Drawing and trimming die

A technology of molds and trimming knives, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems that the oblique wedge is difficult to reach the working state, affects product quality, and affects the life of the mold, so as to achieve stable clearance and improve service life , Guarantee the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

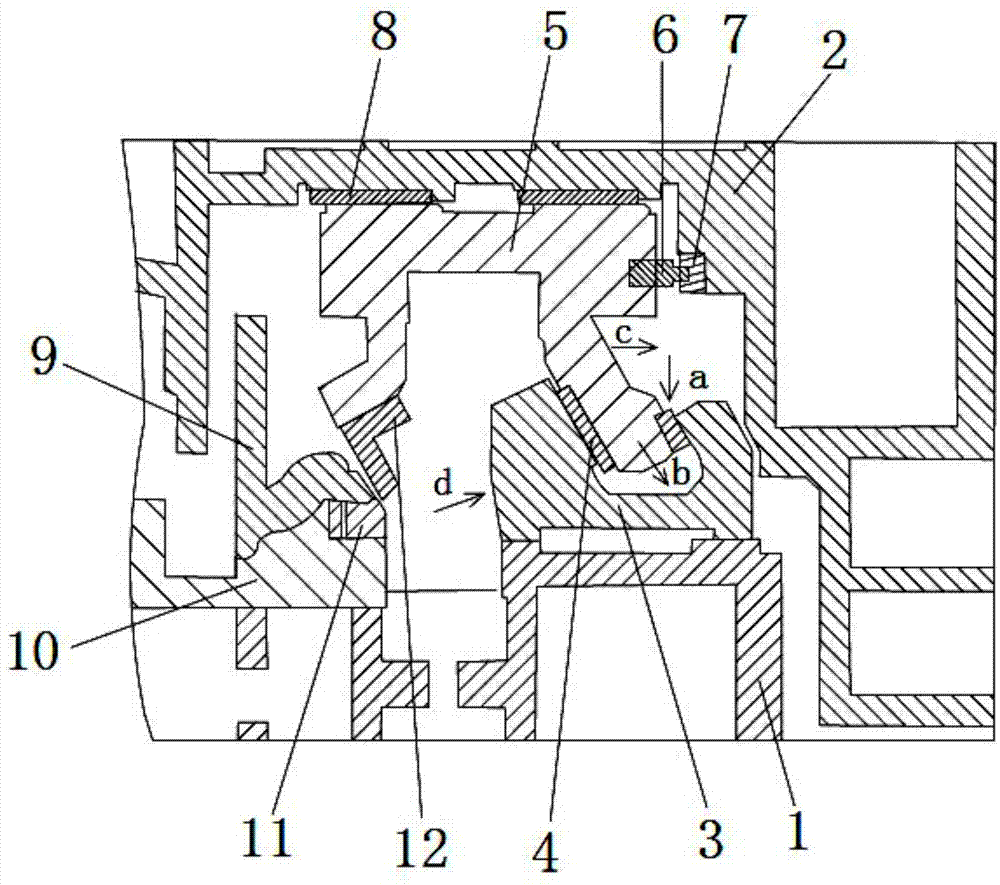

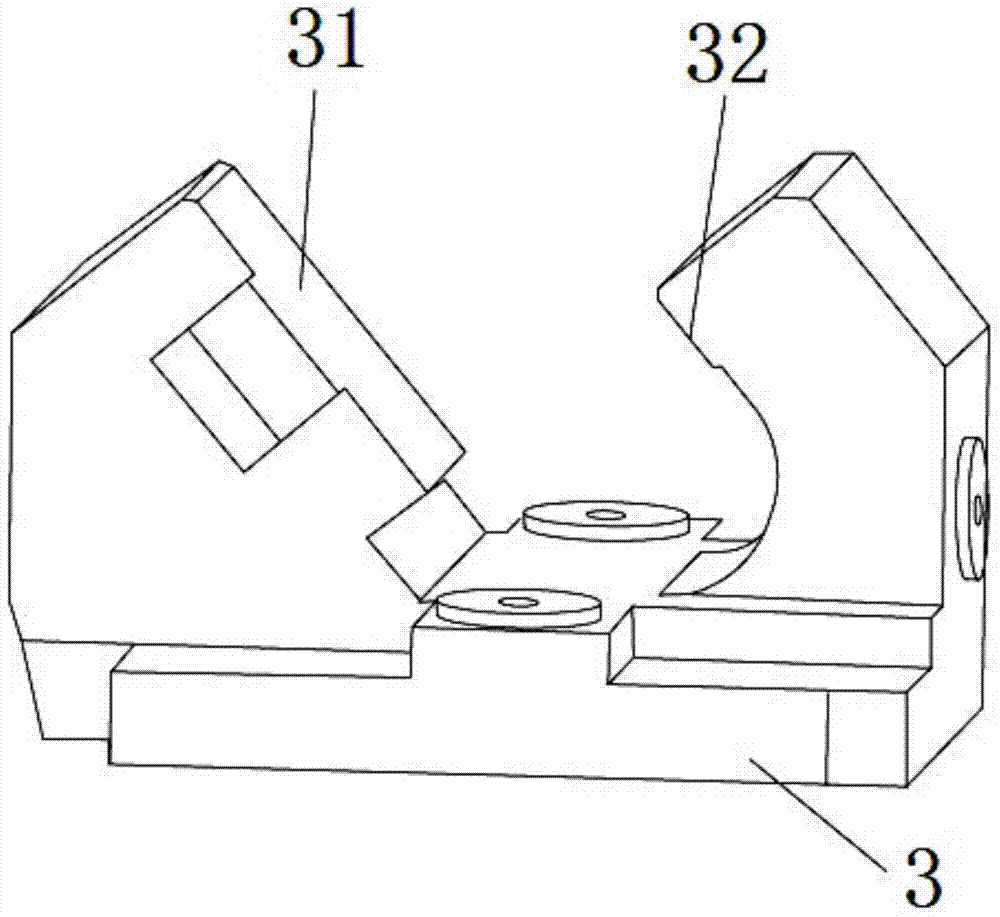

[0021] The present invention pulls repair mold, as figure 1 As shown, including lower die 1, upper die 2, upper trimming cutter block 12, lower trimming cutter block 11, wedge slide block 5 is arranged in upper die 2, driving block 3 is located on lower die 1, driving block 3 It is a double-sided sliding drive block with two opposite slopes. The downward movement of the upper mold 2 drives the wedge slider 5 to move, and the wedge slider 5 is placed between the two slopes of the driving block 3 and slides in contact with the two slopes. The upper trimming knife block 12 is located at one end of the wedge slide block 5, opposite to the plate to be trimmed, and the lower mold trimming knife block 11 is fixed on the lower mold 1 through the lower mold insert 10. The inclined wedge slide block 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com