Gap adjusting device used for adjusting grain size of bone cement

A gap adjustment device and technology of bone slime machine, applied in application, preparation of animal glue or gelatin, food science, etc., can solve problems such as reducing production efficiency of bone slime machine, inability to realize gap adjustment function, and difficulty in manufacturing large threads, etc. Achieve the effect of reliable and convenient gap adjustment, simple structure and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

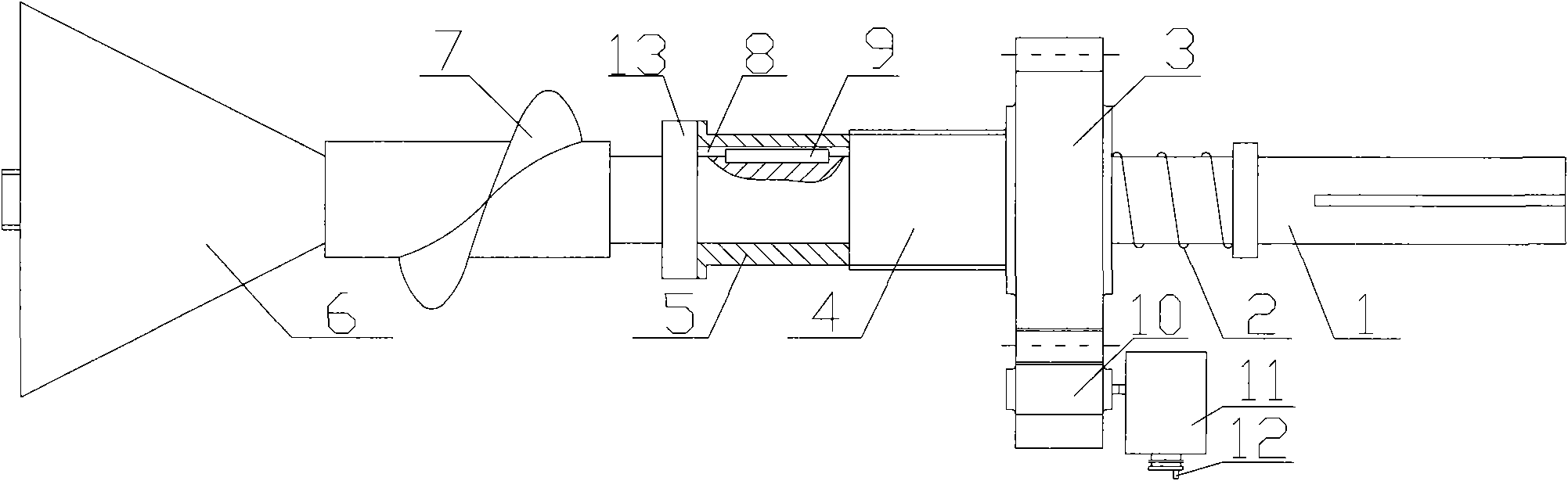

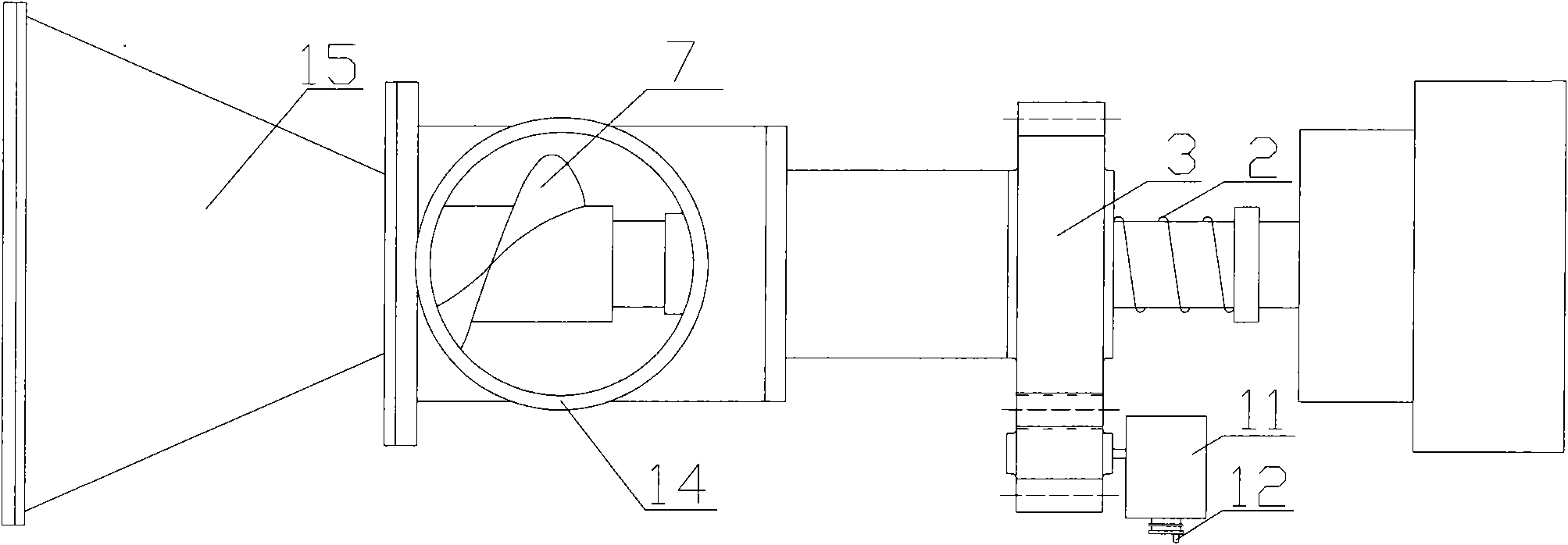

[0012] As shown in the figure, the shaft is in a non-working state. The left end of rotating shaft 1 is fixedly provided with inner cone 6, i.e. dynamic mill, rotating shaft 1 drives inner cone 6 to move, and outer cone is arranged on the outside of inner cone 6 and is fixed on housing 15. The middle position of rotating shaft 1 is provided with externally threaded shaft sleeve 4, and externally threaded shaft sleeve 4 slides on rotating shaft 1, and its outer surface is provided with screw thread, and the outer surface of externally threaded shaft sleeve 4 is spun into gear 3, and the inner surface of gear 3 The surface is provided with threads that mesh with the externally threaded bushing 4, that is, the gear 3 and the externally threaded bushing 4 are threadedly connected. The gear 3 is meshed with the gear 10 for transmission, and the gear 10 is fixed on the rotating mechanism 11 . By manually turning the adjusting handle 12 on the rotating mechanism 11, the gear 10 is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com