Mechanical double-acting disc brake

A mechanical, disc brake technology, applied in the field of mechanical double-action disc brakes, can solve the problems of easy deformation of the disc, hindering the normal running of the bicycle, and easy contact between the disc and the friction plate, so as to avoid the deformation of the disc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

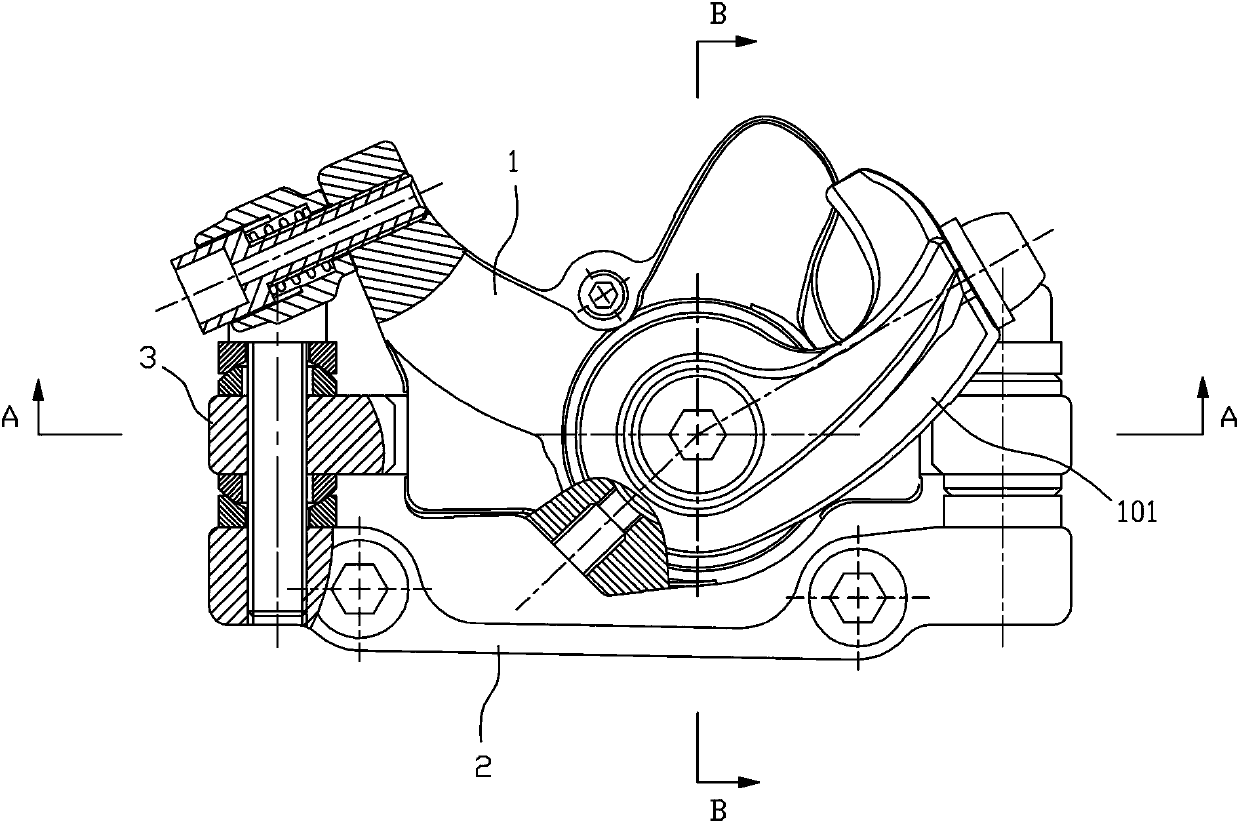

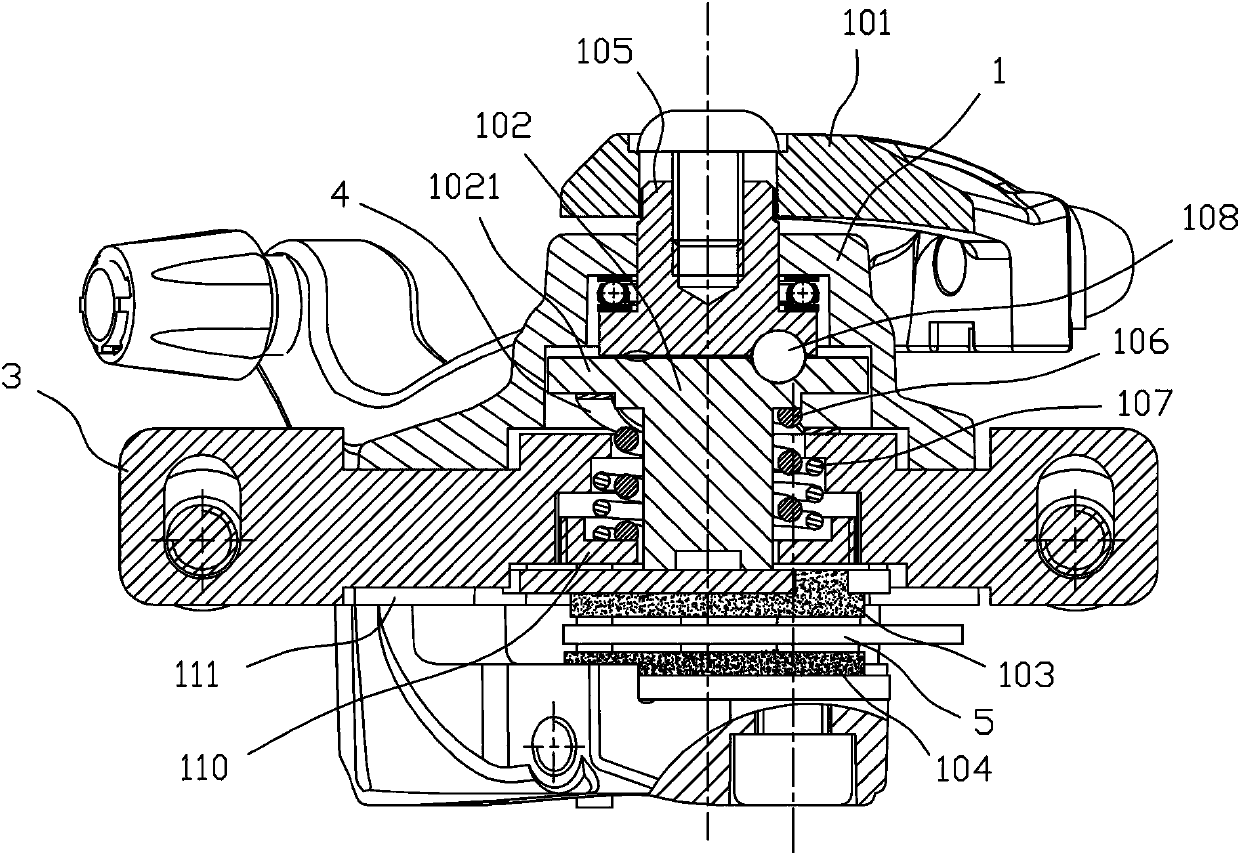

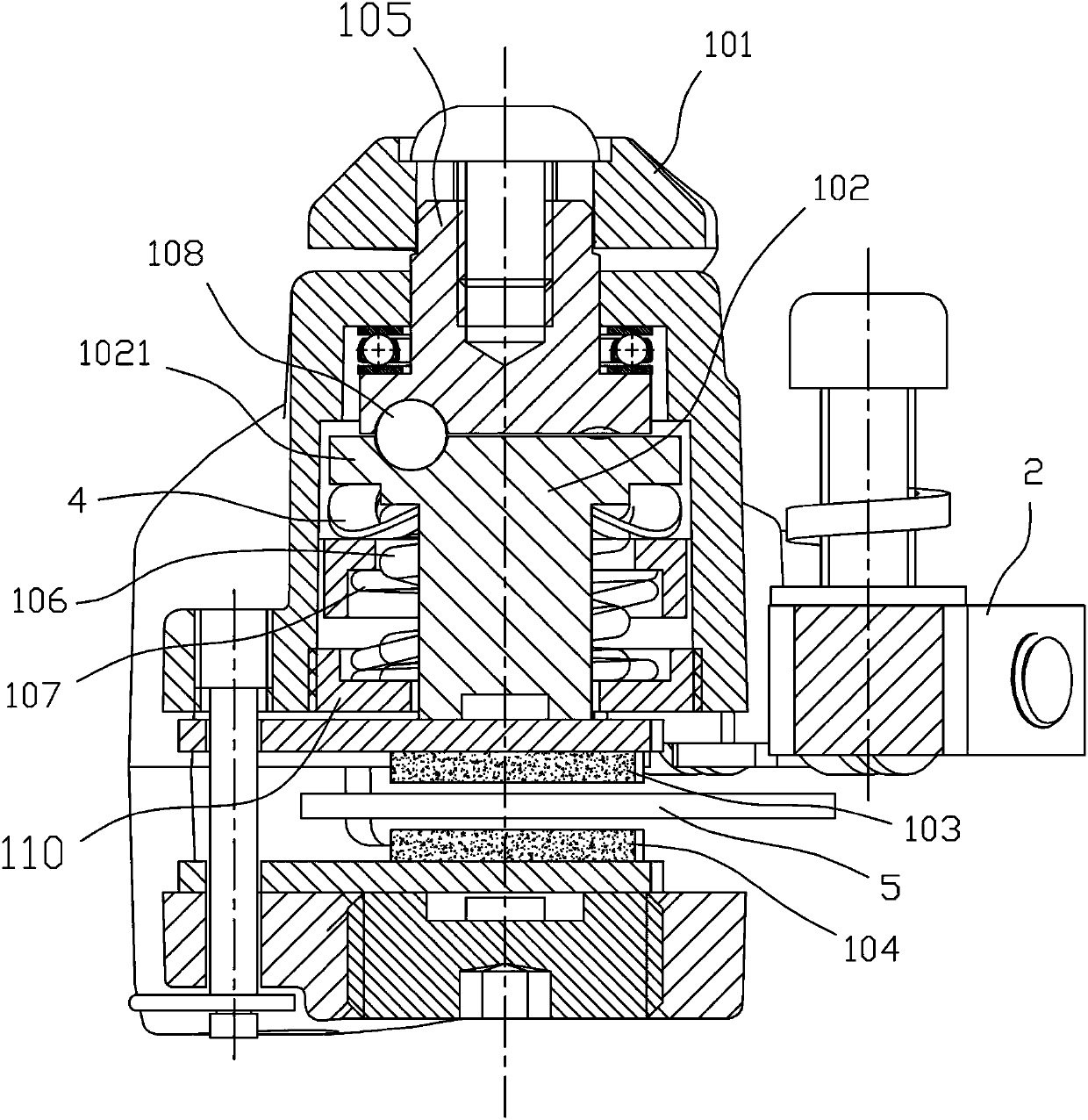

[0018] Depend on figure 1 , figure 2 , image 3 As shown, the mechanical double-action disc brake of the present invention includes a disc 5 and a caliper. The disc 5 is installed on the bicycle hub, and the disc 5 rotates synchronously with the wheel. The caliper is installed on the bicycle frame. The caliper includes a housing 1, a Based on the bracket 2 fixed to the car body and the connecting parts used to connect the bracket 2 and the housing 1, the housing 1 is provided with a driving arm 101, a driving disc 102 and a mechanism for resetting the driving disc 102 after moving. The first return spring 106 is connected between the drive arm 101 and the drive disc 102 to be used to convert the rotational motion of the drive arm 101 into the drive part of the axial movement of the drive disc 102, and the drive part and the housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com