Brake for railway vehicle unit

A rail vehicle and brake technology, which is applied to the operating mechanism of the brake of the railway vehicle, the brake wear compensation mechanism, the railway braking system, etc., can solve the problems of weakening the braking effect, slow stroke adjustment, low transmission efficiency, etc. Uniform, space-saving, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

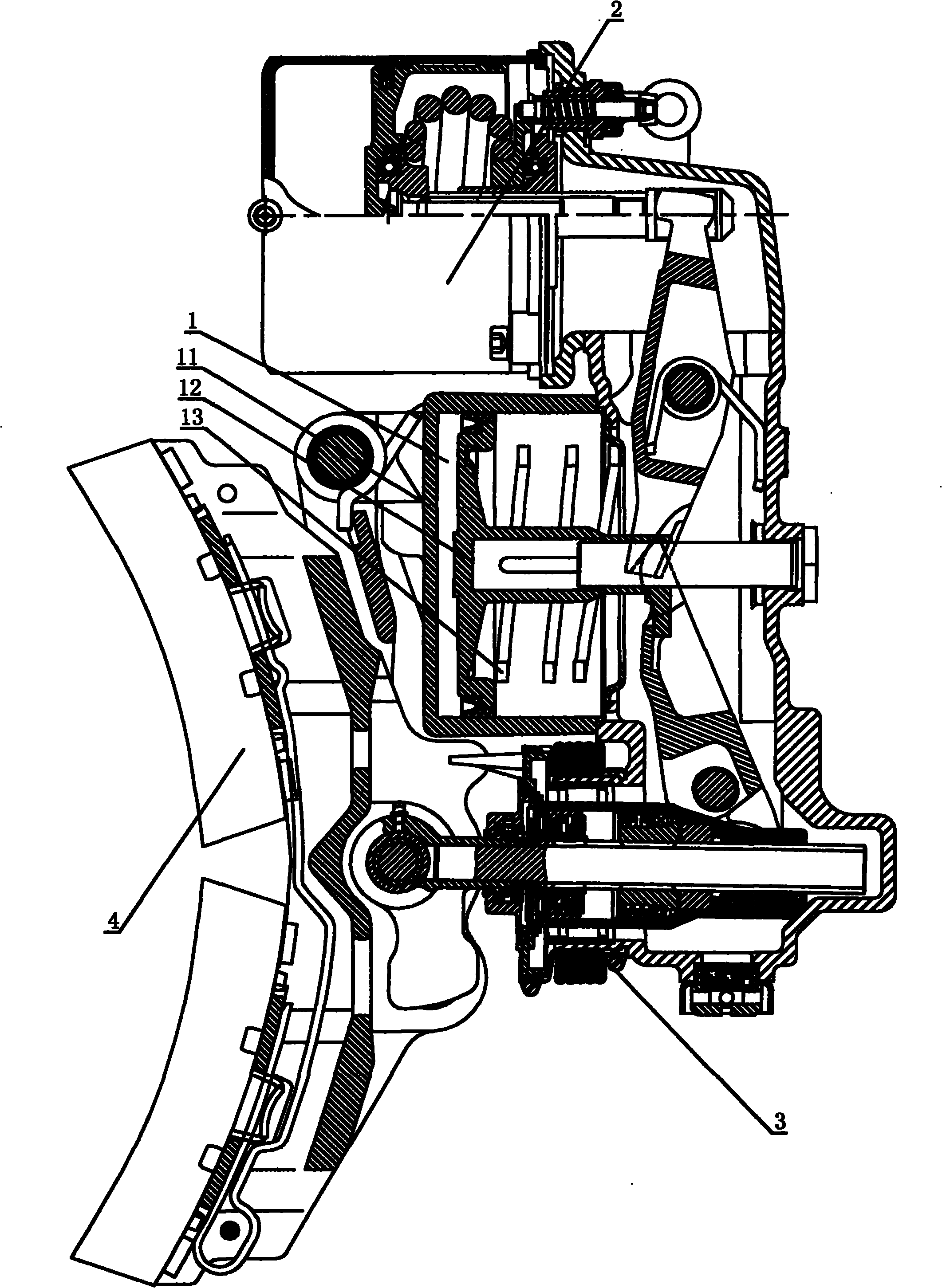

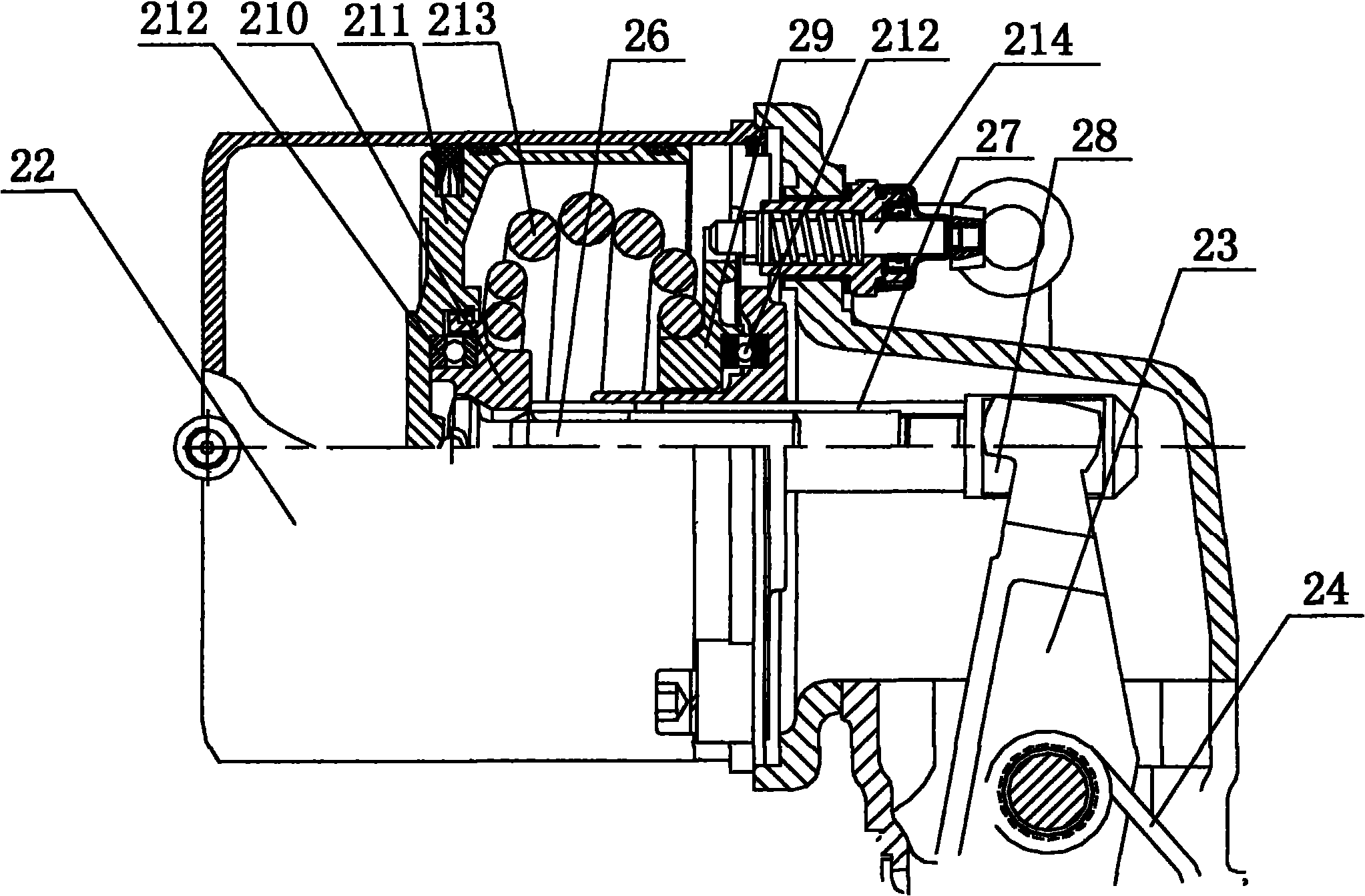

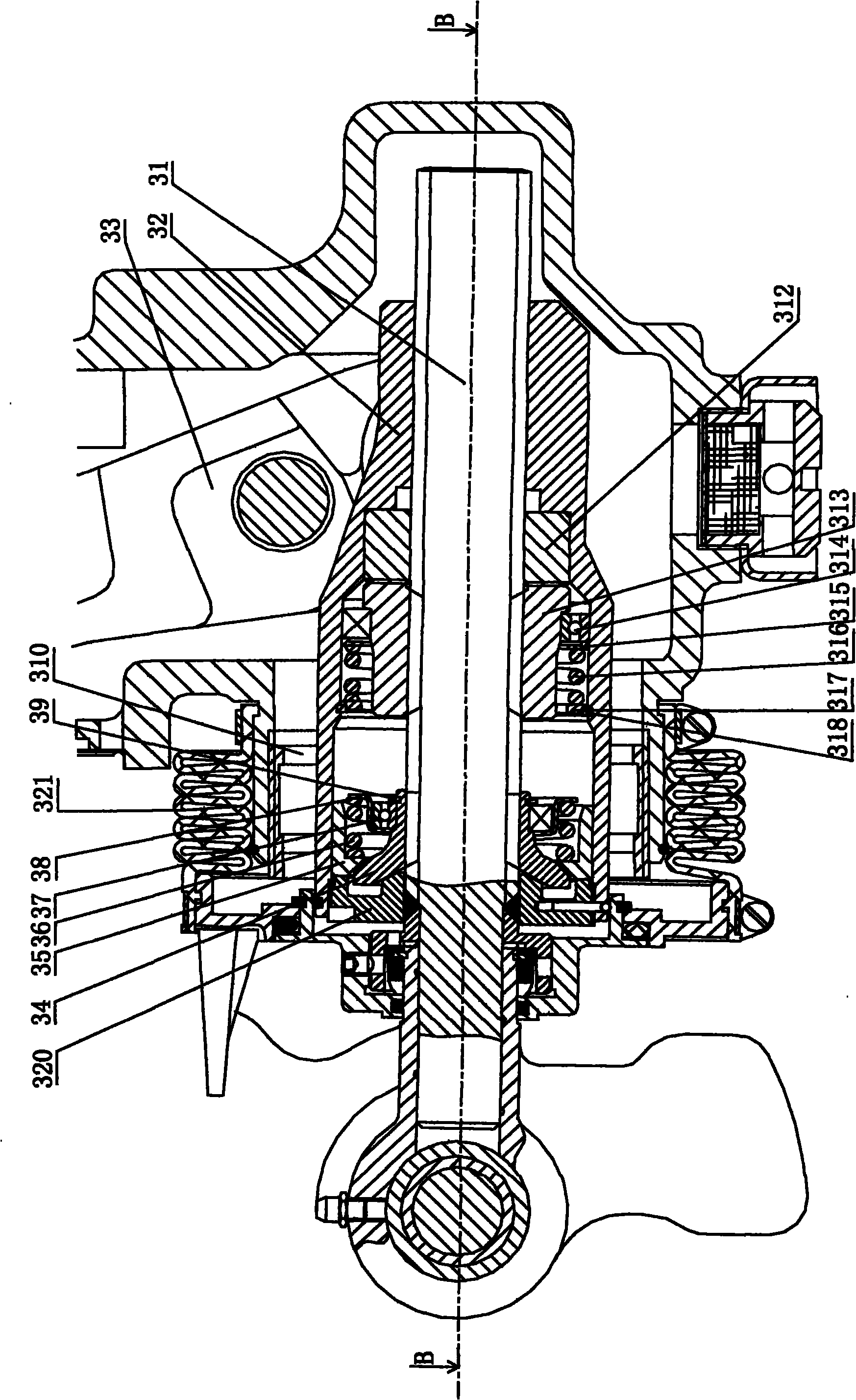

[0019]A rail vehicle unit brake, provided with a brake box, a brake release device 1 located on the brake box, a spring parking device 2, a brake shoe wear gap compensation adjustment device 3, and a brake shoe component 4 located in the brake shoe wear gap The end of the compensation adjustment device 3, the brake relief device includes a brake cylinder 11, the brake lever 12 of the brake cylinder 11 is linked with the brake lever 33 and the spring parking lever 23, and the end of the brake lever 33 Cooperate with the brake shoe wear gap compensation adjustment device, the spring parking lever 23 cooperates with the spring parking device; the spring parking device includes a spring cylinder 22 arranged on the brake box, and the power of the spring cylinder 22 The spring parking lever 23 connected by the output rod, the spring parking lever 23 is axially connected to the brake box, and a torsion spring 24 is arranged between the spring parking lever 23 and the brake box. During...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com