Embedded part construction process for assembled building

A construction technology and technology of embedded parts, which is applied in the direction of construction and building structure, can solve the problems of skewed embedded parts, shifting target position, affecting efficiency, etc., and achieve the goal of reducing workload, improving efficiency and maintaining stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

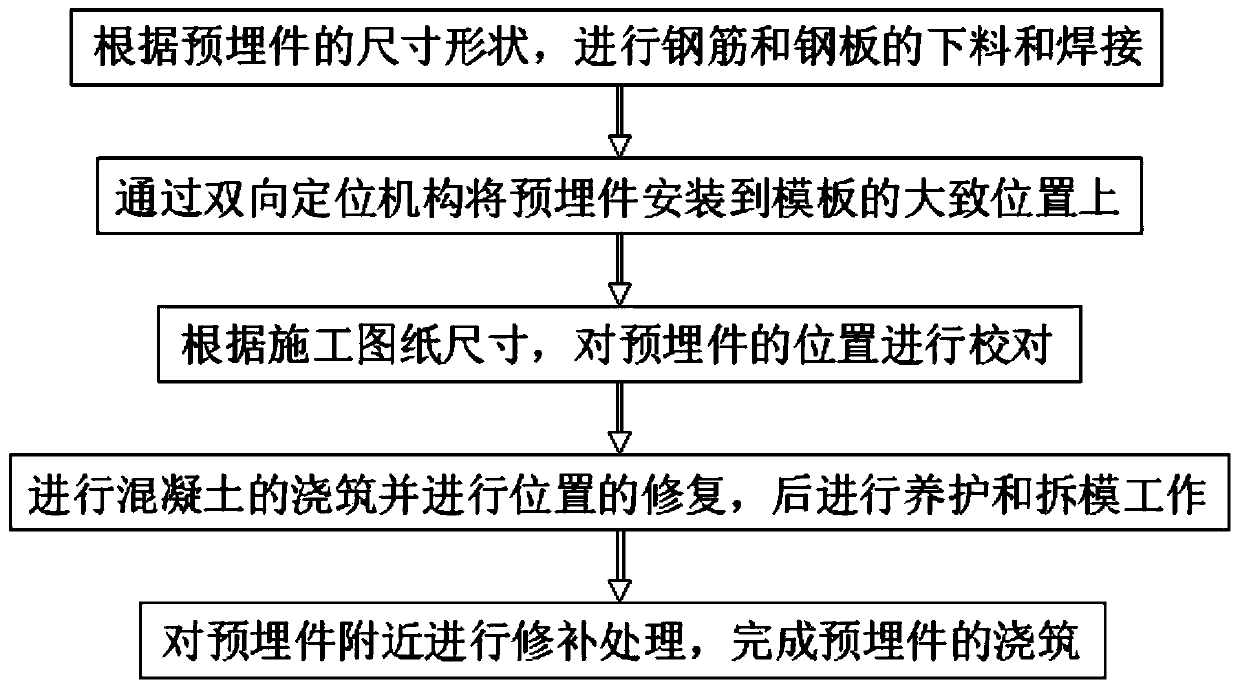

[0050] see Figure 1-2 , a construction process for pre-embedded parts for prefabricated buildings, comprising the following steps:

[0051] S1. First, according to the size and shape of the embedded parts, the blanking and welding of steel bars and steel plates are carried out;

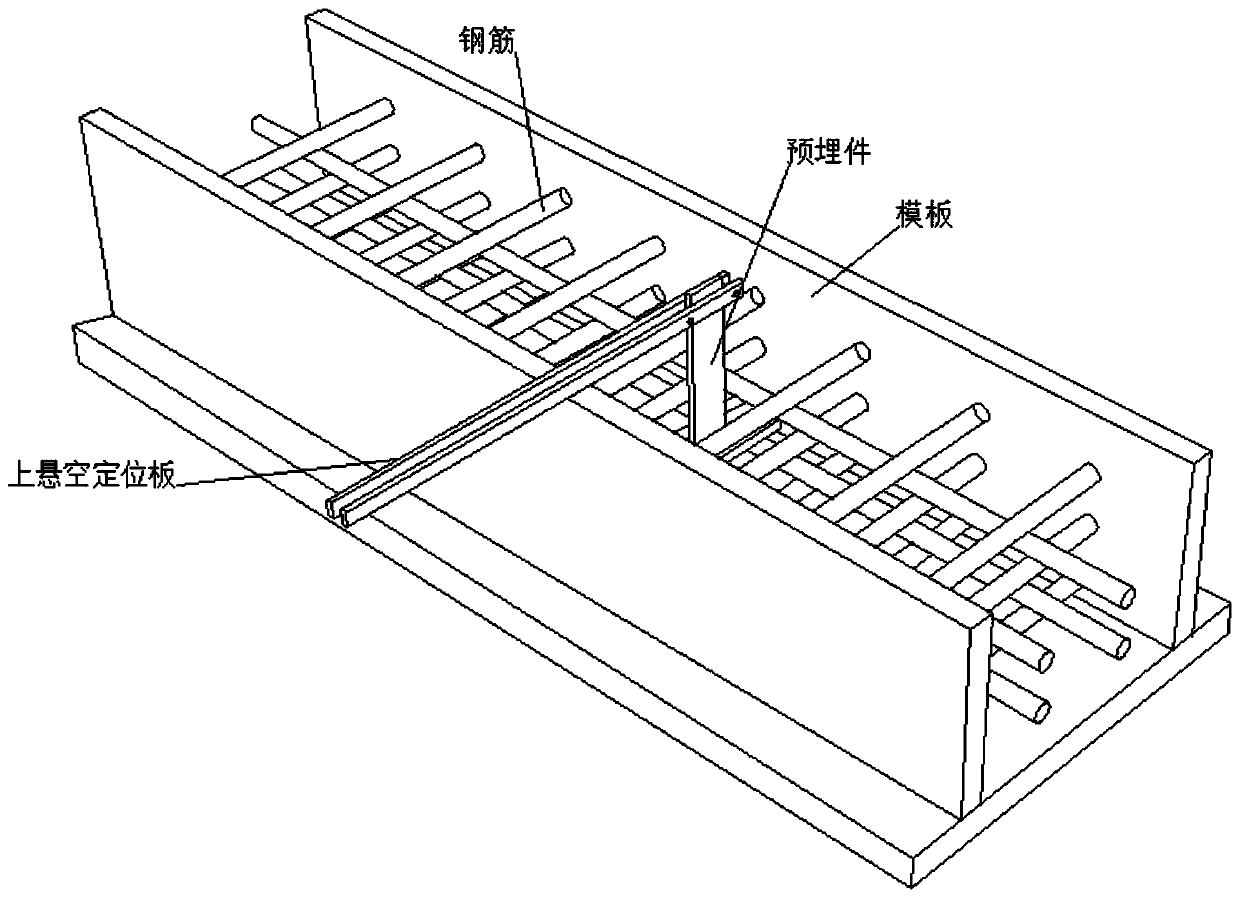

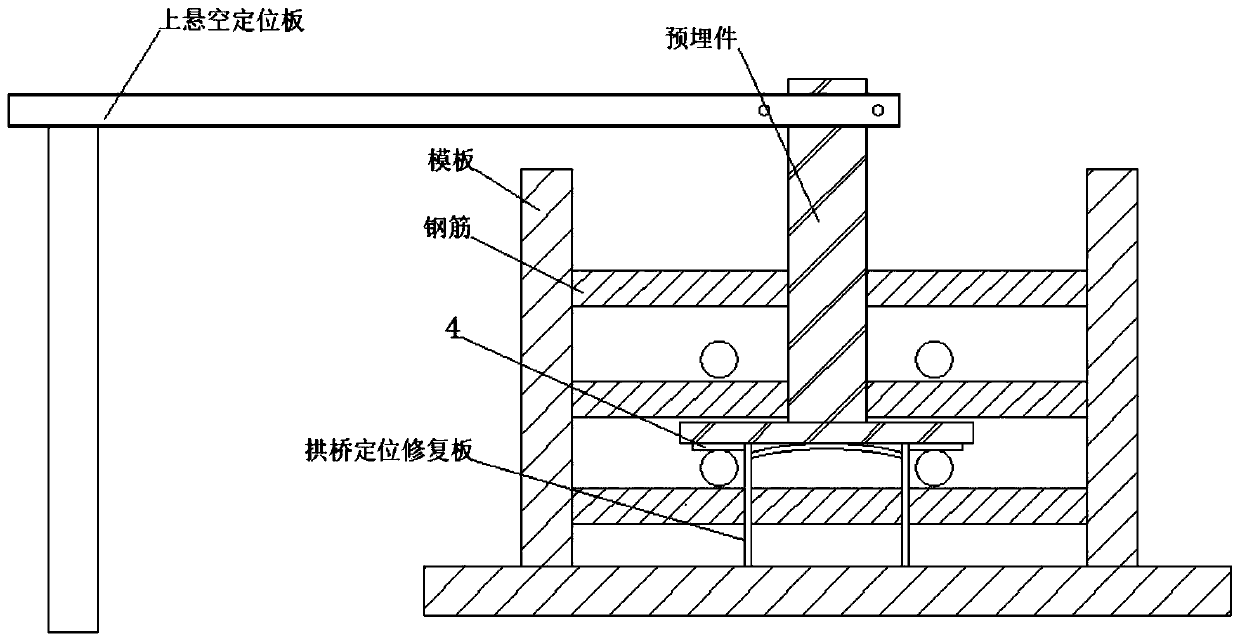

[0052] S2, then set up the formwork, install the steel bars and steel plate columns after blanking on the supported formwork, and then install the embedded parts to the approximate position of the formwork through the two-way positioning mechanism, and the embedded parts are located on the horizontal and vertical steel bars between and without contact with the two;

[0053] S3. Proofread the position of the embedded parts according to the size of the construction drawings;

[0054] S4, then carry out pouring of concrete and carry out the maintenance of concrete after carrying out slight repair treatment of the position, carry out demoulding after finishing;

[0055] S5. Check the actual position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com