Asymmetric clamping device and experimental method for sheet compressing

A clamping device, asymmetric technology, applied in the direction of measuring device, using stable tension/pressure testing material strength, instruments, etc., can solve problems such as instability and wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

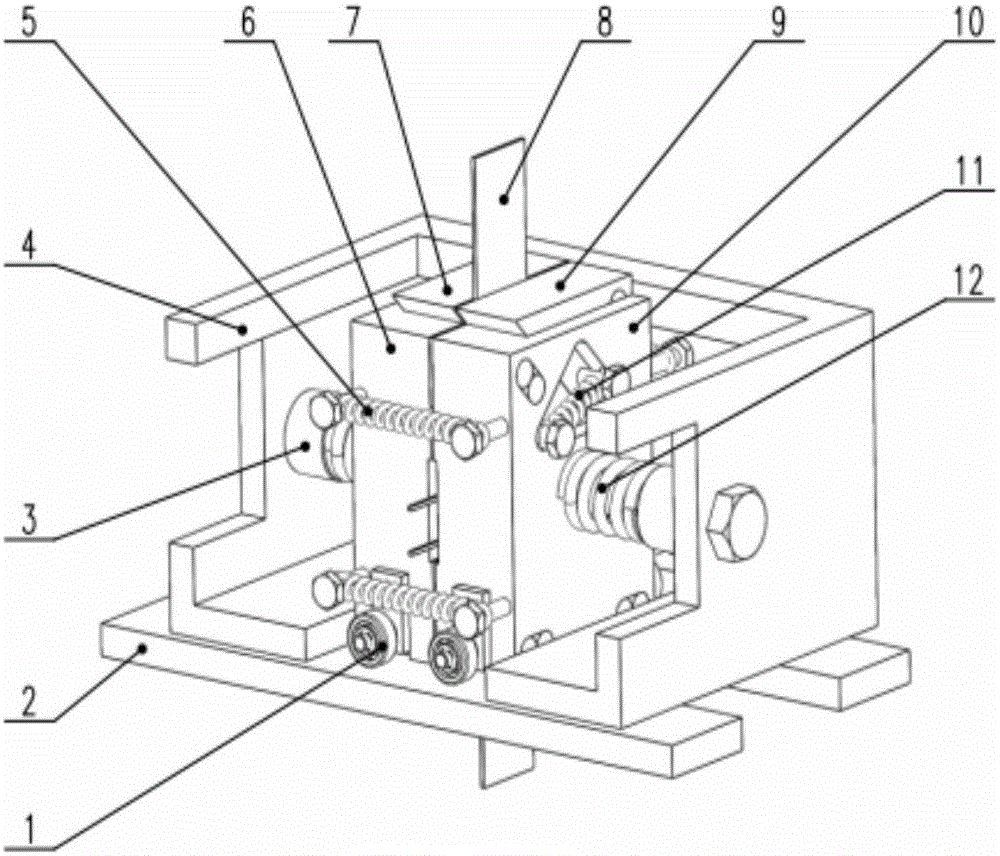

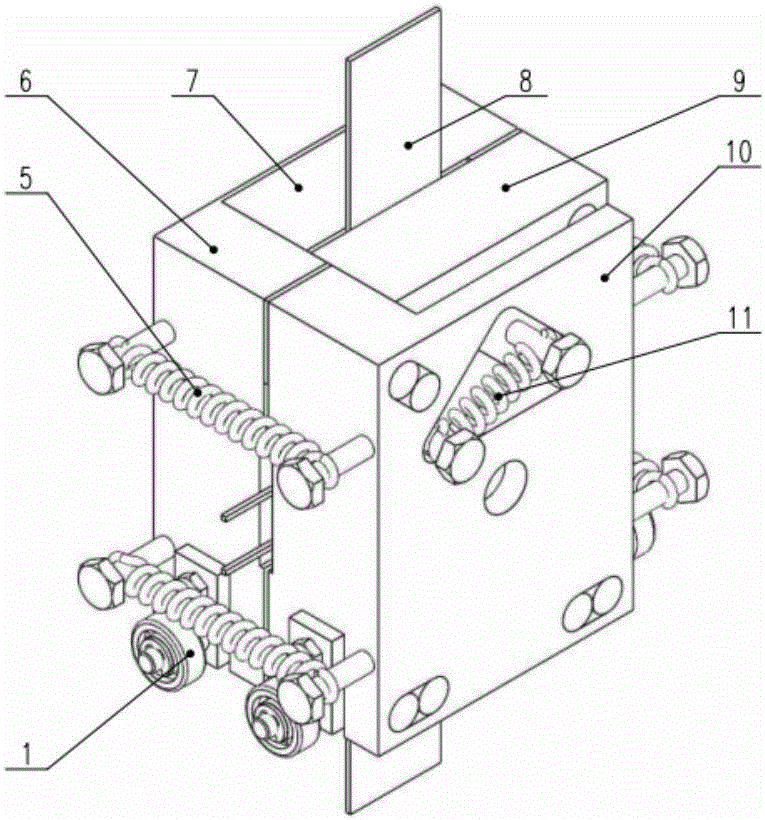

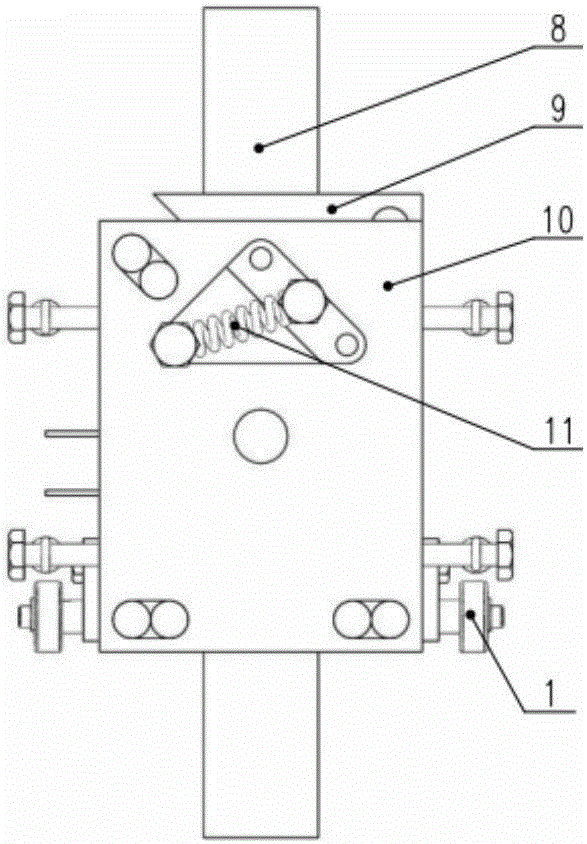

[0139] This embodiment is an asymmetric clamping device for thin plate compression, including a guide wheel 1, a test machine work surface 2, a central spring seat 3, a central spring support 4, side springs 5, a first clamping plate 6, a first Slide block 7, second slide block 9, second clamping plate 10, return spring 11, center spring 12, guide key 14, guide wheel frame 15, slide block guide rod 16 and splint guide rod 17.

[0140] The first clamping plate 6 and the second clamping plate 10 are located in the draw-in slots on the bottom plate of the central spring support 4, are installed on the working table of the experimental machine, and are respectively fixed on the central spring support by the central spring 12 4 on. The working surface of the installed first clamping plate 6 is opposite to the working surface of the second clamping plate 10 to clamp the thin plate in the middle. There are four guide wheels 1, which are divided into two groups, one group is inserted...

Embodiment 2

[0159] This embodiment is a method for carrying out a thin plate compression test using the asymmetric clamping device described in Embodiment 1. The thickness of the sample is 1 mm, and the material is DP600. The measuring lug 39 protrudes 10 mm outside the device, and the sample extends up and down 12 mm outside the device for clamping by the chuck of the testing machine. The sample is asymmetrical up and down. The upper part of the non-gauge length section is 15mm longer than the lower part. The upper part of the non-gauge length section bears the friction force in the width direction, which can eliminate the friction force in the width direction caused by the movement of the slider. Impact.

[0160] The concrete process of this embodiment is:

[0161] Step 1. Install the experimental device, the specific process is as follows:

[0162] Ⅰ. Place the central spring support 4 on the working table 2 of the testing machine, so that the center of the collet of the multifunctio...

Embodiment 3

[0191] This embodiment is a thin plate tension-compression experiment carried out using the asymmetric clamping device; the stretching amount is 5 mm, and the compression amount is 10 mm.

[0192] The sample thickness of this embodiment is 1 mm, and the material is DP600. The measuring lug 39 protrudes 10 mm outside the device, and the sample extends up and down 12 mm outside the device for clamping by the chuck of the testing machine. The sample is asymmetrical up and down. The upper part of the non-gauge length section is 15mm longer than the lower part. The upper part of the non-gauge length section bears the friction force in the width direction, which can eliminate the friction force in the width direction caused by the movement of the slider on the sample. Impact.

[0193] The concrete steps of the thin plate continuous tension-compression experiment of the present embodiment are as follows:

[0194] Step 1. Install the experimental device, the specific process is as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com