Metal plate rolling and cooling integrated equipment

A metal plate, integrated technology, applied in the field of metal plate rolling, can solve the problems of metal plate offset, increase the labor and danger of the staff, avoid deflection, improve safety and automation, and reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

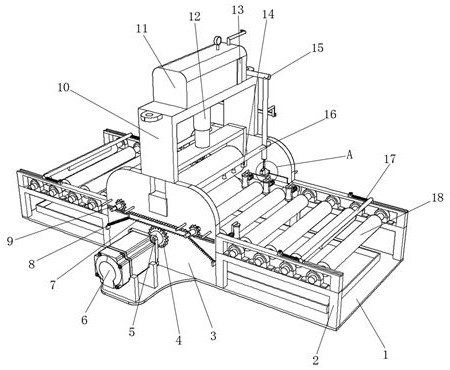

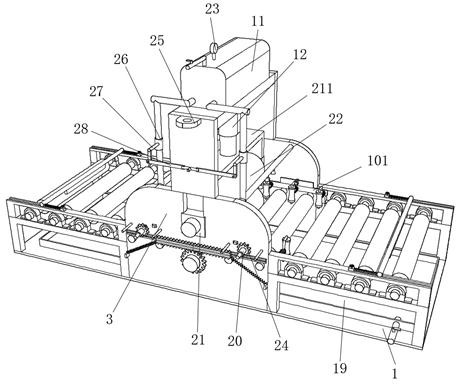

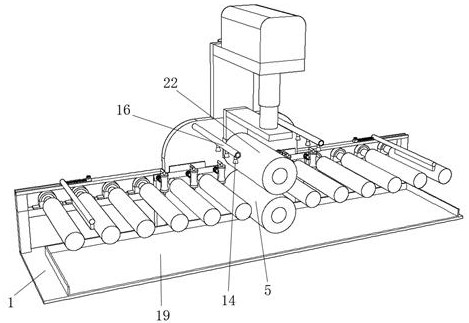

[0034] Such as Figure 1-Figure 7 As shown, a metal plate rolling and cooling integrated equipment includes a bottom plate 1, the upper surface of the bottom plate 1 is fixed with a frame 3 and a support frame 2 by bolts, and the support frame 2 is symmetrically distributed on both sides of the frame 3, and the frame The top of the frame 3 is fixed with a gantry 10 by bolts, and the inner wall of the top of the gantry 10 is fixed with a hydraulic cylinder 12 by bolts. Both sides of the frame 3 are provided with a first chute, and the first chute is slidingly connected with a first chute. Sliding block 21, the first sliding block 21 is rotatably connected with pressing roller 22, is fixed with lifting frame 211 by bolt between the tops of two first sliding blocks 21, and the top of lifting frame 211 and hydraulic cylinder 12 hydraulic rods One end is fixed, and the hydraulic cylinder 12 is activated, which can drive the lifting frame 211 to move, so that the pressure roller 22 ...

Embodiment 2

[0038] refer to Figure 1-Figure 7 , the present invention provides a new technical solution, a metal plate rolling and cooling integrated equipment, including a base plate 1, the upper surface of the base plate 1 is fixed with a frame 3 and a support frame 2 by bolts, and the support frame 2 is symmetrically distributed on the machine Both sides of the frame 3, the top of the frame 3 is fixed with a gantry 10 by bolts, the both sides of the gantry 10 are welded with a pull plate 25, and one side of the pull plate 25 is provided with a hanging hole, and the top inner wall of the gantry 10 The hydraulic cylinder 12 is fixed by bolts, the first chute is provided on both sides of the frame 3, the first slider 21 is slidably connected in the first chute, and the pressure roller 22 is rotatably connected between the first slider 21 A lifting frame 211 is fixed between the tops of the two first sliders 21 by bolts, and the top of the lifting frame 211 is fixed to one end of the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com