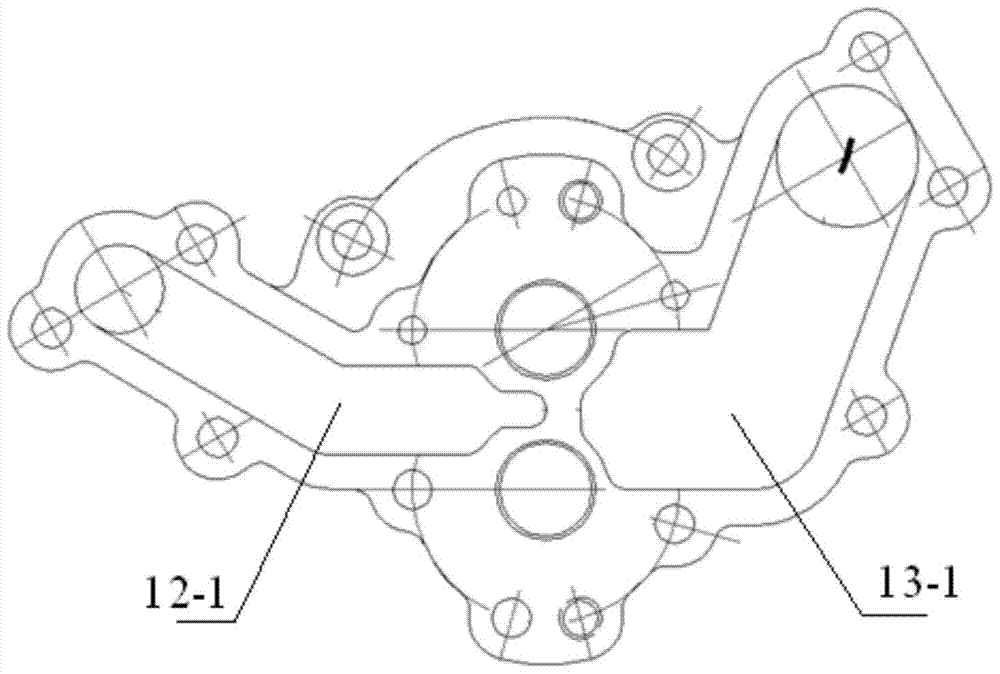

[0049] like image 3 , Figure 4 As shown, the front casing is provided with a front casing oil suction port 13-1 and a front casing oil pressure port 12-1, and the rear casing 8 is provided with a rear ca...

Embodiment 3

[0051] In an external gear pump provided by an embodiment of the present invention, the design value of the thickness difference between the driving gear 2 and the driven gear 1 is not greater than 0.01mm. The flatness design index of the sealing surfaces of the front housing 4, the middle housing 6 and the rear housing 8 is 0.012mm, and the surface roughness is Ra1.6; the flat sealing gasket 5 uses the power cable paper GB7969-2003.

[0052] Due to the actual load and operating speed characteristics of the external gear pump, the embodiment of the present invention chooses the open stamped outer ring full complement needle roller bearing, which has a large number of needle rollers and a very high load-carrying capacity. The needle roller bearings must meet the following requirements:

[0053] (1) The basic rated load, fatigue limit load, reference speed and other parameters of the selected bearing must meet the actual working conditions of the bearing;

[0054] (2) Temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com