Optical fiber laser lamp pattern painting device

A technology of laser light and optical fiber, applied in the direction of spraying device, paint booth, etc., can solve problems such as accuracy improvement, pattern damage, poor pattern quality, etc., to achieve the effect of improved accuracy, convenient use, and avoidance of skew.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

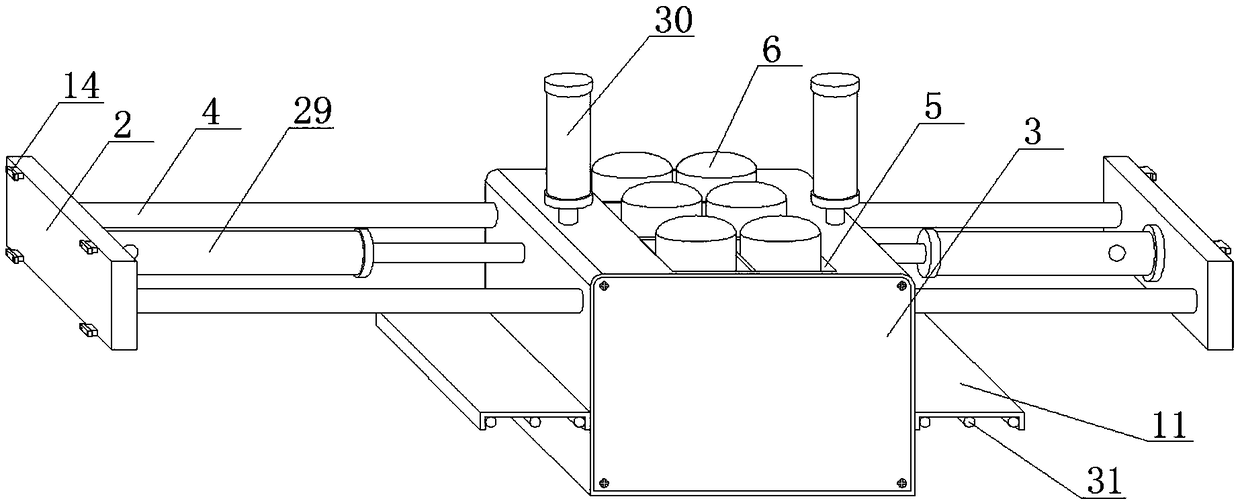

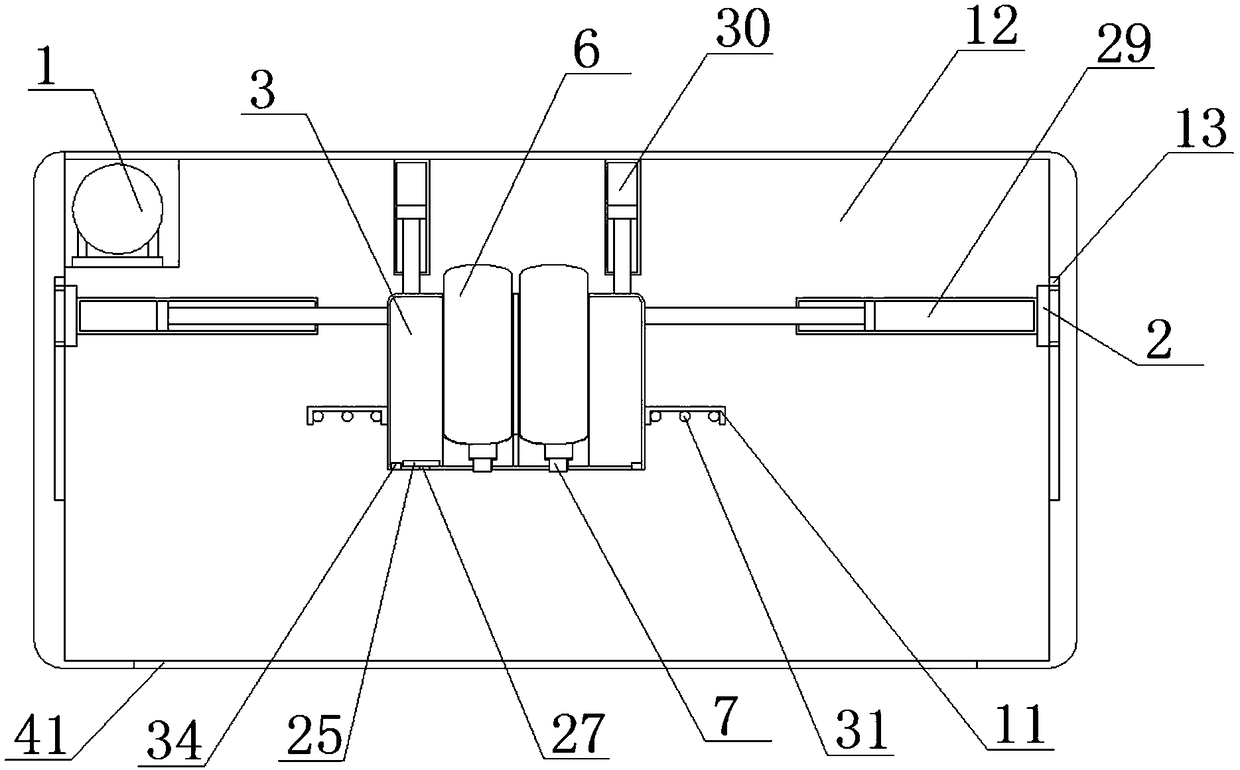

[0033] As a preferred embodiment of the present invention, the third electrode sheet 35 and the fourth electrode sheet 36 are electrically connected to the positive pole and the negative electrode of the electric valve 32 respectively, and the first electrode sheet 9 and the second electrode sheet 10 are connected to the electrode sheet three respectively. 35 contacts with electrode sheet four 36.

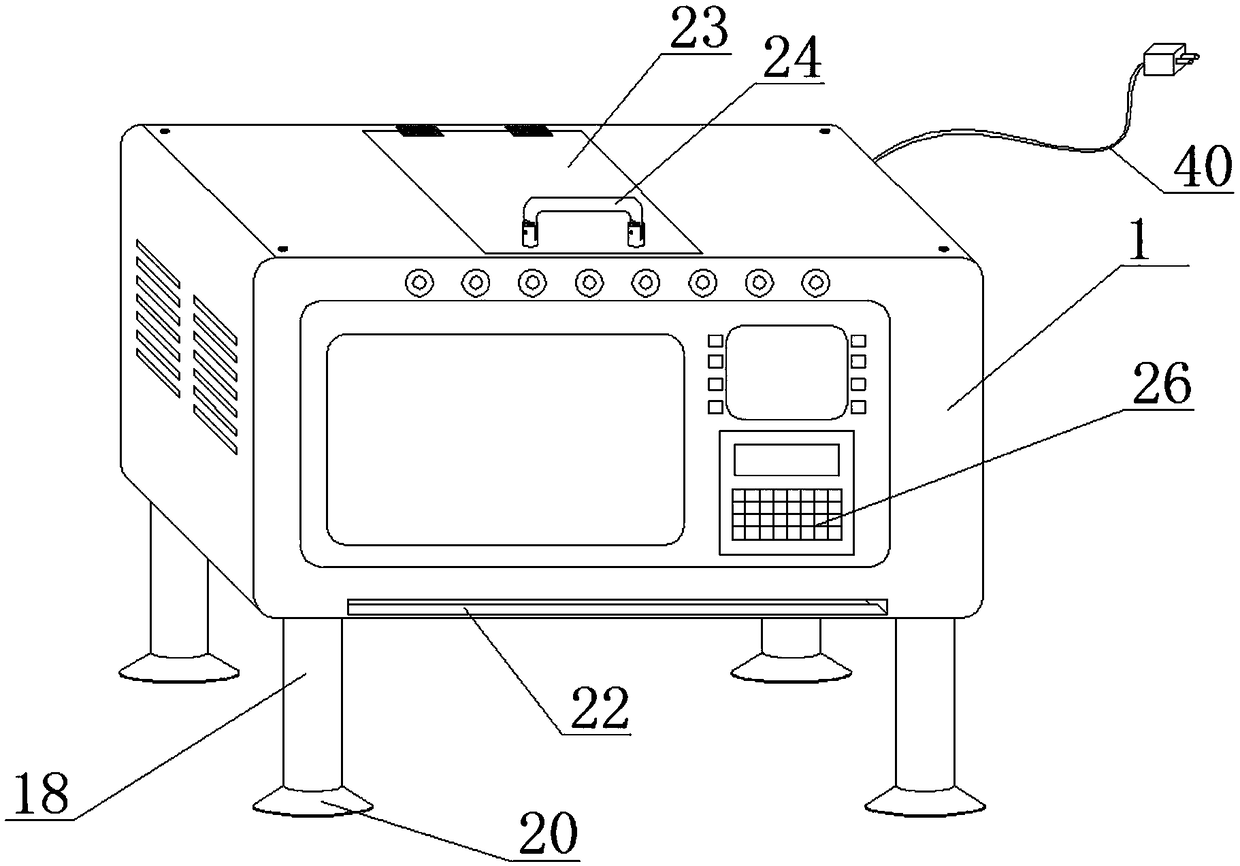

[0034] As a preferred embodiment of the present invention, the power cord 40 is respectively connected to the single chip microcomputer 25, the operation button 26, the distance sensor 27, the hydraulic rod one 28, the hydraulic rod two 29, the hydraulic rod three 30, the electric heating rod 31, Vacuum pump 33 and fiber laser lamp 34.

[0035] As a preferred embodiment of the present invention, a plug is connected to the power cord 40 , and a spraying port 41 is opened at the bottom of the housing 1 .

[0036] As a preferred embodiment of the present invention, the single-chip mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com