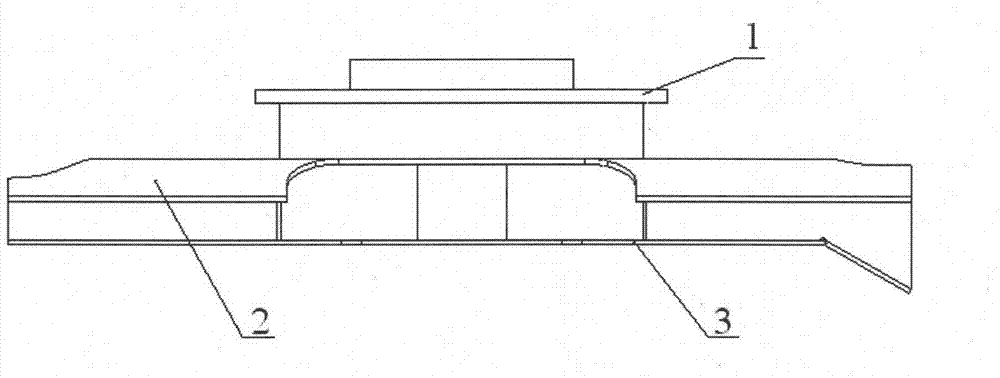

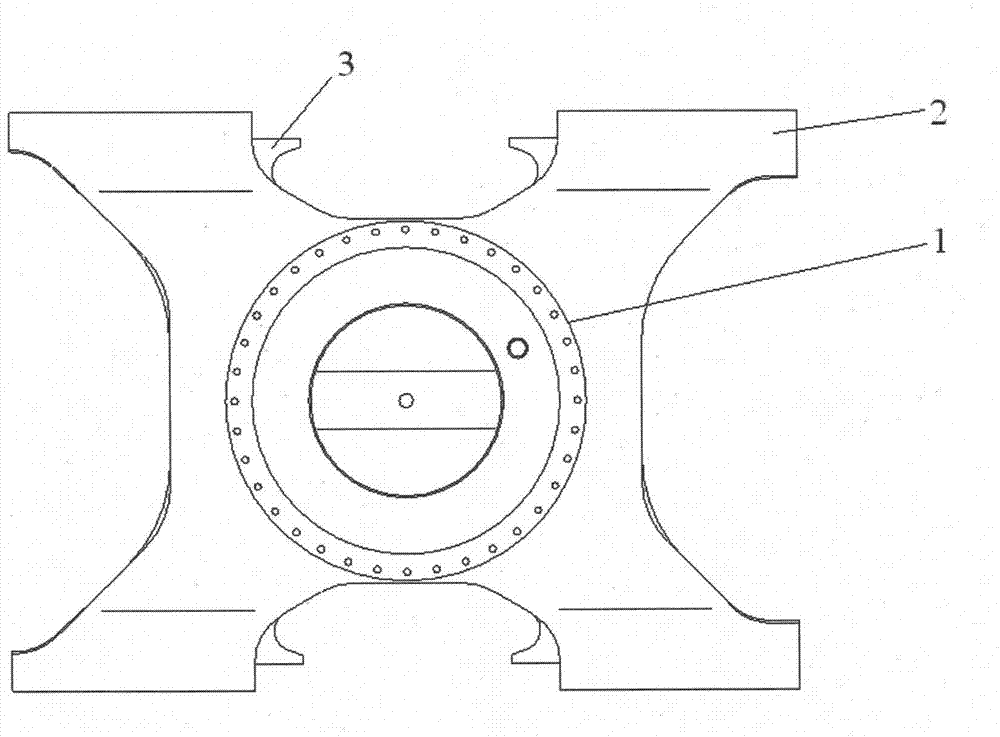

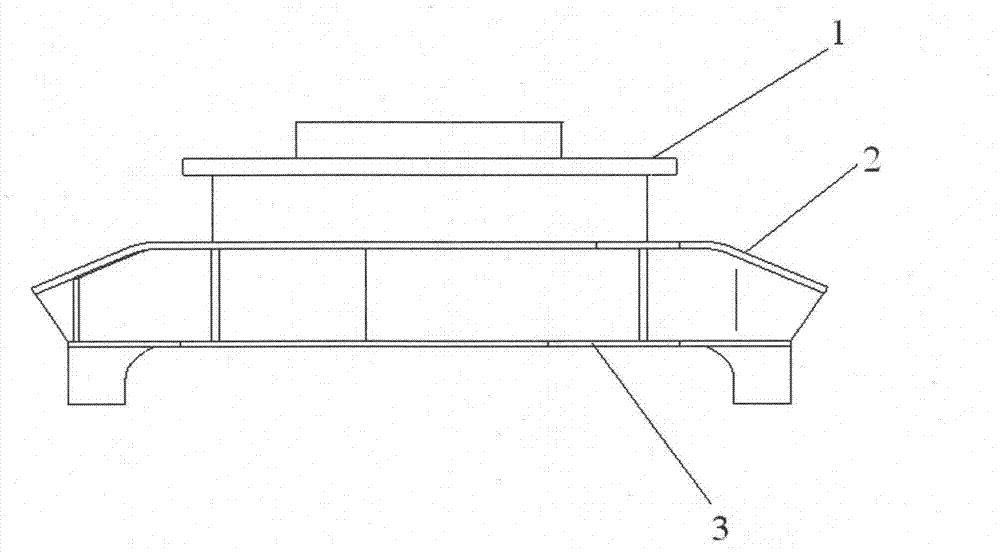

Machining method for hydraulic excavator walking bar body

A hydraulic excavator and machining technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of uneven thickness of the connecting plate 1 of the slewing bearing seat, affecting the performance of the whole machine, etc. The effect of size, improvement of processing efficiency, and reduction of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

[0024] A mechanical processing method for the main body of a hydraulic excavator walking frame, using a clamp body, combining Figure 4 ~ Figure 6 , The clip body is divided into left and right parts. Left part: there are four lifting lugs 8 on the left bottom plate 10, which is convenient for hoisting; two linear slide rails 17 are fixed on the left bottom plate 10, and the sliding support 6 is installed on the linear slide rail 17 through the seat slide 18, and the sliding support 6 Connect together with the left V-shaped block 11. The left V-shaped block 11 can slide left and right along the linear slide rail 17 by manual promotion. A first support 9 and a second support 15 are respectively installed on the outer sides of the two linear slide rails 17 . When clamping, the movable crossbeam 5 is supported on the first support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com