Patents

Literature

105results about How to "Avoid skewed situations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

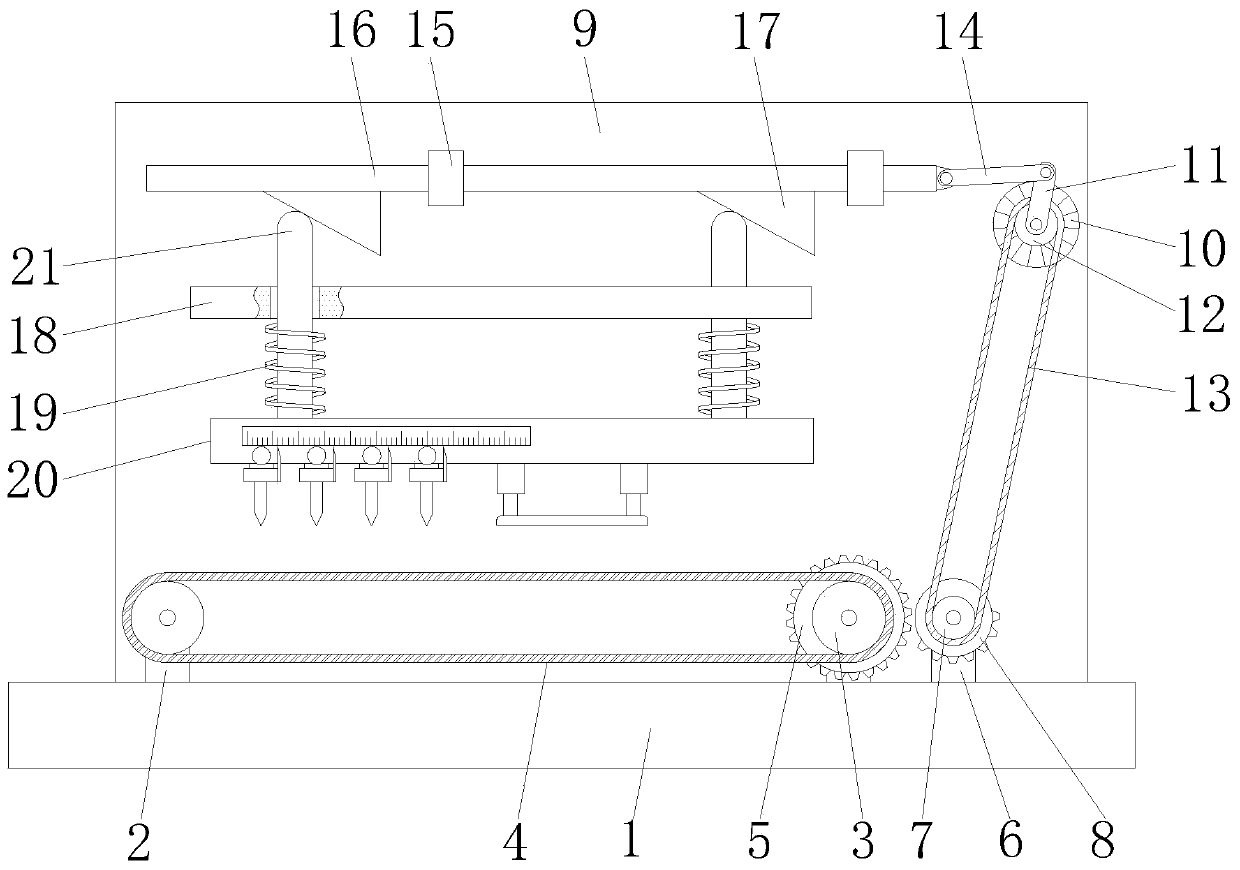

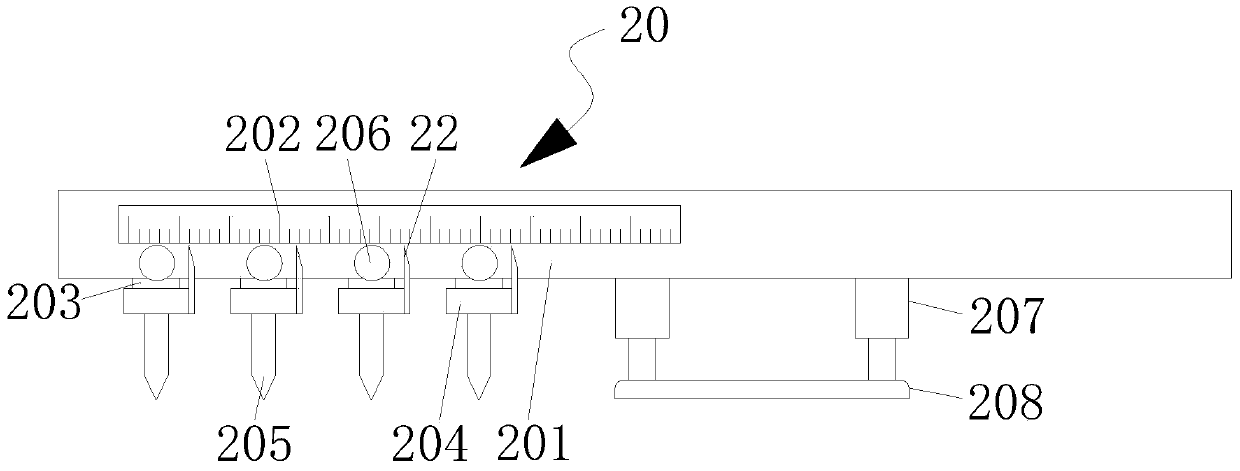

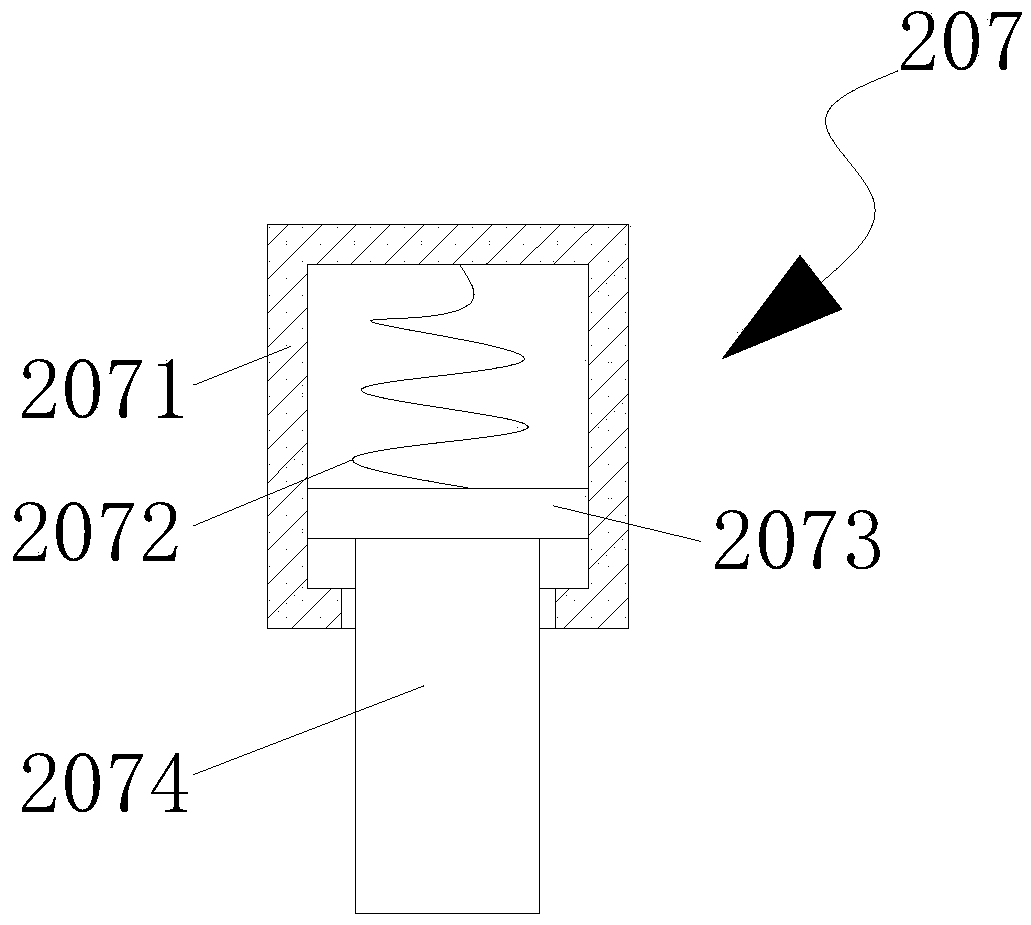

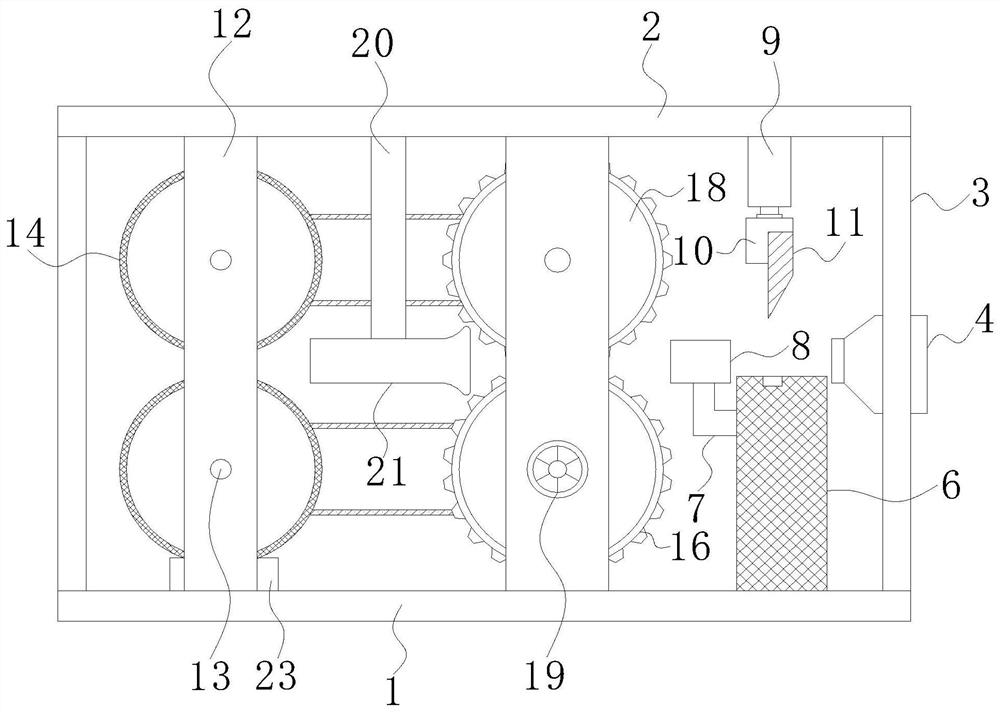

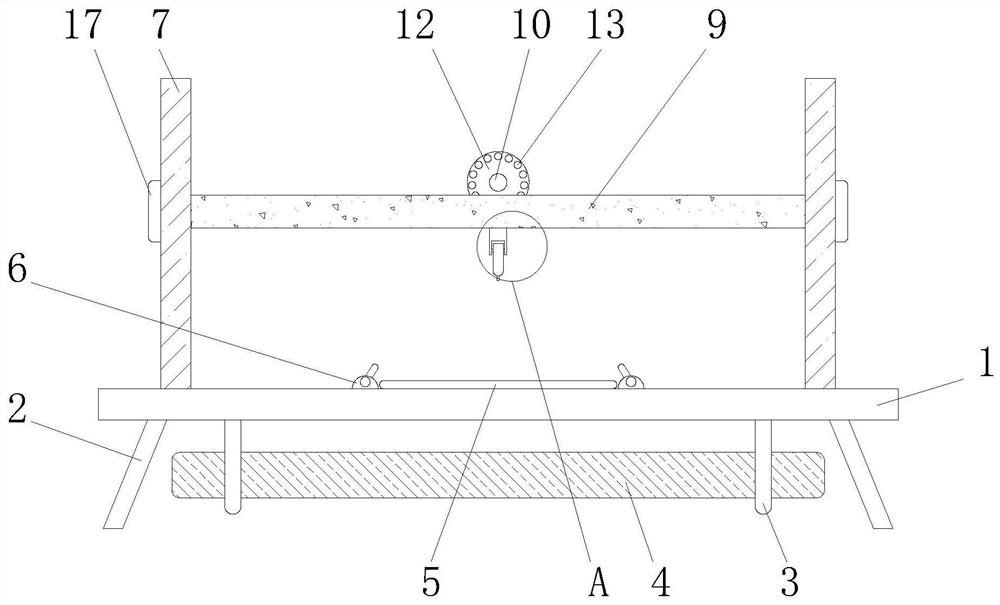

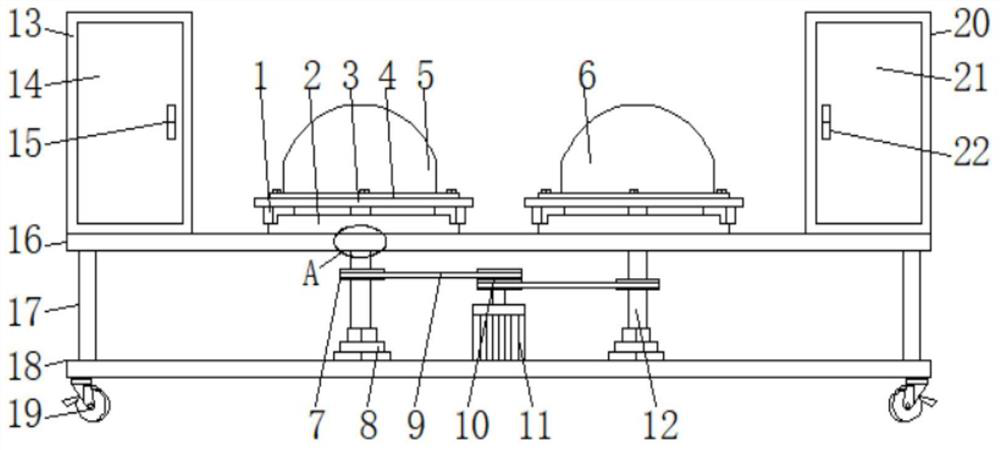

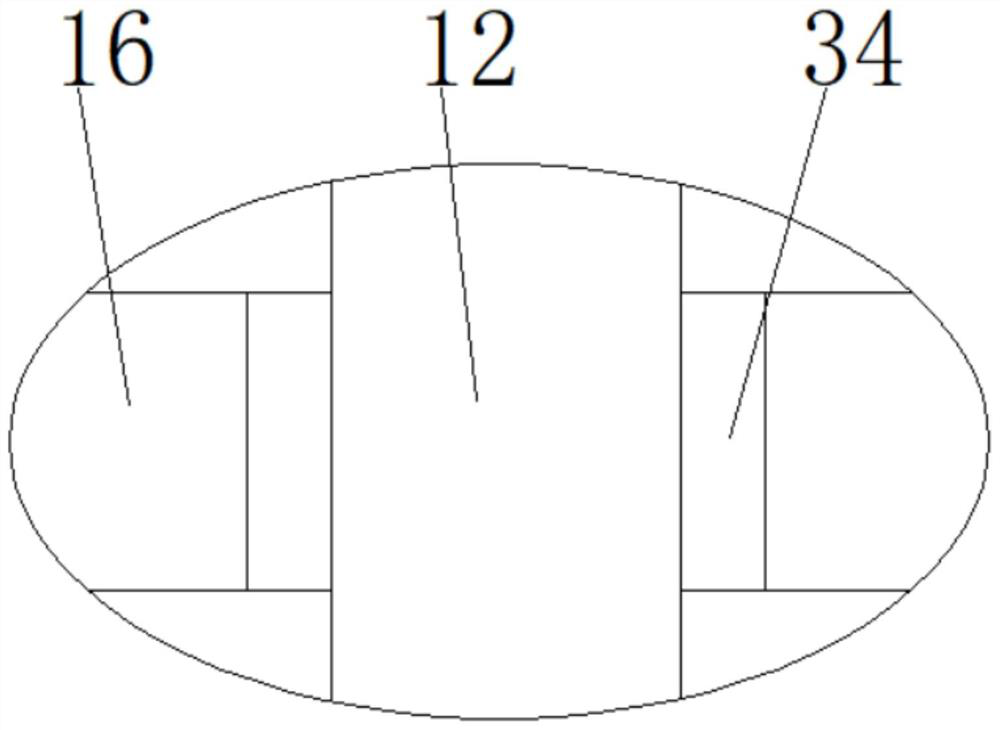

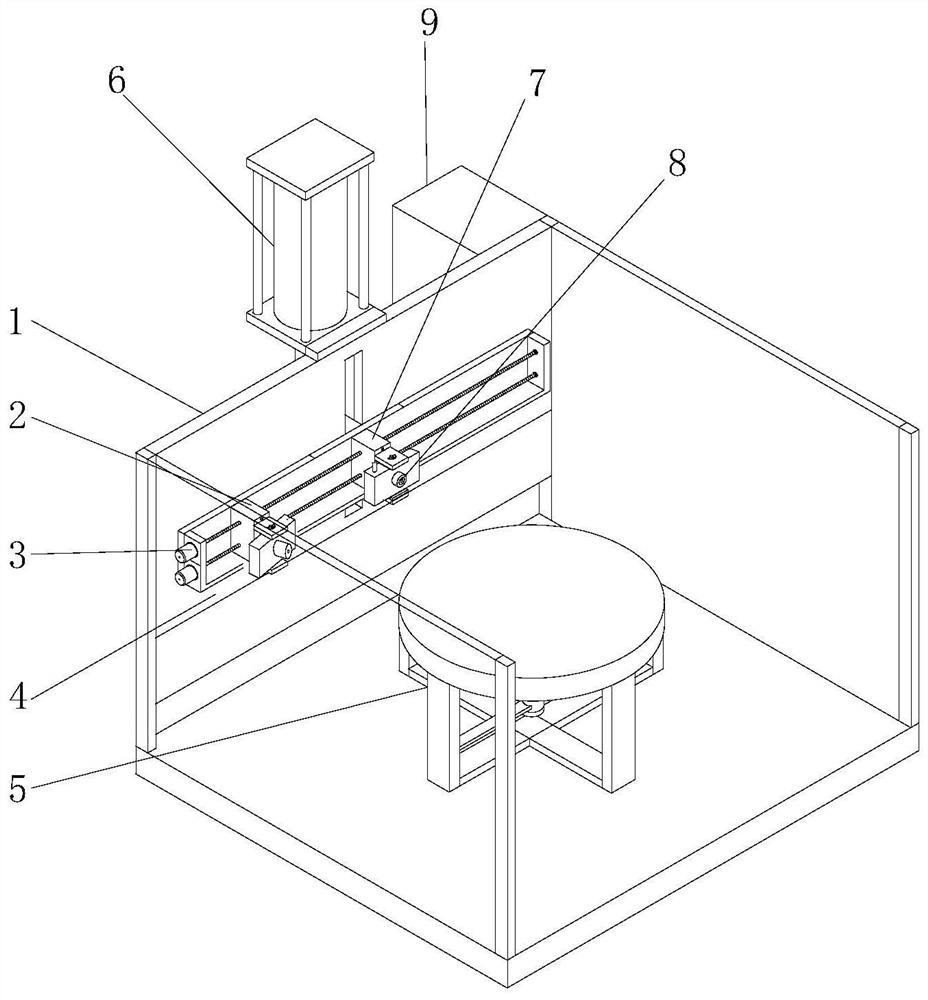

Automaticcake slicing devicewithhigh efficiency

InactiveCN109794973AHigh degree of automationReduce work intensityMetal working apparatusEngineeringCircular surface

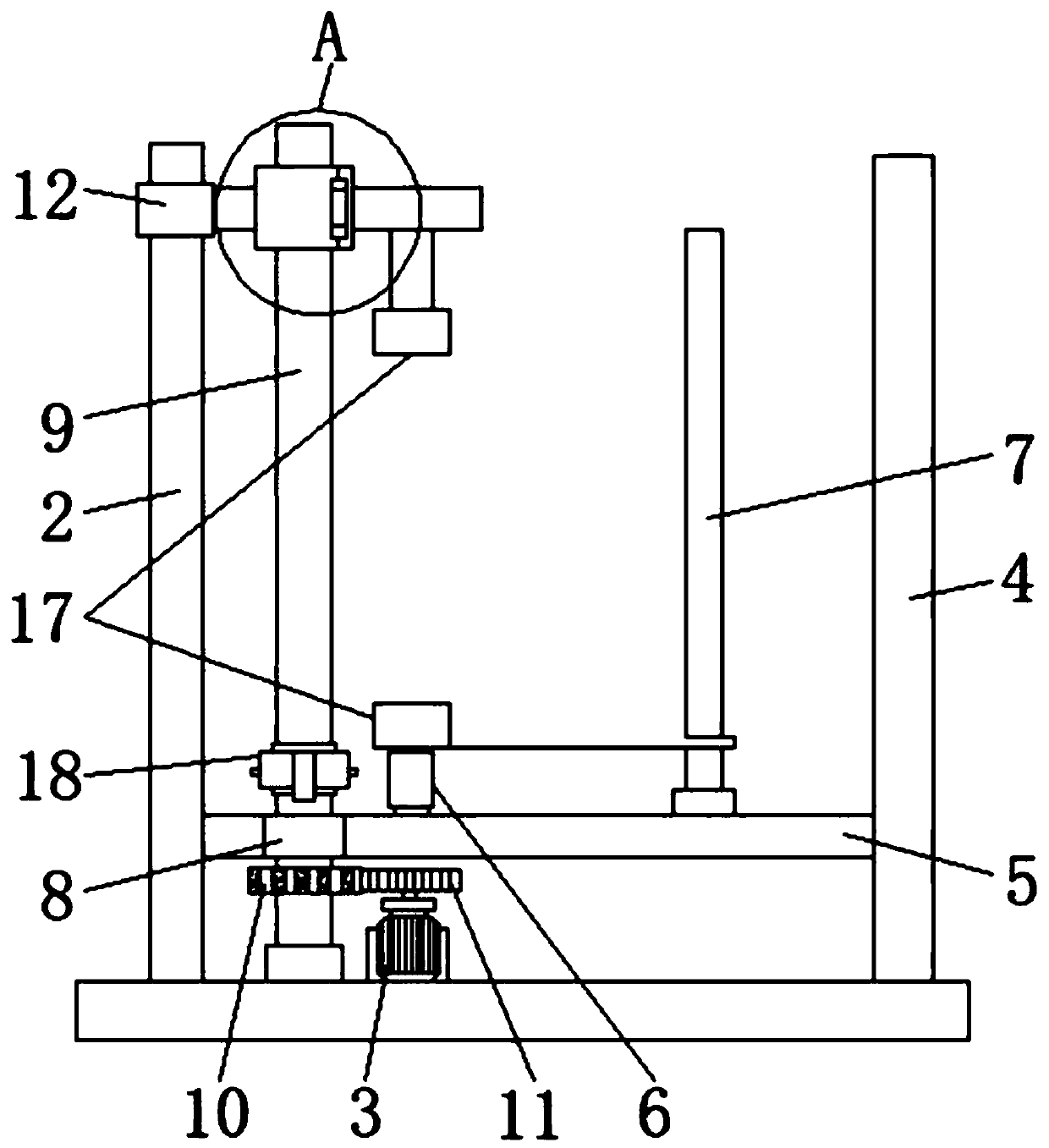

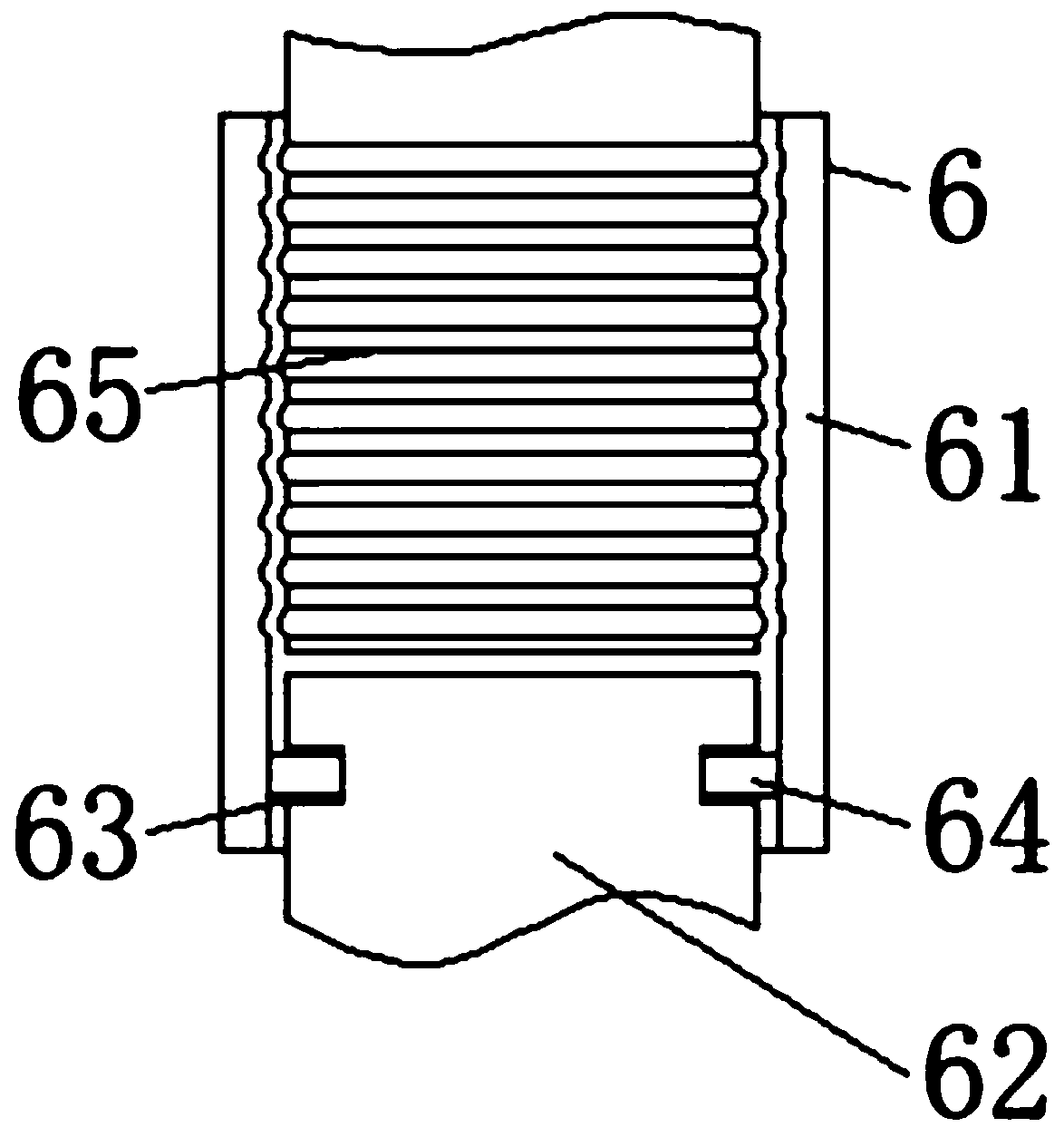

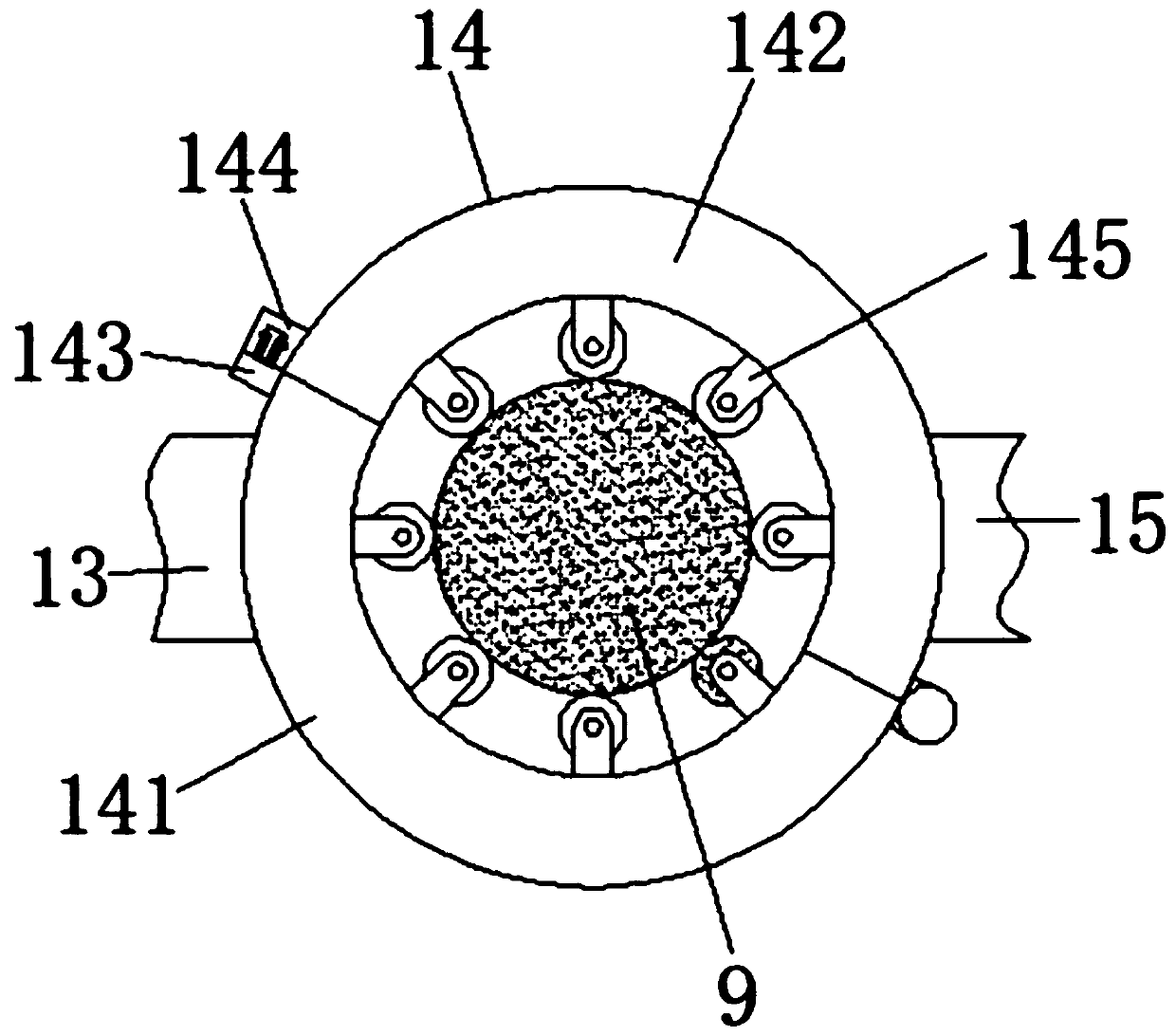

The invention relates to the technical field of slicing devices for slicing cakes, and discloses an automatic cake slicing devicewith the high efficiency. Theautomatic cake slicing device with the high efficiency comprises a base, two first brackets are fixedly connected to the top of the base, roller wheels are rotatably connected to the upper ends of the first brackets, a conveyor belt sleeves between the outer circular surfaces of the two roller wheels, the position, on the right side, of the first bracket is rotatably connected with a circular gear, the circular gear and the roller wheel on the right side are coaxial, a second bracket is fixedly installed at the top of the base, the upper end of the second bracket is rotatably connected with a first belt pulley and a missing gear, andthe first belt pulley and the missing gear are coaxial, a fixing plate is fixedly installed at the top of the base, and the front face of the fixing plate is fixedly connected with a motor. Accordingto theautomatic cake slicing devicewith the high efficiency, the problems that according to existing slicing devices for the slicing cakes, the working efficiency is low, the yield is not high, operation of workers is tedious, the labor intensity is high, and during slicing, the condition of deviation can appear sometimes, and the quality of the sliced cakes is affected are solved.

Owner:安徽皖源食品有限公司

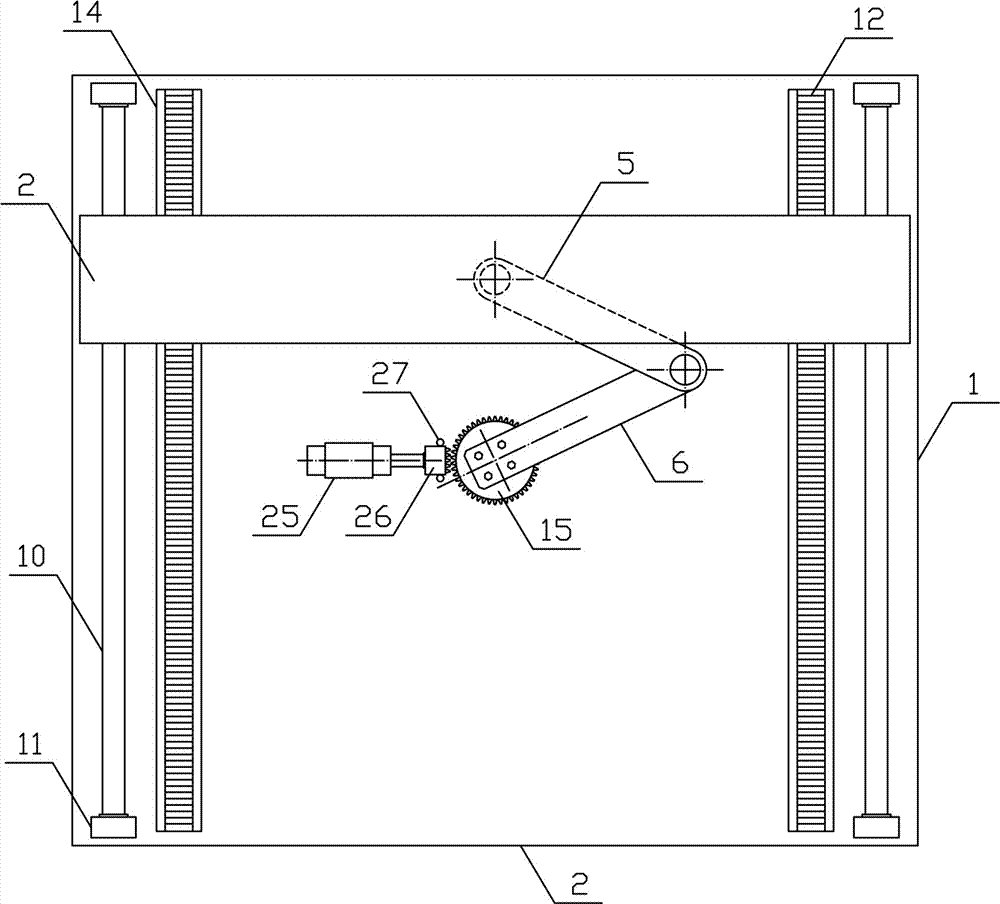

Platform reciprocating mechanism

The invention discloses a platform reciprocating mechanism, and belongs to the field of conveying mechanical equipment. The platform reciprocating mechanism comprises a translation support, a material bearing platform, a driving support, a driving shaft, an upper connecting plate, a lower connecting plate, an adjusting shaft, an output shaft and a translation motor. The two sides of the material bearing platform are arranged on translation guide rods in a sliding mode in the horizontal direction. The upper end of the driving shaft and the middle part of the material bearing platform are sequentially connected from top to bottom to be provided with the upper connecting plate and the lower connecting plate. A main output gear is horizontally arranged in the middle part of the output shaft. The driving support located between the output shaft and the driving shaft is vertically connected with the adjusting shaft in a rotating mode. The adjusting shaft is horizontally and fixedly provided with an upper connecting gear and a lower connecting gear from top to bottom in sequence. The platform reciprocating mechanism is reasonable in structural design, the material bearing platform can be quickly driven to reciprocate stably and efficiently for translation, the reciprocating frequency of the material bearing platform can be adjusted conveniently and rapidly as required, and the conveying use needs are met.

Owner:浙江绿康农产品配送有限公司

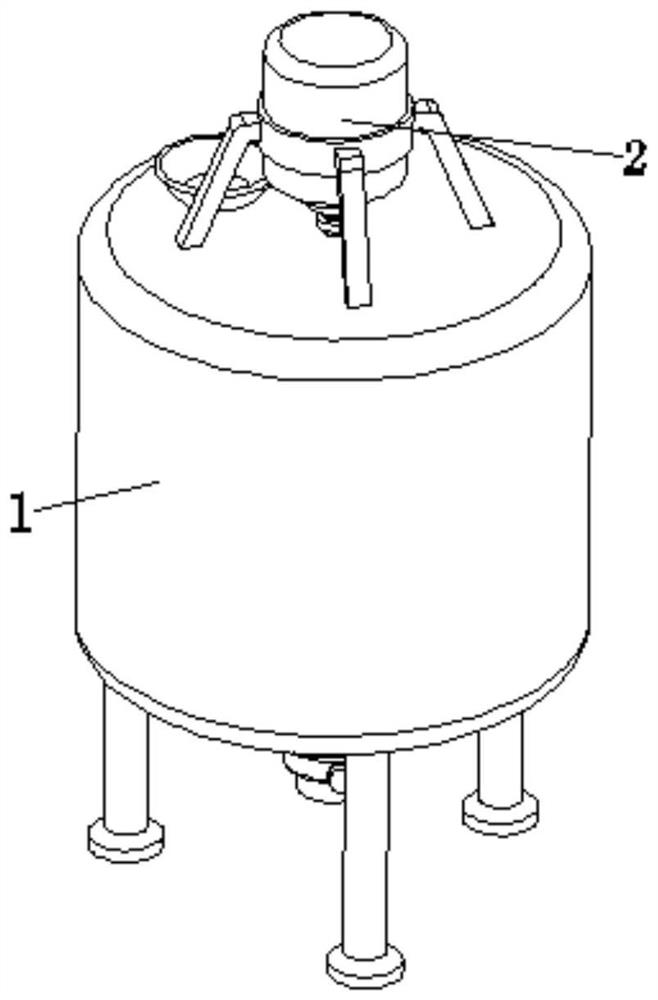

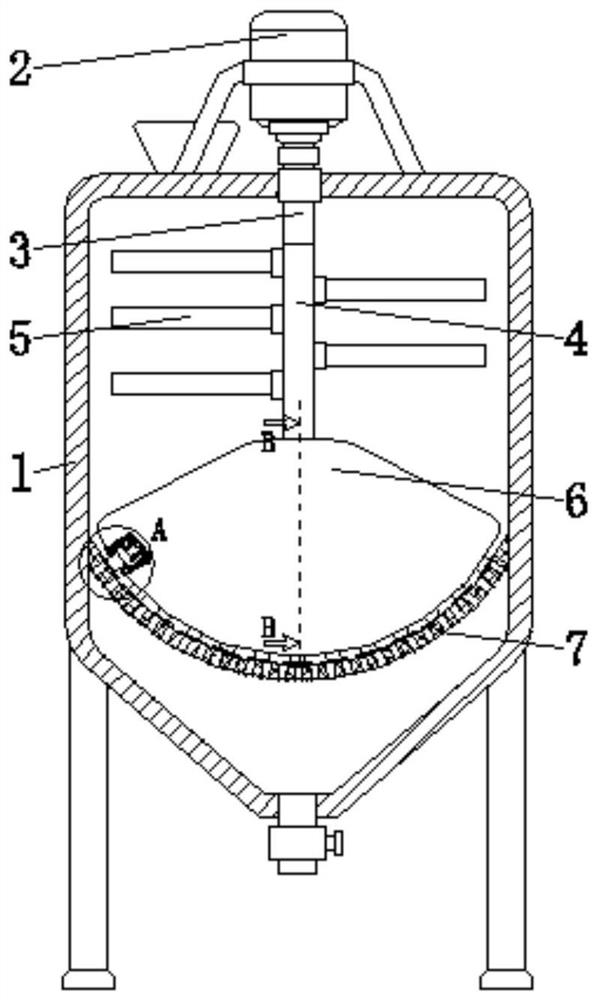

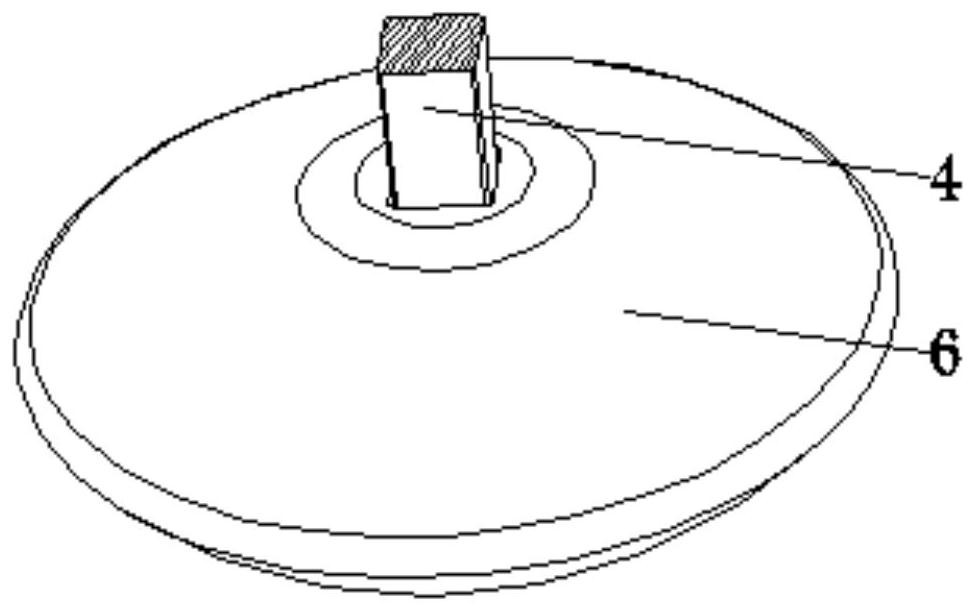

Feed processing equipment

The invention discloses feed processing equipment. The feed processing equipment comprises a grinding tank and a driving motor, wherein a rotating shaft is rotatably connected to the center of the topof the grinding tank; the top end of the rotating shaft is fixedly connected with an output shaft of the driving motor through a coupling; a square connecting rod is fixed to the bottom end of the rotating shaft and located in the center of the interior of the rotating shaft; deflector rods are fixed to the surface of the square connecting rod; a grinding device is arranged at the bottom end of the square connecting rod, the grinding device is in sliding connection with the square connecting rod; and a sieve plate is fixed to the position, close to the bottom of the grinding device, in the grinding tank. The invention relates to the technical field of feed processing. According to the feed processing equipment, the effects of uniform grinding and adhesion prevention are achieved; elasticpressing can be carried out, and the grinding space is automatically and moderately increased, so that large and small granular materials uniformly leak, and grinding is rapid and uniform; and meanwhile, sticky materials on the inner wall can be automatically scraped off, so that the working efficiency and the use performance are improved.

Owner:莱阳和美华饲料有限公司

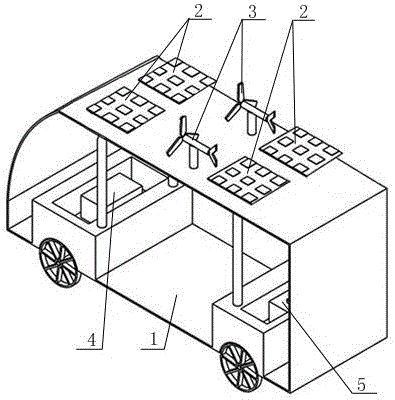

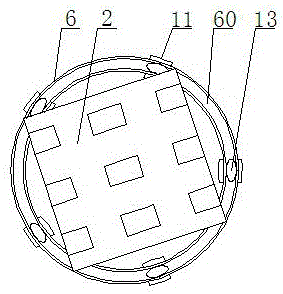

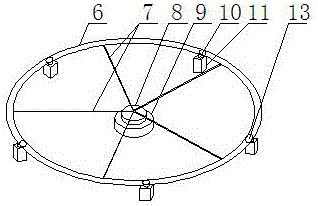

Wind-solar complementary power generation system used for electric automobile

InactiveCN105034825AAvoid skewed situationsStrong wind resistanceAuxillary drivesVehicular energy storageAutomotive engineeringWind force

A wind-solar complementary power generation system used for an electrical automobile comprises solar cell panels and miniature wind driven generators, wherein the solar cell panels and the miniature wind driven generators are arranged at the top of the automobile. A super-capacitor and a storage battery are installed on an automobile body. The wind-solar complementary power generation system further comprises a matrix converter. Energy generated by the solar cell panels and the miniature wind driven generators is transmitted to the matrix converter through a DC-DC converter in a one-way mode, the super-capacitor and the storage battery are in two-way transmission connection with the matrix converter through the DC-DC converter, when the energy of the system is sufficient, the super-capacitor and / or the storage battery supply power to the matrix converter, and when the electric quantity is insufficient, the super-capacitor and / or the storage battery obtain current from the matrix converter, wherein the solar cell panels are installed at the top of the automobile through rotating devices which achieve circular-ring rotation through gear transmission, and the solar panels track solar light by 360 degrees in the horizontal plane. The wind-solar complementary power generation system is applied to the electric automobile, in this way, solar energy and wind energy can be complementary, and an all-weather power generation function is achieved.

Owner:HENAN UNIV OF SCI & TECH

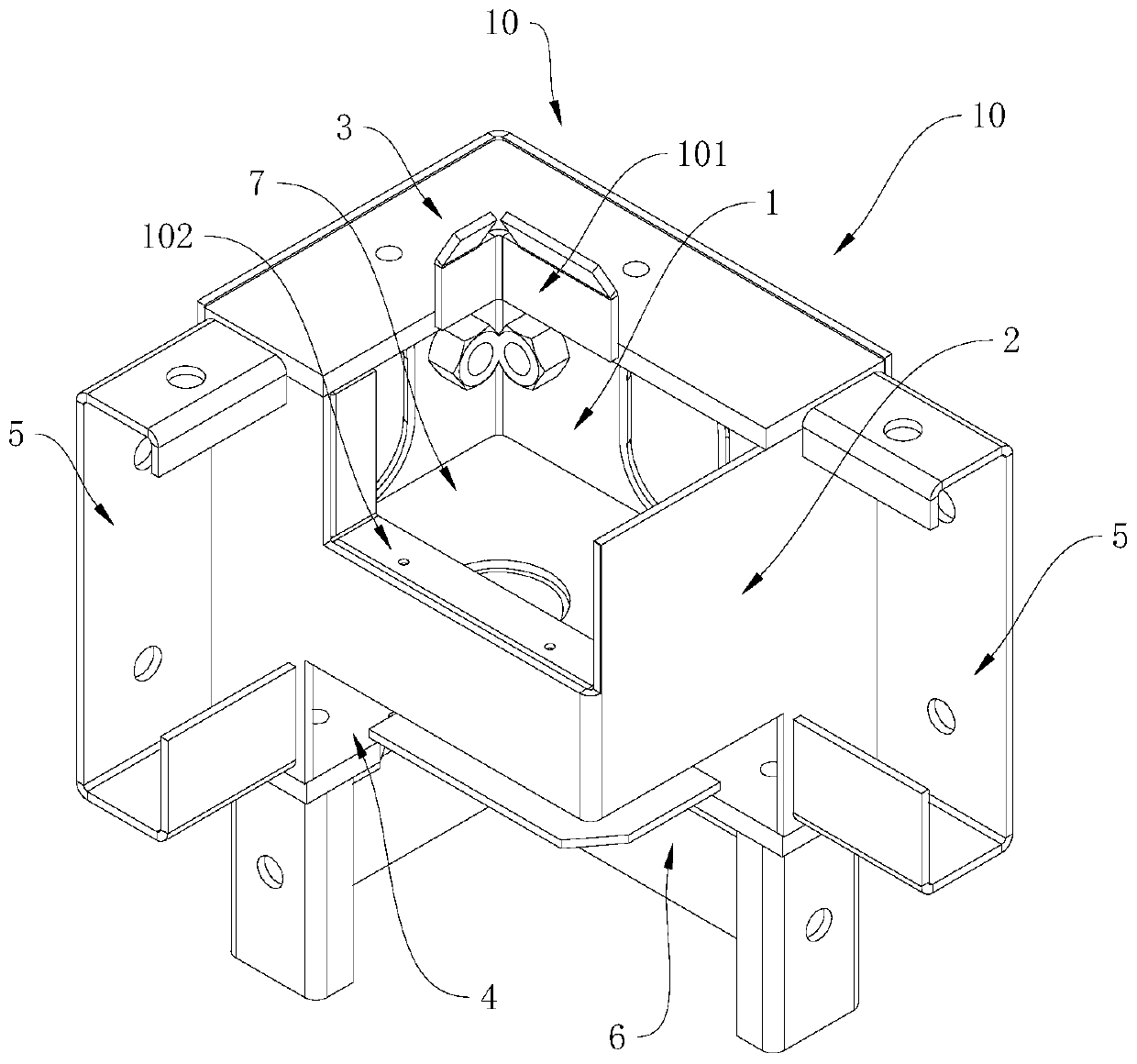

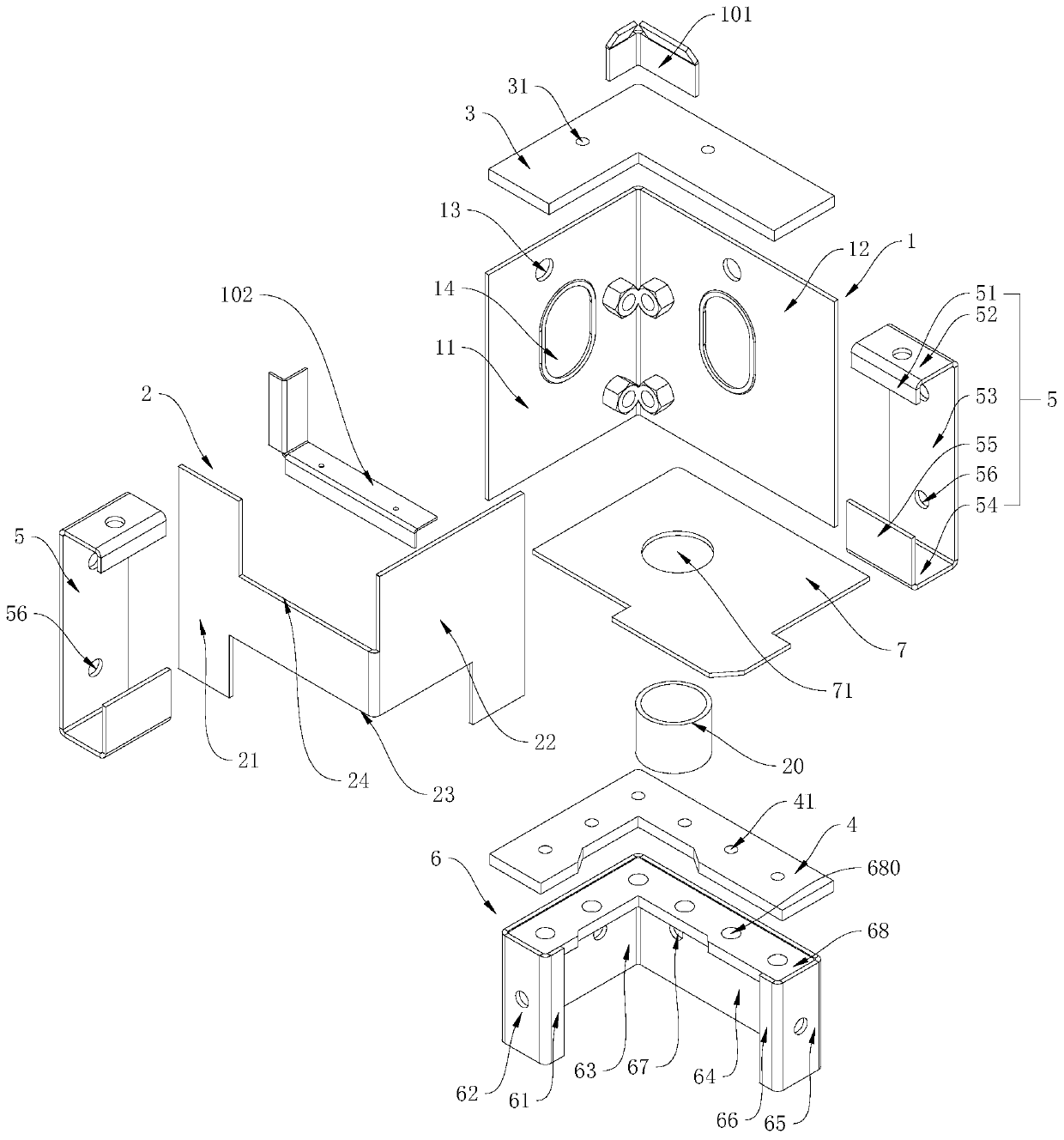

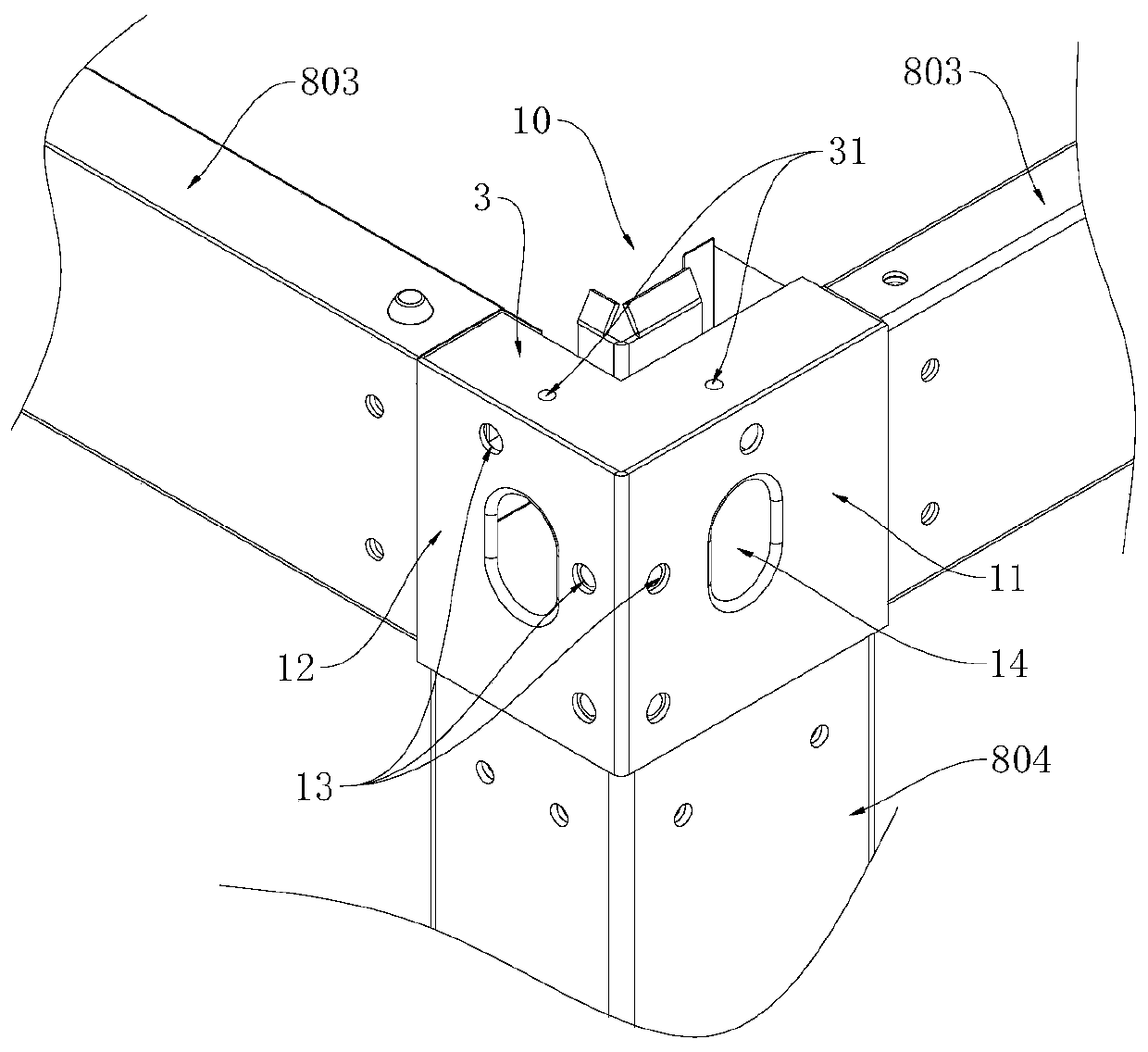

Container house corner connector and container house

PendingCN110029840AImprove stabilityImprove stress resistanceSpecial buildingBuilding constructionsEngineeringBolt connection

The invention discloses a container house corner connector and a container house, and belongs to the technical field of container houses and container house accessories. The container house corner connector includes a corner folding outer plate, a corner folding inner plate, an upper connection plate, a lower connection plate, a first groove-shaped plate, and a second groove-shaped plate, whereinthe corner folding outer plate is provided with a first panel and a second panel which are perpendicular to each other, the corner folding inner plate is provided with a third panel and a fourth panelwhich are perpendicular to each other, the side of the third panel is connected with the side of the first panel, the side of the fourth panel is connected with the side of the second panel, and thefirst panel, the second panel, the third panel and the fourth panel jointly form a four-square box-shaped structure with an upper opening and a lower opening. According to the container house corner connector and the container house, when the container house is assembled, bolt connection is adopted, welding steps are reduced, processing is simple and convenient, the structure is simple, disassembly is convenient, and the installation accuracy is high.

Owner:CHINA RAILWAY SIXTH GROUP +1

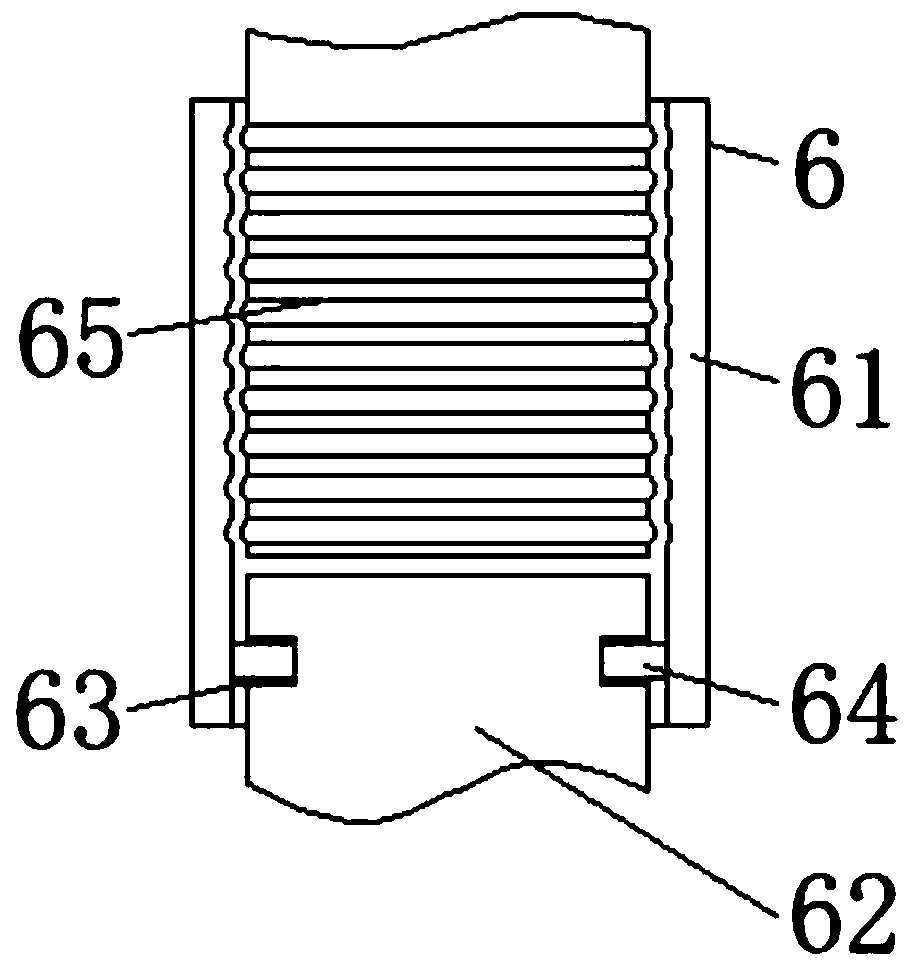

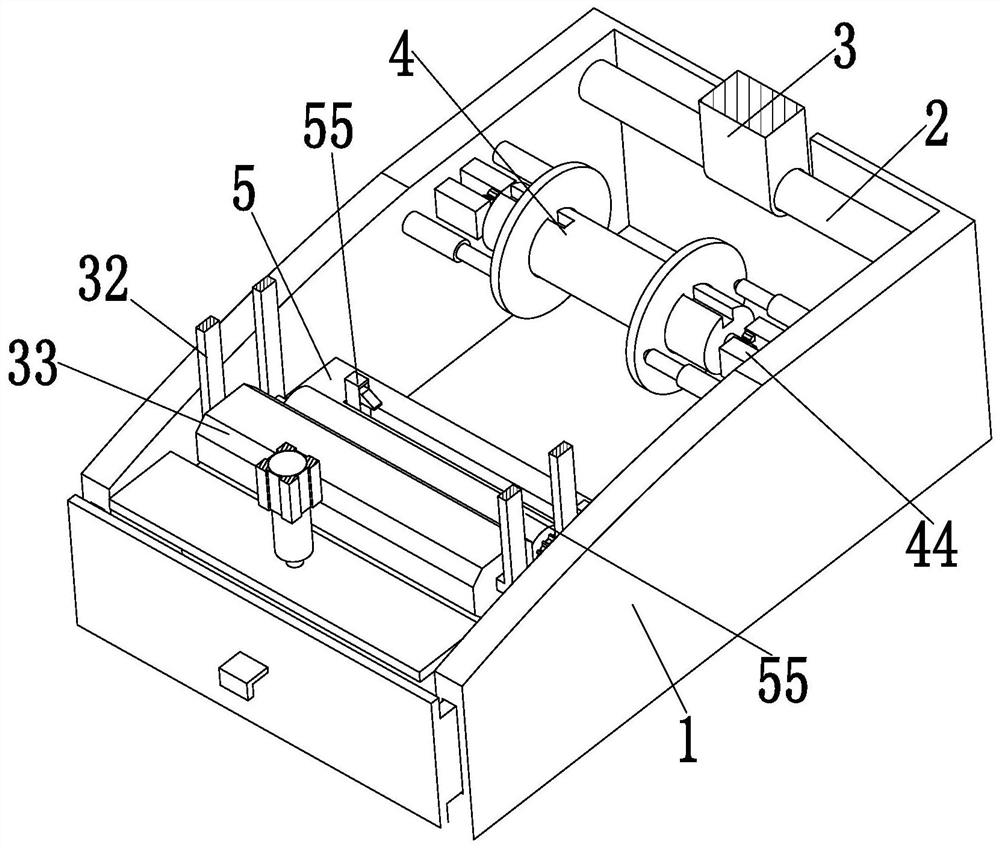

Food plastic bag winder with edge alignment function

The invention relates to the technical field of food packaging and discloses a food plastic bag winder with an edge alignment function. The winder comprises a base, the top of the base is fixedly connected with a support column, a motor and a fixing rod from left to right in sequence, a limiting transverse plate is fixedly connected between the opposite sides of the support column and fixing rod,and an extension mechanism is fixedly connected to the top of the limiting transverse plate; the top of the limiting transverse plate is movably connected with an auxiliary winding rod through a firstbearing base, the top of the limiting transverse plate is movably connected with a bag winding sleeve rod through a first fixing bearing, the bottom of the bag winding sleeve rod penetrates through the limiting transverse plate and is movably connected with the top of the base through a second bearing base, and the bag winding sleeve rod is fixedly sleeved with a first gear. The winder solves theproblem that the edges of plastic bags cannot be aligned when food plastic bag winders are used for winding and achieves the effects that the plastic bags are more stable during winding and the edgesof the plastic bags after winding are aligned.

Owner:广东富华通环保科技有限公司

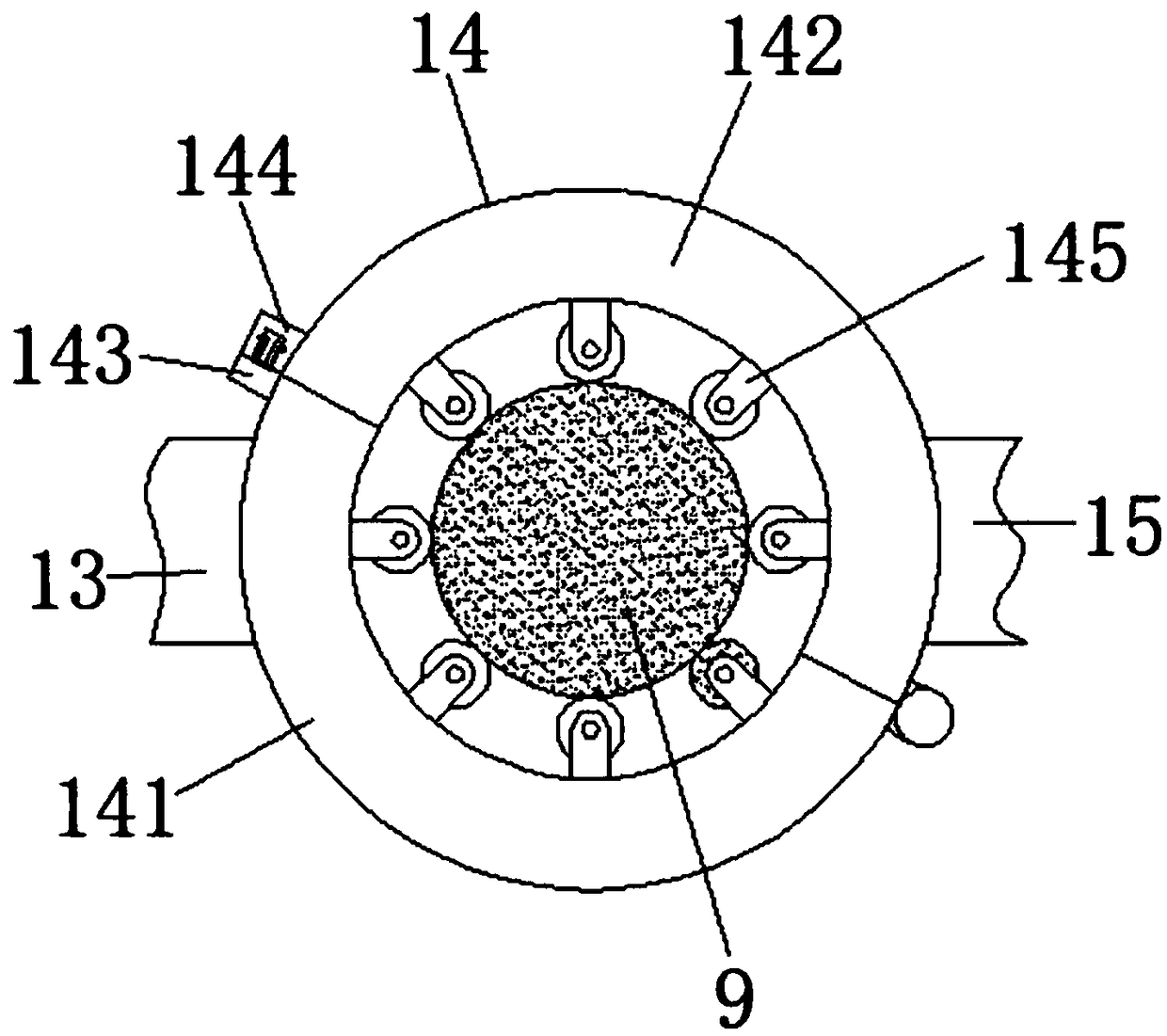

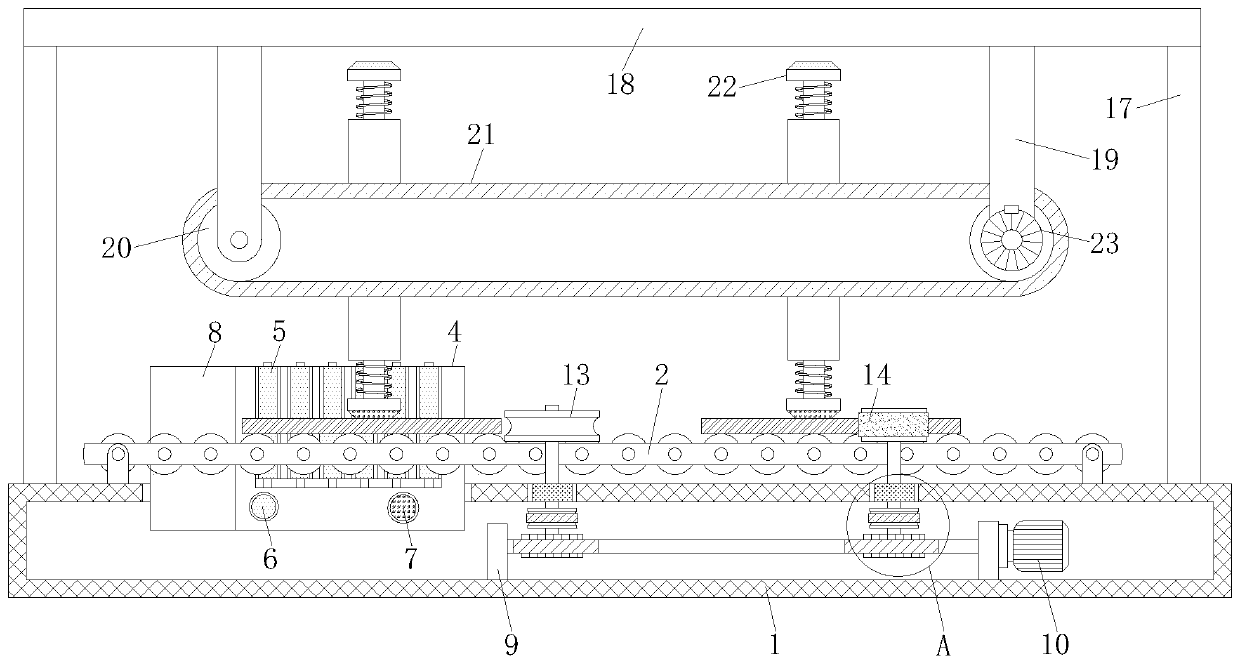

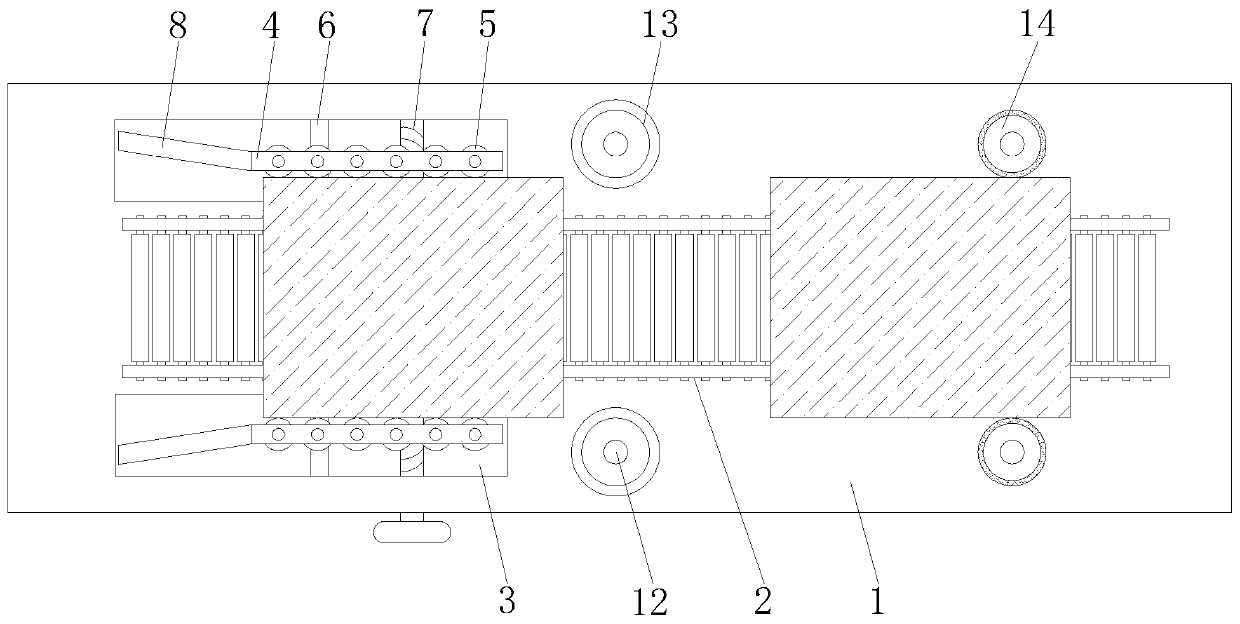

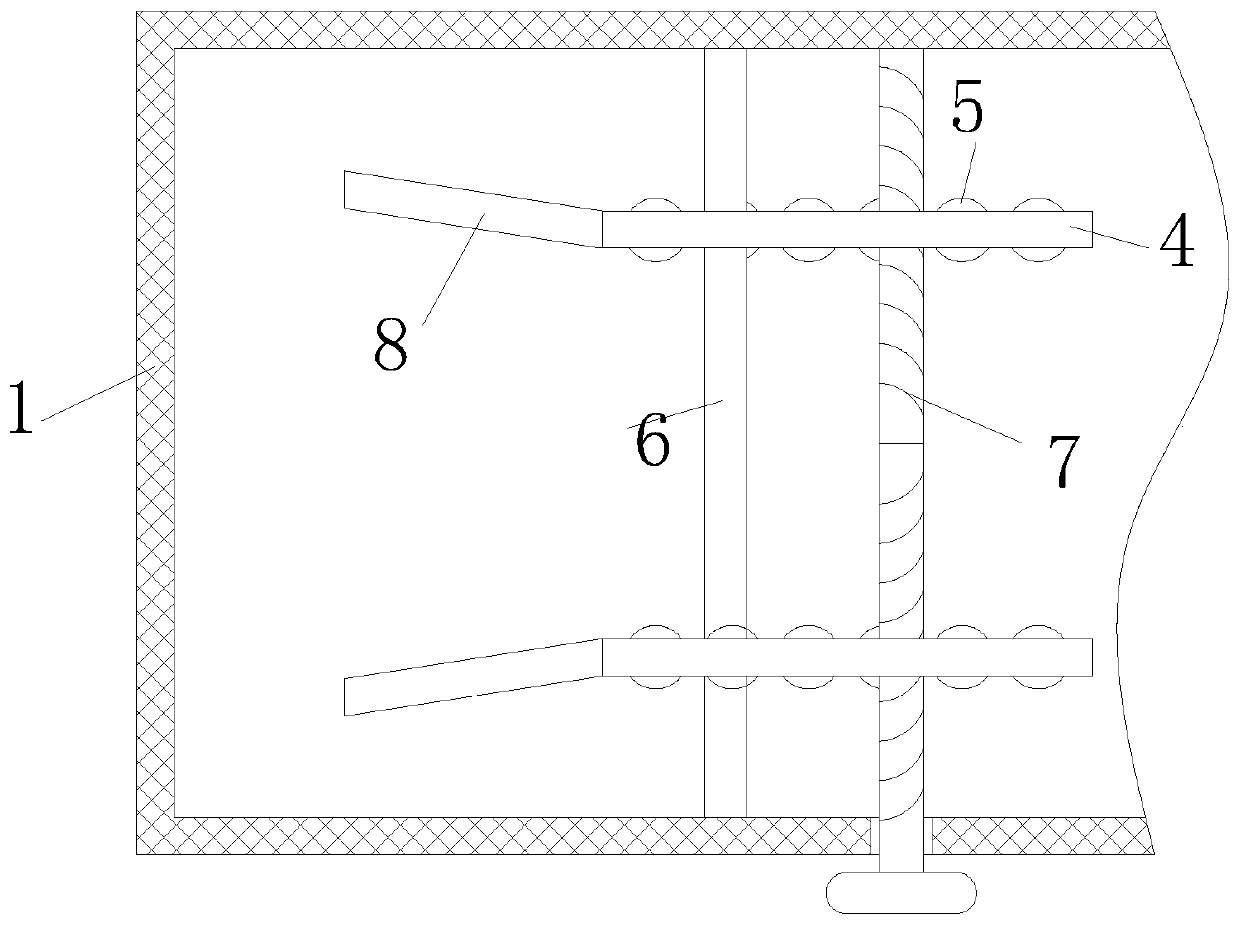

Edge and corner grinding device for light steel structure connecting pieces

ActiveCN110039396ANeat transfer sandingArrange neatlyEdge grinding machinesGrinding drivesEngineeringMechanical engineering

The invention relates to the technical field of treatment performed after lightweight steel structure connecting pieces are cut off, and discloses an edge and corner grinding device for the light steel structure connecting pieces. The edge and corner grinding device for the light steel structure connecting pieces comprises a device bottom box, a conveying roller is fixedly arranged at the top of the device bottom box, two open grooves are formed in the top of the device bottom box, fixing plates are arranged in the open grooves, moreover, the two fixing plates are parallel to each other, rollers are arranged on the fixing plates, a sliding rod is movably connected between the bottoms of the side surfaces of the two fixing plates, the two ends of the sliding rod penetrate through the side surfaces of the fixing plates correspondingly and are fixedly connected with the front inner wall and the rear inner wall of the device bottom box, a two-way screw is connected between the bottoms of the side surfaces of the two fixing plates in a threaded mode, one end of the two-way screw penetrates through the side surfaces of the fixing plates to be rotationally connected with the front inner wall and the rear inner wall of the device bottom box. According to the edge and corner grinding device for the light steel structure connecting pieces, the problems that after the light steel structure connecting pieces are cut off, the hand is prone to be cut and hurt during mounting, moreover, an existing device capable of performing deburring grinding is held by the hand for grinding, so that the efficiency is low, and the safety is not high are solved.

Owner:安徽皖国动力科技有限公司

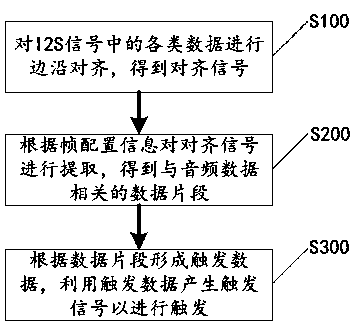

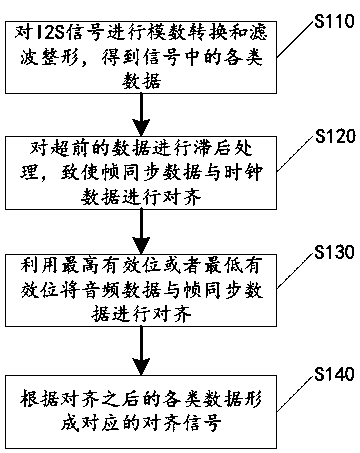

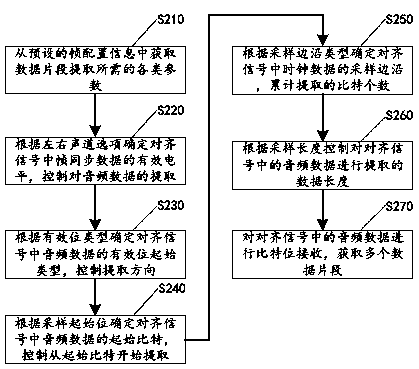

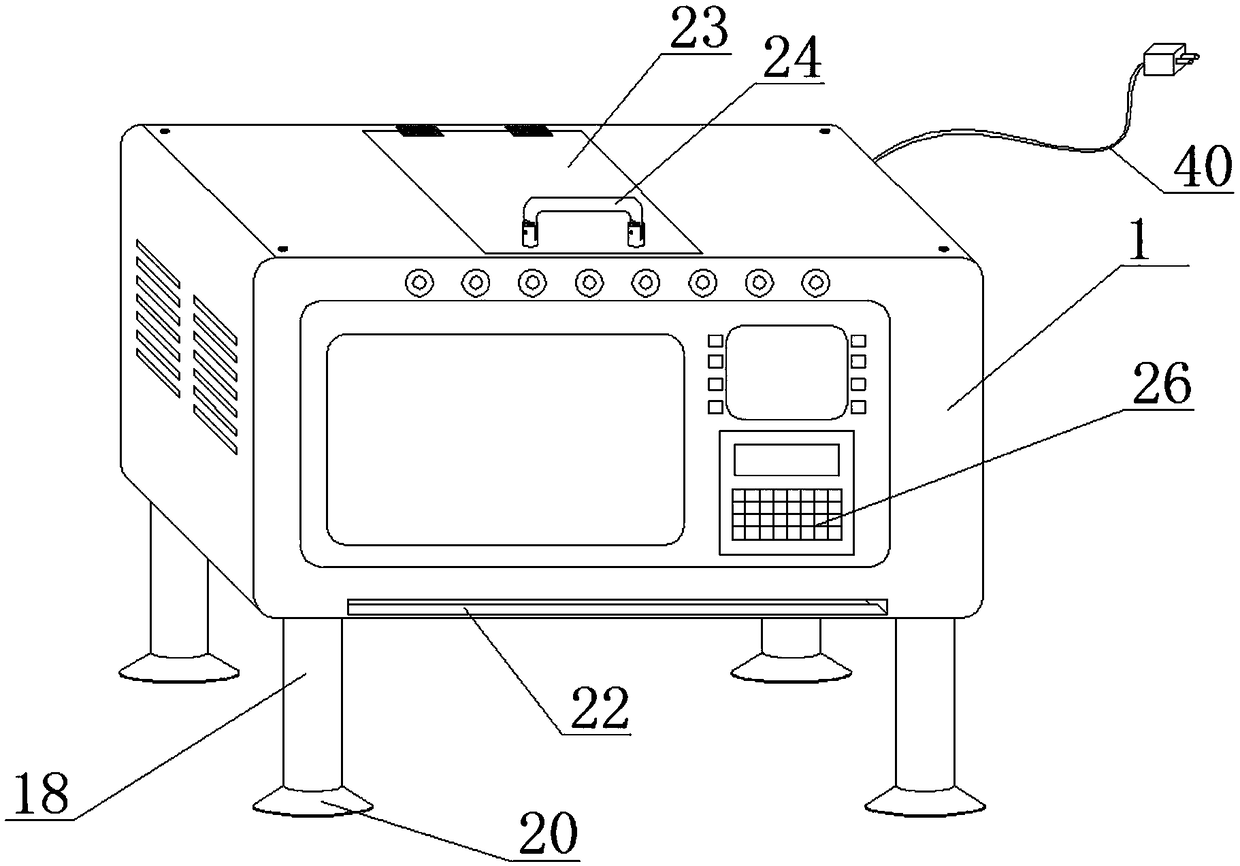

Triggering method based on I2S signal and oscilloscope

InactiveCN110749763AOvercoming Application LimitationsExtended trigger functionDigital variable displayReal-time computingComputer hardware

The invention discloses a triggering method based on an I2S signal and an oscilloscope. The triggering method comprises the steps of performing time sequence alignment on various data in the I2S signal to obtain an alignment signal, wherein the I2S signal comprises frame synchronization data, clock data and audio data; extracting the alignment signal according to preset frame configuration information to obtain a plurality of data fragments related to the audio data in the alignment signal; and forming triggering data according to the data fragments, and generating a triggering signal by utilizing the triggering data to perform triggering. According to the triggering method, the triggering signal is generated according to the I2S signal, so that a triggering event occurs after external triggering, the application limitation that the conventional oscilloscope cannot perform real-time triggering by utilizing the I2S signal is overcome, the triggering function of the oscilloscope is expanded, and an engineer can be helped to quickly analyze problems at multiple angles.

Owner:SHENZHEN CITY SIGLENT TECH

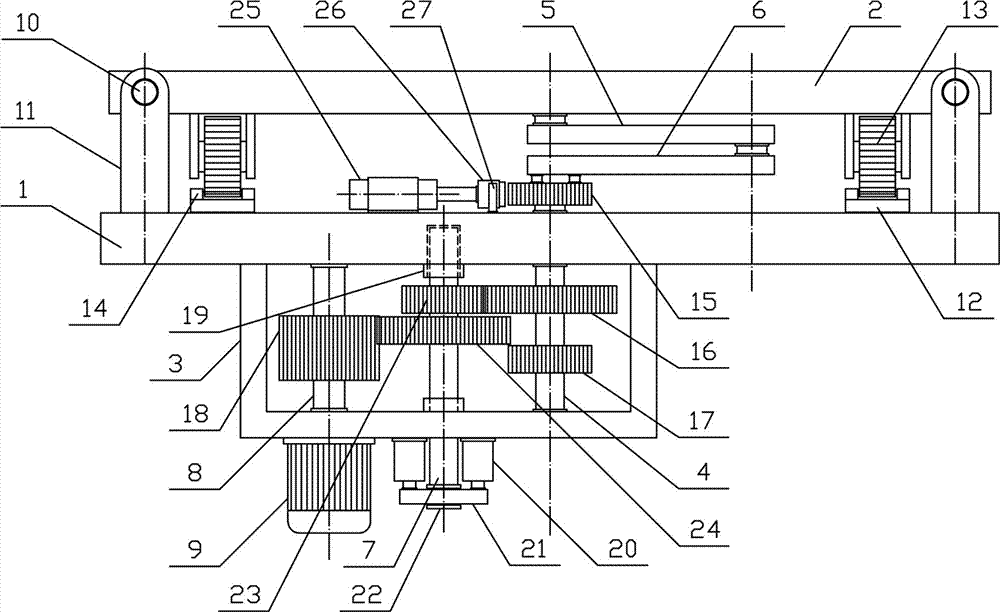

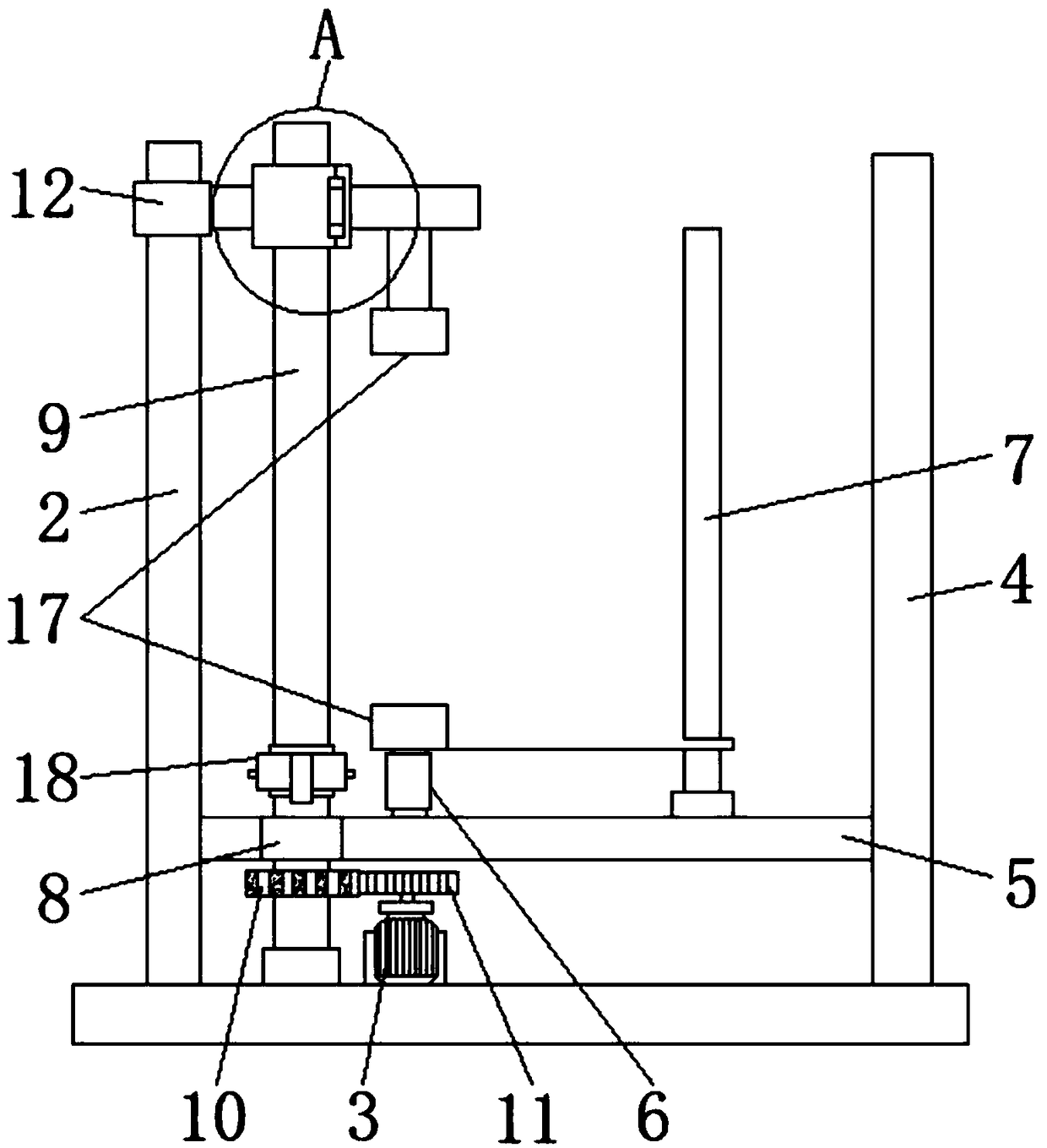

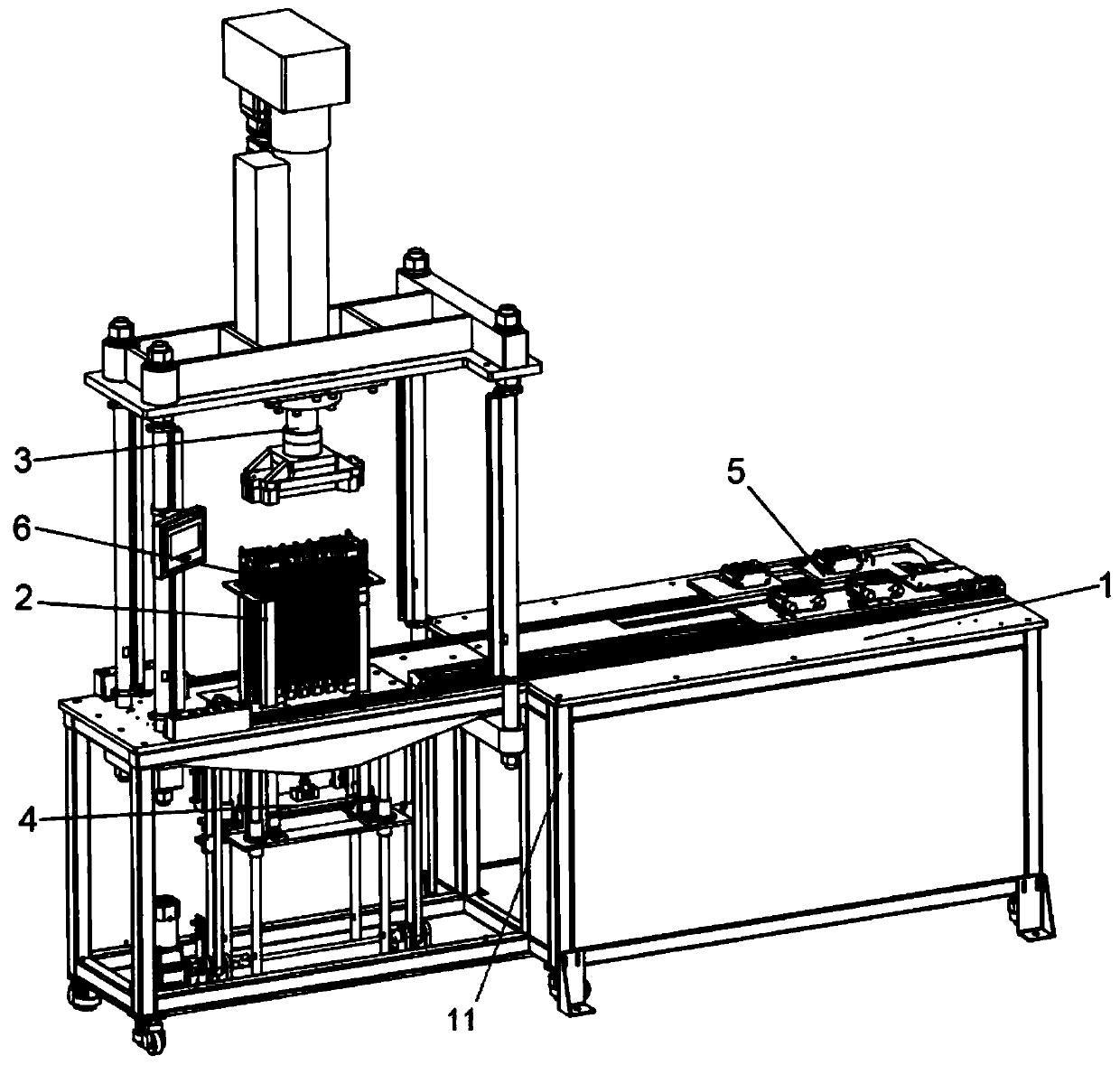

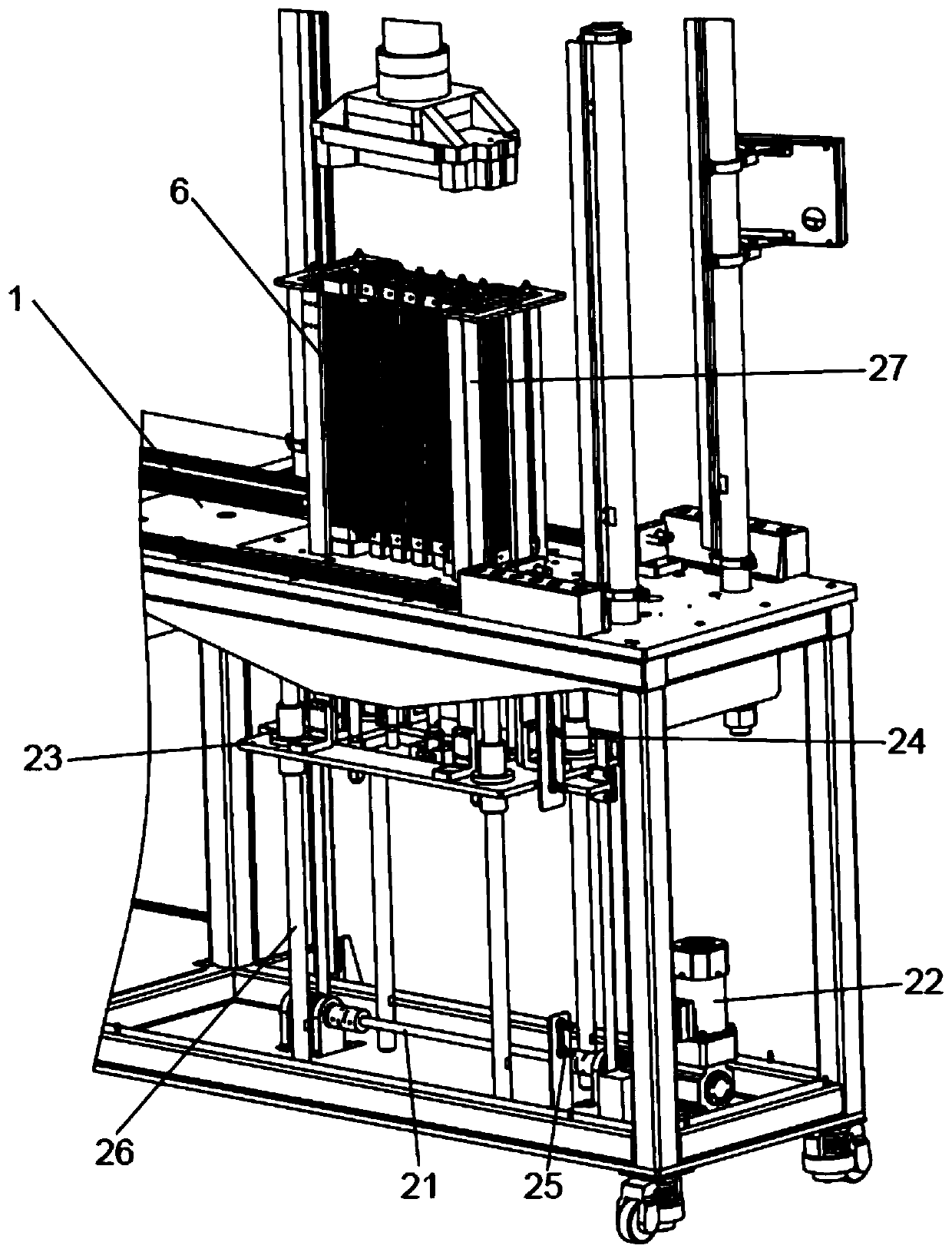

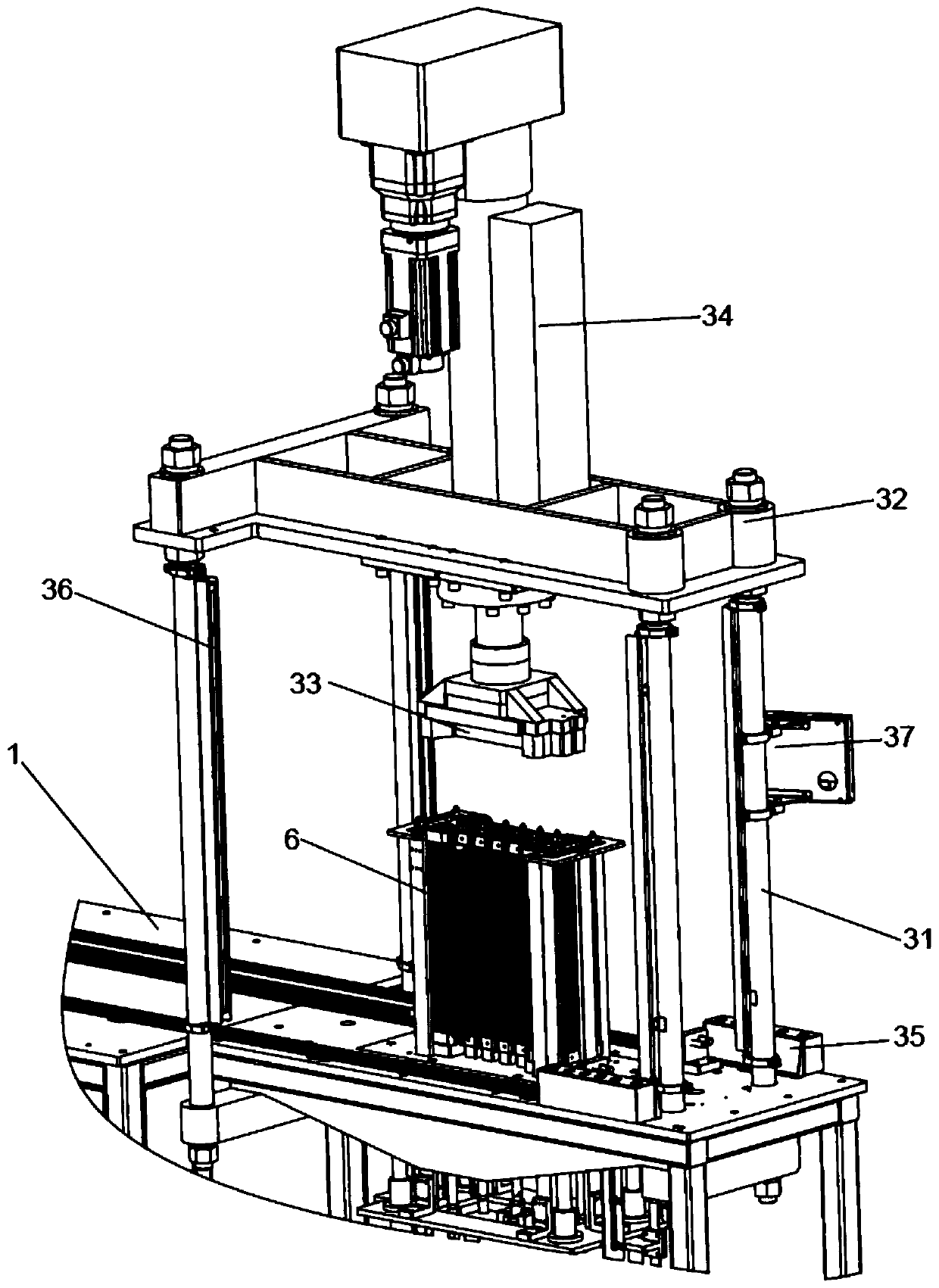

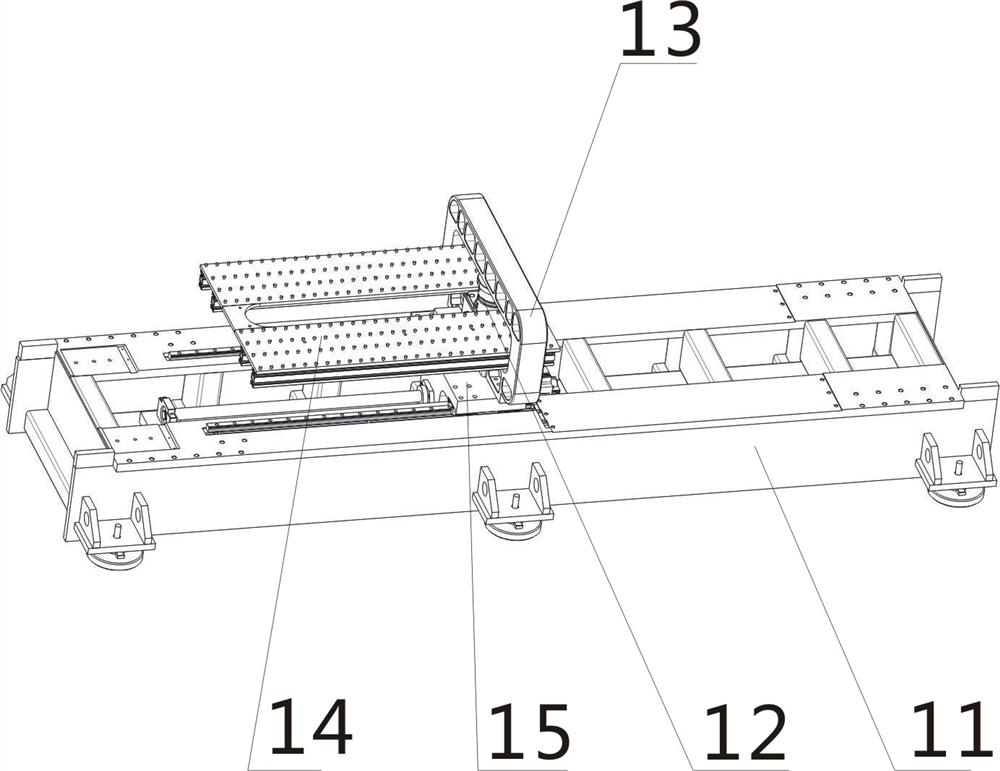

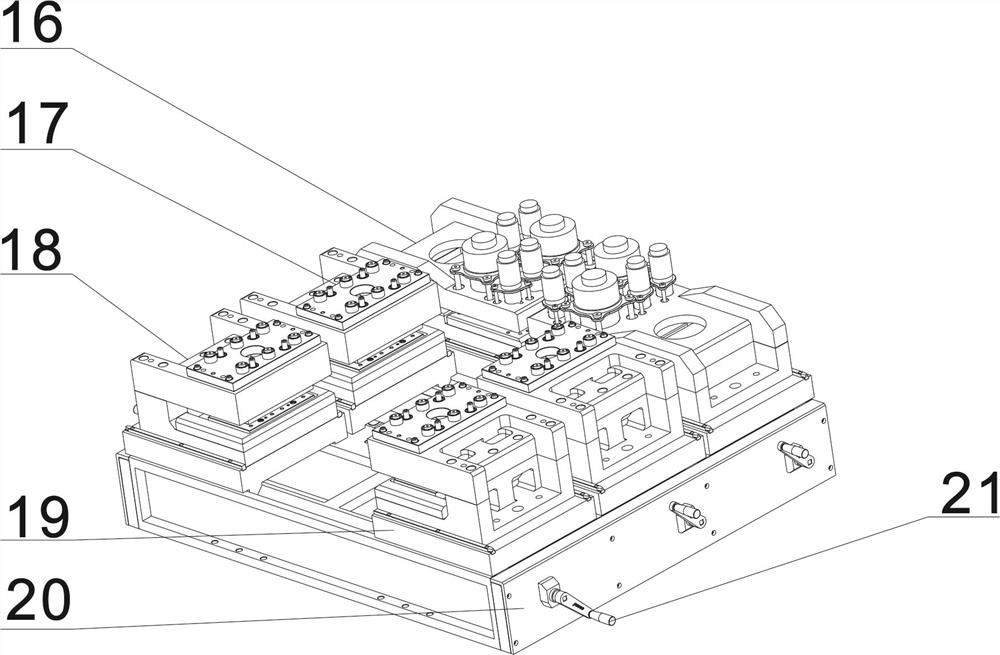

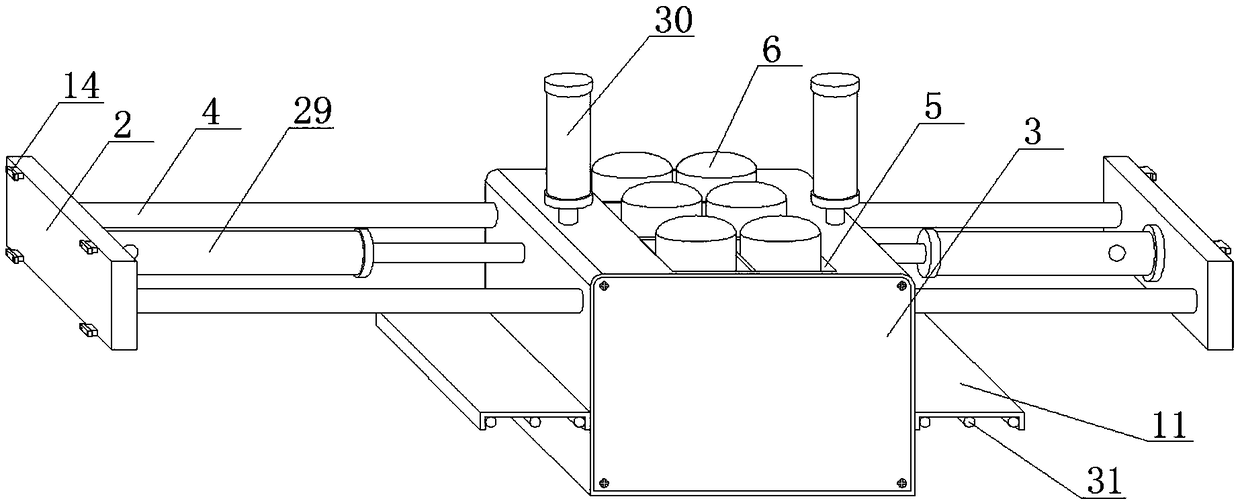

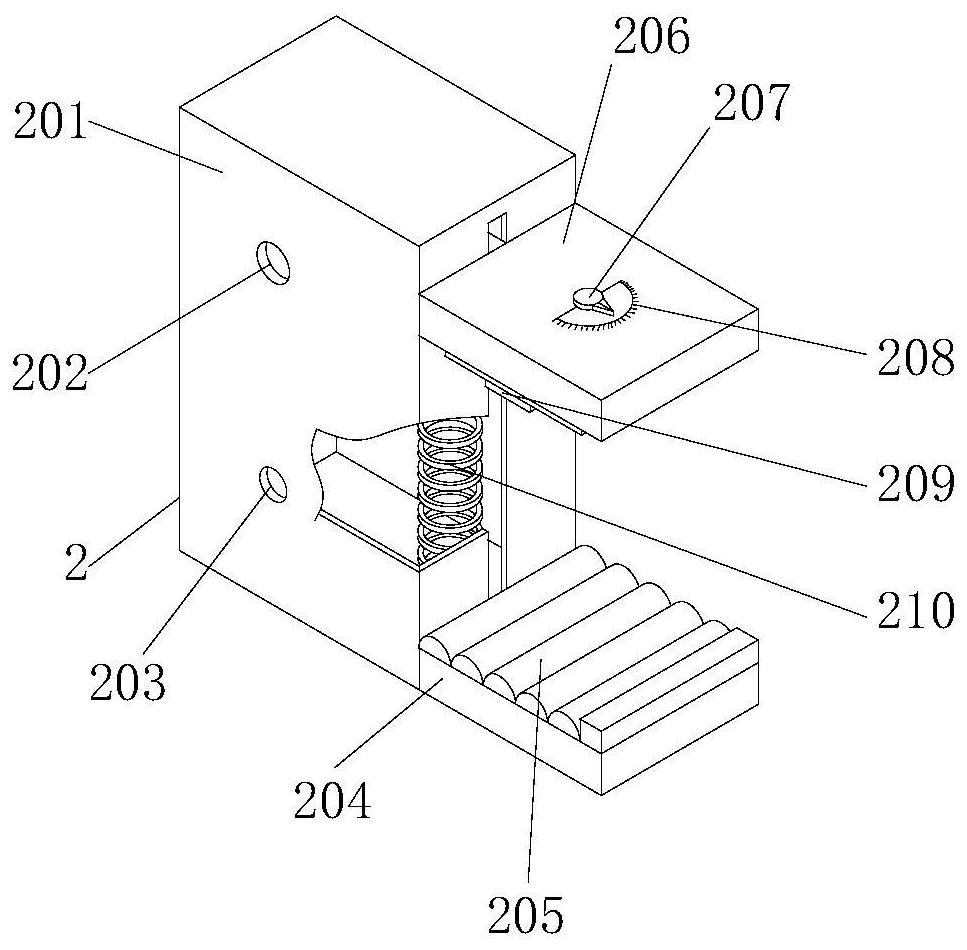

Hydrogen cell packing device and packing method thereof

ActiveCN109841887AThe position is stable during the pressing processGap stabilityFinal product manufactureFuel cellsHydrogen fuel cellPole piece

The invention provides a hydrogen cell packing device which comprises a base, a stack limiting mechanism, a pole piece compaction mechanism, a lifting-up mechanism and transfer mechanism. The invention also provides a hydrogen cell packing method based on the device. Via the stacking limiting mechanism, cell pole pieces can be stacked directly and compacted and packed by the pole piece compactionmechanism, the positions of the cell poles pieces are kept stable in the compaction process, a stable gap is kept among the pole pieces, the packing device integrates the stacking limiting mechanism with the pole piece compaction mechanism, labor force is reduced, and the production efficiency and yield rate of hydrogen fuel cell packing are improved.

Owner:SUZHOU JEE INTELLIGENT EQUIP CO LTD

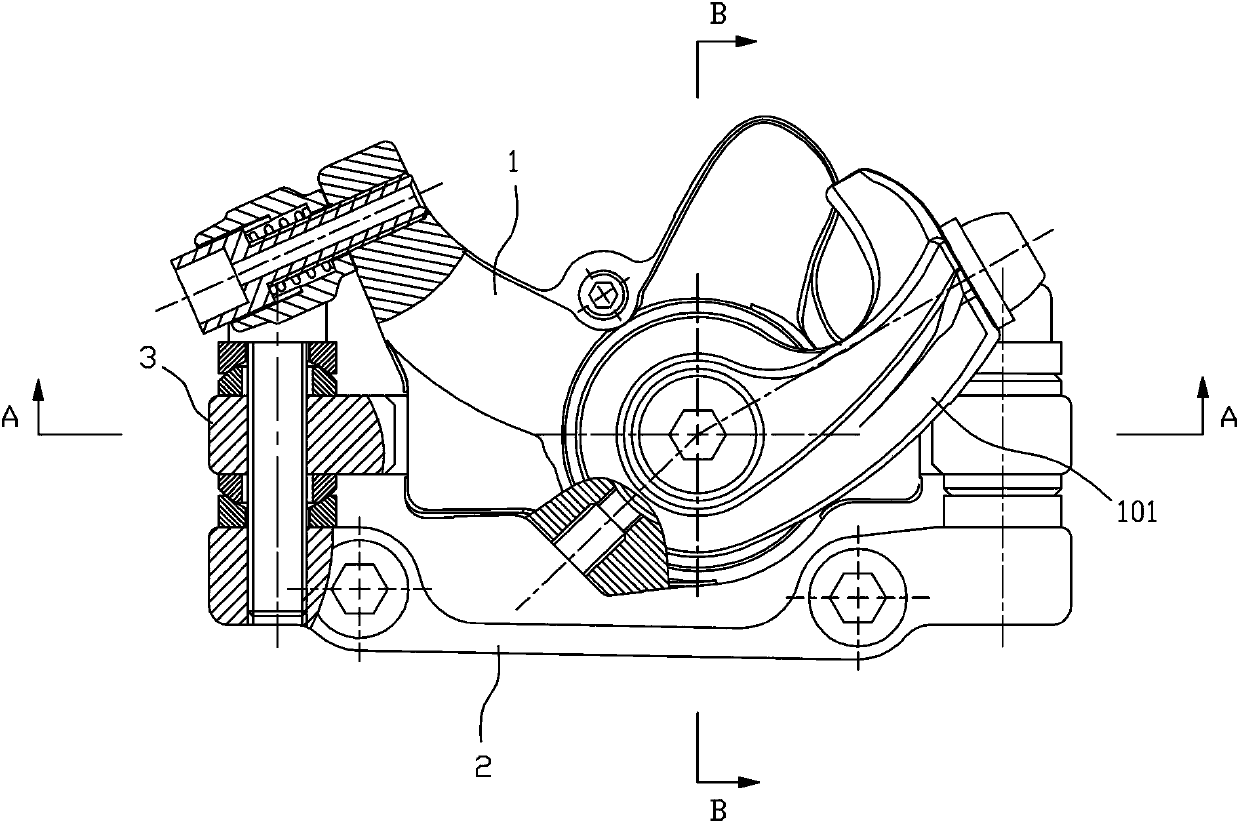

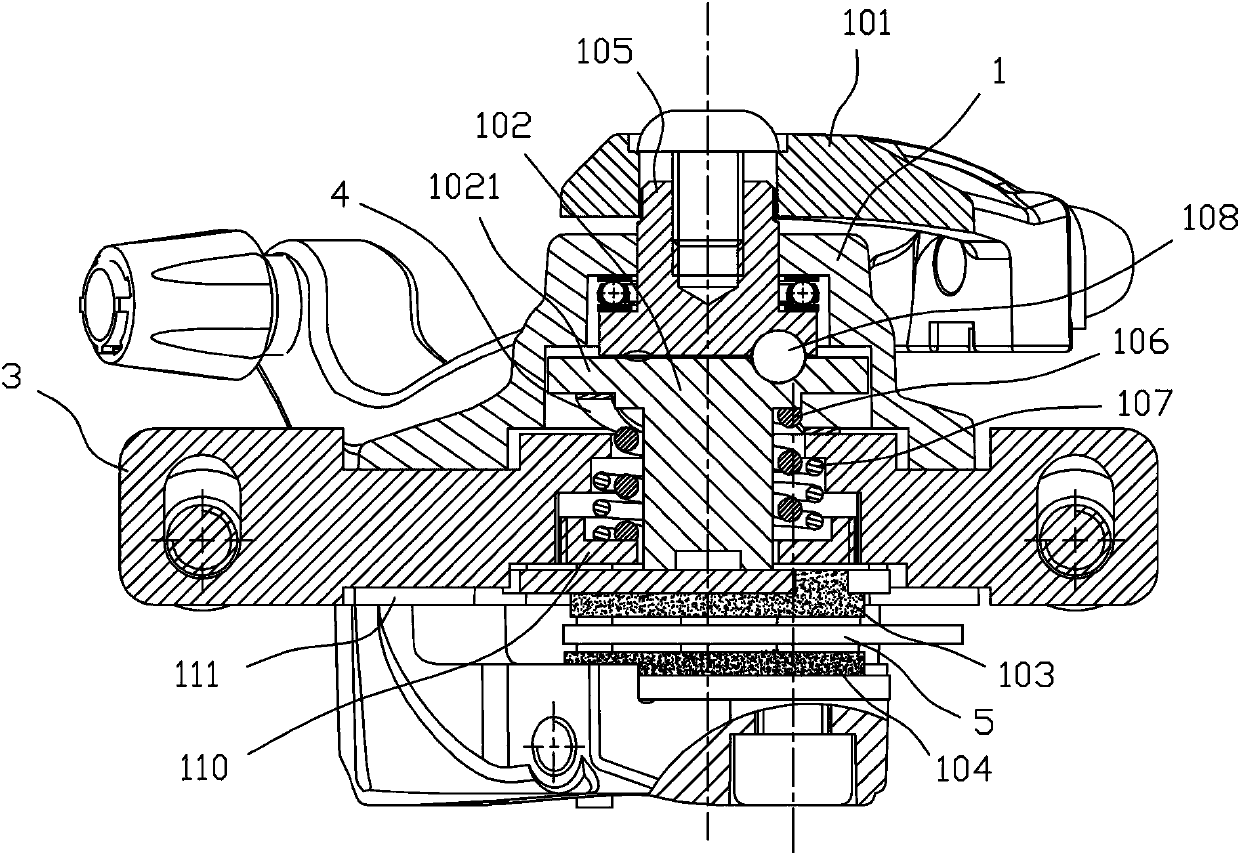

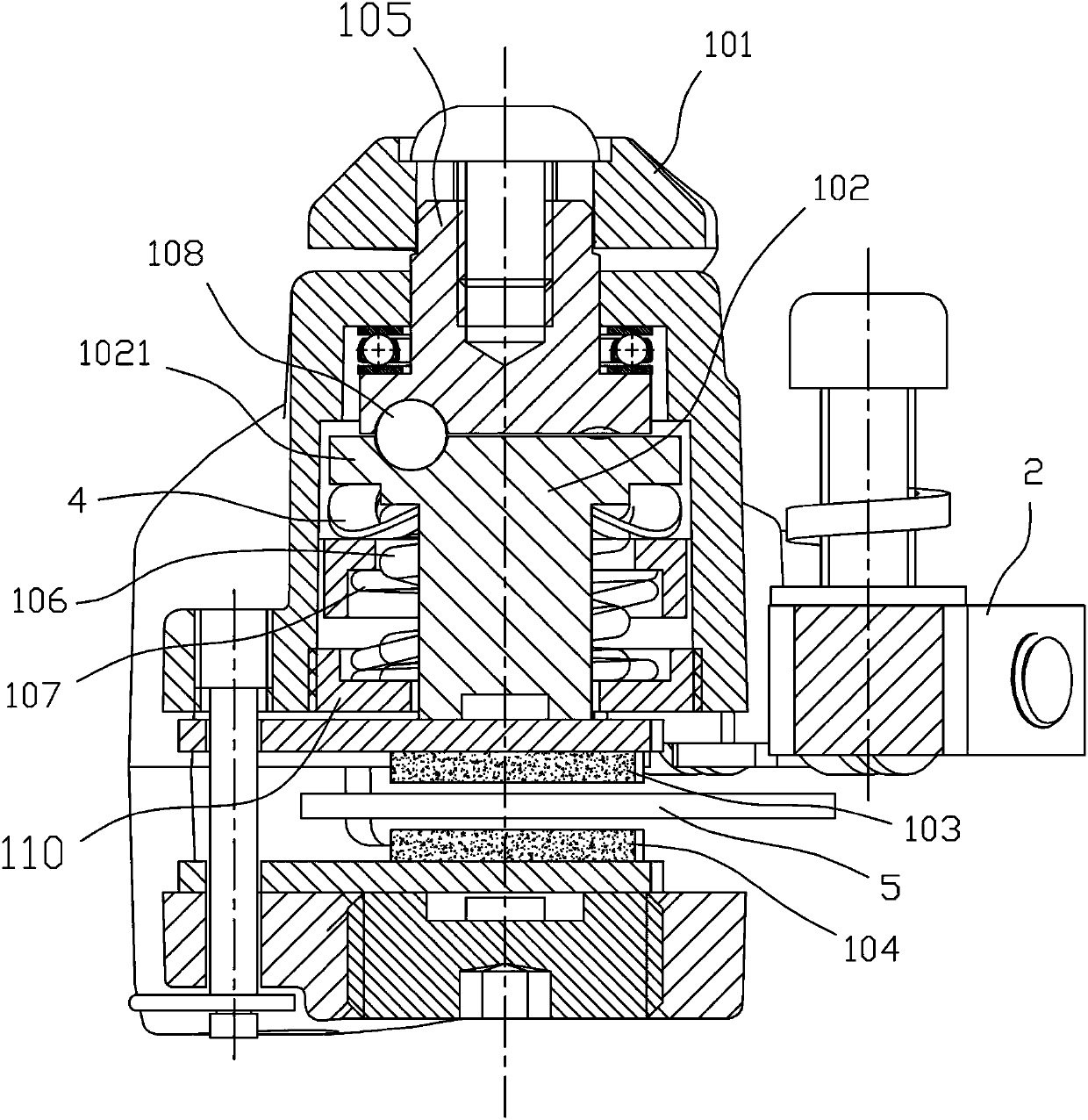

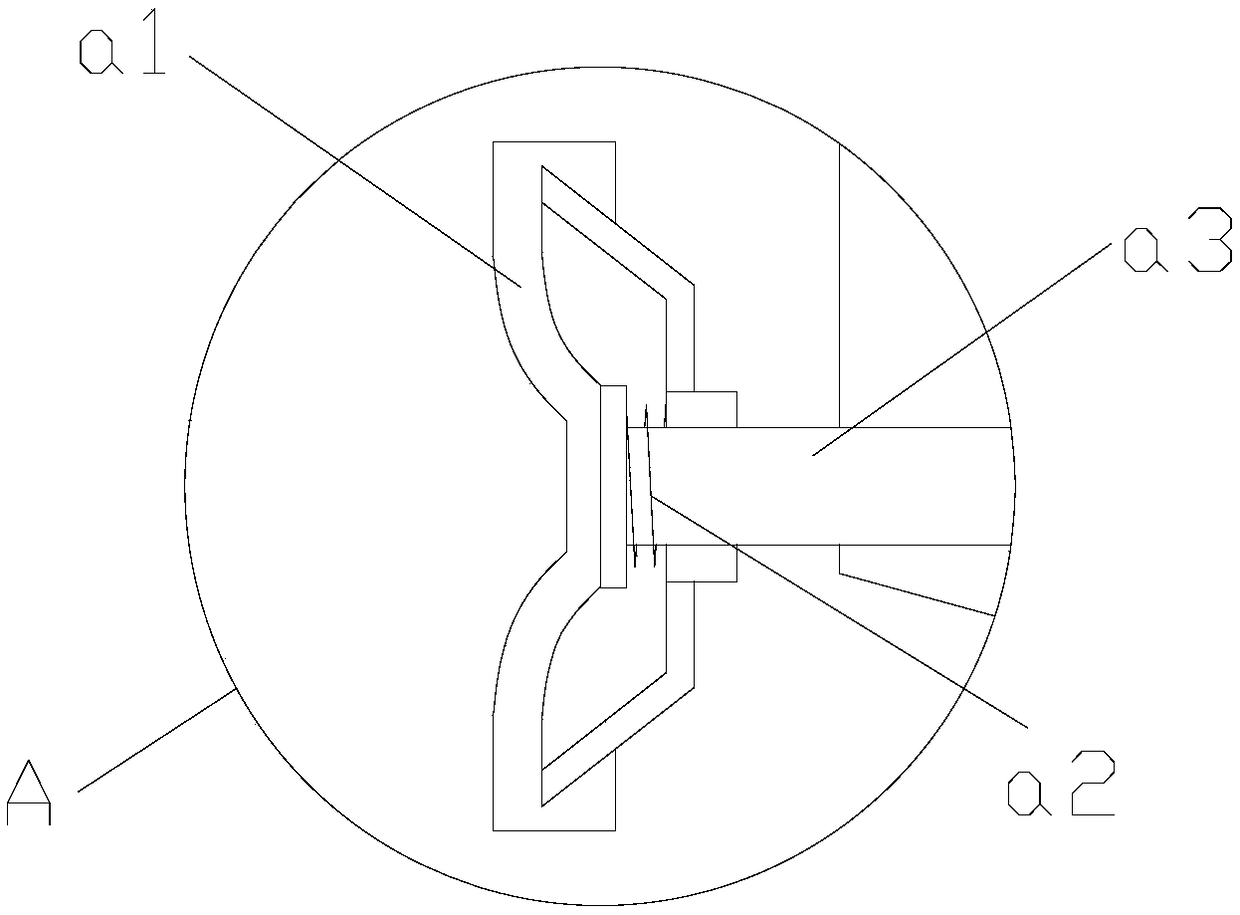

Mechanical double-acting disc brake

InactiveCN103738450AAvoid Disc DistortionWill not deformAxially engaging brakesCycle brakesDisc brakeMechanical engineering

The invention discloses a mechanical double-acting disc brake. The mechanical double-acting disc brake comprises a disc plate and a calliper, wherein the calliper comprises a shell, a support and a connection component; a drive arm and a drive plate are arranged on the shell; a drive component used for converting the rotary motion of the drive arm to the axial motion of the drive plate is connected between the drive arm and the drive plate; a first friction sheet is installed on the end surface of the drive plate; a second friction sheet is installed on the shell; the disc plate is arranged between the first friction sheet and the second friction sheet; the connection components comprises a connection seat which is movably connected to the shell and capable of axially moving relative to the drive plate, an annular bulge edge is arranged at one end close to the drive component, of the drive plate; and an elastic gasket is arranged between the connection base and the annular bulge edge. According to the mechanical double-acting disc brake disclosed by the invention, the two friction sheets can move towards the disc plate simultaneously, and the deformation of the disc plate is not required during braking, thus obstruction on the normal running of a vehicle due to the deformation of the disc plate can be avoided.

Owner:宁波久和车业有限公司

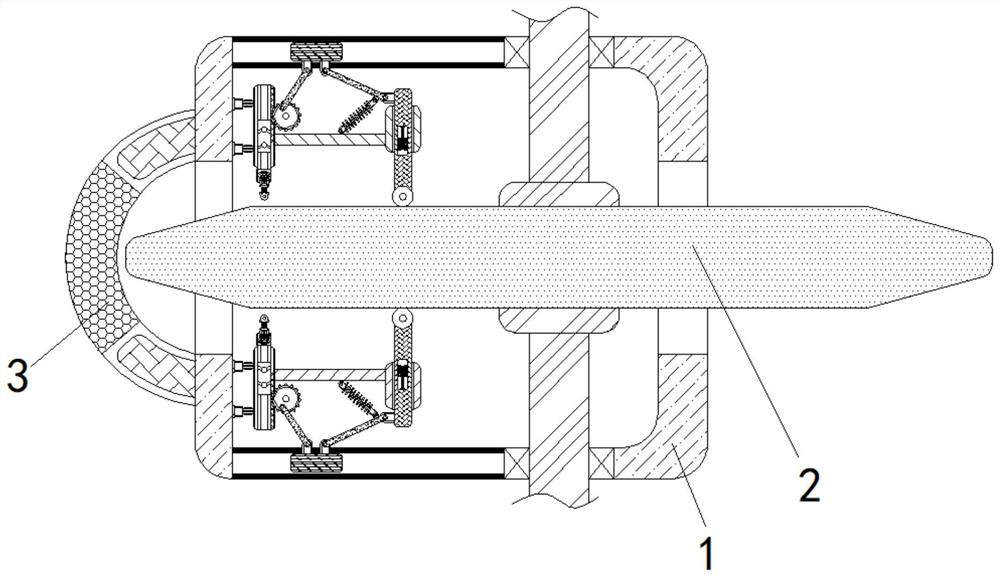

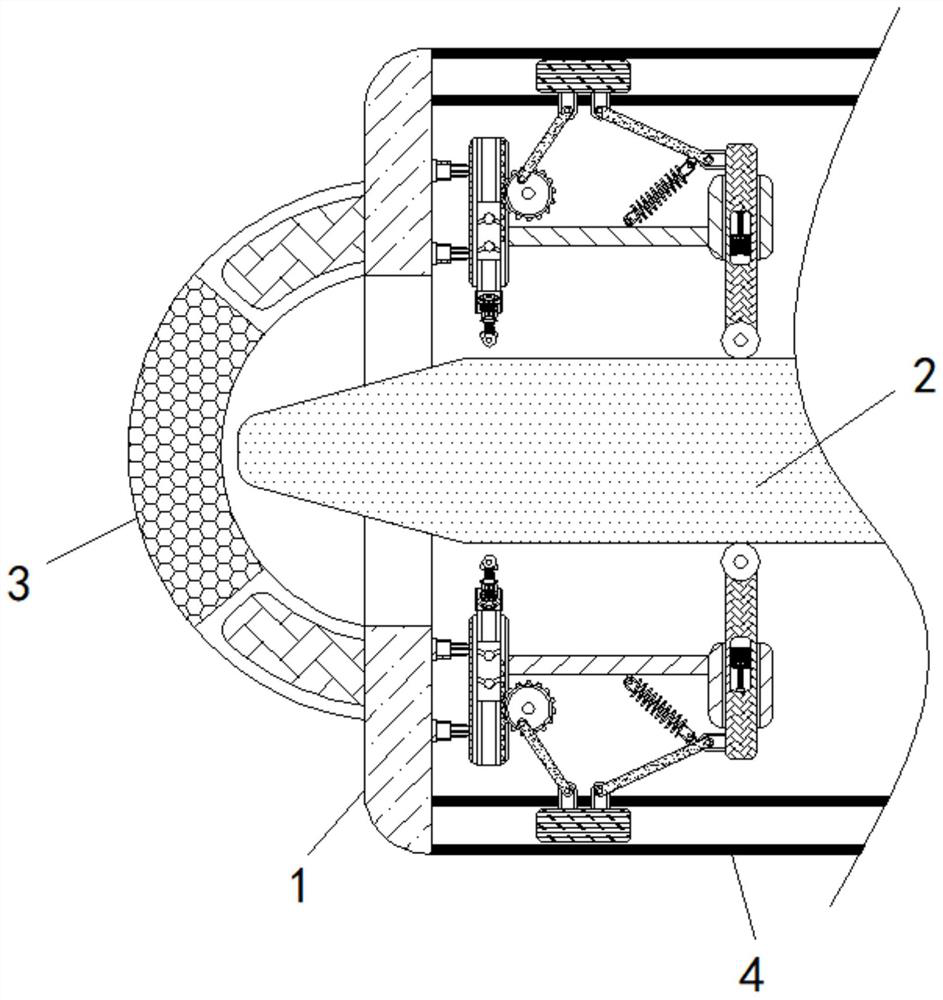

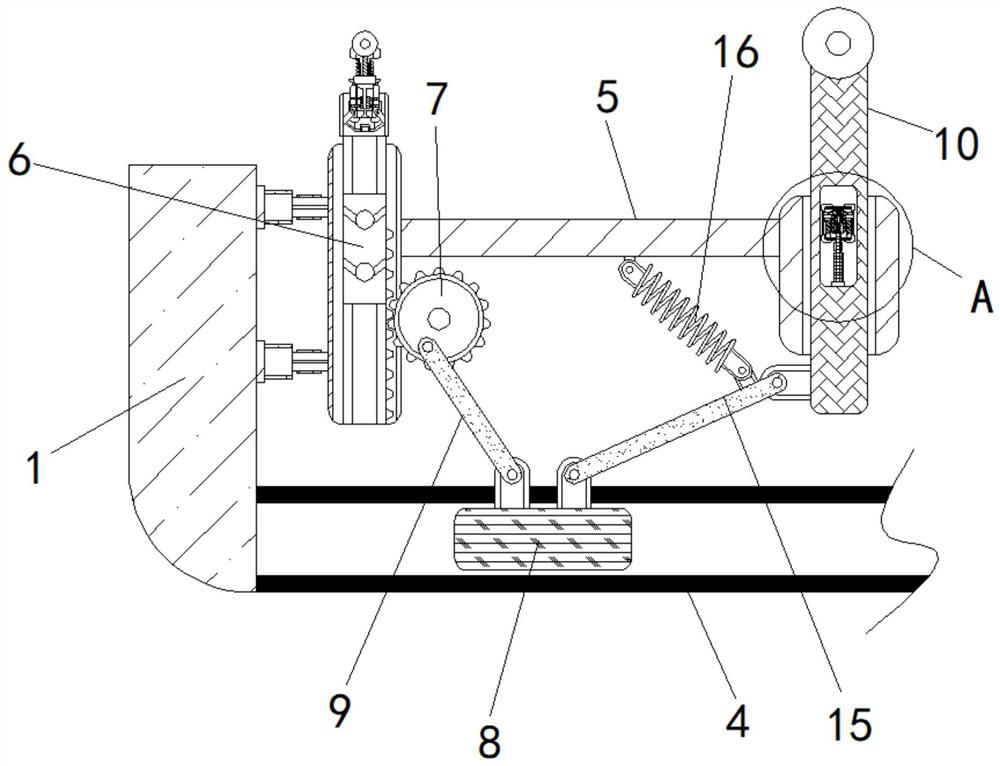

Waste cable cut-off type stripping device

ActiveCN111817215AEffective guidanceAvoid skewBasic electric elementsApparatus for removing/armouring cablesHydraulic cylinderEnvironmental engineering

The invention relates to the technical field of waste cable treatment and further discloses a waste cable cut-off type stripping device. The device comprises a bottom plate and a top plate, wherein asupporting column is fixedly installed between the top of the bottom plate and the bottom of the top plate, a lead cover is fixedly installed between the middles of the two supporting columns on the right side, guide wheels are fixedly mounted on an inner top wall and an inner bottom wall of the lead cover, a cutting base is fixedly installed at the top of the bottom plate, an L-shaped frame is fixed to an upper end of a left side wall of the cutting base, a sleeve is fixedly installed at a top end of the L-shaped frame, a hydraulic cylinder is fixedly installed at the bottom of the top plate,a fixing base is fixedly installed at an output end of the hydraulic cylinder, and a cutter is fixedly installed at the bottom of the fixing base. The waste cable cut-off type stripping device solvesproblems that an existing waste cable stripping device is simple in structure and easy to break during stripping, and the other whole cable is inconvenient to strip and collect.

Owner:ANHUI ZHONGRUN CABLE GRP SHARES CO LTD

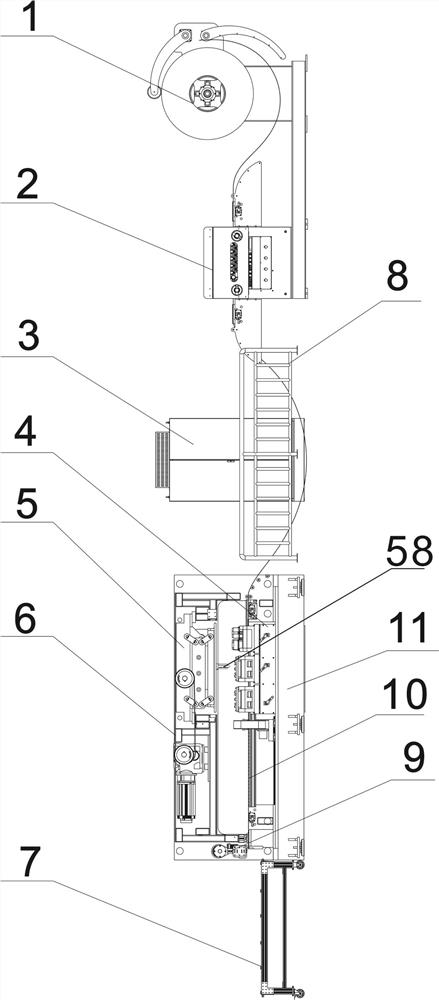

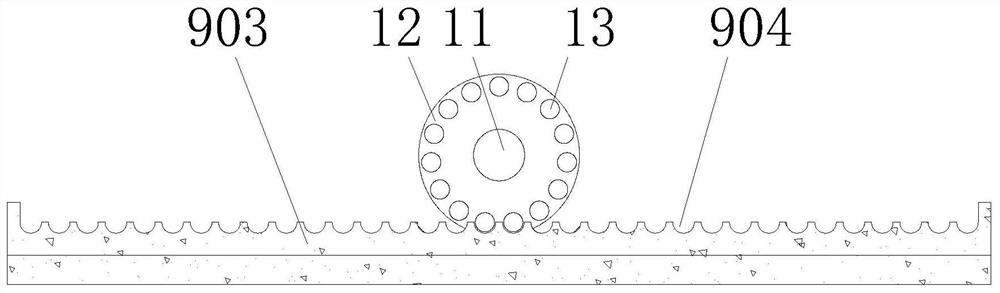

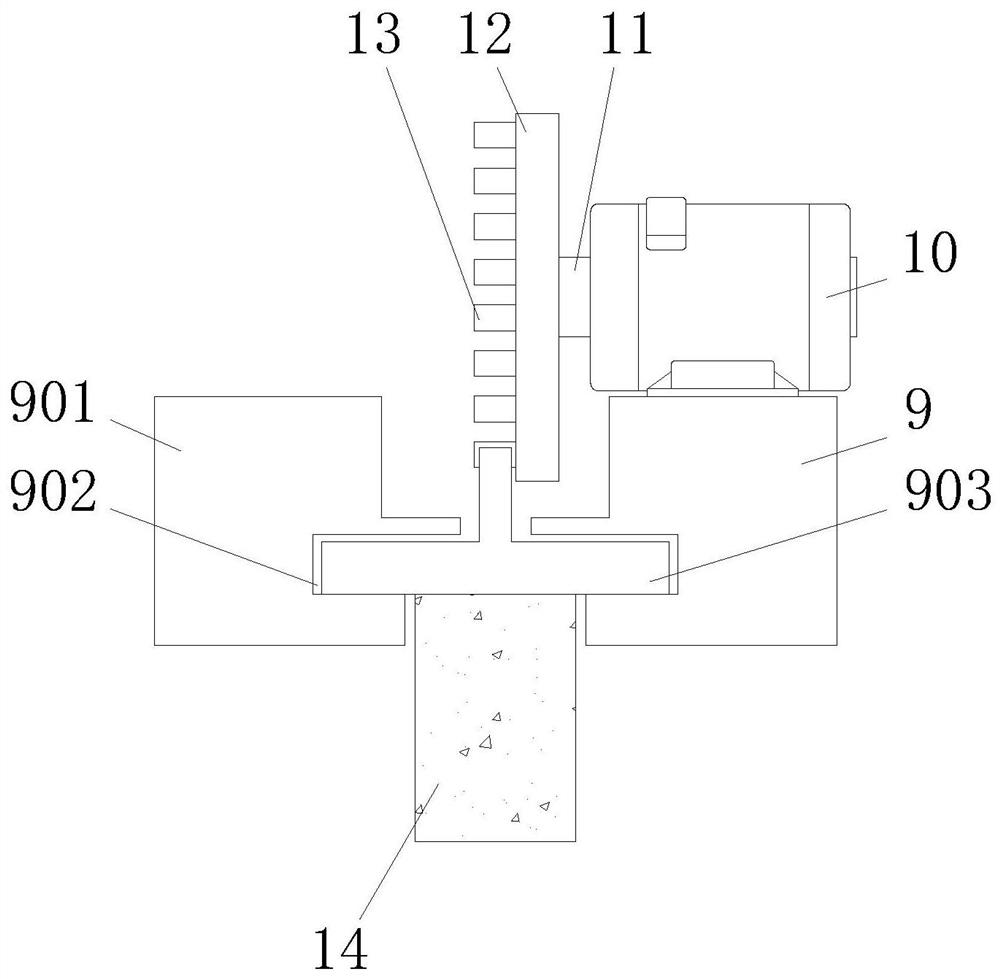

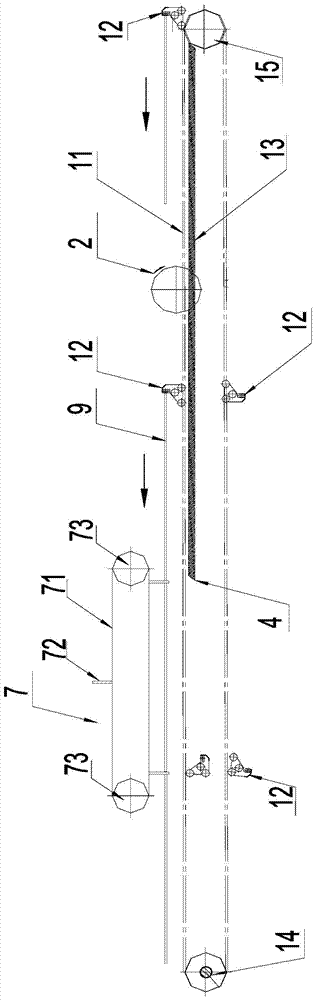

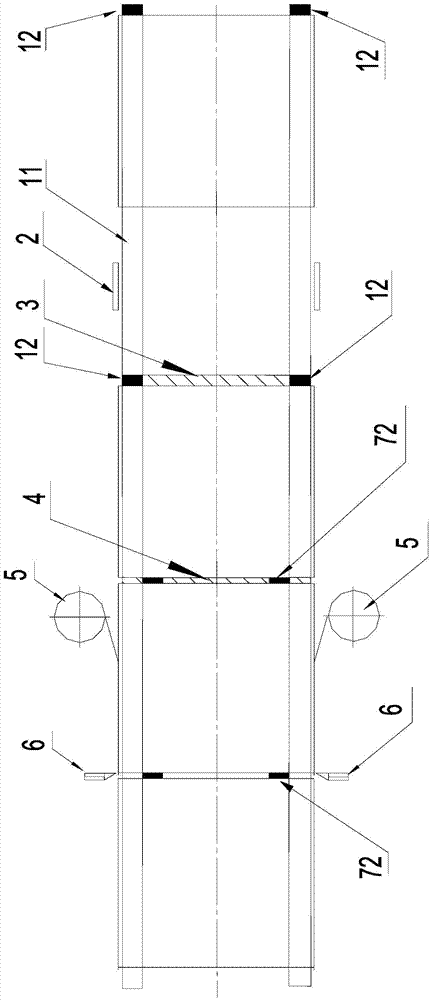

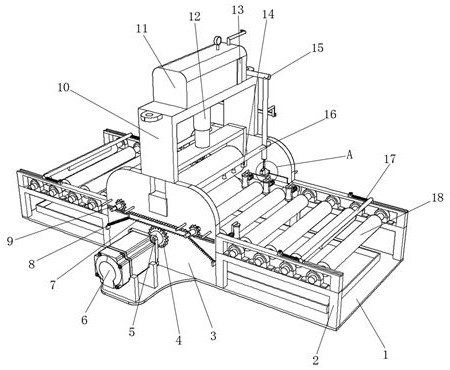

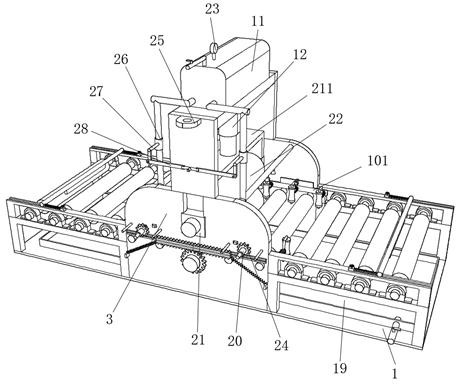

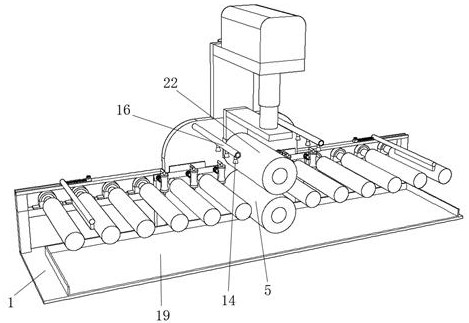

Full-automatic metal plate punching and shearing production line and using method thereof

The invention relates to a full-automatic metal plate punching and shearing production line and a using method thereof. The full-automatic metal plate punching and shearing production line comprises adischarging frame, a leveling machine, a punching machine and a material trolley; the discharging frame is arranged on one side of the leveling machine, the punching machine is arranged on the otherside of the leveling machine, and corresponding guardrails are arranged on the two sides between the punching machine and the leveling machine; the material trolley is arranged outside the dischargingend of the punching machine; the punching machine comprises a machine body, a rack, a gantry material pulling device, a workbench, a striking device and a plate shearing device, wherein the rack is arranged on the upper portion and the two sides of the machine body; the workbench is arranged on the side, close to the guardrails, of the upper portion of the gantry material pulling device; and thestriking device is correspondingly arranged on the upper portion of the workbench, the striking device is fixed to the rack at the upper portion of the machine body, and a plate shearing device is arranged on the inner side of the outer end part of the rack and close to the material trolley. According to the full-automatic metal plate punching and shearing production line and the using method thereof, automatic machining is achieved, the production efficiency is effectively improved, the cost is reduced, manpower is reduced, the consistency of machined metal plates is good, and the yield is effectively increased.

Owner:LUOYANG YOUNENG AUTOMATION EQUIP CO LTD

Welding device for electrical engineering

PendingCN113414526AFast pushAvoid skewed situationsWelding/cutting auxillary devicesAuxillary welding devicesElectrical engineering technologyEngineering

The invention relates to the technical field of electrical engineering, and discloses a welding device for electrical engineering. The welding device comprises a supporting plate. Supporting rods are fixedly connected to the bottom of the supporting plate, frames are fixedly connected to the bottom of the supporting plate, and a balancing weight is fixedly connected to the tops of the frames. A silicone rubber pad is arranged at the top of the supporting plate, clamping mechanisms are fixedly installed at the top of the supporting plate, and portal frames are fixedly connected to the top of the supporting plate. Electric push rods are fixedly connected to the inner top walls of the portal frames, a supporting mechanism is fixedly installed at the output ends of the electric push rods, and the supporting mechanism comprises a cross beam. Through the arrangement of the portal frames, the electric push rods and limiting mechanisms, the cross beam can be pushed or pulled up more quickly. Meanwhile, through the arrangement of the two portal frames, the electric push rods and the limiting mechanisms, the situation that the cross beam inclines due to the self-weight of the cross beam during welding work can be avoided, and use is safe and reliable.

Owner:姚宇龙

Edge cutting, edge banding and cutting-off integrated equipment and operating method thereof

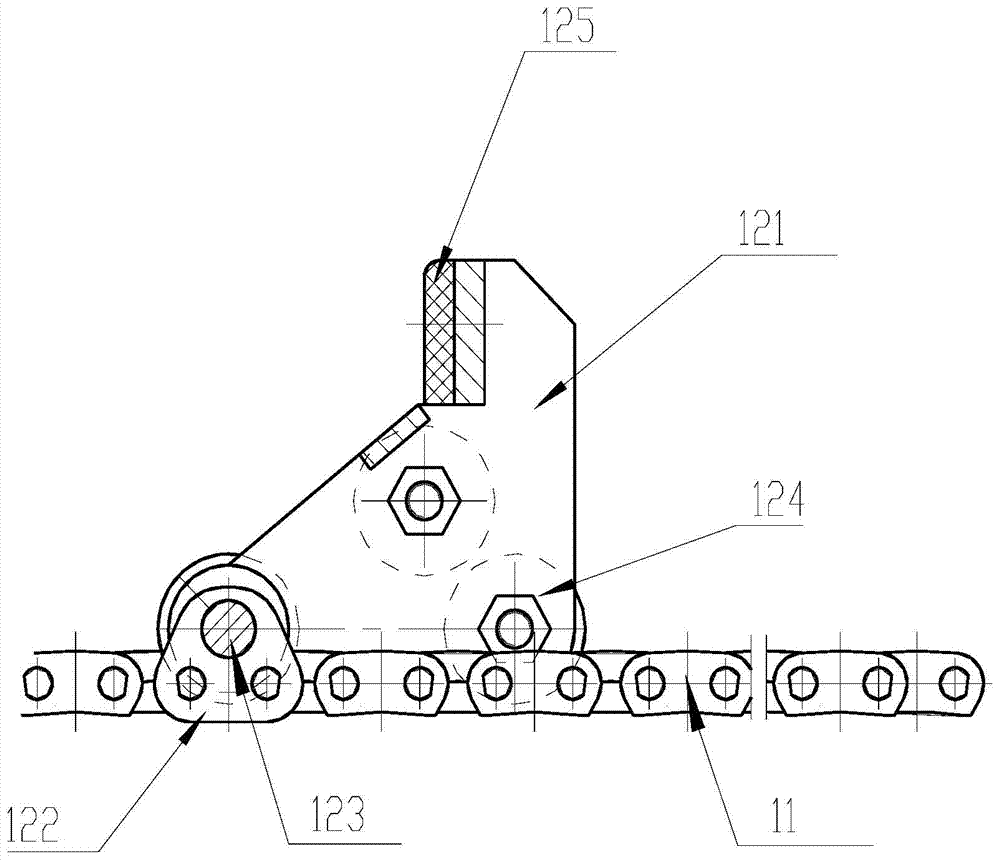

ActiveCN104723445AReduce corner breakageImprove appearance qualityConveyorsAuxillary shaping apparatusEngineeringGypsum

The invention provides edge cutting, edge banding and cutting-off integrated equipment which comprises a chain transmission device, a belt spacing device and a controller. The chain transmission device is provided with an edge cutting device, a stop position, a descending position, an edge banding device and a band cutoff device sequentially along the transmission direction. The chain transmission device comprises a transmission chain, a plurality of board pushing trolleys are arranged at equal intervals along the transmission chain, and an operation guide rail matched with the trolleys is arranged below the transmission chain. A belt conveyor comprises a belt and partition plates arranged at equal intervals on the belt. The controller is used for controlling the cutoff device to cut off a band between each two adjacent boards after the trolleys move to the descending position and descend. Therefore, edge cutting, edge banding and cutoff of gypsum boards can be carried out on the equipment, and the condition of deflection of the boards due to inharmonious operations of the transmission chain and the belt conveyor in a conveying process is avoided.

Owner:北新建材(苏州)有限公司

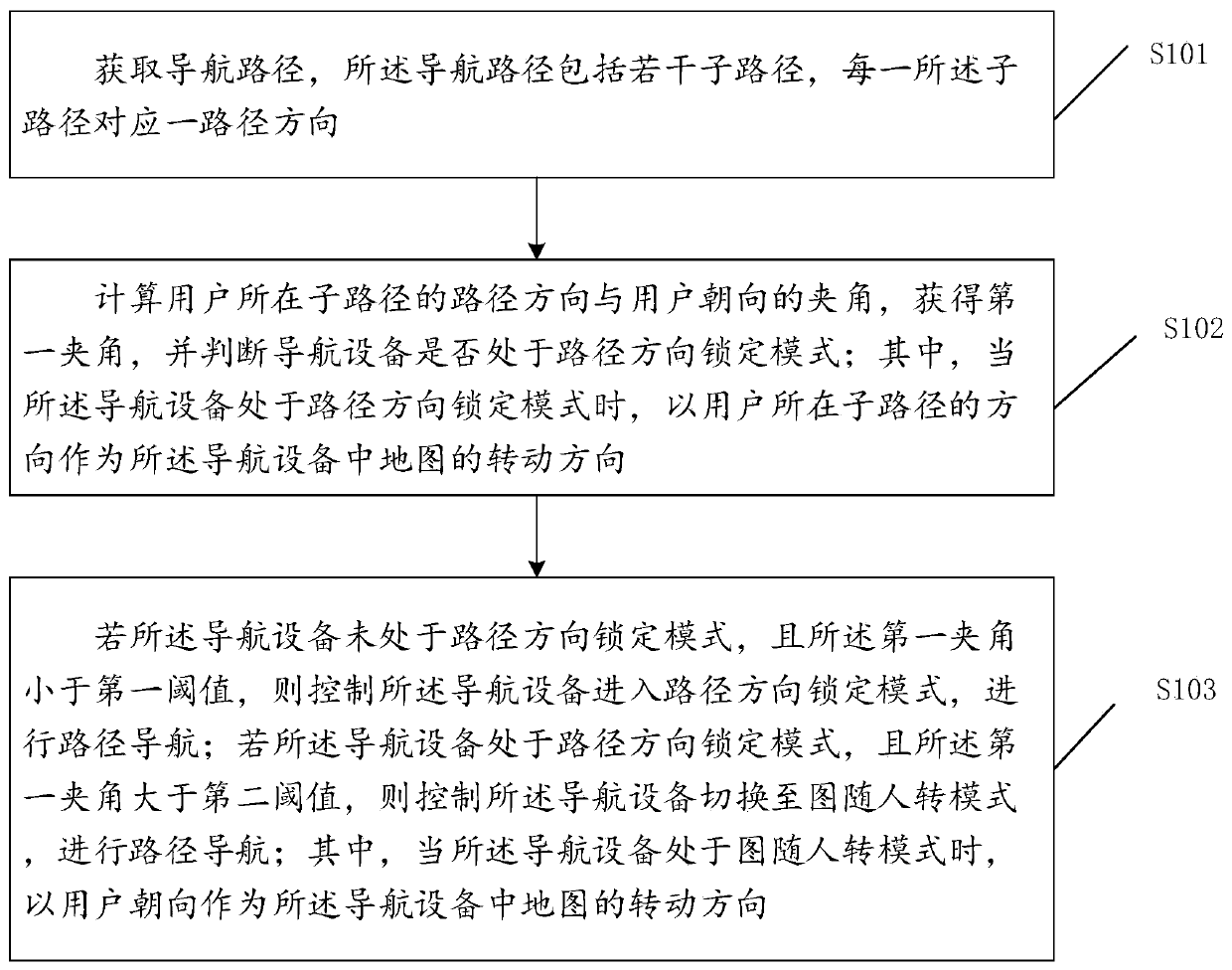

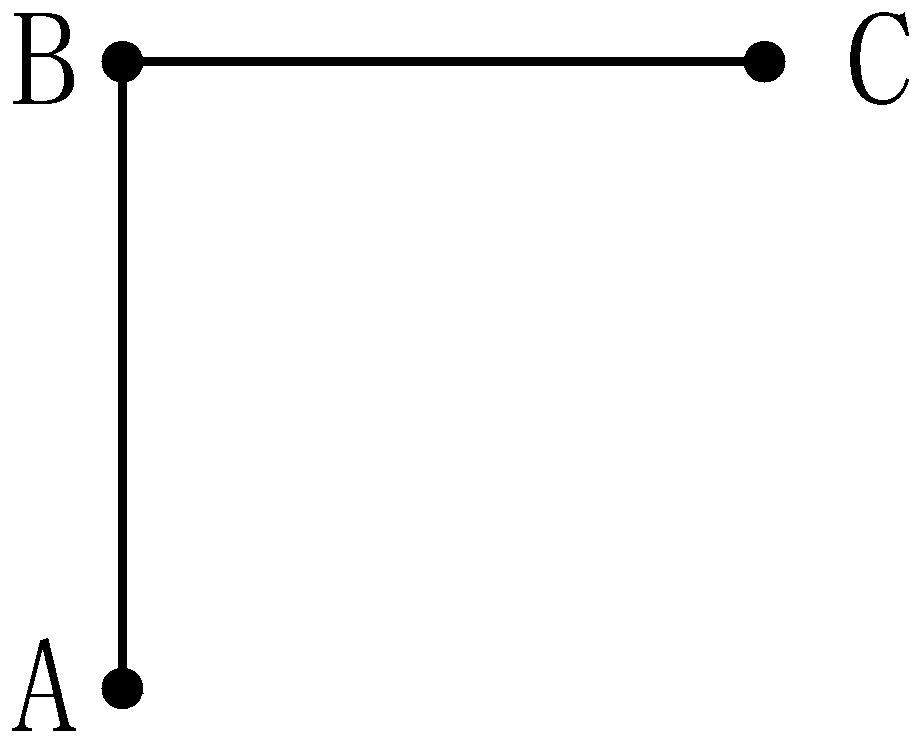

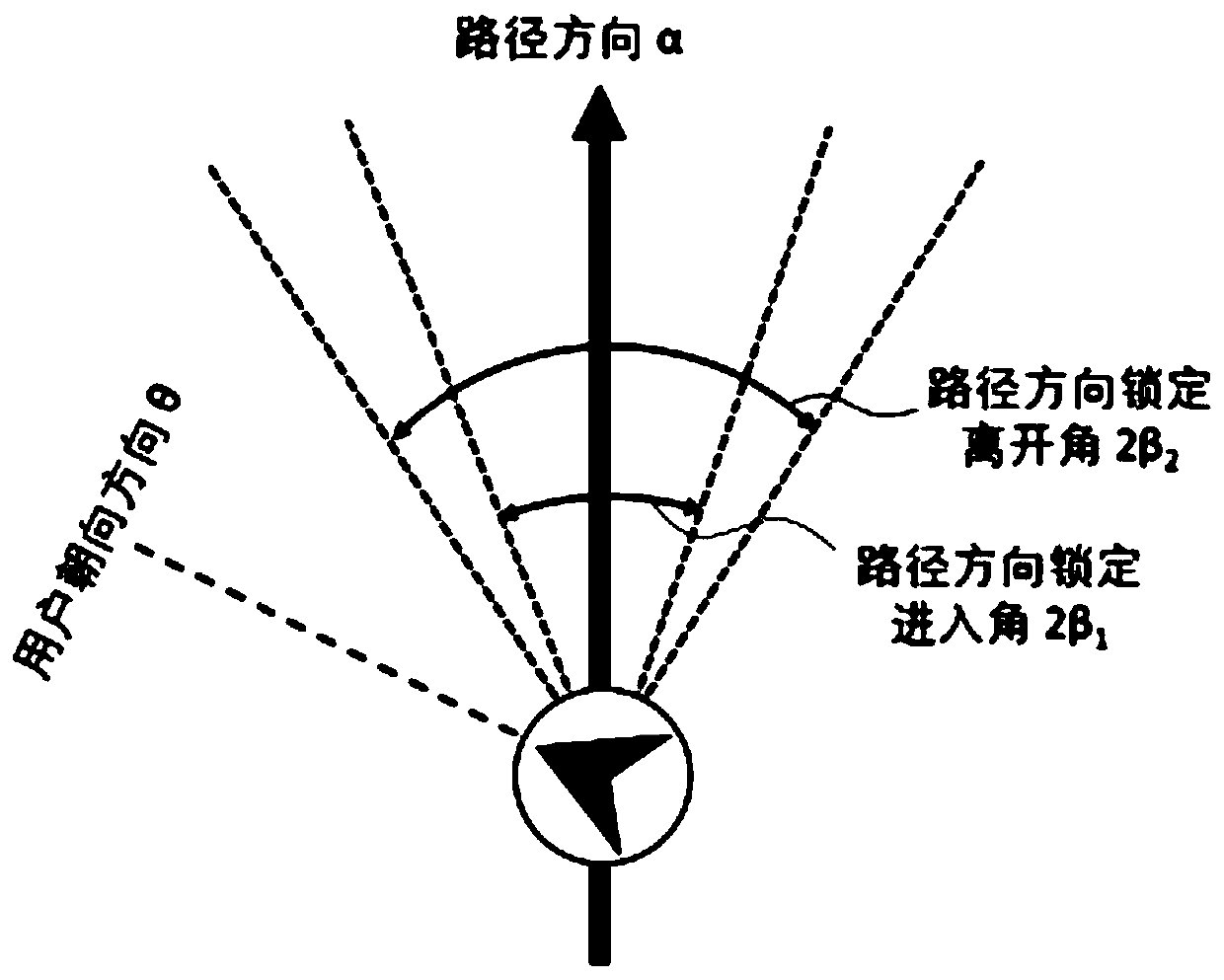

Path navigation method and device based on path direction locking

ActiveCN111289004AAvoid skewed situationsInstruments for road network navigationSimulationNavigation path

The invention discloses a path navigation method and a path navigation device based on path direction locking. The path navigation method comprises the steps of: acquiring a navigation path which comprises a plurality of sub-paths, and enabling each sub-path to correspond to one path direction; calculating an included angle between the path direction of the sub-path where a user is located and theorientation of the user to obtain a first included angle, and judging whether navigation equipment is in a path direction locking mode; if the navigation equipment is not in the path direction locking mode and the first included angle is smaller than a first threshold value, controlling the navigation equipment to enter the path direction locking mode to perform path navigation; and if the navigation equipment is in the path direction locking mode and the first included angle is greater than a second threshold value, controlling the navigation equipment to switch to a mode of rotating a map along with people, and carrying out path navigation. By implementing the path navigation method and the path navigation device of the invention, the problem of deviation between a user advancing path displayed on the map and an actual advancing path of the user due to the error of the compass sensor in the navigation equipment in the existing navigation technology can be solved.

Owner:众虎物联网(广州)有限公司

Optical fiber laser lamp pattern painting device

The invention provides an optical fiber laser lamp pattern painting device. The optical fiber laser lamp pattern painting device comprises a shell, a painting mechanism and an intelligent processing system. The painting mechanism comprises a movable painting base and two movable plates. A sliding rod is fixedly arranged between the two movable plates. Sliding holes are formed in the movable painting base. The movable painting base sleeves the sliding rod through the sliding holes. A plurality of accommodating grooves are formed in the top of the movable painting base. Pressure paint cans are arranged in the accommodating grooves. Paint spray nozzles are arranged at the bottoms of the pressure paint cans. A plurality of convex through holes in one-to-one correspondence with the accommodating grooves are formed in the bottom of the movable painting base and communicate with the accommodating grooves. The inner side walls of the thicker ends of the convex through holes are provided with electrode plates I and electrode plates II. Drying seats are arranged on the two sides of the movable painting base respectively. The optical fiber laser lamp pattern painting device is reasonable in design, convenient to use, high in accuracy and capable of realizing high-efficiency painting.

Owner:苏州高新区建金建智能科技有限公司

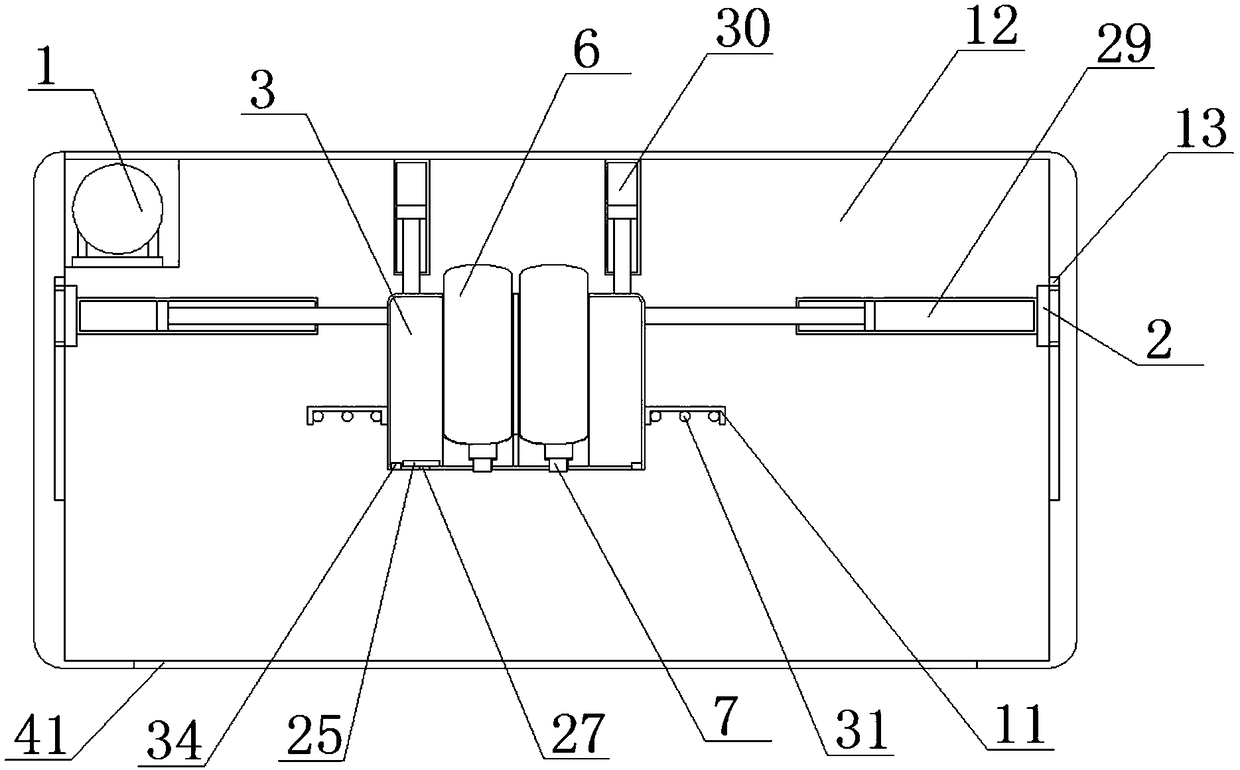

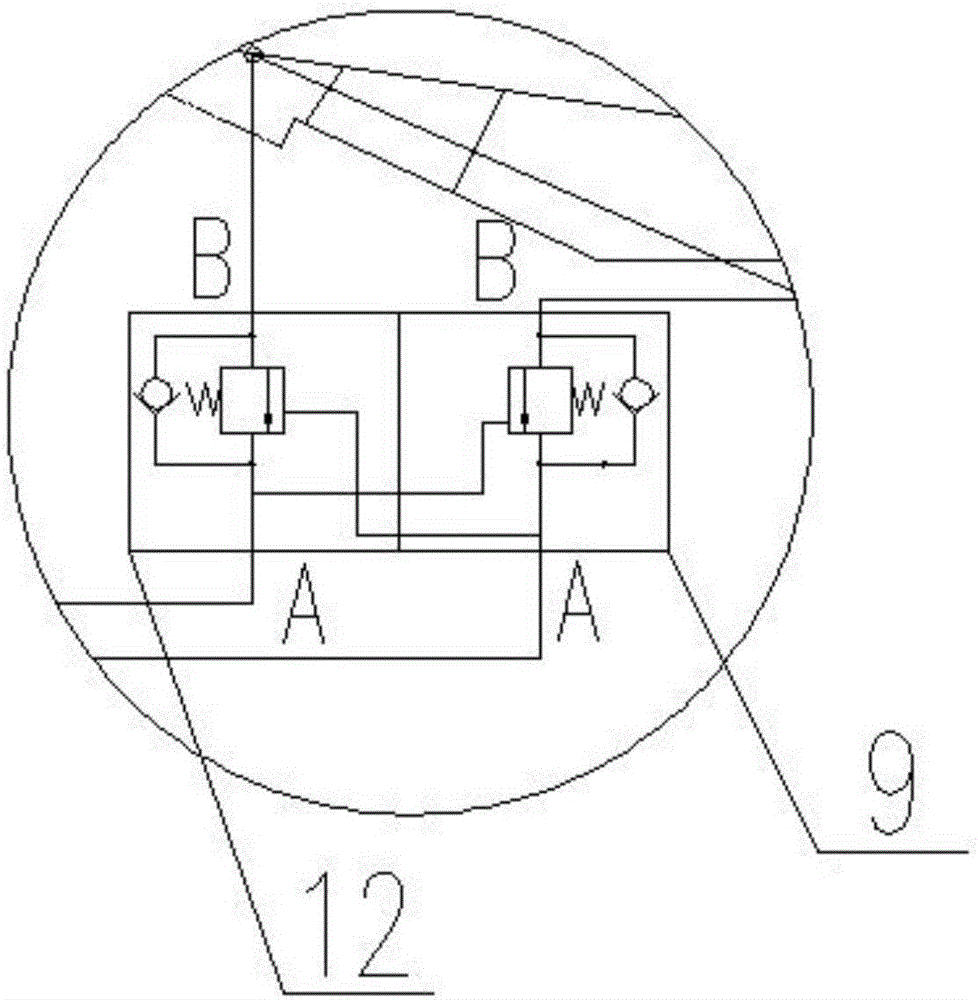

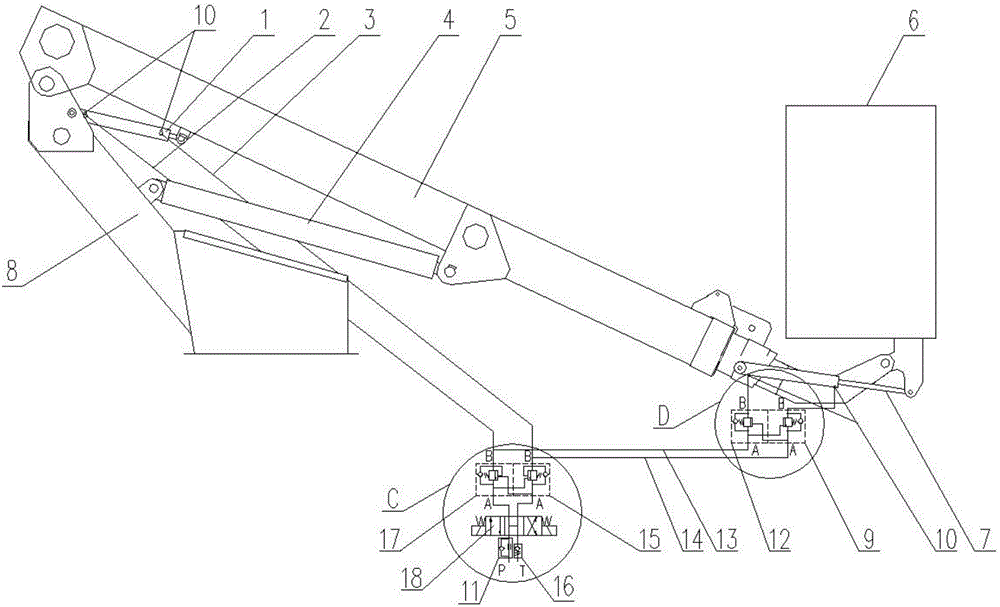

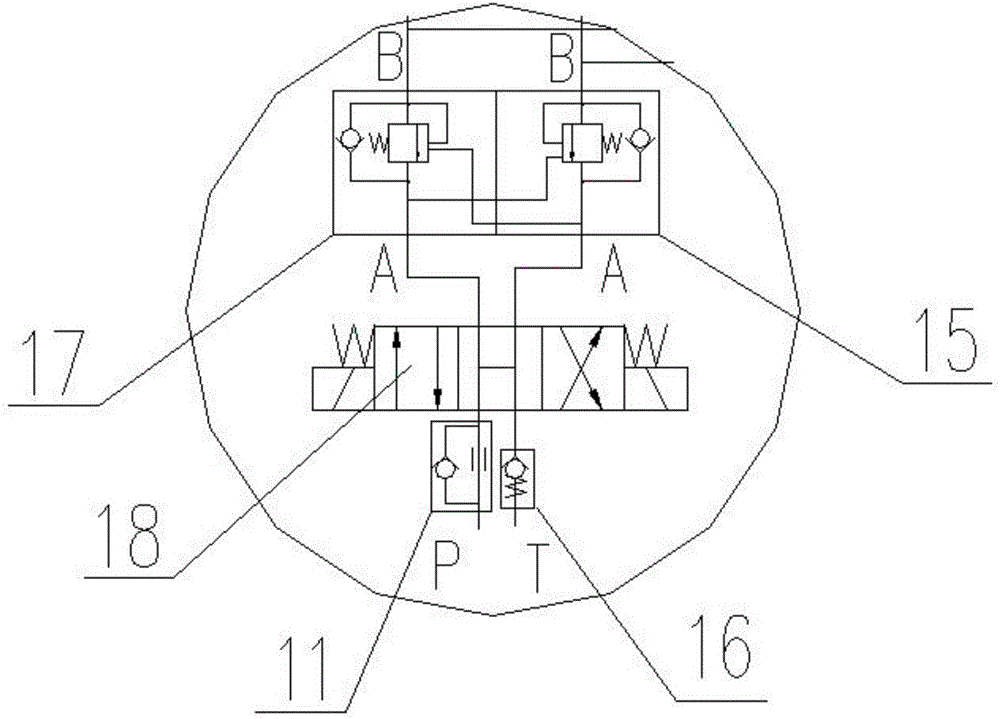

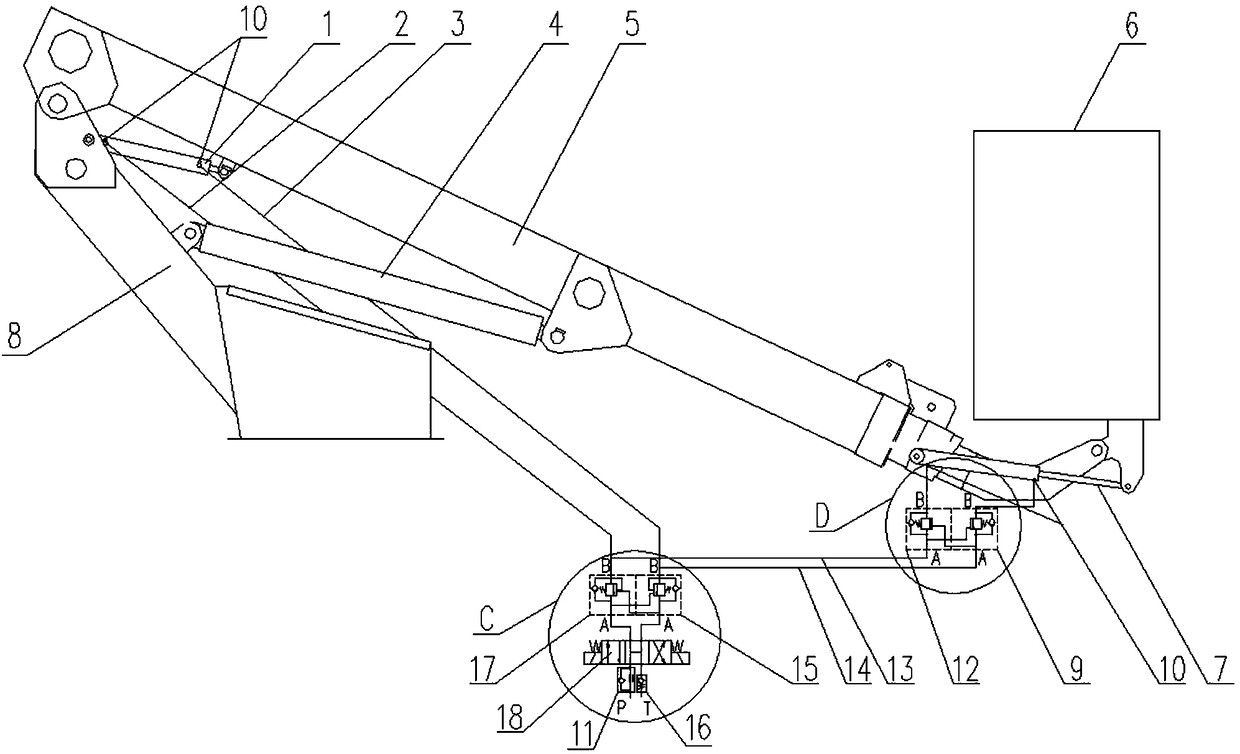

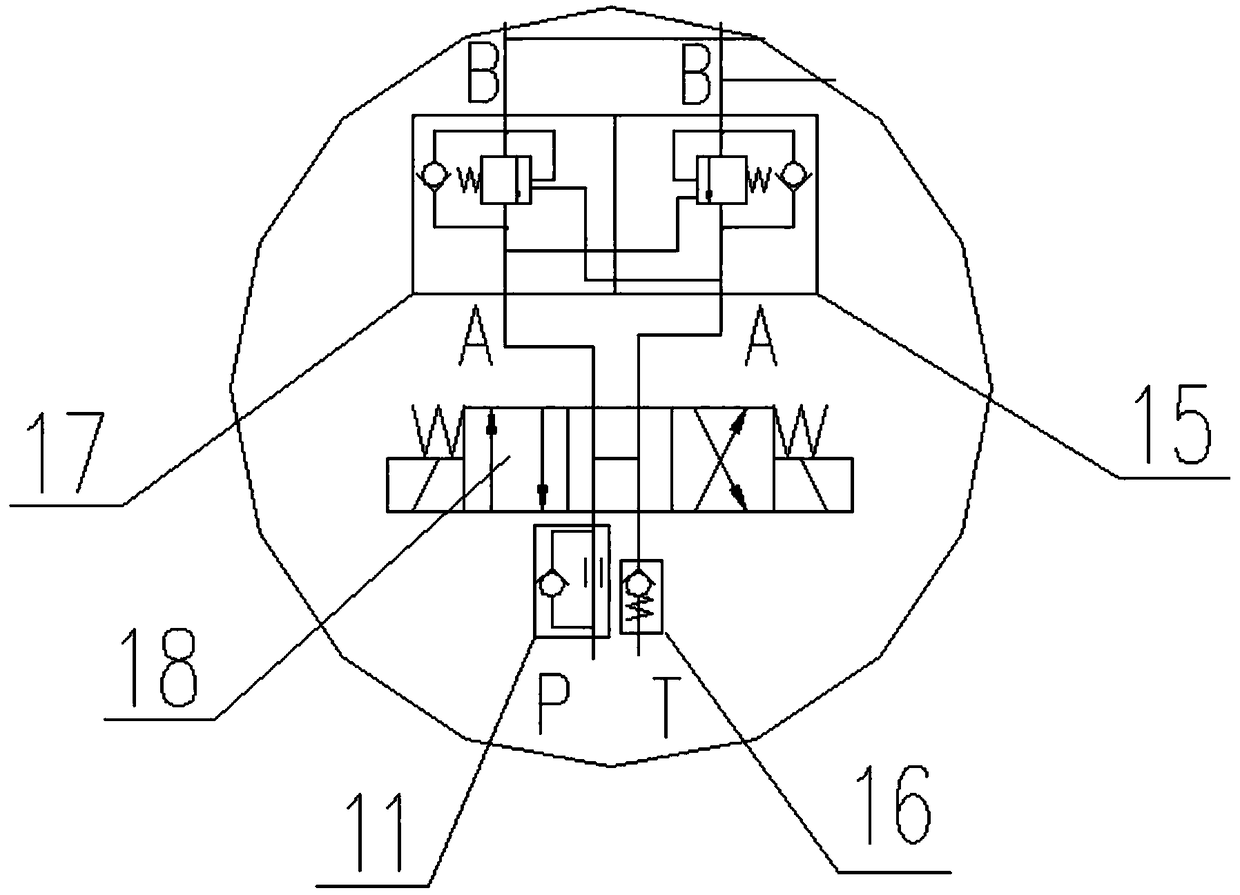

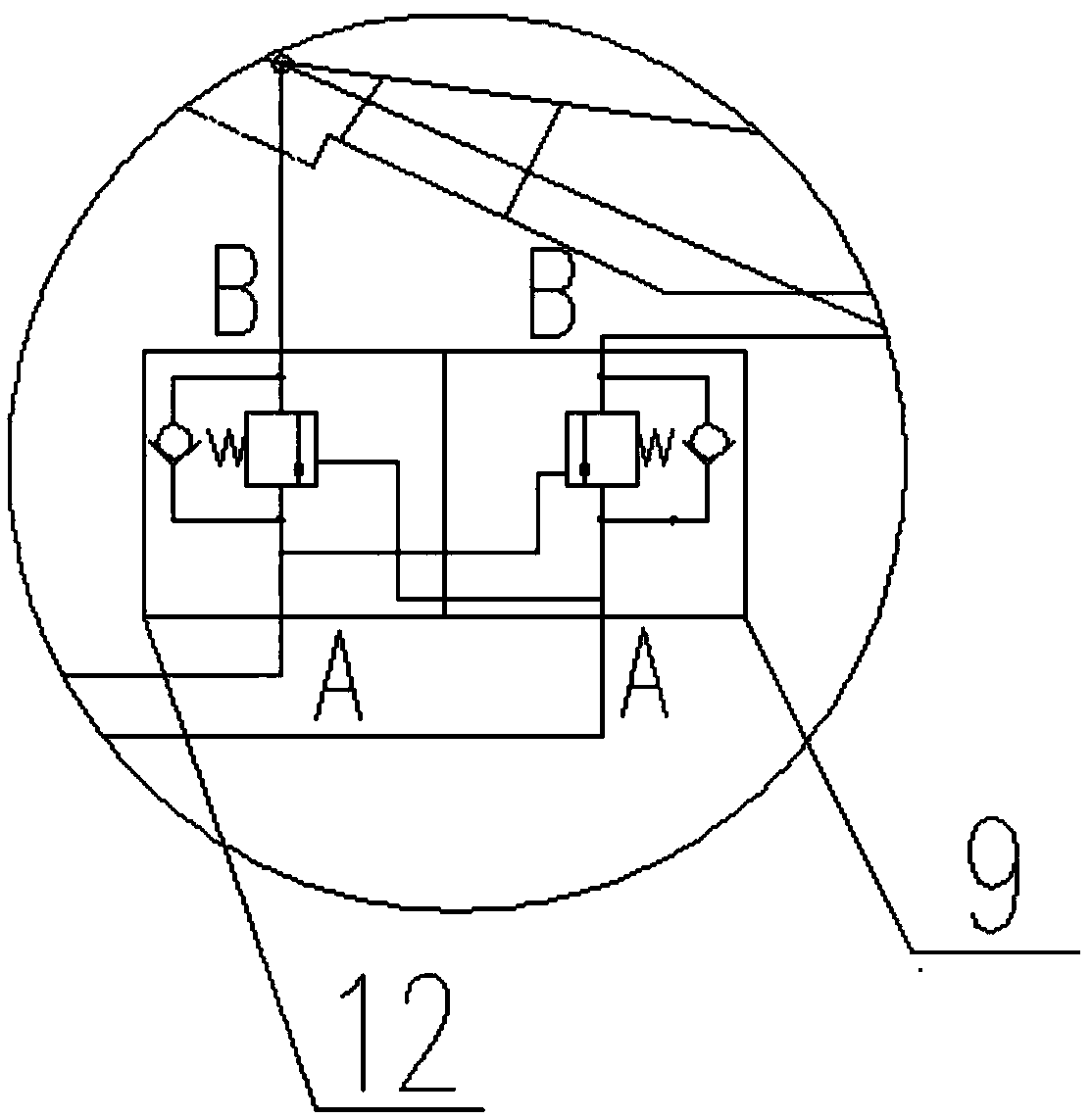

Hydraulic pressure leveling system of high-altitude operation car

ActiveCN106678096AImprove leveling efficiencyImprove securityServomotor componentsServomotorsMagnetic exchangeEngineering

Disclosed is a hydraulic pressure leveling system of a high-altitude operation car. A magnetic exchange valve is connected with a first balance valve and a second balance valve. The first balance valve and the second balance valve communicate with two cavities of an active leveling oil cylinder correspondingly. The first balance valve and the second balance valve communicate with two cavities of a slave leveling oil cylinder correspondingly. Vent valves are arranged in the two cavities of the active leveling oil cylinder and the two cavities of the slave leveling oil cylinder. A back pressure valve is arranged in the opening T of the magnetic exchange valve, and a flow controlling valve is arranged in the opening P of the magnetic exchange valve. The reverse control opening of the first balance valve communicates with the opening B of the first balance valve, the forward control opening of the first balance valve communicates with the opening A of the second balance valve, the reverse control opening of the second balance valve communicates with the opening B of the second balance valve, the forward control opening of the second balance valve communicates with the opening A of the first balance valve, the forward control opening of a third balance valve communicates with the opening A of a fourth balance valve, and the forward control opening of the fourth balance valve communicates with the opening A of the third balance valve. Both the forward opening pressure of the third balance valve and the forward opening pressure of the fourth balance valve are smaller than or equal to 2 Mpa, and both the reverse control oil opening of the third balance valve and the reverser control opening of the fourth balance valve are unloaded. According to the hydraulic pressure leveling system, the problems of lag and deflection in operating platform leveling can be solved.

Owner:XUZHOU HANDLER SPECIAL VEHICLE

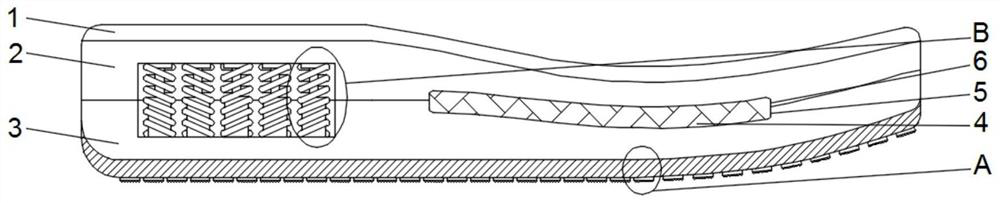

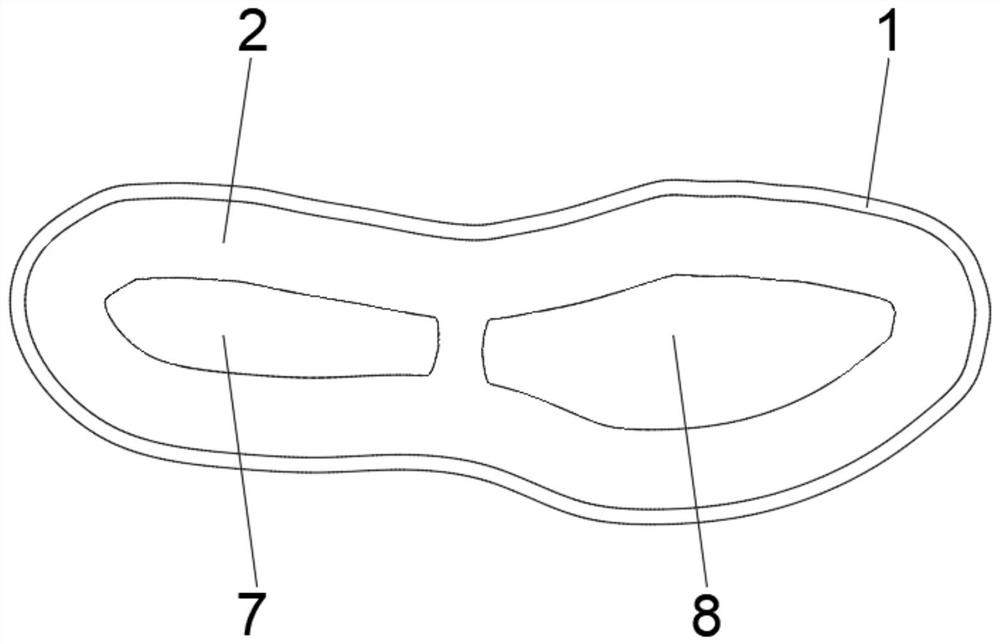

Anti-skid wear-resistant reinforced sole

PendingCN113116020AReduce vibration intensityAvoid damageSolesInsolesEngineeringStructural engineering

Owner:晋江闽荣橡塑有限公司

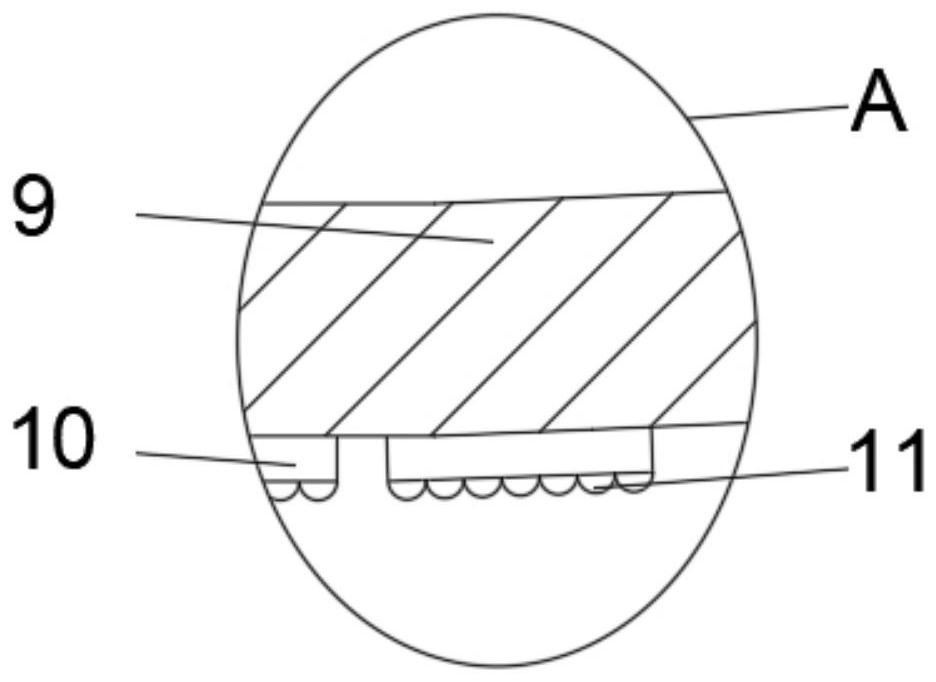

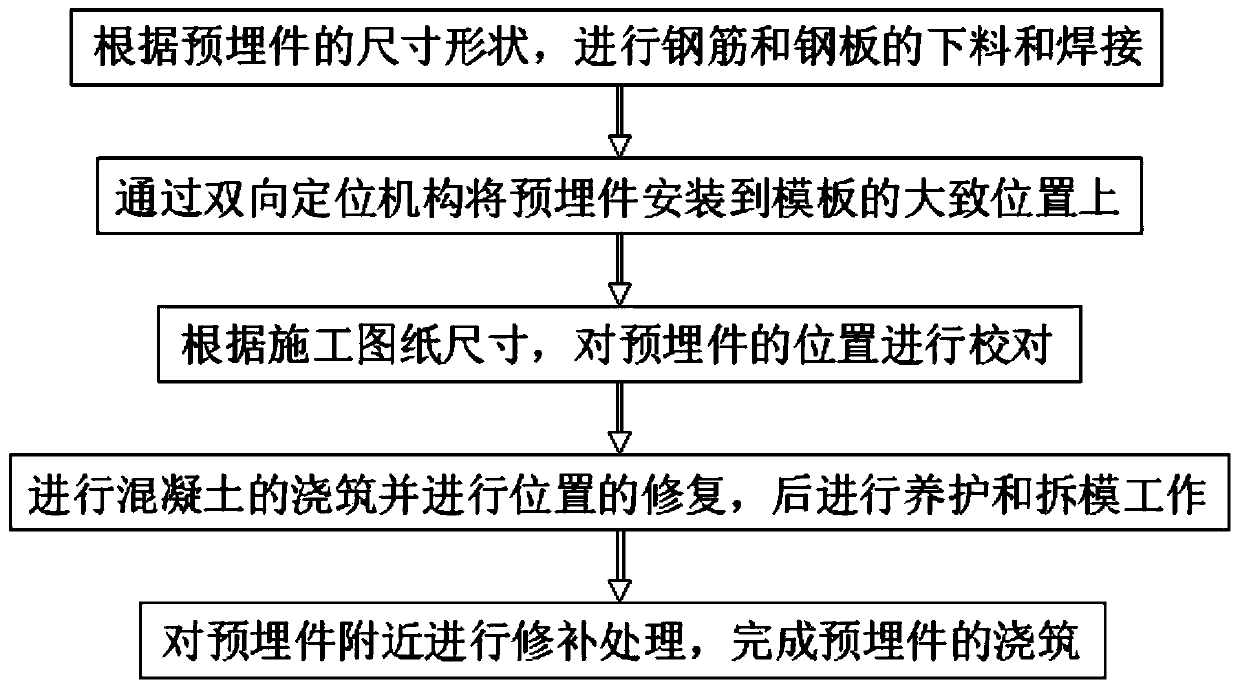

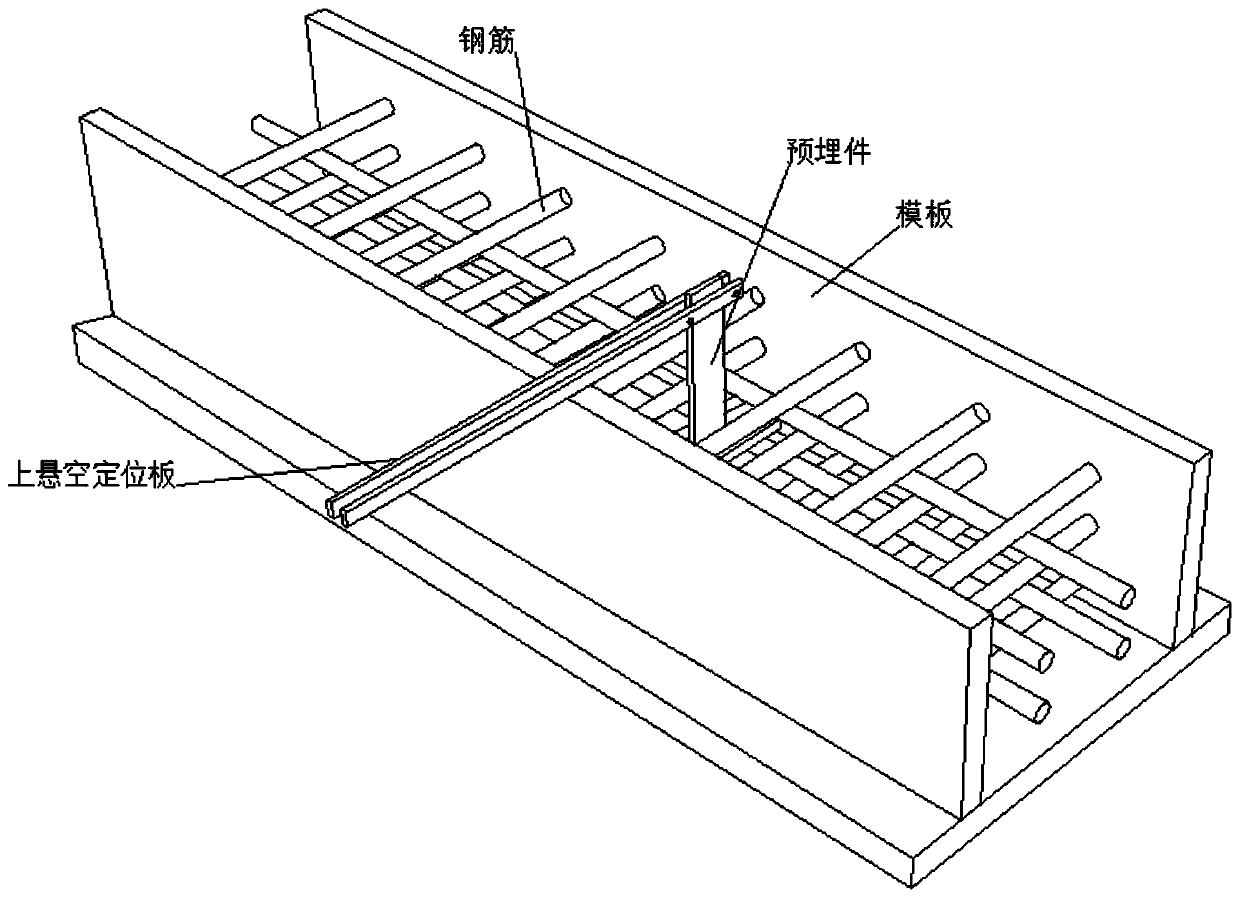

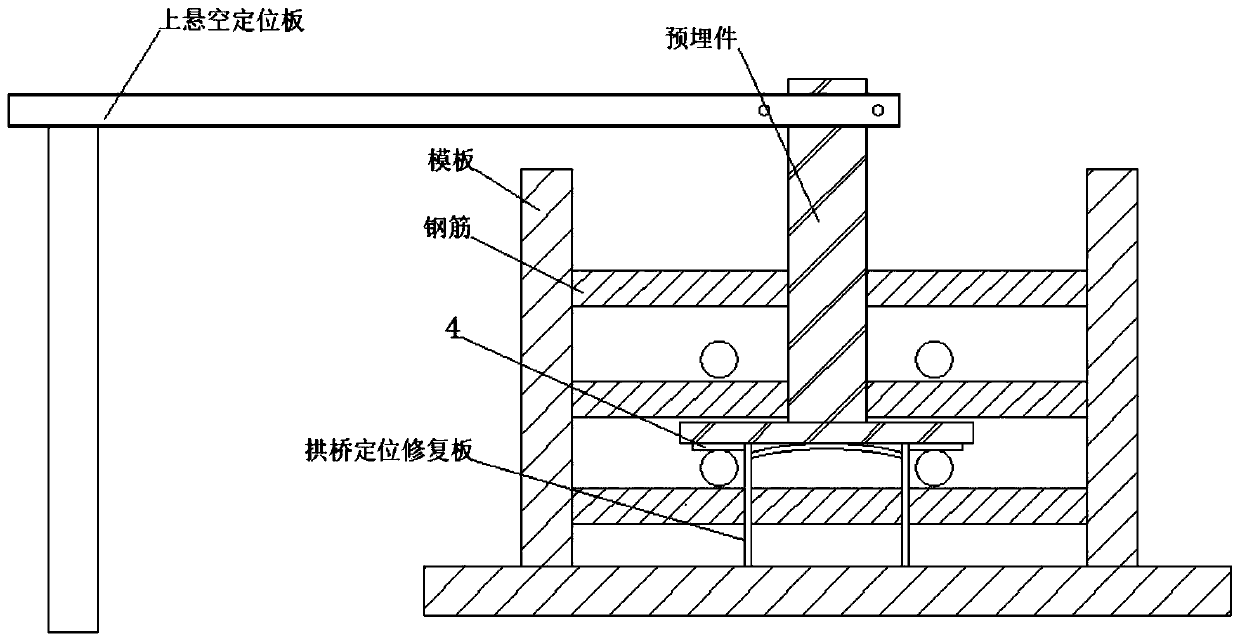

Embedded part construction process for assembled building

ActiveCN110924535AGuaranteed stabilityImprove efficiencyBuilding constructionsArchitectural engineeringRebar

The invention discloses an embedded part construction process for an assembled building and belongs to the field of embedded part construction. According to the embedded part construction process forthe assembled building, by means of a double-way positioning mechanism, under the action of an upper hang-in-the-air positioning plate, an embedded part can be fixed into a form board from above in ahang-in-the-air state of no contact with the form board and a steel bar; meanwhile, under the action of an arch bridge positioning repair plate, a certain supporting force can be provided for the embedded part from below, thus the stability of the embedded part is effectively maintained, and occurrence of skewing of the embedded part during pouring is reduced; by means of the double-way fixing function on the embedded part, the workload of position adjustment of the embedded part at later stage is effectively reduced, and thus the efficiency of pouring the embedded part into a concrete layer of a pre-fabricated part is improved remarkably; and under the action of a foam board and a rainfall factor, moisture nearby the steel bar and the embedded part can be effectively absorbed, and the situation of severe rusting of the steel bar and the embedded part caused by too much accumulated water in the position where the steel bar and the embedded part are close to each other is effectively avoided.

Owner:杨涛

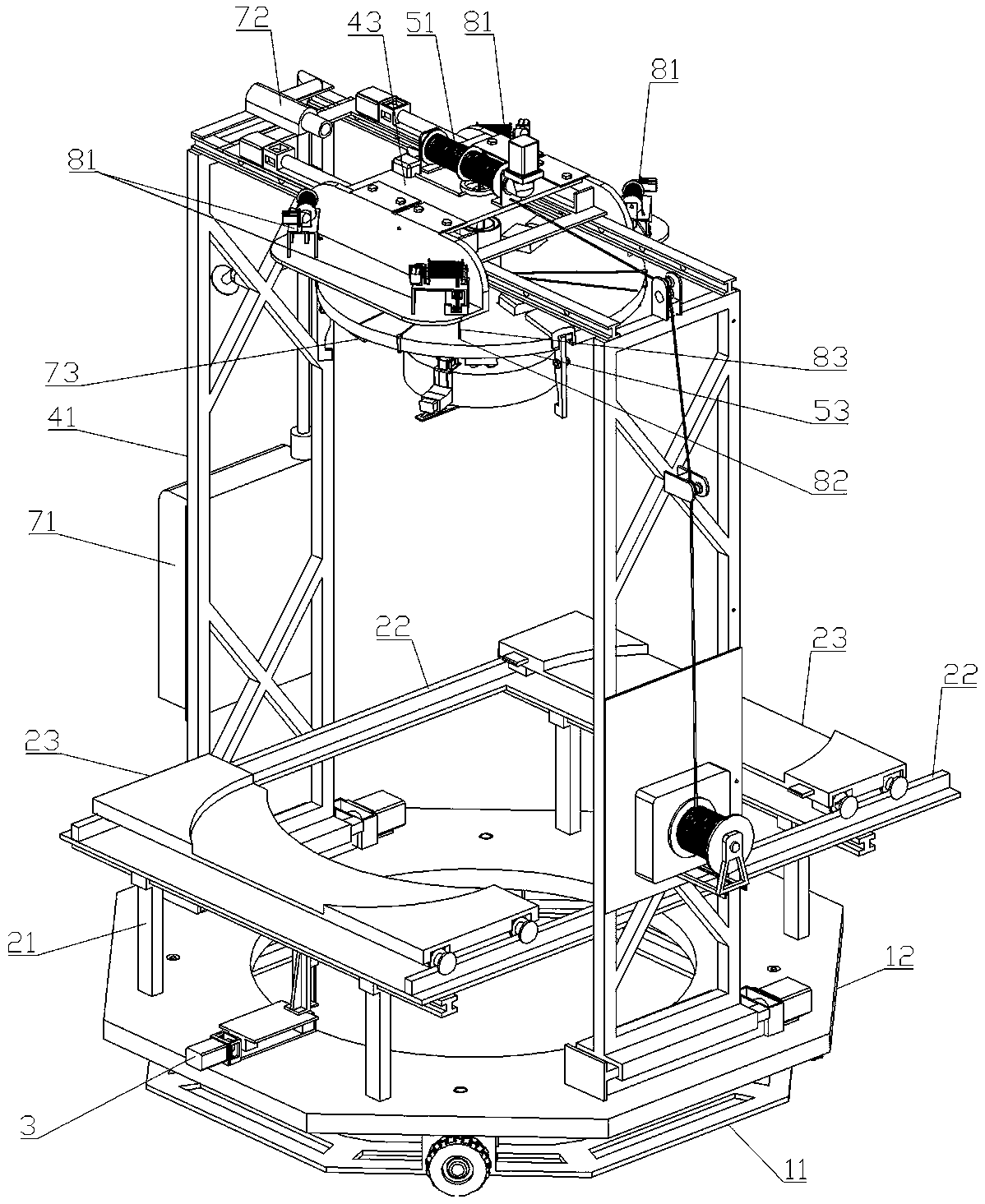

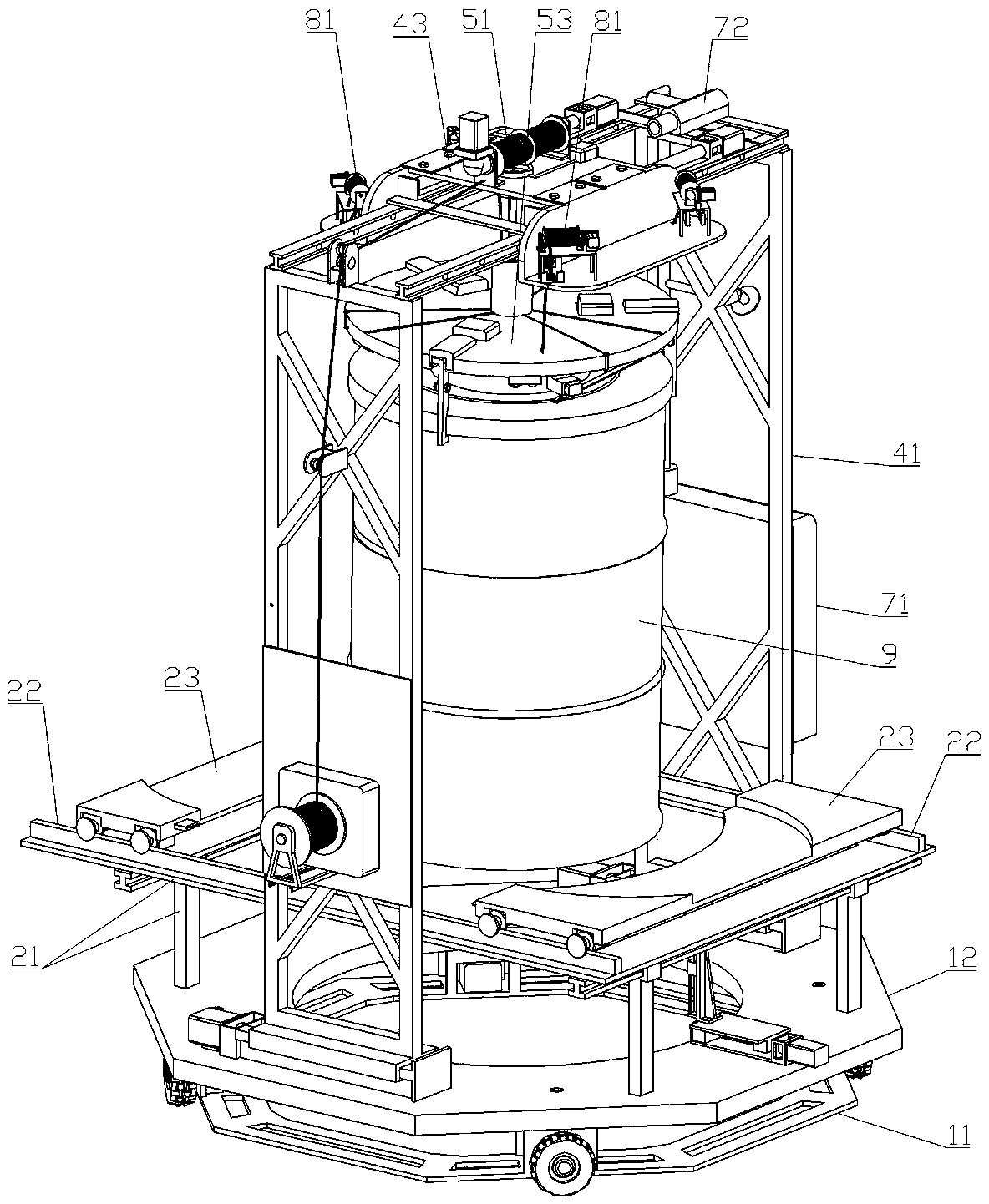

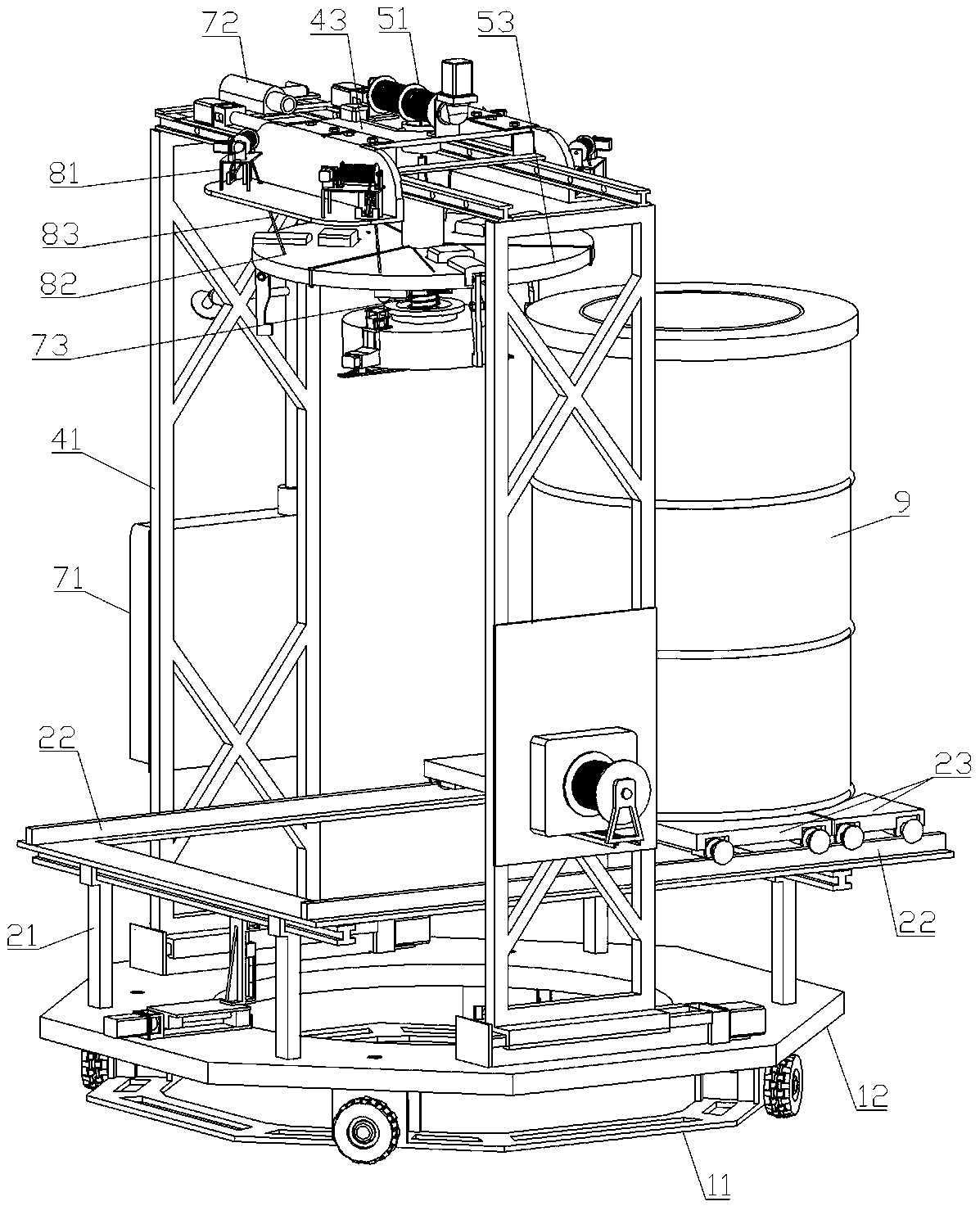

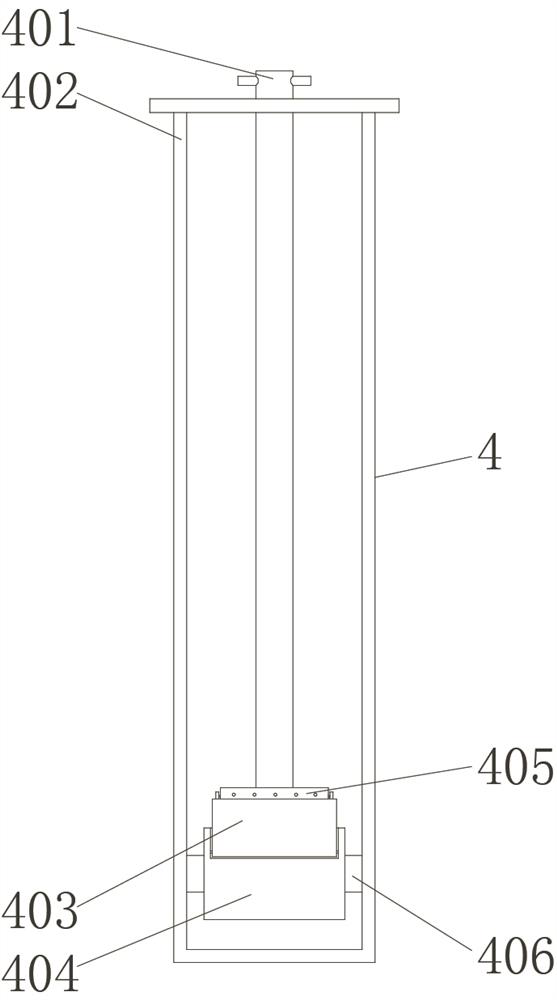

Deep well curing barrel hoisting system and method

ActiveCN108726388AHarmful to healthAvoid nuclear radiationTrolley cranesLoad-engaging elementsNuclear radiationSurface cleaning

A deep well curing barrel hoisting system comprises a running gear, a horizontal transfer device, a logging center device, a hanging scaffold shifting mechanism, a hanging scaffold, a barrel surface cleaning device and a spray and dust reduction mechanism. A curing barrel hoisting method based on the deep well curing barrel hoisting system comprises the following step 1 of setting a coordinate system; the step 2 of locating a wellhead center; the step 3 of regulating a hoisting position; the step 4 of removing wastes and floating dust on a curing barrel; the step 5 of further centering the curing barrel through a hook claw; the step 6 of hoisting the curing barrel; and the step 7 of transferring the curing barrel onto a barrel carrier vehicle. The deep well curing barrel hoisting system and method has the advantages that the deep well curing barrel hoisting system can be controlled remotely for avoiding nuclear radiation effectively; an electromagnetic chuck can be in butt joint with the curing barrel accurately; and the curing barrel is hoisted steadily and prevented from colliding with walls.

Owner:NANHUA UNIV

A hydraulic leveling system for an aerial work vehicle

ActiveCN106678096BImprove leveling efficiencyImprove securityServomotor componentsServomotorsMagnetic exchangeEngineering

Owner:XUZHOU HANDLER SPECIAL VEHICLE

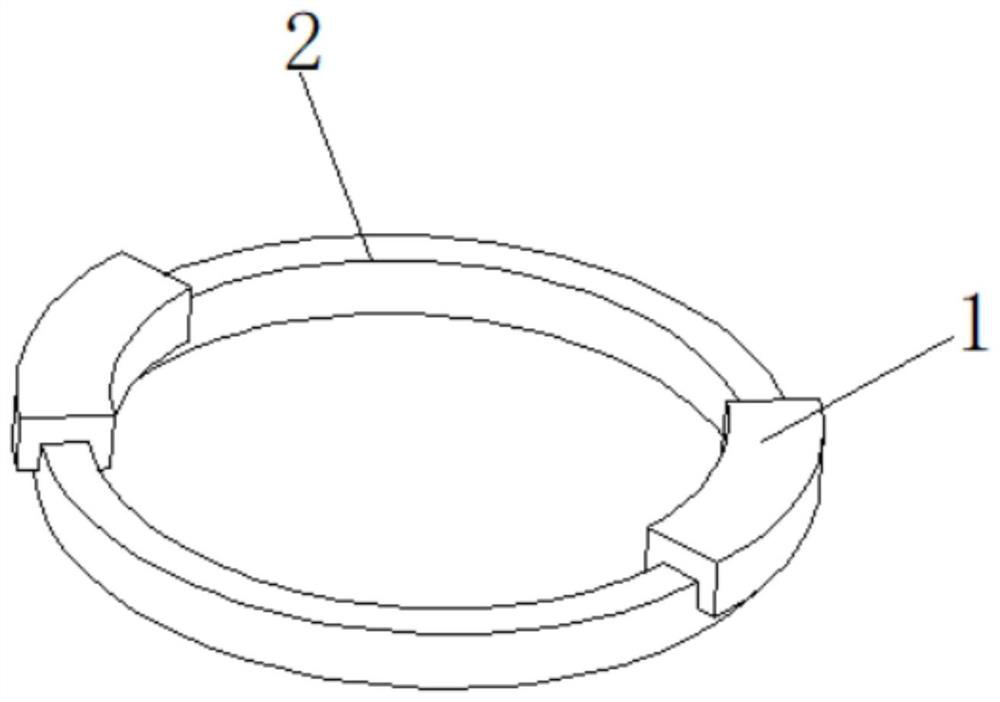

Polishing device for mining equipment manufacturing

InactiveCN112428111AImprove stabilityAvoid skewed situationsGrinding drivesGrinding machinesPolishingWorking environment

The invention discloses a polishing device for mining equipment manufacturing. The polishing device comprises a supporting plate, wherein a coarse polishing head and a fine polishing head are arrangedon the two sides of the upper portion of the supporting plate correspondingly, annular protruding blocks are arranged on the outer walls of the bottom ends of the coarse polishing head and the fine polishing head, the annular protruding blocks are fixedly connected with a mounting plate through fastening bolts, arc-shaped sliding blocks are mounted on the two sides of the lower surface of the mounting plate correspondingly, the arc-shaped sliding blocks are mounted on a hollow annular sliding rail, the arc-shaped sliding blocks are slidably connected with the hollow annular sliding rail, thehollow annular sliding rail is mounted on the upper surface of the supporting plate, and a rotating shaft is mounted in the center of the lower surface of the mounting plate. According to the polishing device for mining equipment manufacturing, coarse polishing and fine polishing can be conducted on parts for manufacturing mining equipment, dust generated in the polishing process can be removed, the working environment is improved, it is avoided that the working environment is affected by the dust generated in the polishing process, it is avoided that the dust generated in the polishing process is inhaled by a worker, safety is improved, and high practicability is achieved.

Owner:JIAHE FUSHUN MACHINERY IND

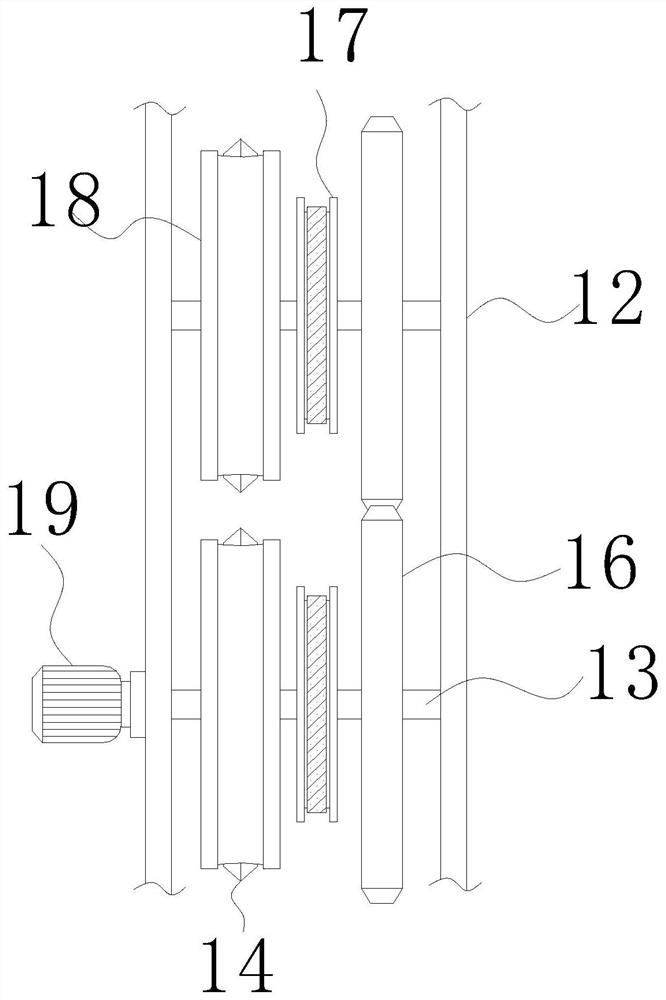

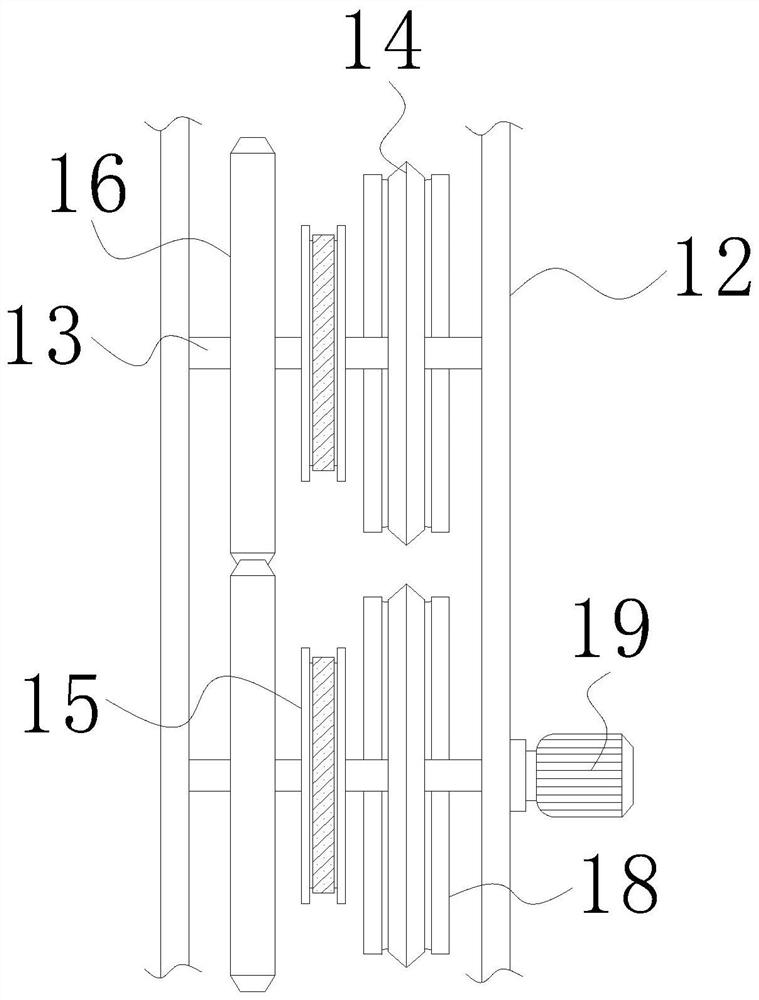

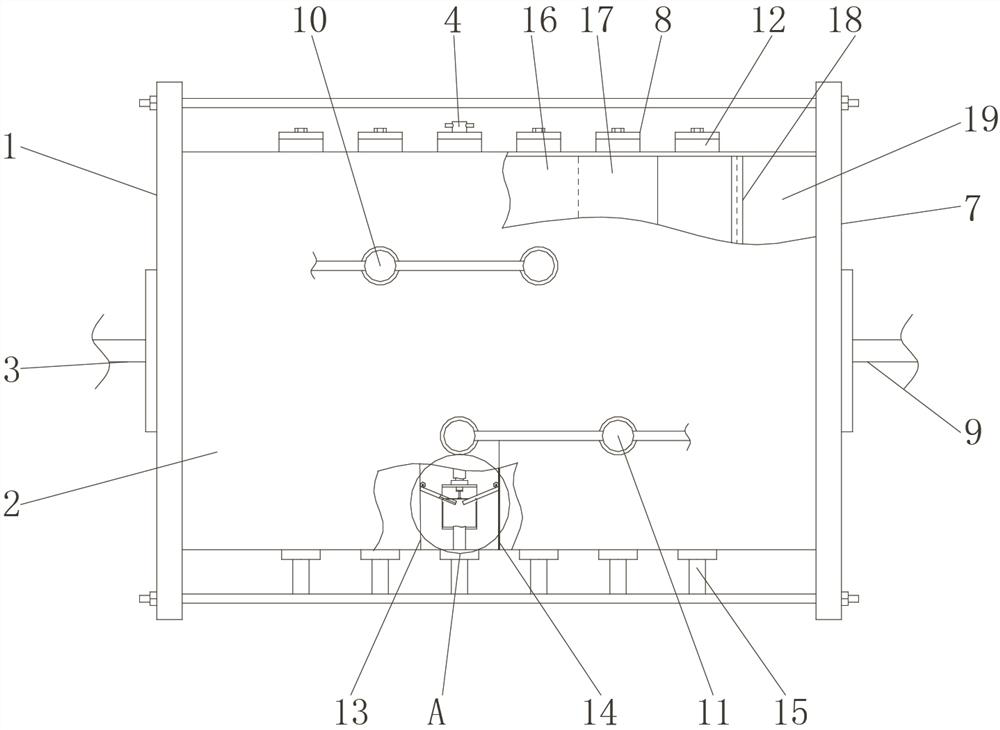

Metal plate rolling and cooling integrated equipment

ActiveCN113560347AAvoid skewed situationsAvoid manual operationMetal rolling stand detailsWork cooling devicesHydraulic cylinderThermodynamics

The invention relates to metal plate rolling and cooling integrated equipment, and belongs to the technical field of metal plate rolling. The metal plate rolling and cooling integrated equipment comprises a bottom plate, a rack and supporting frames are fixedly connected to the upper surface of the bottom plate, the supporting frames are symmetrically distributed on the two sides of the rack, a portal frame is fixedly connected to the top of the rack, a hydraulic cylinder is fixedly connected to the inner wall of the top of the portal frame, first sliding grooves are formed in the two sides of the rack, first sliding blocks are movably connected into the first sliding grooves, a pressing roller is movably connected between the first sliding blocks, and a lifting frame is fixedly connected between the tops of the two first sliding blocks. After a metal plate is extruded, the extruded metal plate is limited through a limiting plate, so that the situation that the extruded metal plate deflects on a supporting roller is avoided, and meanwhile, through automatic discharging of a cooling liquid, waste of the cooling liquid is reduced, the metal plate can be automatically pushed, manual operation is avoided, and the automation degree of the equipment is improved.

Owner:江苏超璞智能装备有限公司

Food plastic bag winding machine

The invention relates to the technical field of food packaging and discloses a food plastic bag winding machine which comprises a base, wherein a support column, a motor and a fixed rod are sequentially fixedly connected with the top of the base from left to right; a limiting transverse plate is fixedly connected between two opposite sides of the support column and the fixed rod; an extending mechanism is fixedly connected with the top of the limiting transverse plate; an auxiliary winding rod is movably connected with the top of the limiting transverse plate through a first bearing pedestal;a bag winding loop bar movably connected with the top of the limiting transverse plate through a first fixed bearing; the bottom end of the bag winding loop bar penetrates through the limiting transverse plate and is movably connected with the top of the base through a second bearing pedestal; and the outer surface of the bag winding loop bar is fixedly connected with a first gear in a sleeving manner. The food plastic bag winding machine solves the problem that the edge of a plastic bag is not level when the food plastic bag winding machine winds and realizes the effects that higher stabilityis realized when the plastic bag is wound and the edge of the wound plastic bag is in order.

Owner:HAINING CHANGKUN PACKAGING

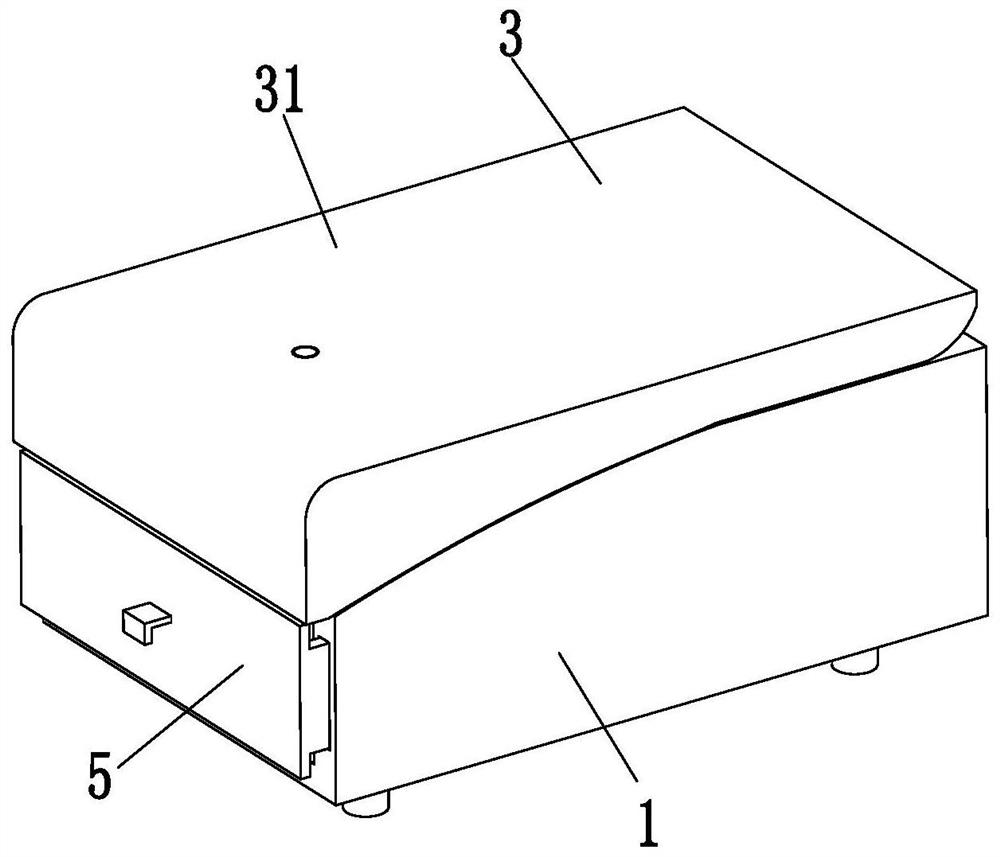

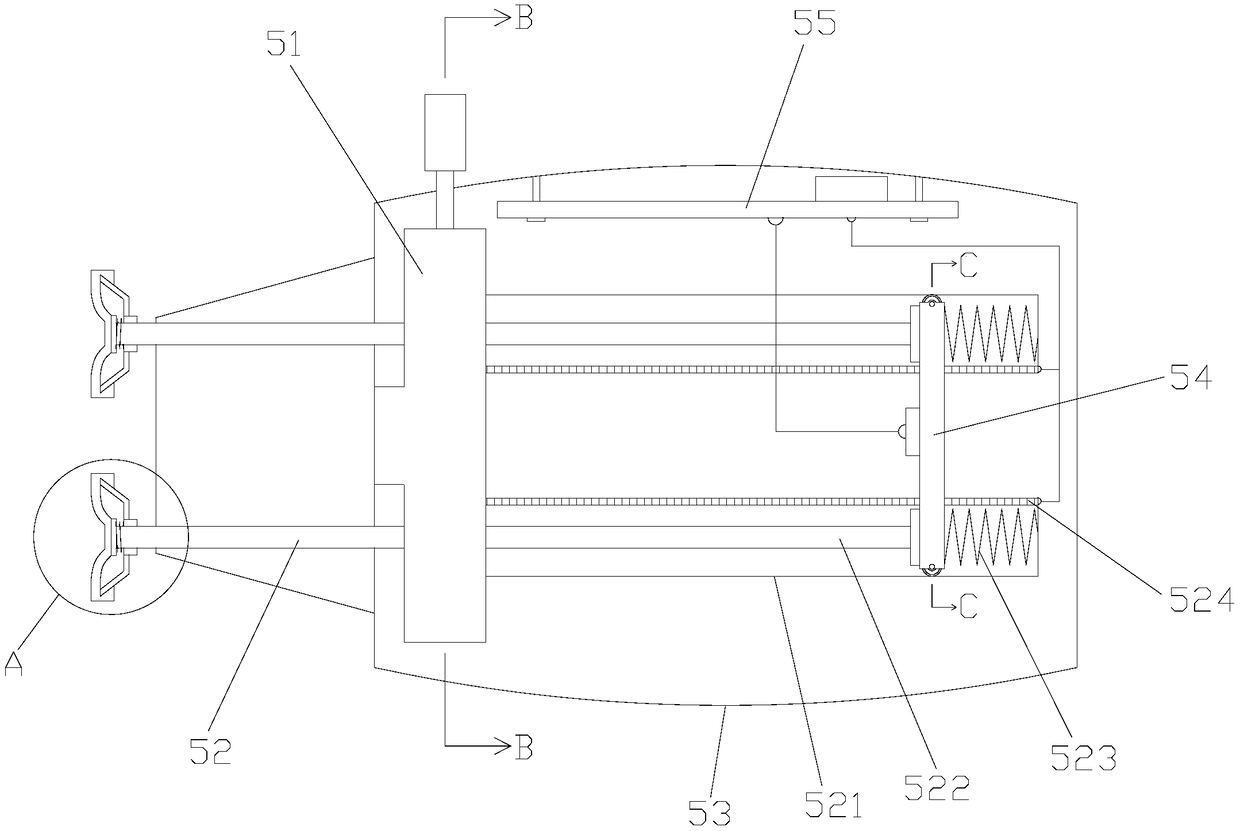

Thermosensitive label bar code intelligent printer

InactiveCN112937129AAvoid skewed situationsBeautify the shapeTypewritersOther printing apparatusComputer printingBarcode

The invention relates to a thermosensitive label bar code intelligent printer. The printer comprises a working box, a rotating shaft, an end cover, a coiled material mounting device and a leveling limiting device, the rotating shaft is mounted on the upper right side in the working box, the end cover is rotationally arranged in the middle of the rotating shaft, the coiled material mounting device is arranged on the right side in the working box, and the leveling limiting device is arranged on the left side in the working box. The printer can solve the problems that when a traditional thermal-sensitive barcode printer prints a label coiled material, since two sides of a label are prone to bending, the position of a barcode on the label tends to be inclined, the attractiveness of the barcode is reduced, the barcode is inconvenient to identify, when the traditional thermal-sensitive barcode printer continuously prints a large number of labels at a high speed, printed labels are directly output from a printer, unsorted label strips are disorderly wound together, and use and collection are inconvenient.

Owner:马鞍山克宇包装服务有限公司

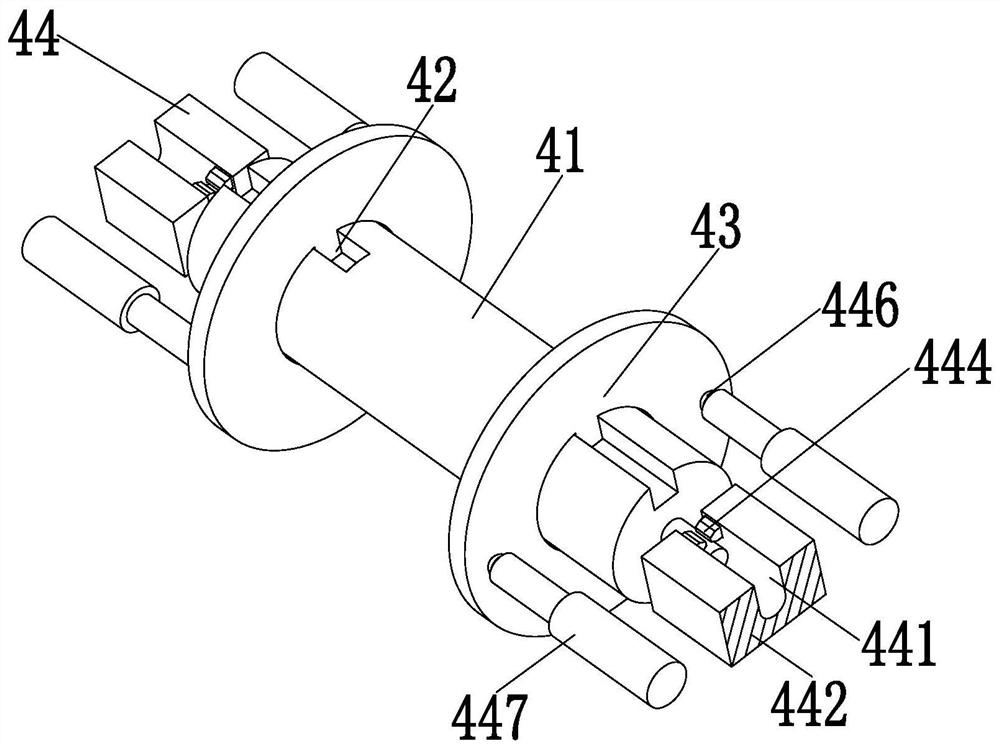

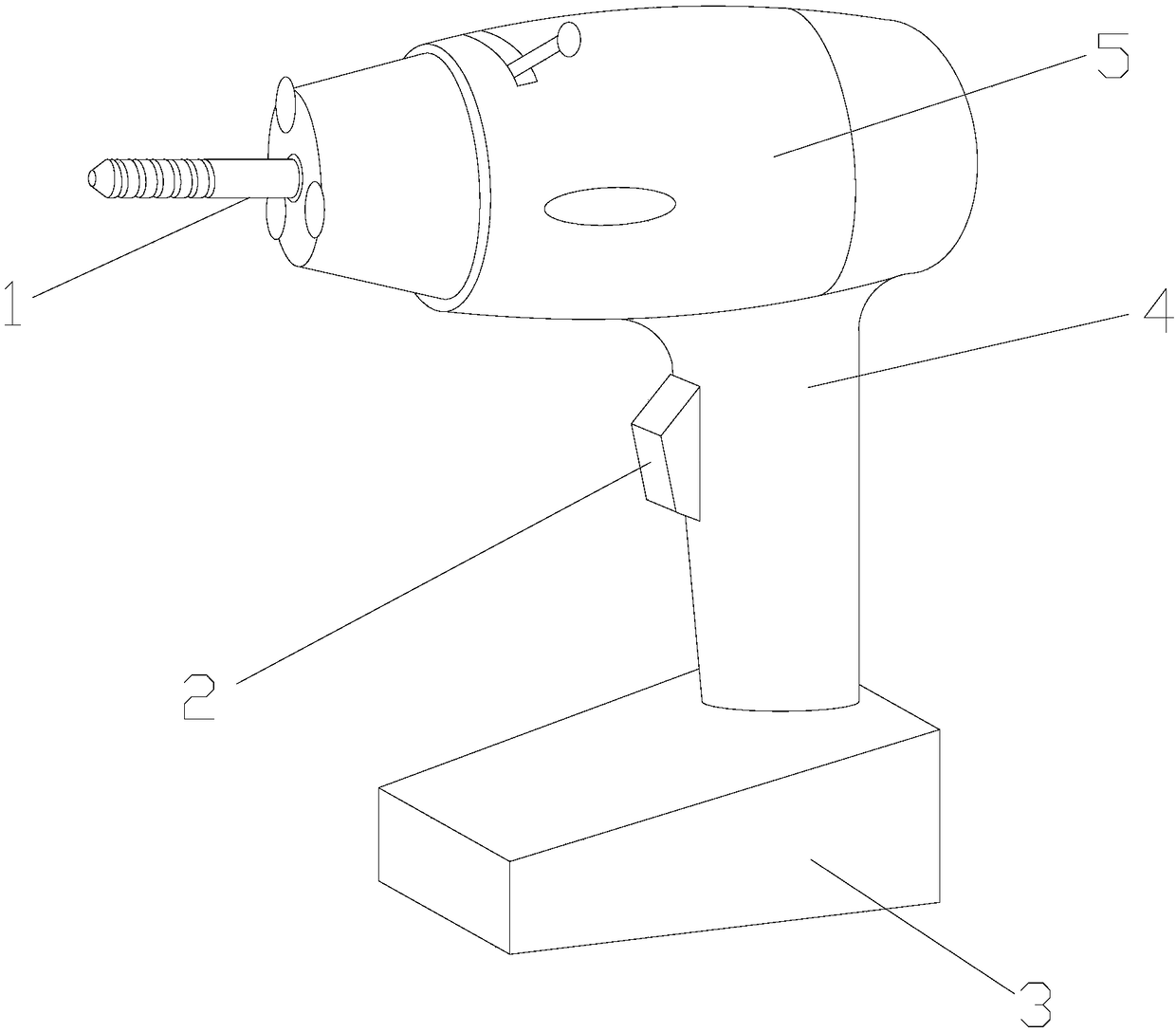

Anti-slip electric drill for building construction interior decoration

ActiveCN109108336AImprove stabilityQuick drillPortable power-driven toolsWorking accessoriesPunchingEngineering

The invention discloses an anti-slip electric drill for building construction interior decoration. The anti-slip electric drill structurally comprises an electric drill bit, an electric drill shift knob, a lithium battery fixing seat, an anti-slip handle and an electric drill body. The electric drill is matched with a tilt detecting device through a tile fixing structure, and when tiles of a bathroom are subjected to punching, the electric drill and the tiles are fixed by the tile fixing structure in a sucked mode to improve the stability of the electric drill when the tiles are subjected to punching. An electric drill bit tool can be drilled quickly when the tiles are subjected to punching to avoid the occurrence of slipping between smooth ceramic tiles and the bit tool after the bit toolis rotated. When deflection occurs during the punching process, an alarm can be performed in time to remind an operator to cut off the power of the bit tool, and the staff can adjust the bit tool intime to avoid that the attractiveness of a wall surface is affected due to repeated punching after the deflection occurs during punching, and the quality of punching is effectively improved.

Owner:聊城泽润装饰工程有限公司

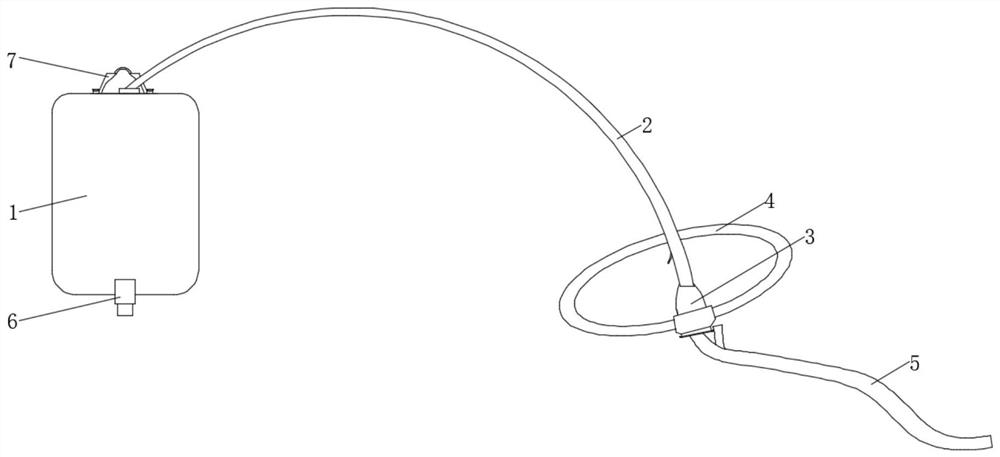

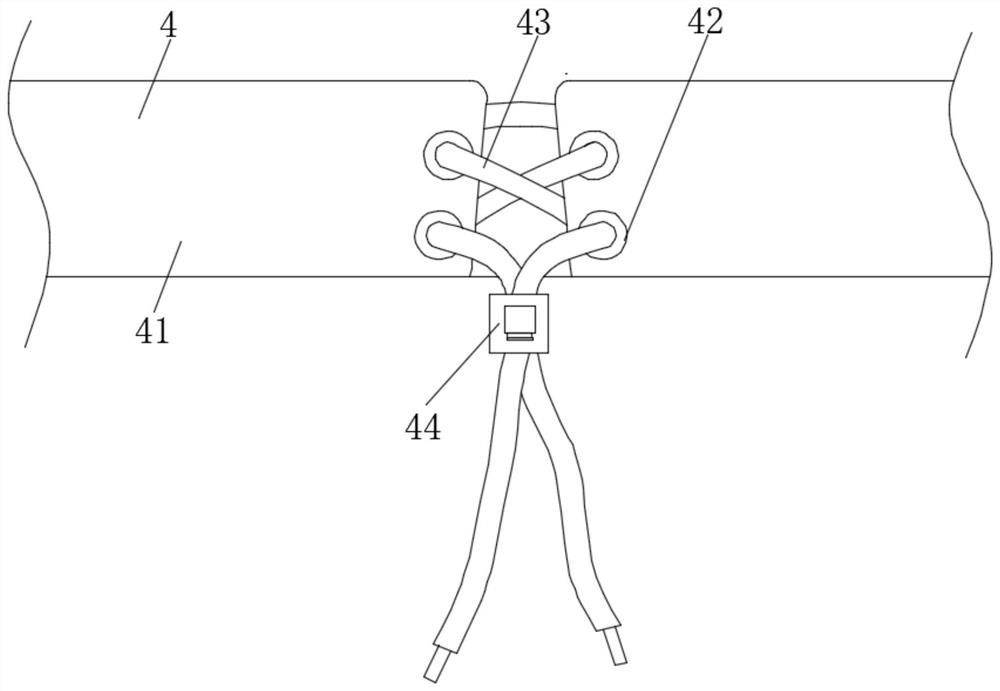

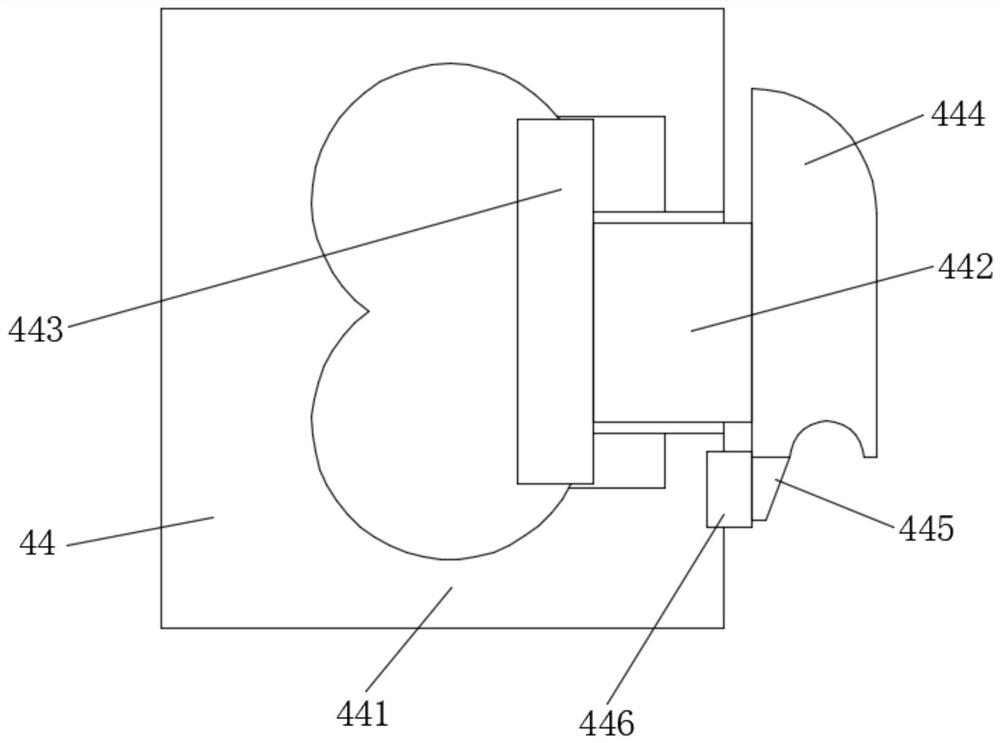

Drainage device special for urology department

InactiveCN111744060AFirmly connectedAvoid skewed situationsCatheterIntravenous devicesUrinary catheterUrology department

The invention discloses a drainage device special for the urology department. The device comprises a urinary catheterization bag, a connecting pipe is connected to the top of the urinary catheterization bag, a connecting sleeve is installed at the other end of the connecting pipe, a binding mechanism is arranged on the outer side of the connecting sleeve, a urinary catheter body extending to the outer side is arranged in the connecting pipe, and a connecting opening is formed in the bottom of the urinary catheterization bag; through the arrangement of the binding mechanism, a binding belt canbe arranged on the outer side of the leg of a patient in a sleeving mode, then the two ends of the pull rope are pulled, the two ends of the binding belt can be tensioned, and therefore the binding belt is fixed to the outer side of the leg of the patient, and stable connection can be guaranteed in the mode that the metal pad is attracted to the outer side of the magnet block; through the arrangement of a hook mechanism, when the urethral catheterization bag is hung, the positioning sleeve at the top of the fixing sleeve can play a role in positioning, the situation that the urethral catheterization bag inclines when hung is avoided, and hanging stability is guaranteed.

Owner:杭州福疗医疗科技有限公司

External thread grooving correction device for threaded pipe machining

InactiveCN112427717AImprove processing qualityAvoid skewed situationsShearing machinesShearing machine accessoriesThreaded pipeGear wheel

The invention relates to the technical field of threaded pipes, and discloses an external thread grooving correction device for threaded pipe machining. The external thread grooving correction devicecomprises a shell, the right part of an inner cavity of the shell is rotationally connected with a grooving cutter, the left end of the shell is fixedly connected with a protective cover, and the upper wall and the lower wall of the left part of the shell are both fixedly provided with magnetic tracks. Positioning bases are fixedly connected to the positions, above and below the grooving cutter, on the left wall of the inner cavity of the shell, a correction column is connected to the left portion of each positioning base in a sliding manner, a rotating gear is rotationally connected to the right side of the correction column on the left portion of each positioning base, and an induction block is connected to an inner cavity of each magnetic track in a sliding manner. According to the external thread grooving correction device for threaded pipe machining, corresponding abutting strips are extruded when the grooving cutter deflects, so that the abutting strips drive push rods to push the induction blocks to move, the rotating gears can synchronously drive the correction columns to reset the grooving cutter, and therefore the machining quality of threaded pipes is effectively improved, and the machining cost of enterprises is effectively reduced.

Owner:宿州市骏阳装饰工程有限公司

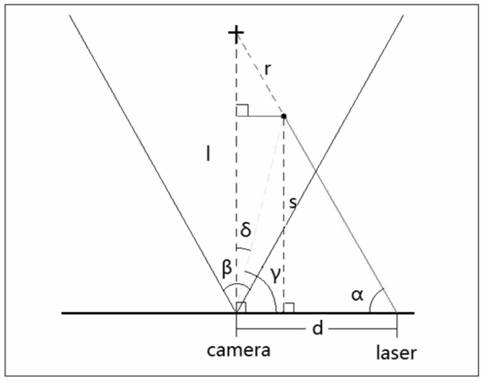

3D laser scanner and ranging scanning method thereof

PendingCN113280738AHigh precisionImprove scan performanceUsing optical meansElectric machineryEngineering

The invention discloses a 3D laser scanner and a ranging and scanning method thereof. The 3D laser scanner comprises a fixed shell, a material rotating mechanism is installed in the center of the fixed shell, a laser emitting mechanism and a camera shooting mechanism are arranged in the fixed shell, and the laser emitting mechanism and the camera shooting mechanism are electrically connected with a control mechanism; and the control mechanism performs dual polarization on picture information shot by the camera mechanism. According to the 3D laser scanner and the ranging and scanning method thereof, in the use process, shot data can be calculated through an independent algorithm, meanwhile, the data are processed through noise reduction and processing, the data accuracy is improved, the scanning effect is improved, meanwhile, the device is provided with a clamping mechanism of laser equipment and camera equipment, accurate control can be carried out through a stepping motor, the accuracy of laser irradiation and image shooting is improved, and the scanning effect is improved.

Owner:时沐朗

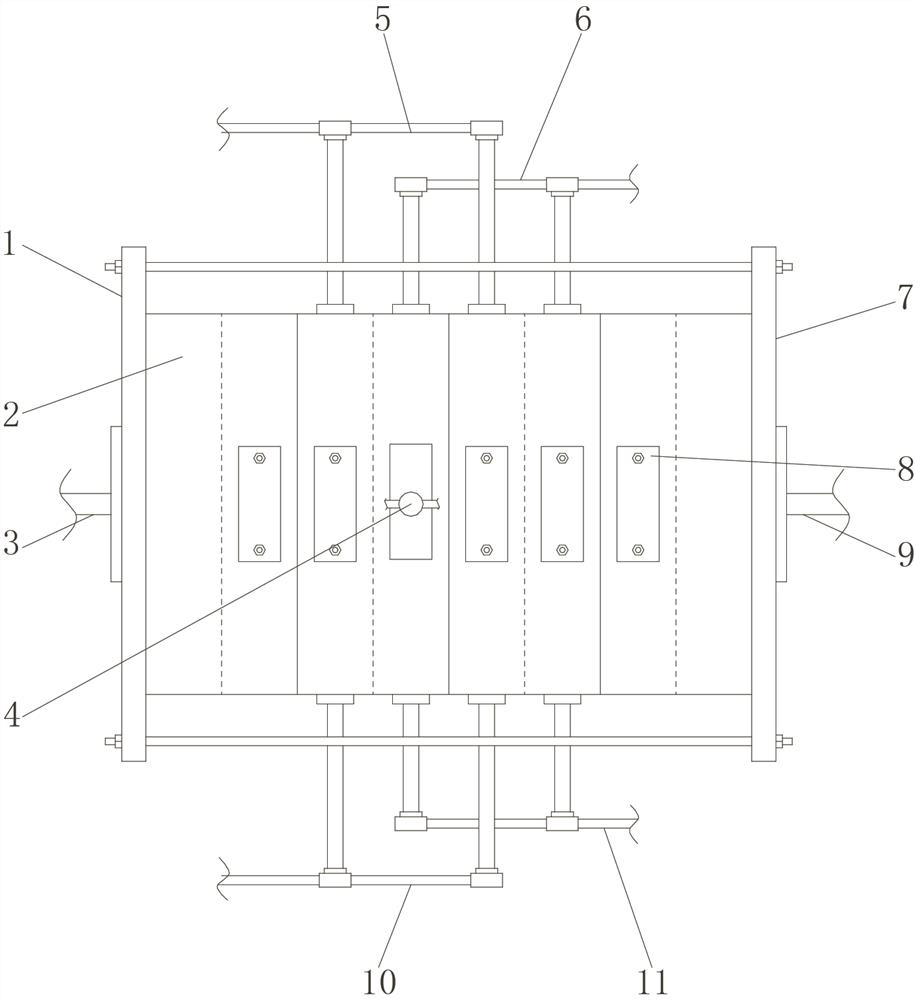

Salting electrodialysis device and use method thereof

ActiveCN113354040AImprove cleaning effectReduce corrosionGeneral water supply conservationSpecific water treatment objectivesElectrodialysisAnalytical chemistry

The invention discloses a salting electrodialysis device and a using method thereof. The salting electrodialysis device comprises a salting-out outer shell, at least six external fixing bases are arranged above the salting-out outer shell, a cation membrane, an anion membrane and an electrode membrane are arranged in the salting-out outer shell, and sampling mechanisms or sealing covers are arranged in through holes in the outer walls of the external fixing bases; and the sampling mechanism is positioned among the cation membrane, the anion membrane or the electrode membrane. According to the salting electrodialysis device and the use method thereof, the sampling structure is arranged, impurities on the surface of an ionic membrane in the device can be rapidly sampled, a sample can be detected after being sampled, a cleaning solution is prepared according to the content of substances in the sample, therefore, the surface of the ionic membrane can be effectively cleaned according to the prepared cleaning liquid, the cleaning effect of the device is improved, meanwhile, the condition that the ionic membrane is corroded can be reduced, and the service life of the ionic membrane is prolonged.

Owner:HANGZHOU BEISITE ENERGY SAVING & ENVIRONMENT PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com