Disk brake slack self-adjusting mechanism

A technology of disc brakes and brakes, applied in the direction of slack adjusters, etc., can solve the problems affecting the safety of driving brakes, brake failure, and low gap accuracy, and achieve the effects of compact structure, convenient maintenance, and guaranteed sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

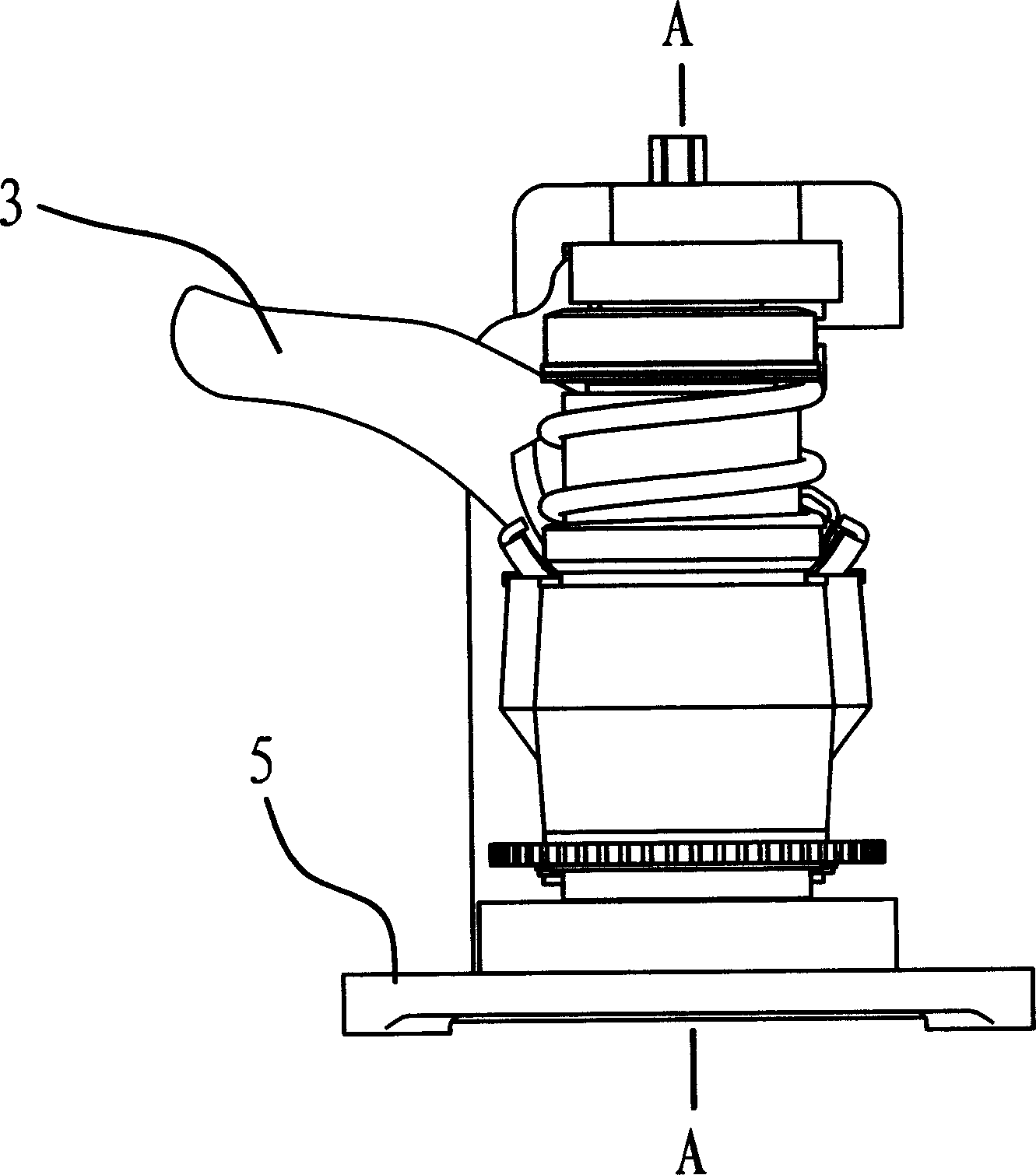

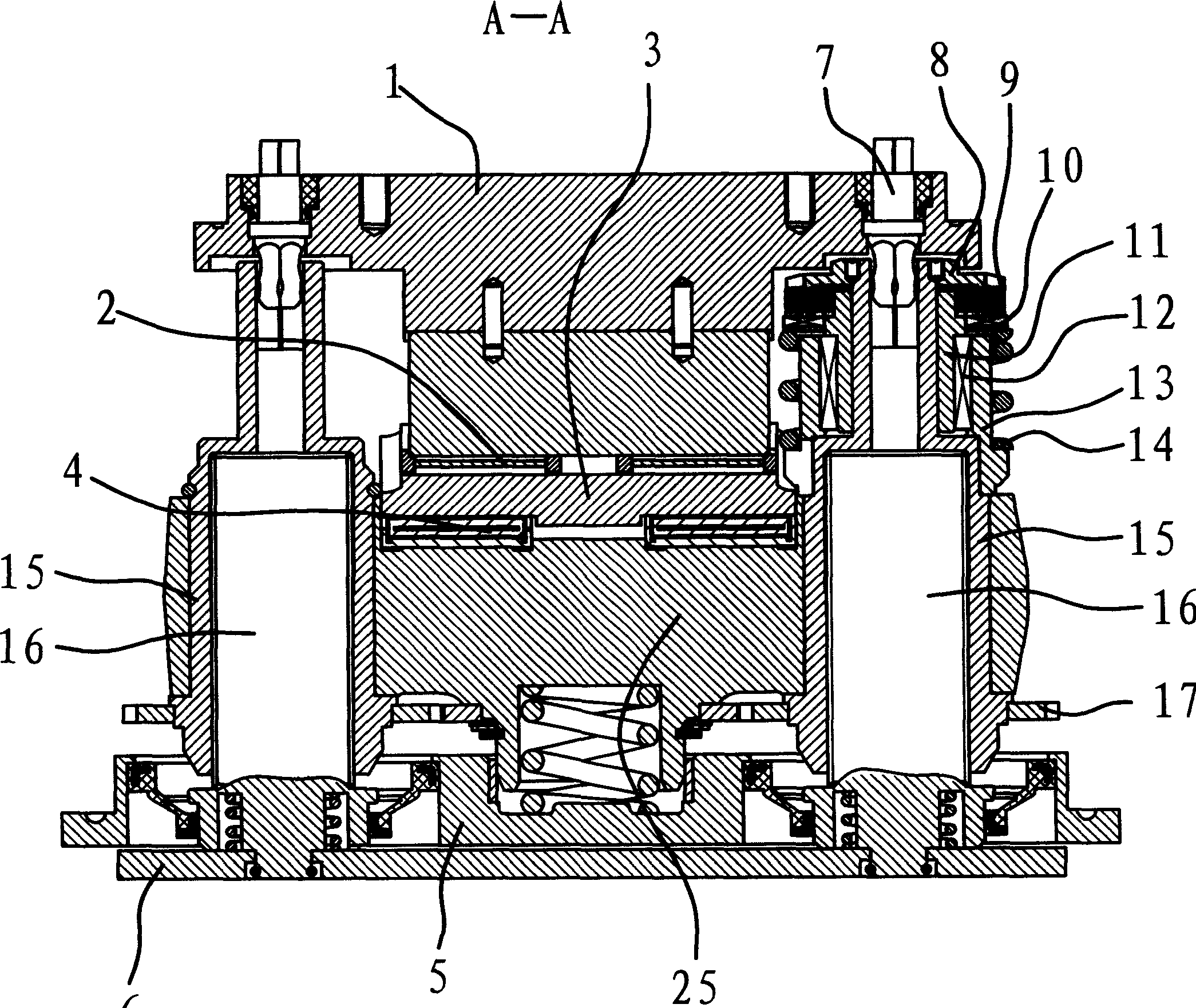

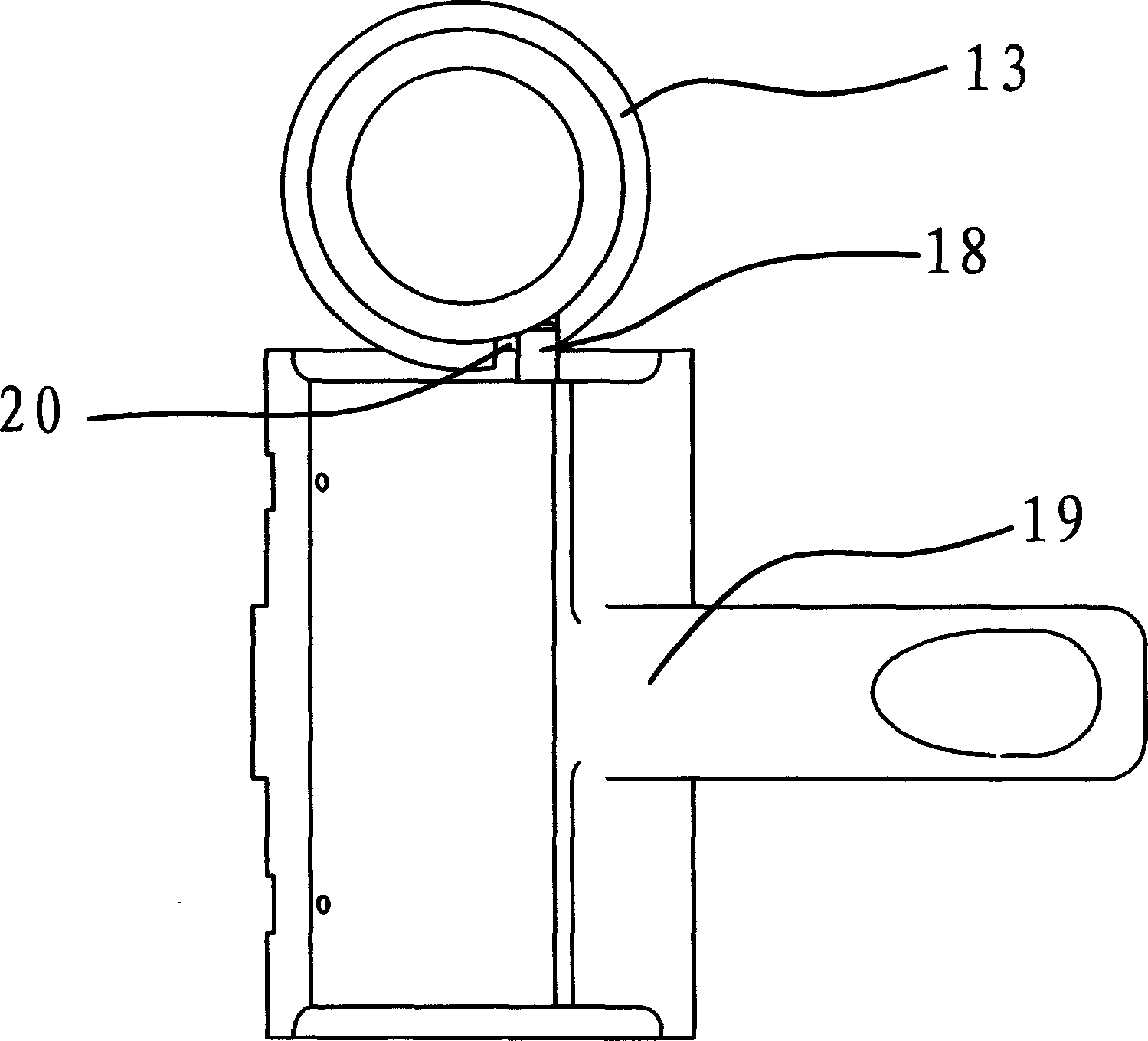

[0020] combine figure 1 and figure 2 It can be seen that the disc brake mainly includes a cam lever seat assembly 1, a cam lever bracket 25, and an end cover assembly 5, wherein the end cover assembly 5 is connected with the cam lever bracket 25. An eccentric cam lever 3 is arranged between the cam lever seat assembly 1 and the cam lever bracket 25, an inner semicircular bearing 2 is arranged between the cam lever 3 and the cam lever seat assembly 1, and the cam lever 3 and the cam lever bracket 25 is provided with an outer semicircular bearing 4, and the outside of the cam lever 3 has a force arm 19, which impels the cam lever 3 to move towards the position between the cam lever seat assembly 1 and the cam lever bracket 25 after receiving the external pressing power. Internal deflection, due to its eccentric setting, the cam lever 3 will impel the cam lever bracket 25 to run towards the brake disc during the rotation.

[0021] exist figure 1 It can be seen from the figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com