Method for improving installation flatness of ship distribution board

A switchboard, flatness technology, used in switchgear, electrical components, ships, etc., can solve the problems of the installation accuracy of switchboards that are difficult to meet the requirements on land, large loss, and labor, material and financial resources. , to achieve the effect of easy installation and adjustment, high precision and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

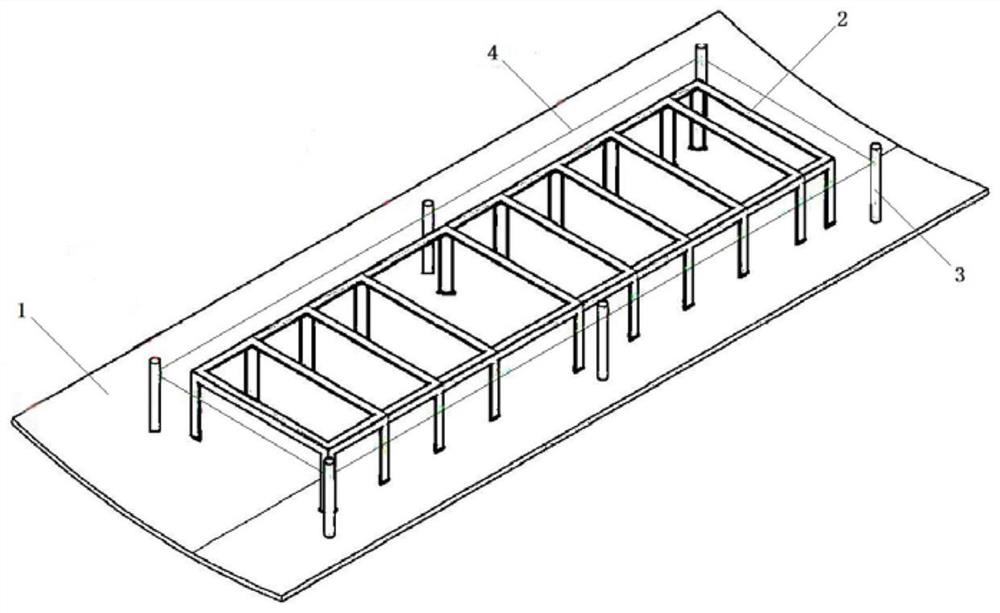

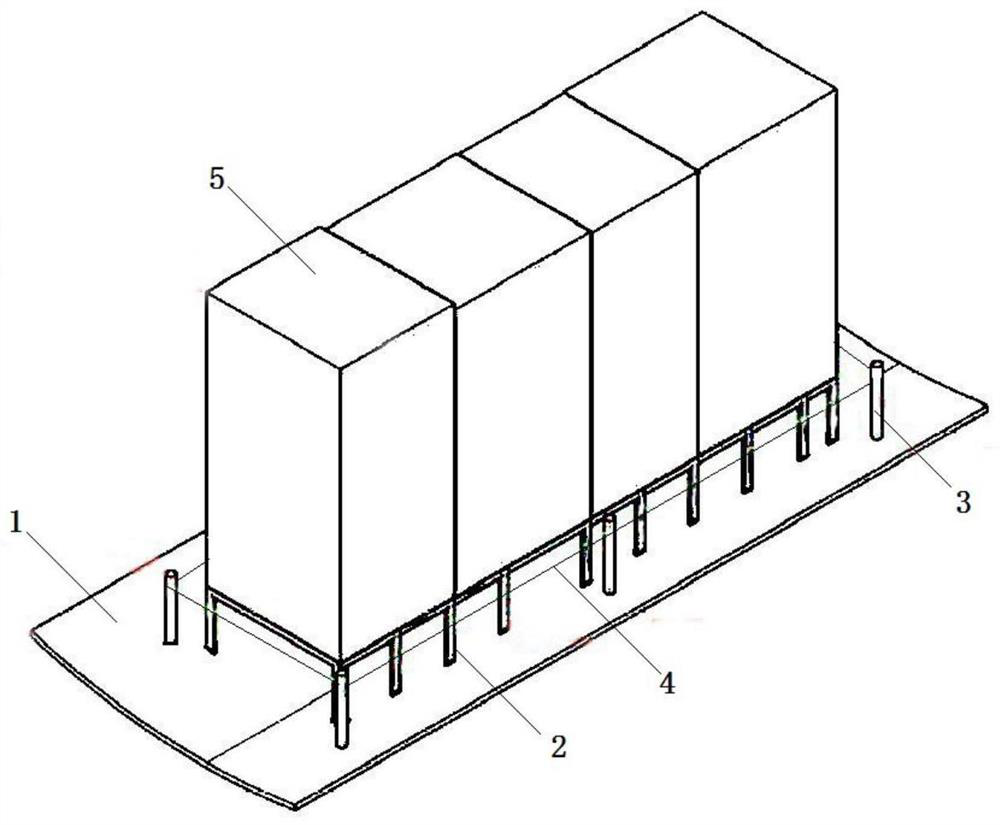

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing: a kind of method for improving the flatness of ship switchboard installation, comprises hull deck 1 and switchboard 5, and hull deck 1 is provided with base 2 and several The column 3 and the hull deck 1 are formed by butt jointing of segmented steel plates, specifically including the following steps:

[0024] Step 1. Measure the flatness of the hull deck 1 in the power distribution room. If the measured height difference between the segmented steel plates is greater than the range of plus or minus 3 millimeters, fire attack the segmented steel plates to meet the structural requirements. .

[0025] Step 2, adjust the level of the base 2, position the base 2 to the specified position, and install several columns 3 at equal intervals on the hull deck 1 around the base 2, use a total station or a horizontal laser Measure the horizontal plane found on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com