Manufacturing method for cast aluminum type engine blocking cover

A manufacturing method and engine technology, applied in the field of machining, can solve the problems of concave in the middle part of the end face, the flatness of the end face cannot meet the expected requirements, and without any support, so as to increase the pressing force, meet the requirements of lightweight, and facilitate the positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

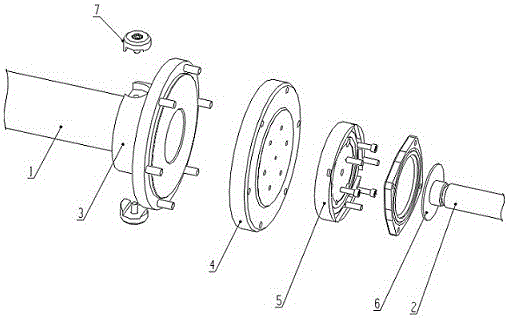

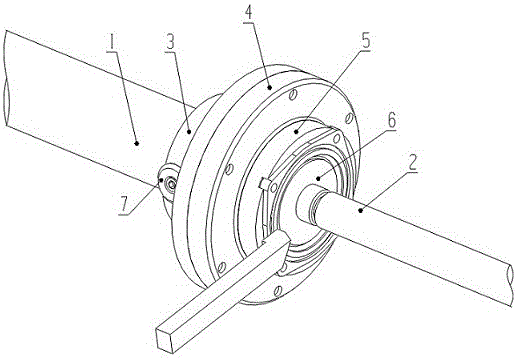

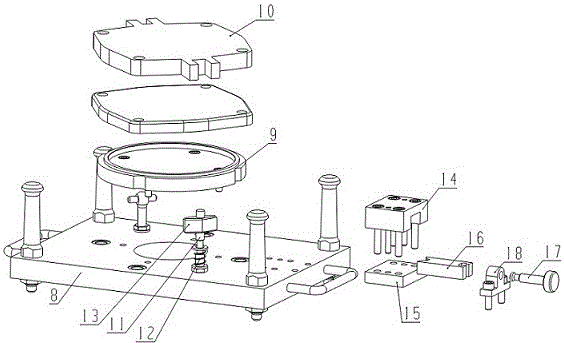

[0042] One end of the flange sleeve 3 with the flange and the seat plate 4 are fixedly installed by bolts. There are two ways of positioning the seat plate 4 and the flange sleeve 3: one is that the side of the seat plate 4 in contact with the flange sleeve 3 is provided with a positioning groove, and the flange sleeve 3 is provided with a groove that passes through the positioning groove. Cooperate with the protrusion for positioning the seat plate 4; the other is that the side of the seat plate 4 in contact with the flange sleeve 3 is provided with a protrusion, and the flange sleeve 3 is provided with a protrusion for positioning the seat plate 4 by cooperating with the protrusion positioning groove. The cooperation mode between the above-mentioned boss and the positioning groove is a transition fit. The other side of the seat plate 4 is fixedly installed with a disc-shaped blocking cover clamping plate 5, and the blocking cover clamping plate 5 completes fastening and pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com