Disc type scanning electrode mask film microelectrolysis electrical discharge machining system and machining method

A scanning electrode and electrical discharge machining technology, which is applied in the field of disk-shaped scanning electrode mask micro-electrolytic electrical discharge machining systems, can solve the problems of poor verticality of the sidewall of the microstructure, unbalanced loss, and difficult to control the cross-sectional shape, and achieves high localization and loss. Balanced, updated and effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

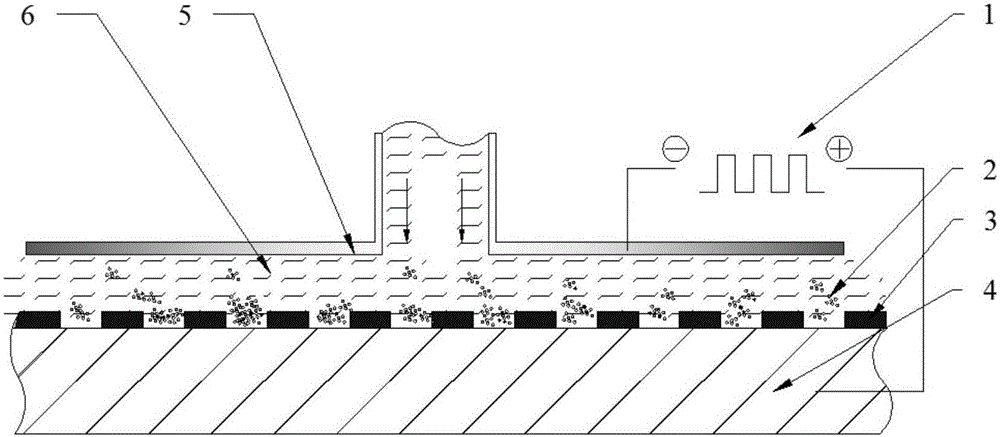

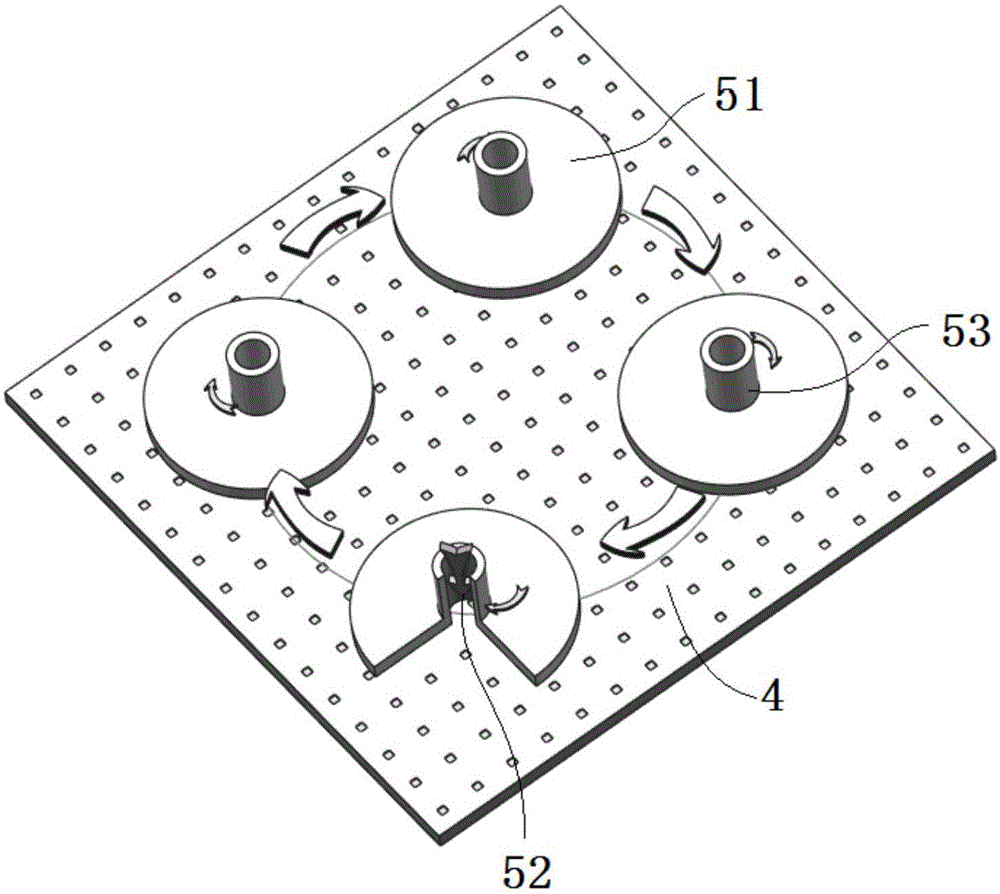

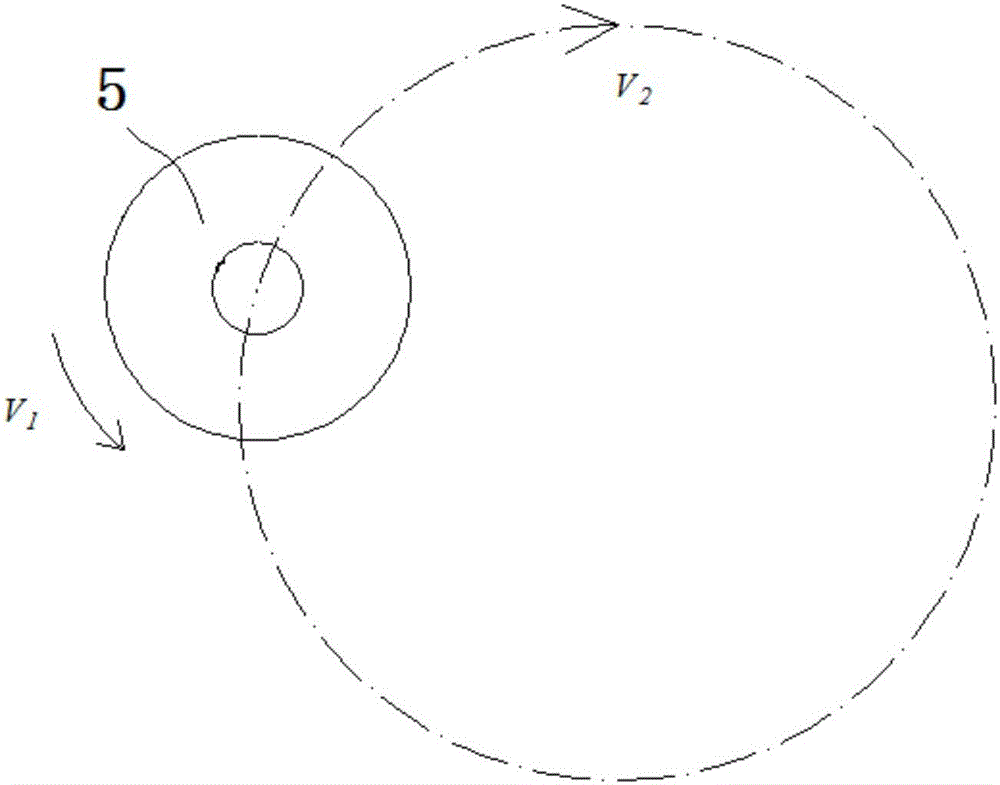

[0028] Disc scanning electrode mask micro-electrolysis EDM system, such as Figure 1-Figure 2 As shown, it includes a workpiece 4, a disc electrode 5 and a working fluid 6. The processing surface of the workpiece 4 is covered with a mask 3, and the mask 3 is provided with a processing window according to processing requirements, and the workpiece 4 is placed in the working fluid. 6, the disc-shaped electrode 5 is located in the working fluid 6 above the workpiece 4, and the workpiece 4 and the disc-shaped electrode 5 are connected to the power source 1 through wires. Bubbles 2 overflow from the processing window during processing. The disk-shaped electrode comprises a rotating surface 51 and a connecting shaft 53 fixed on the rotating surface. cavity. The diameter of the central liquid outlet 52 is 0.1-0.12 times the diameter of the outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com