Rotary fluid machine

a fluid machine and rotary technology, applied in the direction of machines/engines, combination engines, liquid fuel engines, etc., can solve the problems of abnormal wear or leakage, lubricating oil undetected contamination of working medium, and reducing the durability of seals, etc., to suppress the increase of leakage and abnormal wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0040] the present invention is explained below with reference to FIG. 1 to FIG. 21D.

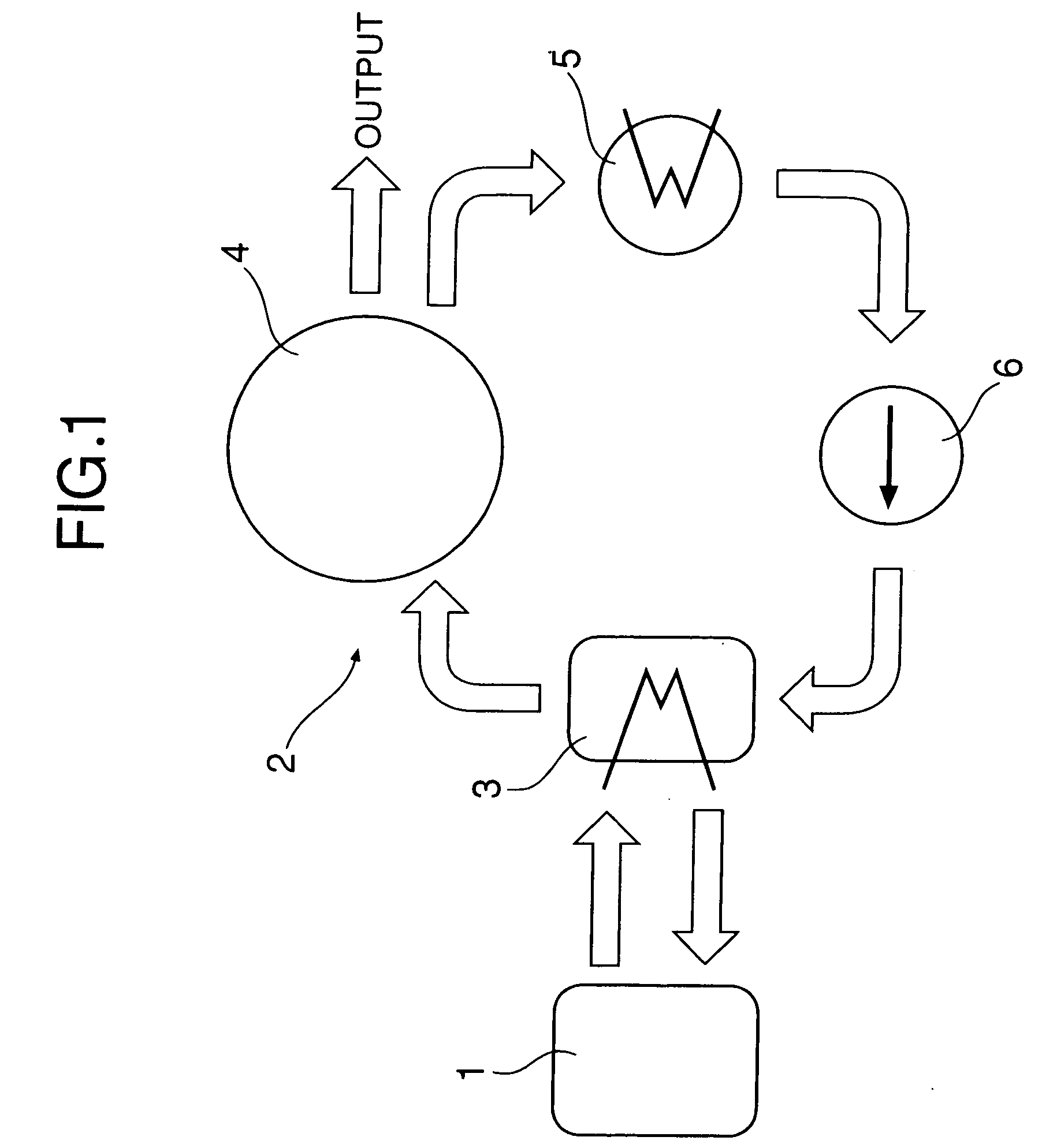

[0041] In FIG. 1, a waste heat recovery system 2 for an internal combustion engine 1 includes an evaporator 3 that generates high temperature, high pressure steam by vaporizing a high pressure liquid (e.g. water) using as a heat source the waste heat (e.g. exhaust gas) of the internal combustion engine 1, an expander 4 that generates an output by expansion of the steam, a condenser 5 that liquefies steam having decreased temperature and pressure as a result of conversion of the pressure energy into mechanical energy in the expander 4, and a supply pump 6 that pressurizes the liquid (e.g. water) from the condenser 5 and resupplies it to the evaporator 3.

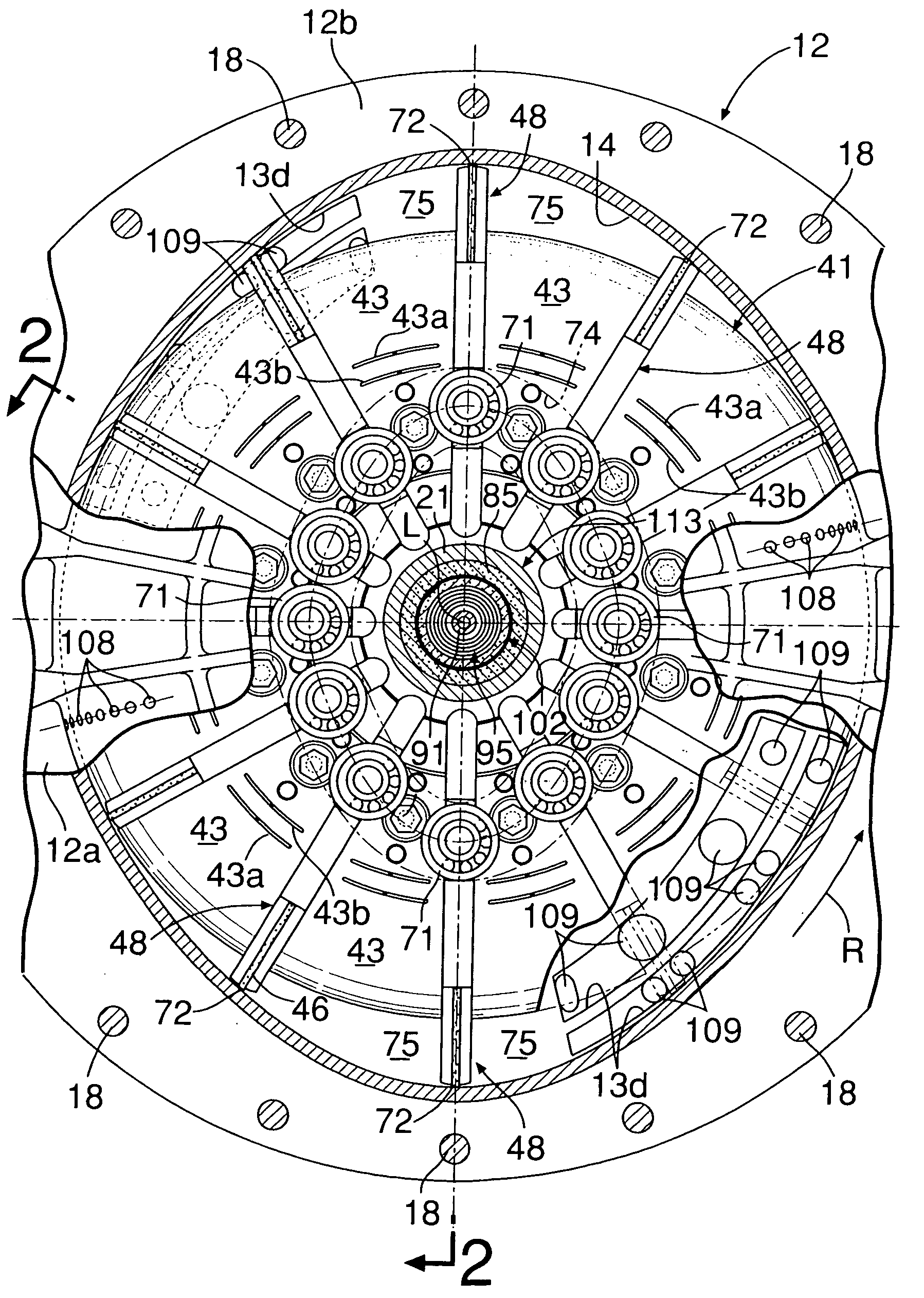

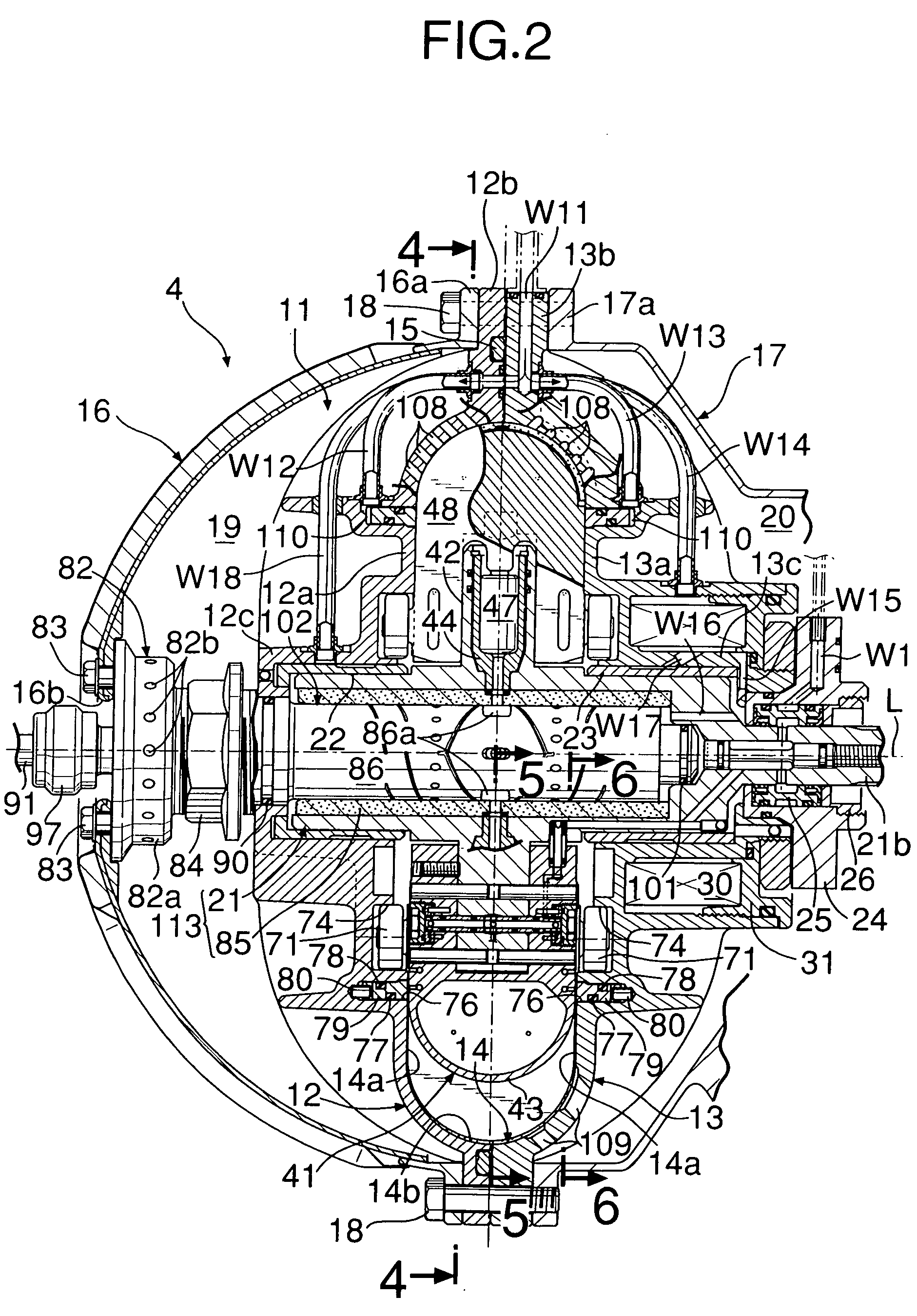

[0042] As shown in FIG. 2 and FIG. 3, a casing 11 of the expander 4 is formed from first and second casing halves 12 and 13, which are made of metal. The first and second casing halves 12 and 13 are formed from main body portions 12a and 13a, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com