Sample fixture used for rock cutting machine

A cutting machine and fixture technology, which is applied in the preparation of test samples, sampling, manufacturing tools, etc., can solve the problems of rock bar scale lines being easily blocked, rock sample cutting troubles, and cumbersome processes, etc., to achieve simple structure and reasonable cost , to ensure the effect of accuracy and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to explain the embodiments of the present invention or the technical solutions in the prior art more clearly, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the drawings in the following description are only These are some embodiments of the present invention. For those of ordinary skill in the art, other drawings can be obtained based on these drawings without creative work.

[0031] The embodiments of the present invention will be further described below in conjunction with the drawings:

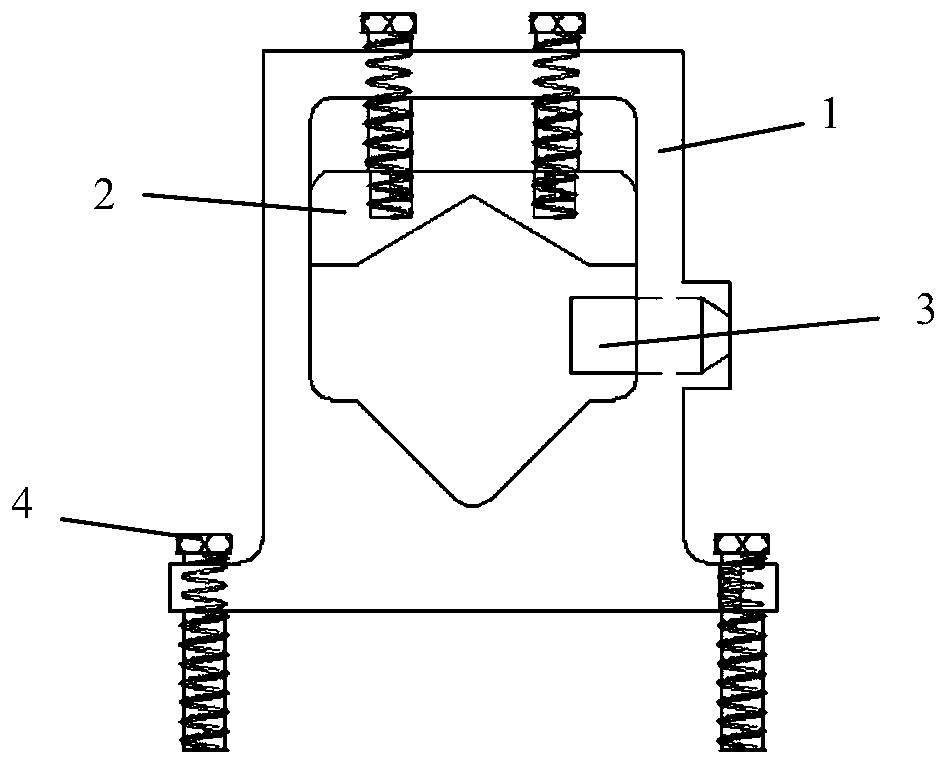

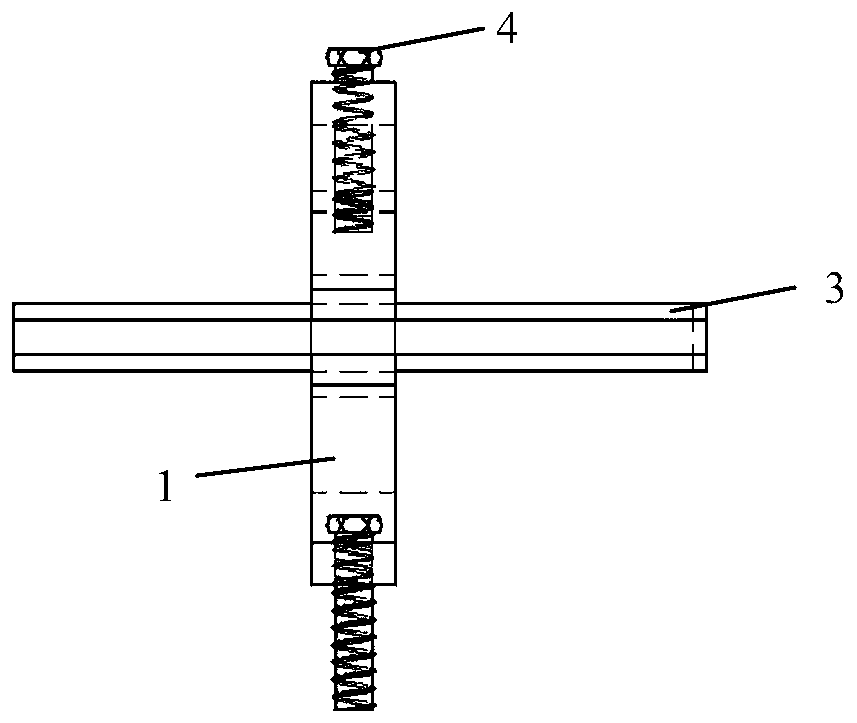

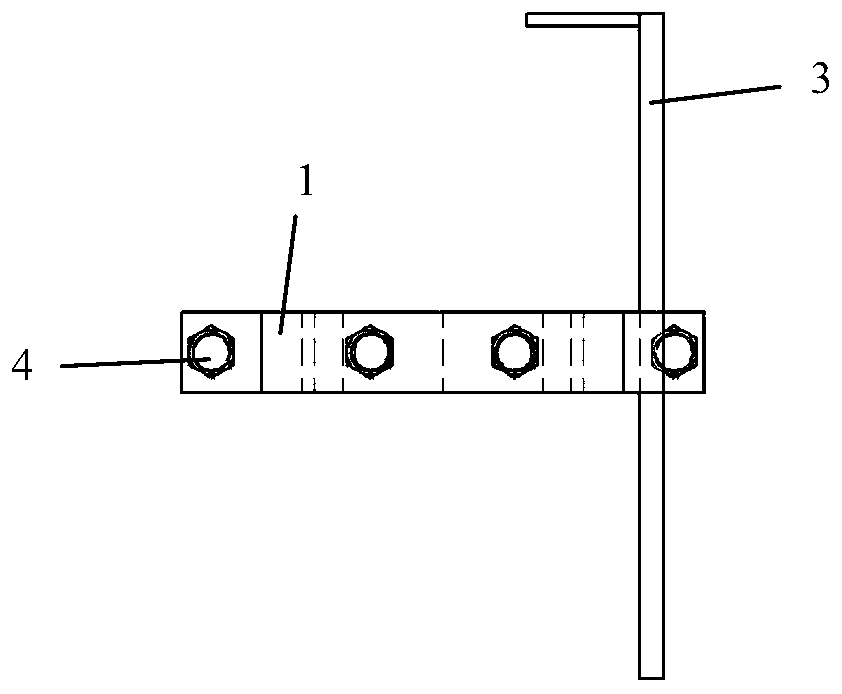

[0032] Such as Figure 1~Figure 8 As shown, the positioning frame 1, the fixed block 2, the L-shaped scale 3, and the bolts 4; the positioning frame 1 is a hollow rectangular frame, which respectively extends outward on both sides of the bottom side to become the base 1-1 of the positioning frame 1. And set the penetrating bolt holes 1-3 in the extension part; set the penetrating bolt hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com