Closed-loop polyester film conveyor belt connecting device of drier and connecting method thereof

A polyester film and connecting device technology, applied in the field of continuous low-temperature film drying, can solve the problems of easy falling off of the joint, wrinkles on the surface of the belt, and uncontrollable straightness, and achieve the effects of simplifying the structure, ensuring the strength of the connection, and ensuring the straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

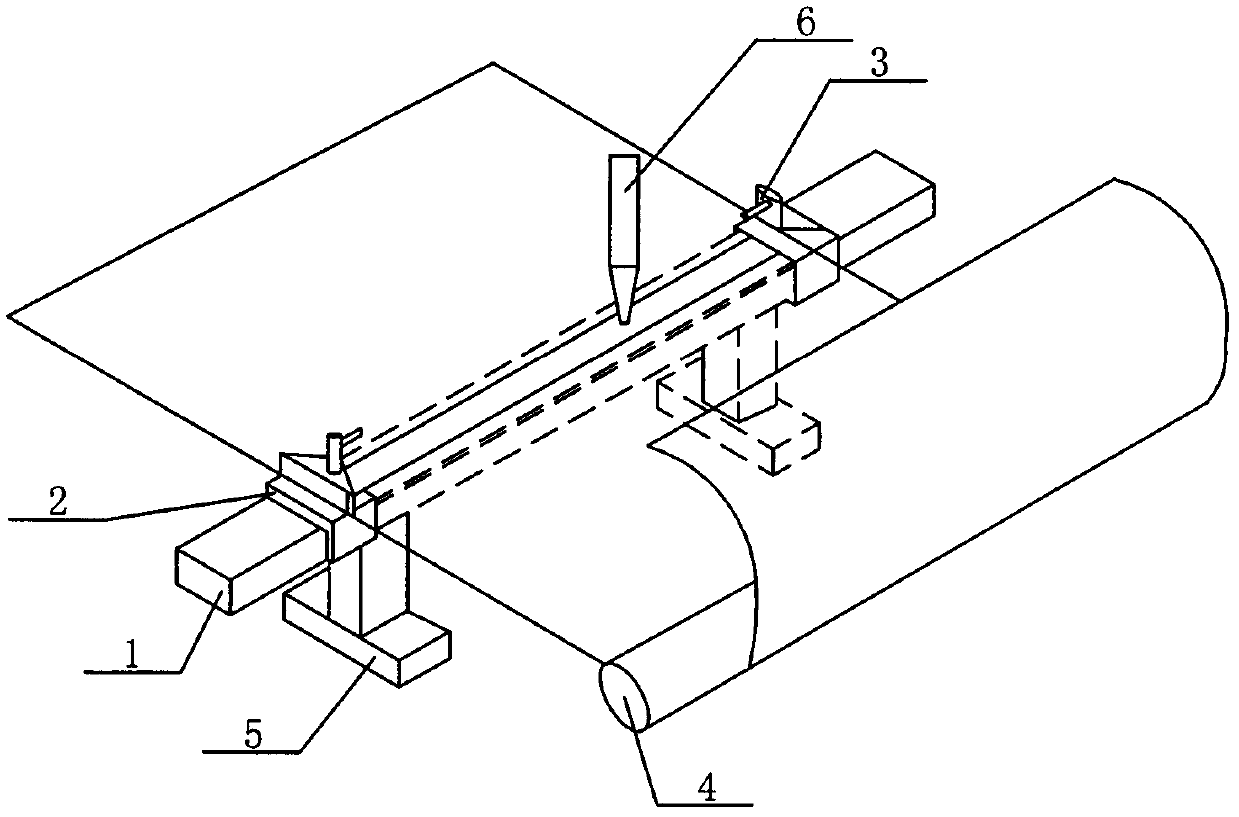

[0015] see Figure 1-2 , the specific embodiment adopts the following technical solutions: it includes a welding platform 1, an adjustment seat 2, a pressing device 3, a drive shaft 4, a base 5 and a high-frequency plastic welding machine 6; the adjustment seat 2 is slidably arranged on the welding platform 1 Above, the pressing device 3 is connected to the adjustment seat 2 through threads, the driving shaft 4 is set on one side of the welding platform 1, the two bases 5 are fixed on the lower part of both ends of the welding platform 1, and the high-frequency plastic welding machine 6 can be moved. On the top of the welding platform 1.

[0016] Connection method of the present invention is:

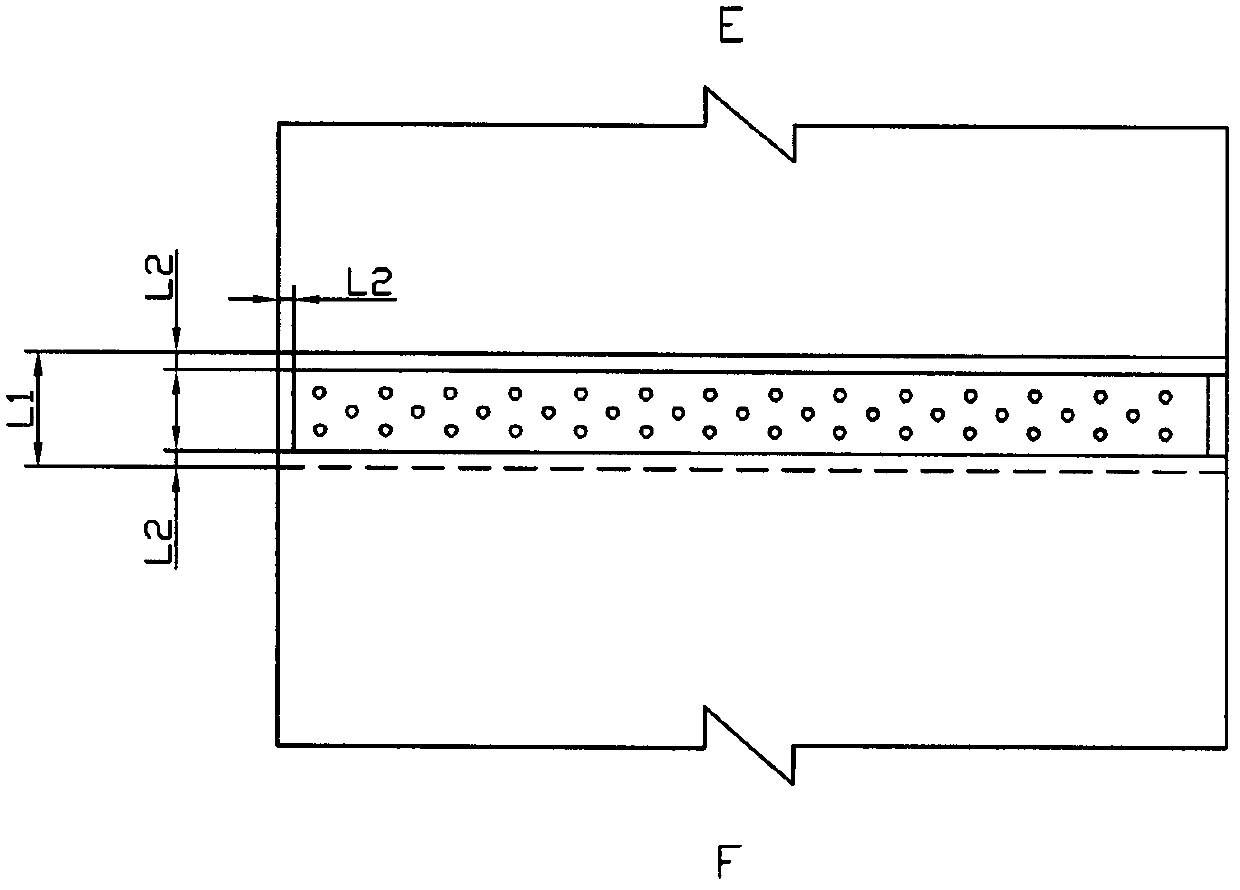

[0017] 1. Move the adjustment seat 2 so that the distance between the inner end surfaces of the two adjustment seats is the width of the welded belt, and the tolerance is within 0 ~ +0.5mm, and tighten the bolts to fix the adjustment seat.

[0018] 2. Rotate the compression device 3 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com