Edge cutting, edge banding and cutting-off integrated equipment and operating method thereof

A kind of equipment and trimming technology, which is applied in auxiliary molding equipment, transportation and packaging, ceramic molding machines, etc., can solve the problems of broken corners of plates, different lengths of tails of edge bands, and difficult control of intervals, etc., to achieve reduction The effect of broken corners and improved appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

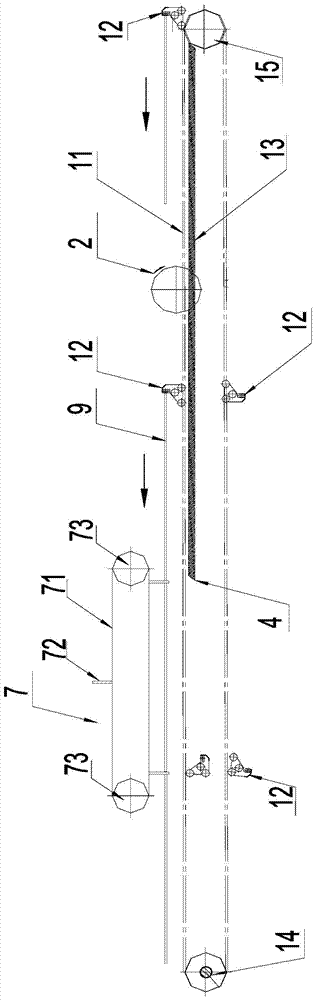

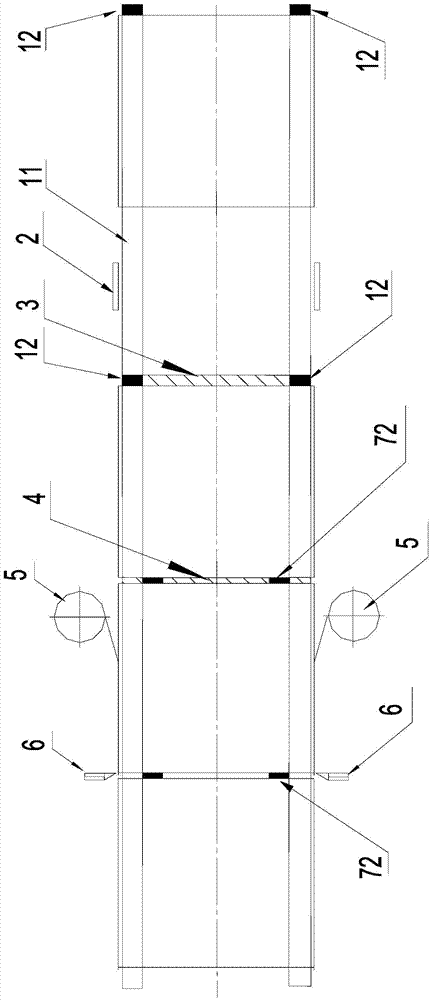

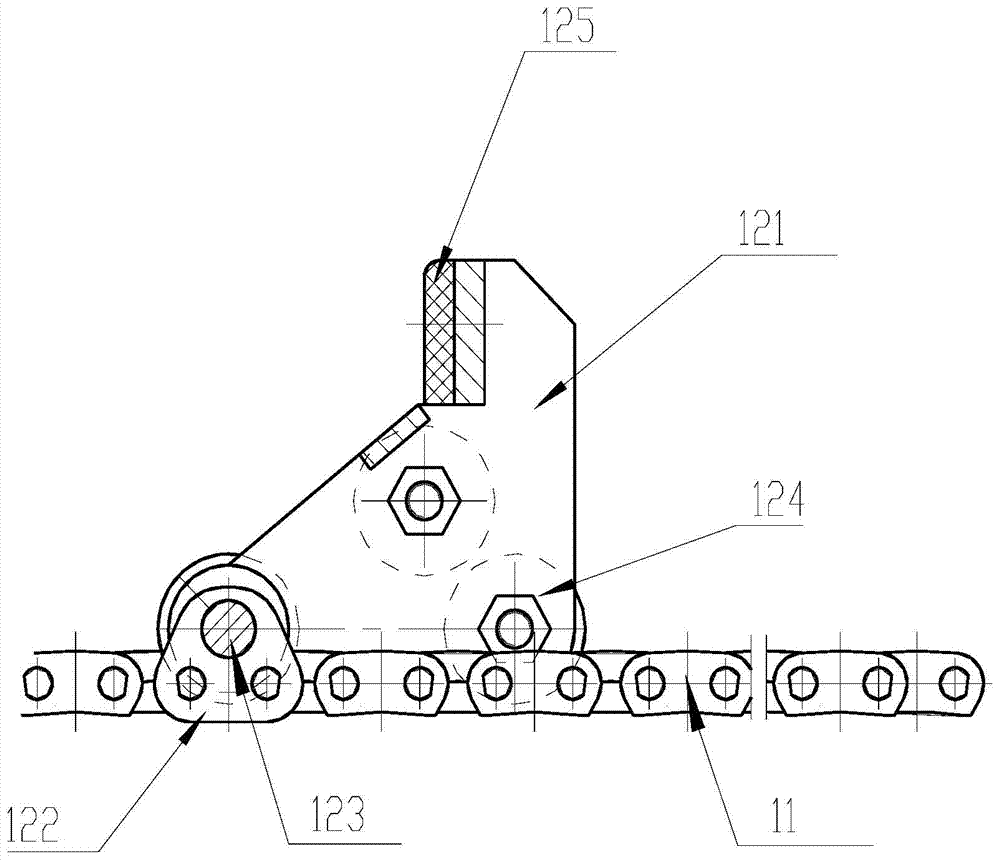

[0036] See figure 1 with 2 As shown, the integrated equipment for edge trimming, edge banding, and cutting in the embodiment of the present invention is realized in such a way that it includes a chain transmission device, a belt spacing device and a controller.

[0037] Along its transmission direction, the chain transmission device is provided with edge trimming device 2, stop position 3, drop position 4, edge sealing device 5, sealing tape cutting device 6, and edge trimming device 2 can adopt conventionally used removable gypsum board edge The edge cutting saw, the edge banding device 5 can adopt the conventionally used edge banding device 5 of gypsum board, and the sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com