Hydraulic pressure leveling system of high-altitude operation car

A technology for aerial work vehicles and work platforms, which is applied in the field of aerial work vehicle leveling, can solve problems such as leveling lag, hidden dangers to the safety of aerial work personnel, and inconvenience for operators to carry out aerial work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

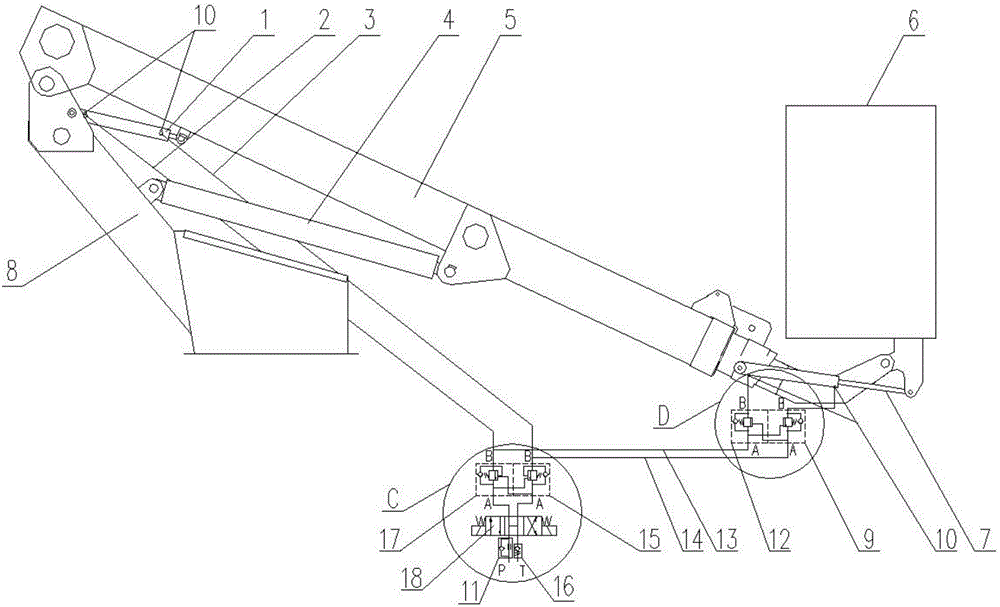

[0016] The present invention will be further described below in conjunction with accompanying drawing.

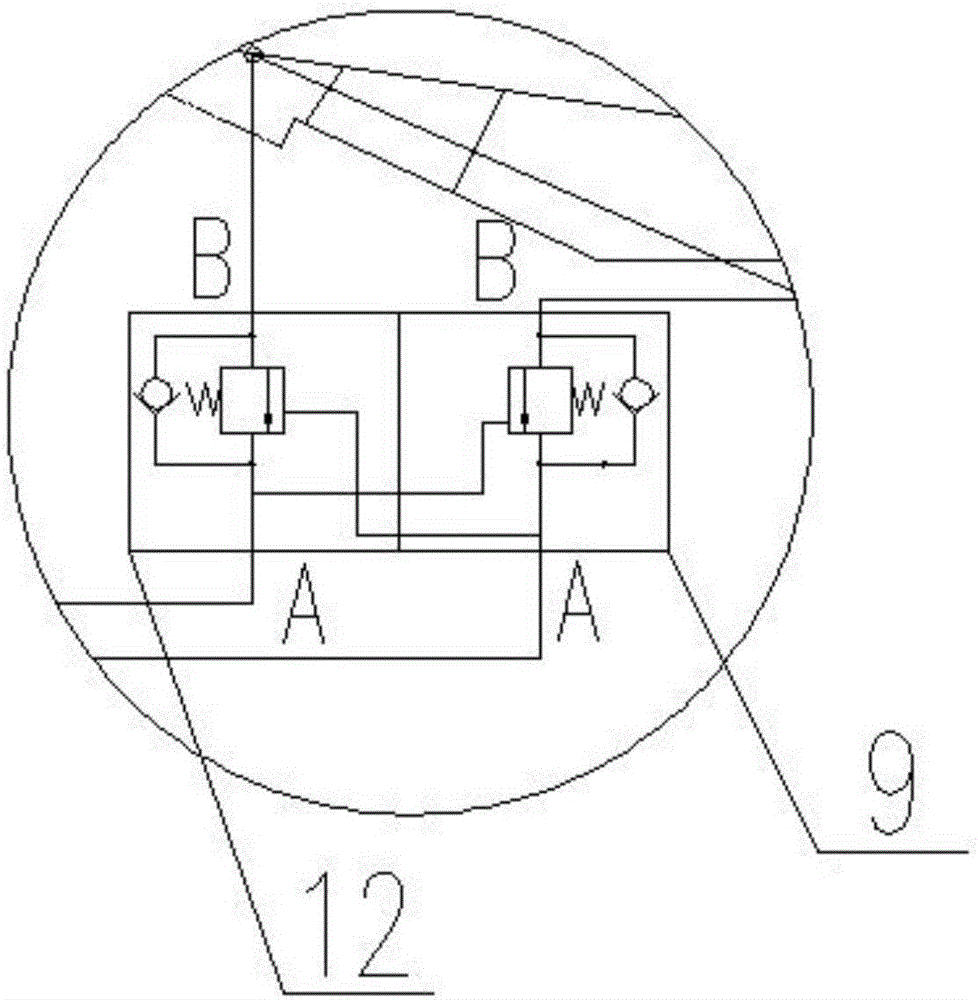

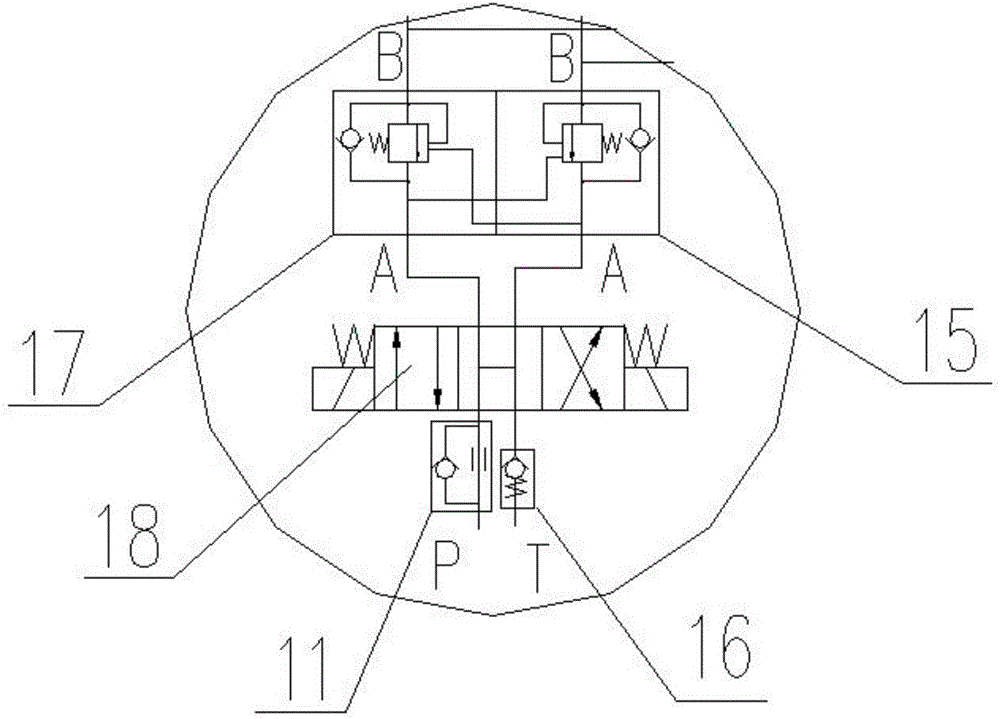

[0017] Such as Figure 1 to Figure 4 As shown, a hydraulic leveling system for an aerial work vehicle includes a primary arm 8, a secondary arm 5, a working platform 6 and an electromagnetic reversing valve 18, and the left end of the secondary arm 5 is hingedly connected to the primary arm 8. At the upper end, the active leveling cylinder 1 is hingedly connected between the left part of the secondary arm 5 and the upper part of the primary arm 8, and the luffing cylinder 4 is hingedly connected between the middle part of the secondary arm 5 and the middle part of the primary arm 8. A driven leveling oil cylinder 7 is hingedly connected between the right part of the secondary arm 5 and the lower end of the working platform 6. The oil inlet of the electromagnetic reversing valve 18 is supplied with high-pressure oil by an oil pump. The first part of the electromagnetic rever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com