Hydrogen cell packing device and packing method thereof

A fuel cell, battery pole piece technology, applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of pole piece skew, battery scrap, large gap, etc., to achieve stable position, avoid skew, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

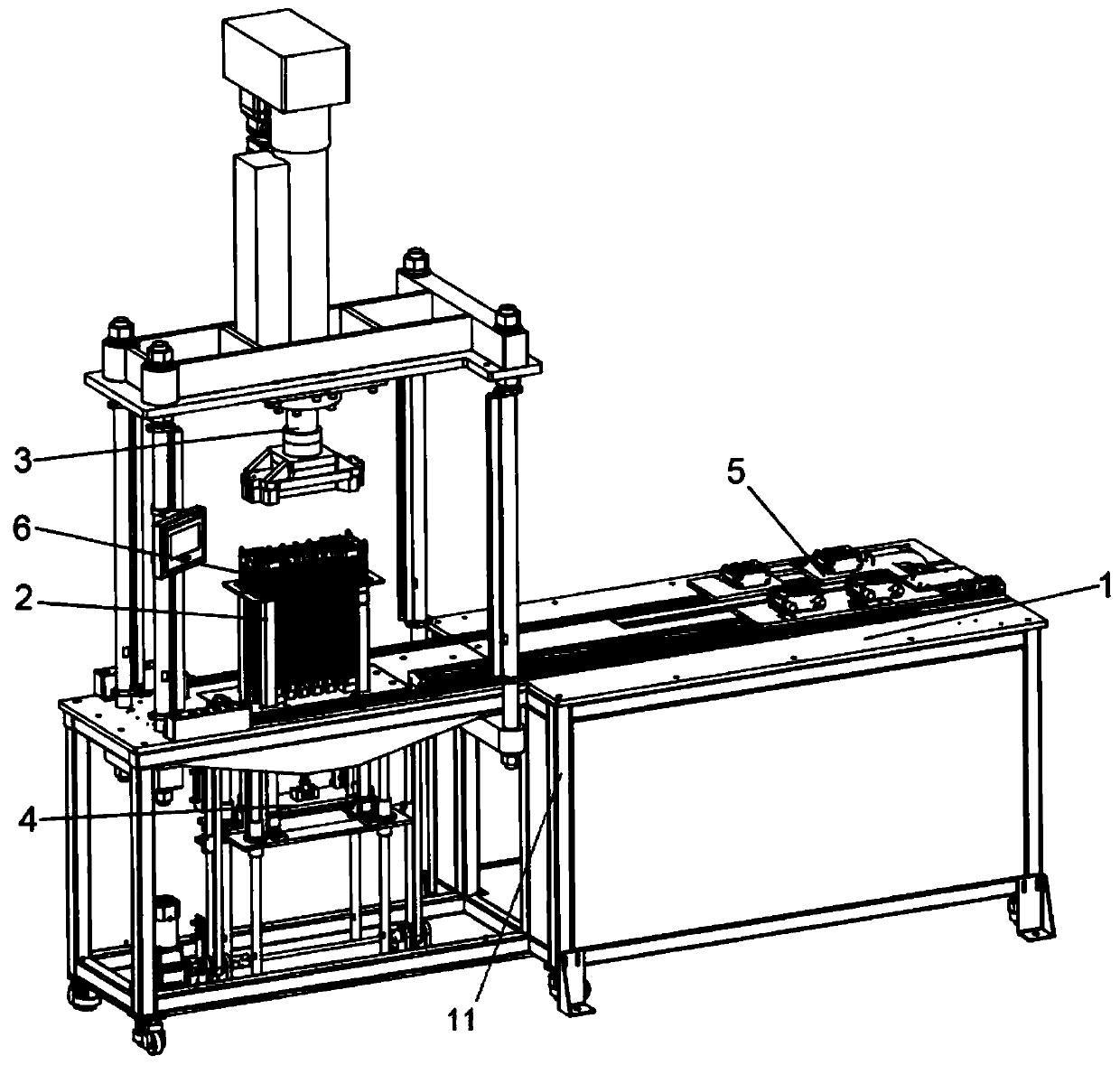

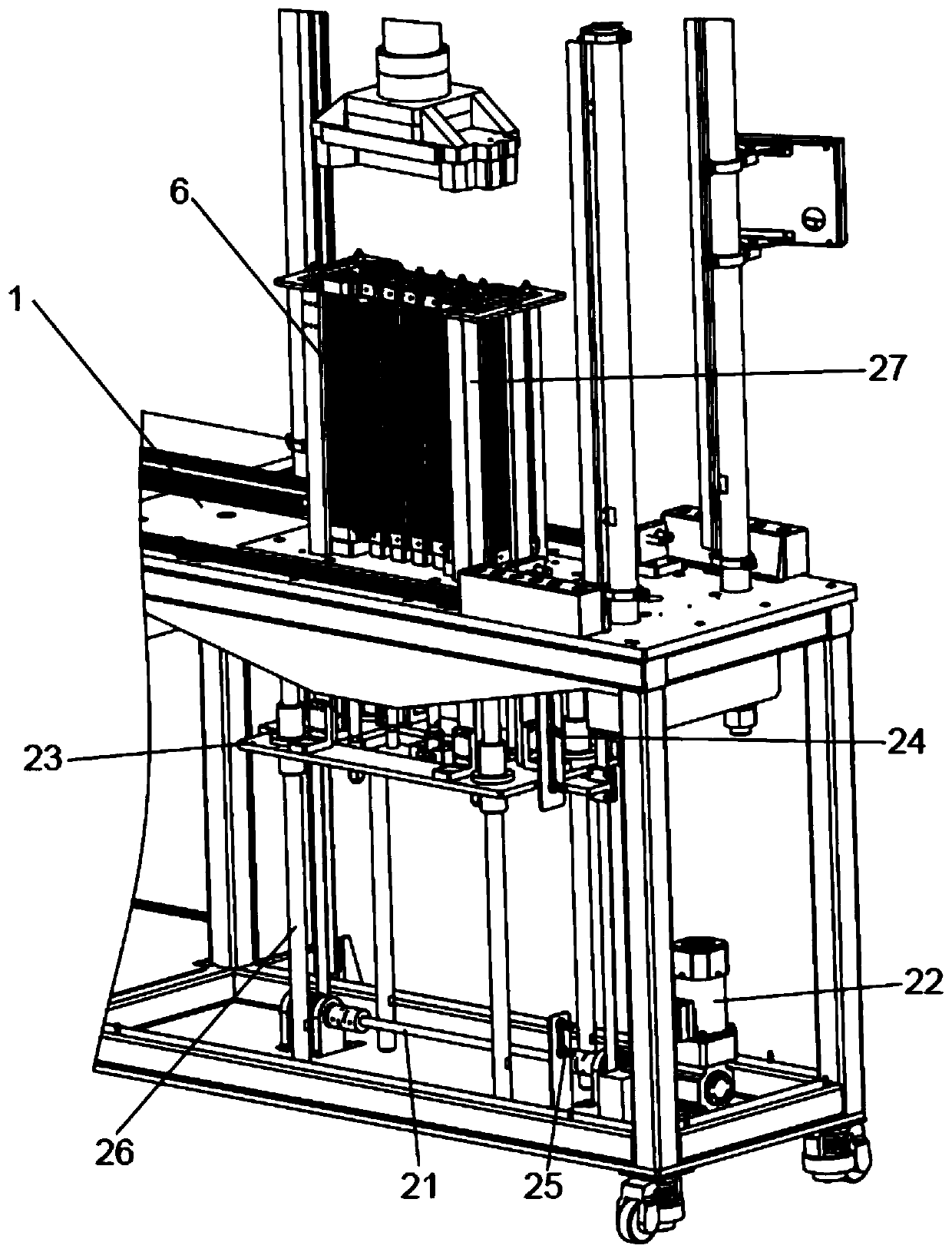

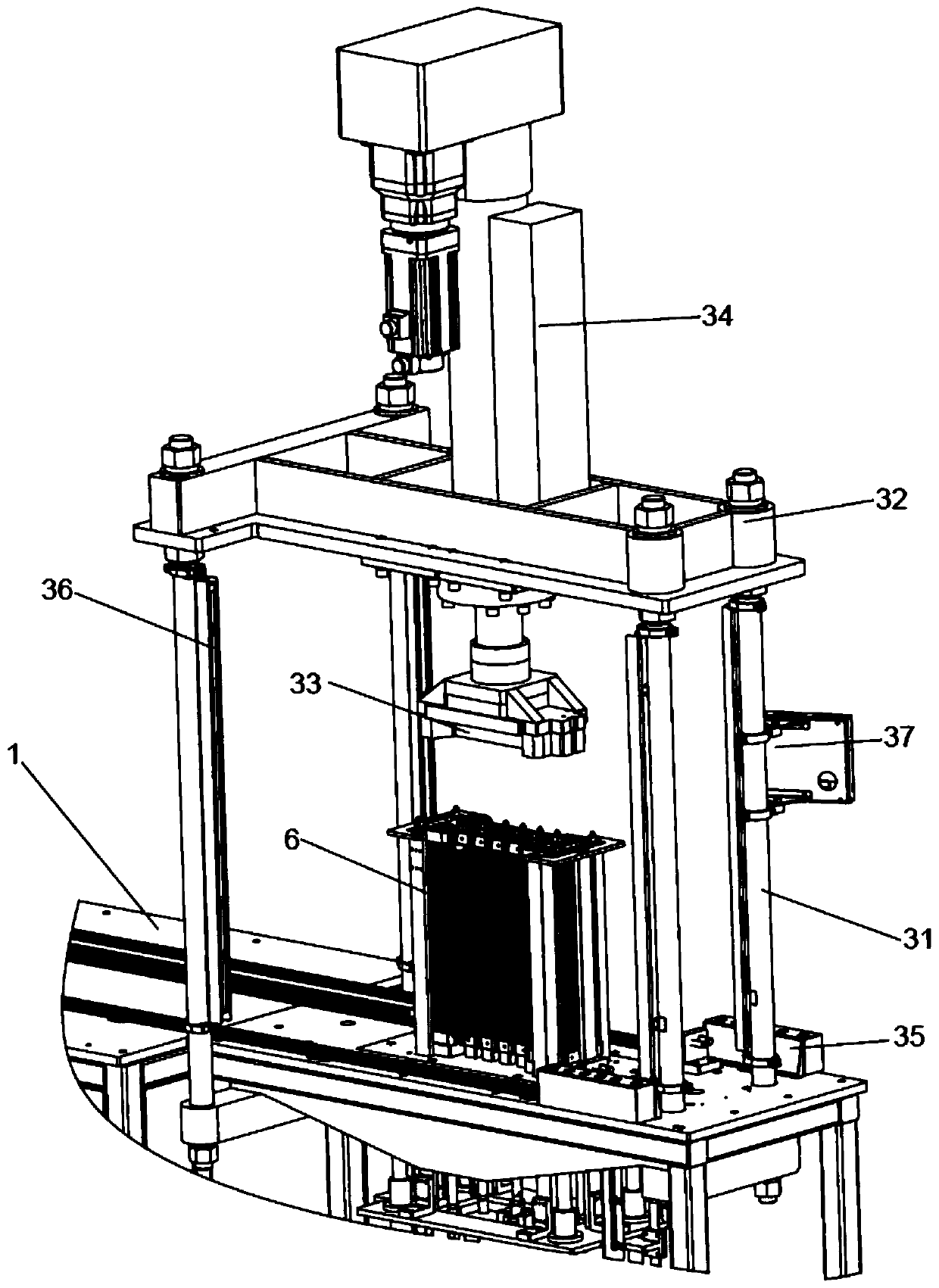

[0043] Such as figure 1 As shown, an embodiment of the present invention is: a hydrogen fuel cell packaging device, comprising:

[0044] The base frame 11 is provided with an abutment 1 on the base frame 11, and the abutment 1 includes a packing station and a reclaiming station:

[0045] A stacking limiting mechanism 2, which is used to limit the battery pole pieces, and the stacking limiting mechanism 2 is installed on the base frame 11 corresponding to the position of the packing station;

[0046] pole piece pressing mechanism 3, which is used to compress the stacked battery pole pieces;

[0047] Jacking mechanism 4, which is used to jack up the compressed and packed hydrogen fuel cell 6;

[0048] The transfer mechanism 5 is used to transfer the lifted hydrogen fuel cell 6 from the packaging station to the reclaiming station.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com