Fabricated cement board force transmission component, cement board and preparation and construction method of cement board

A cement board and assembly technology, which is applied in the direction of manufacturing tools, pavements paved with prefabricated blocks, roads, etc., can solve the problem of damage to the surface texture flatness of prefabricated slabs, the decline of prefabricated slab load transfer performance, and the operation space should not be too large, etc. problems, to achieve the effect of ensuring load transfer capacity, ensuring flatness and aesthetic requirements, and ensuring flatness and aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

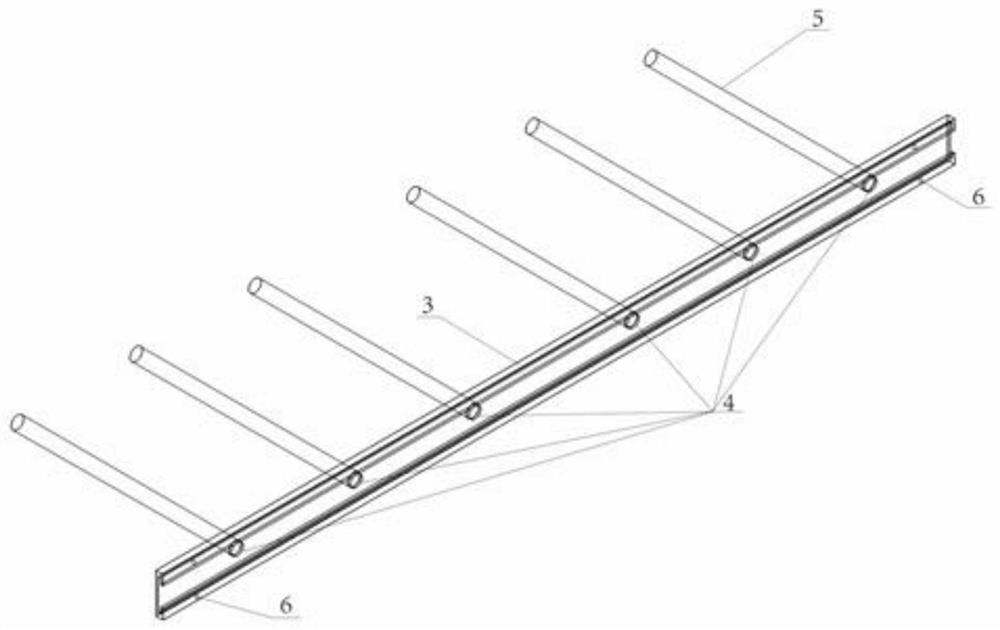

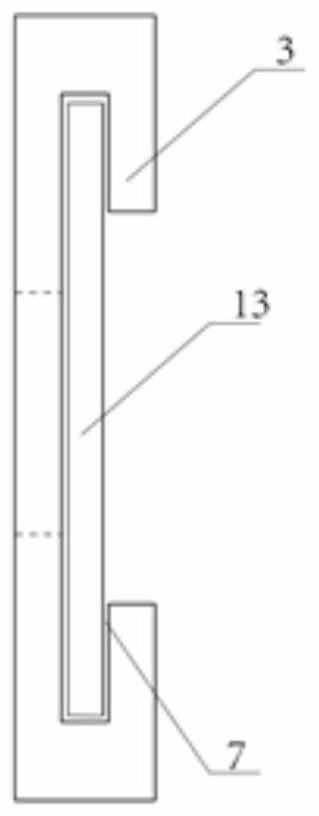

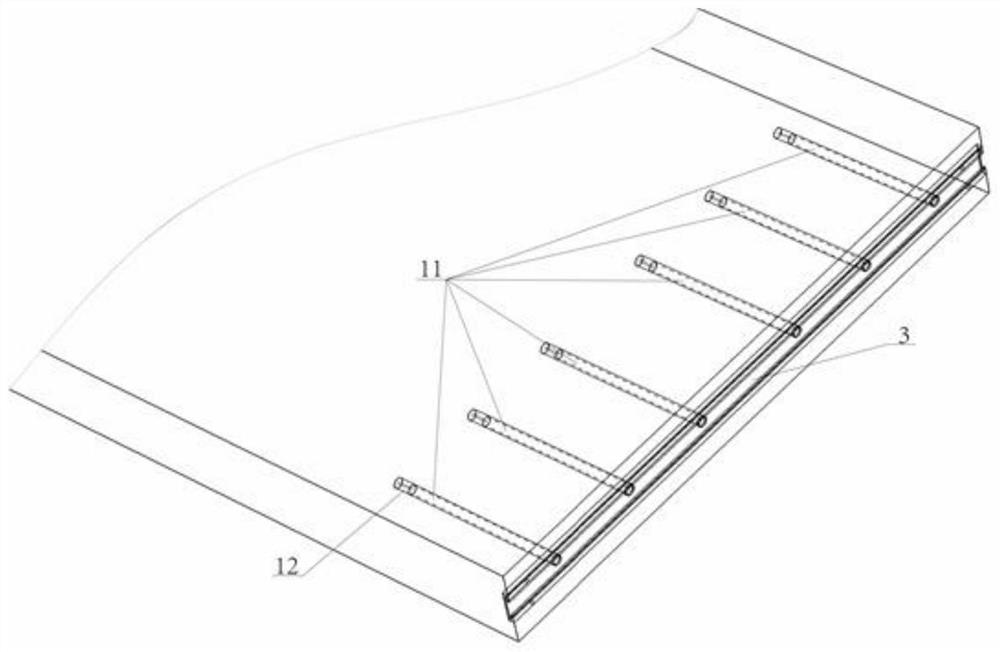

[0041] refer to Figure 1-5As shown, the present embodiment provides an assembled cement board force transmission member, including a guide plate 3, a number of launch sleeves 5 fixedly connected vertically with the guide plate 3, the guide plate 3 is provided with a number of guide holes 4, and the launch sleeve 5 It communicates with the guide hole 4, an elastic dowel assembly is provided in the launching sleeve 5, and the side of the guide plate 3 far away from the launching sleeve 5 is provided with a blocking portion for blocking the elastic dowel assembly, and the blocking portion is away from the launching sleeve 5 by one A targeting sleeve 10 is arranged on the side, and the targeting sleeve 10 is located on one side of the moving direction of the elastic dowel assembly and arranged in line with the launching sleeve 5 .

[0042] The elastic dowel assembly is arranged in the launching sleeve 5, and the blocking part is used to block the elastic dowel assembly. When asse...

experiment example

[0064] Design prefabricated slabs with upper opening and lower opening with the same plate thickness, calculate the maximum stress, strain and vertical displacement of the joints of the prefabricated slabs under the action of the standard shaft load BZZ-100 through finite element software, and compare with the joint structure of this embodiment The mechanical performance is compared, and the three design schemes and their analysis results are shown in Table 1.

[0065] Table 1 The force analysis and calculation results of the joints of precast slabs under the influence of three types of load-transfer structures

[0066]

[0067] According to the above data analysis, the stress and strain levels of the cement boards of this application at the joints are lower than those of the upper and lower open prefabricated boards. The maximum vertical deformation of the joints of the cement board of the present application is reduced by 30% under static load. Compared with the method of...

Embodiment 2

[0069] refer to Figure 6 As shown, the difference between the prefabricated cement board of this embodiment and Embodiment 1 is that the launching sleeve 5 and the targeting sleeve 10 are located on the same side wall of the prefabricated cement concrete board 1 and are arranged in a staggered manner, and the targeting sleeve 10 and the The guide hole 4 communicates, and the launching sleeve 5 corresponds to and is collinear with the targeting sleeve 10 in the adjacent prefabricated cement concrete slab 1 .

[0070] The prefabricated cement board of this embodiment can realize the mutual assembly of the four sides of a prefabricated cement board, which is more convenient in the process of laying the road surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com