Connection assembly for elevator guide rails and connection fixing method for elevator guide rails

A technology for connecting components and elevator guide rails, which is applied in elevators, transportation, and packaging. It can solve the problems of affecting the straightness of the rails, unstable elevator operation, and easy noise generation, so as to improve production efficiency, reduce labor intensity, and improve the efficiency of elevators. running stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

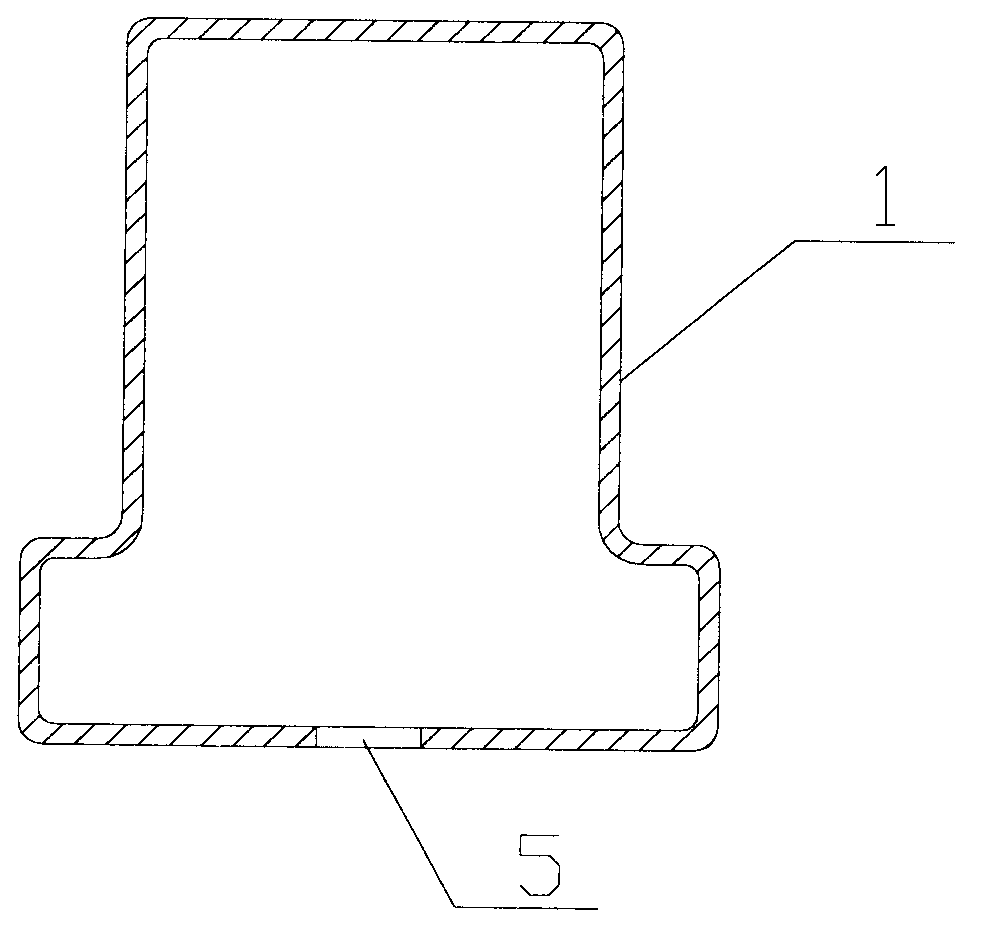

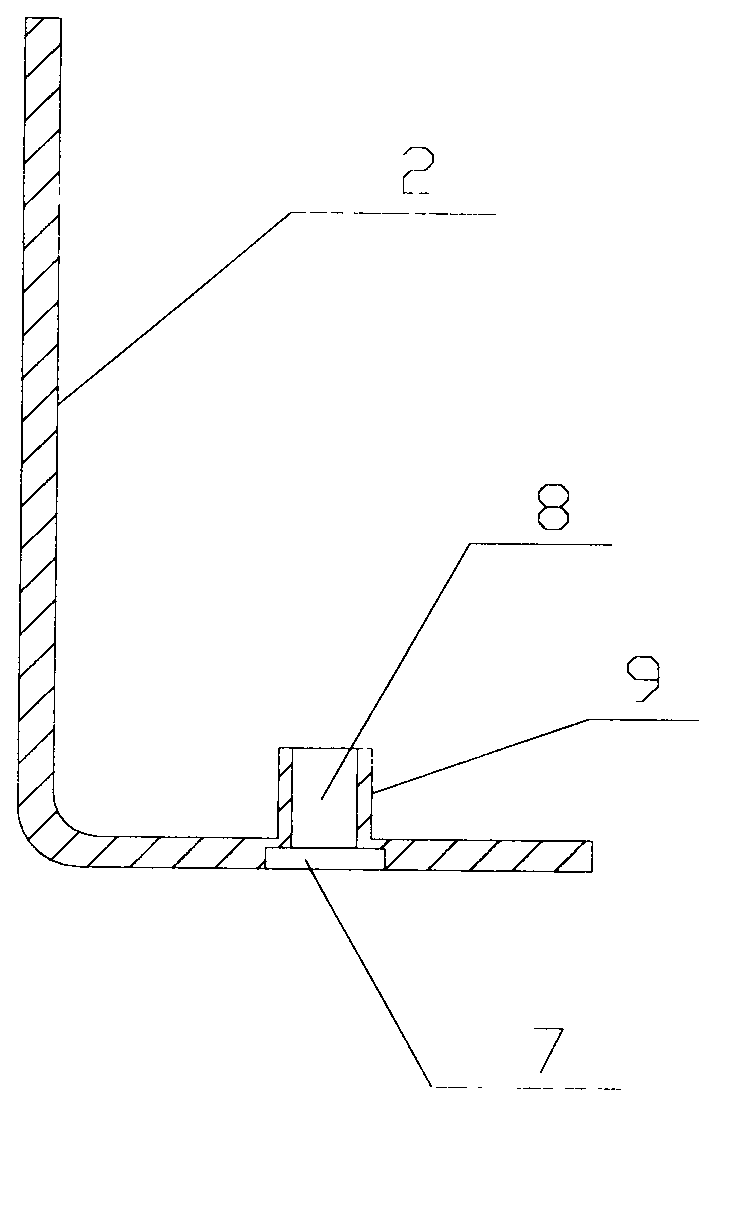

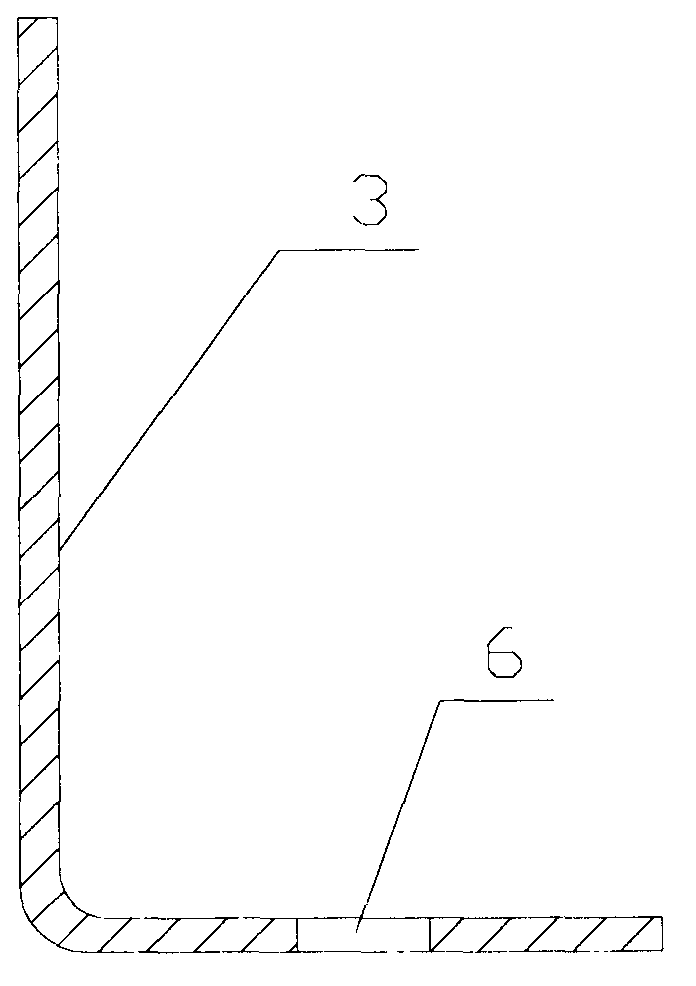

[0037] Please also see Figure 1 to Figure 6 , as shown in the figure, a connecting assembly for the guide rail of an elevator, the connecting assembly is arranged at the junction of multiple sections of guide rails connected end to end in sequence, the guide rail 1 is fixed on the guide rail bracket (not shown), and the guide rail and the guide rail bracket are connected and fixed with The pressing plate 10 effectively fixes the guide rail and the guide rail bracket through the pressing plate 10 .

[0038] The guide rail 1 is a T-shaped closed hollow guide rail, and the two ends of the connecting components are inserted into the guide rail 1 to connect and fix with the guide rail 1; the structural strength of the guide rail is effectively enhanced by adopting the T-shaped closed hollow guide rail. By using connecting components to connect and fix the two end-to-end guide rails from the inside, on the one hand, the strength of the guide rails can be increased, and on the other...

Embodiment 2

[0054] The rest is the same as that of Embodiment 1, except that the connection assembly is a U-shaped structure integrally formed, and the two sides of the U-shaped structure are inclined outward, forming an angle of 92° with the bottom edge.

[0055] The invention discloses a connecting assembly for an elevator guide rail and a method for connecting and fixing the elevator guide rail. The guide rail adopted in the invention is a T-shaped closed hollow guide rail, and the structural strength of the traditional hollow guide rail is correspondingly increased. There is a connecting component between two adjacent guide rails, and the two ends of the connecting component are inserted into the guide rail and fixed with the guide rail; by setting the connecting component on the inner side of the guide rail, unevenness when the guide rails are connected in series can be avoided, and the straightness requirements between the guide rails can be guaranteed. . By arranging the connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com