Real-time leveling system suitable for projection photoetching machine and leveling method of real-time leveling system

A lithography machine and leveling technology, which is applied in the direction of optomechanical equipment, microlithography exposure equipment, optics, etc., can solve the problems of inability to achieve real-time leveling, improve real-time leveling efficiency, achieve leveling, and facilitate operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the technical solution of the present invention, a further detailed description will be made below in conjunction with the accompanying drawings.

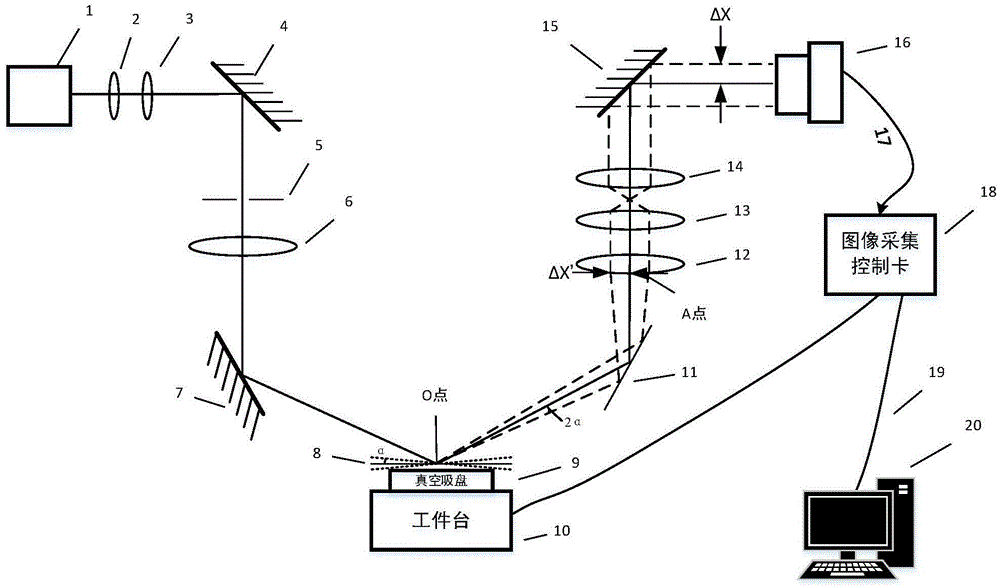

[0024] Such as figure 1 As shown, a real-time leveling system suitable for a projection lithography machine includes a light source 1, a first collimating lens group 2, a second collimating lens group 3, a first reflecting mirror 4, a projection diaphragm 5, a first Imaging group mirror 6, second reflecting mirror 7, silicon wafer 8, vacuum chuck 9, workbench 10, third reflecting mirror 11, second imaging mirror group 12, third imaging mirror group 13, fourth imaging mirror group 14, The fourth reflector 15, linear array CCD16, Cameralink transmission line 17, image acquisition control card 18, RS232 serial port 19, computer 20. The light source 1 passes through the first collimating lens group 2 and the second collimating lens group 3 to form a parallel beam, and passes through the first refle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com